Table of Contents

Advertisement

RETURN TO MAIN MENU

IM529-A

CLASSIC

III & CLASSIC

III D

®

®

October, 1999

For Machines with Code Numbers 10033, 10061, 10072 or 10156

Supersedes IM482

Safety Depends on You

Lincoln arc welding equipment

is designed and built with safety

in mind. However, your overall

safety can be increased by

proper installation ... and

thoughtful operation on your

part. DO NOT INSTALL,

OPERATE OR REPAIR THIS

EQUIPMENT

WITHOUT

READING THIS MANUAL AND

THE SAFETY PRECAUTIONS

CONTAINED THROUGHOUT.

And, most importantly, think

before you act and be careful.

OPERATOR'S MANUAL

• World's Leader in Welding and Cutting Products •

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Lincoln Electric CLASSIC III 10033

- Page 1 RETURN TO MAIN MENU IM529-A CLASSIC III & CLASSIC III D ® ® October, 1999 For Machines with Code Numbers 10033, 10061, 10072 or 10156 Supersedes IM482 Safety Depends on You Lincoln arc welding equipment is designed and built with safety in mind.

-

Page 2: California Proposition 65 Warnings

351040, Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS. -

Page 3: Electric Shock Can Kill

ELECTRIC SHOCK can kill. 3.a. The electrode and work (or ground) circuits are electrically “hot” when the welder is on. Do not touch these “hot” parts with your bare skin or wet clothing. Wear dry, hole-free gloves to insulate hands. 3.b. - Page 4 WELDING SPARKS can cause fire or explosion. 6.a. Remove fire hazards from the welding area. If this is not possible, cover them to prevent the welding sparks from starting a fire. Remember that welding sparks and hot materials from welding can easily go through small cracks and openings to adjacent areas.

- Page 5 PRÉCAUTIONS DE SÛRETÉ Pour votre propre protection lire et observer toutes les instructions et les précautions de sûreté specifiques qui parraissent dans ce manuel aussi bien que les précautions de sûreté générales suiv- antes: Sûreté Pour Soudage A L’Arc 1. Protegez-vous contre la secousse électrique: a.

- Page 6 This statement appears where the information must be followed to avoid minor personal injury or damage to this equipment. for selecting a QUALITY product by Lincoln Electric. We want you to take pride in operating this Lincoln Electric Company product •••...

-

Page 7: Table Of Contents

TABLE OF CONTENTS Installation...Section A Technical Specifications ...A-1 General Description...A-2 Design Features ...A-2 Pre-Operation Installation...A-3 Safety Precautions ...A-3 Exhaust Spark Arrester ...A-3 Location/Ventilation ...A-3 Stacking ...A-3 Angle of Operation ...A-3 Machine Grounding ...A-3 Lift Bail ...A-4 Trailers ...A-4 Polarity Control and Cable Sizes ...A-4 Pre-Operation Service ...A-5 Oil ...A-5 Fuel ...A-5... -

Page 8: Installation

TECHNICAL SPECIFICATIONS – CLASSIC III AND IIID Machine Product Ordering Description Name Information Classic III K1428-2 CSA @ w/o Wire Feed Module K1428-3 CSA @ 300 Amp DC w/ Wire Feed Arc Welder Module All Copper Windings K1433-1 Classic III D CSA @ Pure DC Power w/o Wire Feed... -

Page 9: General Description

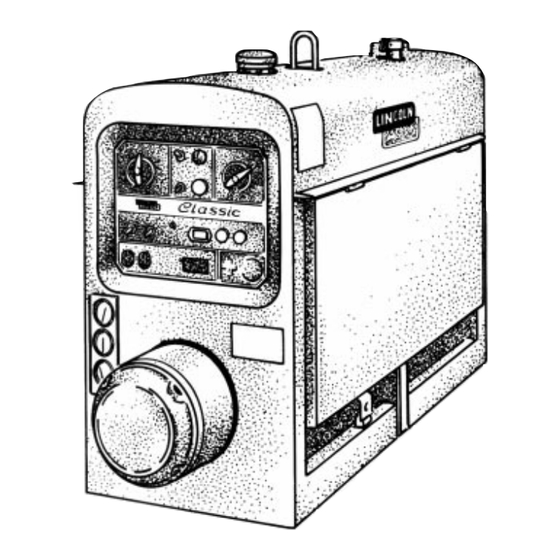

GENERAL DESCRIPTION The Classic ® III and Classic ® III D are heavy duty, engine driven, DC arc welding power sources capable of providing constant current output for stick welding or DC TIG welding. These welders are wound with all copper coils, rated at 300 amps/32 Volts, and provide other Classic features such as improved door latches and stainless hinges. -

Page 10: Safety Precautions

PRE-OPERATION INSTALLATION WARNING Do not attempt to use this equipment until you have thoroughly read the engine manufacturer’s manual supplied with your welder. It includes important safety precautions, detailed engine starting, operating and maintenance instructions, and parts lists. ------------------------------------------------------------------------ ELECTRIC SHOCK can kill. •... -

Page 11: Lift Bail

Lift Bail A lift bail is provided for lifting with a hoist. WARNING FALLING EQUIPMENT injury. • Do not lift this machine using lift bale if it is equipped with a heavy accessory such as a trailer or gas cylinder. •... -

Page 12: Pre-Operation Service

PRE-OPERATION SERVICE CAUTION READ the engine operating and maintenance instruc- tions supplied with this machine. WARNING Fuel can cause fire or explosion. • Stop engine while fueling. • Do not smoke when fueling. • Do not overfill tank. • Keep sparks and flame away from tank. •... -

Page 13: Operation

ENGINE OPERATION WARNING Do not attempt to use this equipment until you have thoroughly read the engine manufacturer’s manual supplied with your welder. It includes important safety precautions, detailed engine starting, operating and maintenance instructions, and parts lists. ------------------------------------------------------------------------ ELECTRIC SHOCK can kill. •... -

Page 14: Welder Operation

WELDER OPERATION WARNING ELECTRIC SHOCK can kill. • Do not touch electrically live parts or electrode with skin or wet clothing. • Insulate yourself from work and ground. FUMES & GASES can be dangerous. • Keep your head out of the fumes. •... -

Page 15: Auxiliary Power

Auxiliary Power The AC auxiliary power, supplied as a standard, has a rating of 3.0 kVA of 115/230 VAC (60 hertz). With the 3.0 kVA, 115/230 VAC auxiliary power, one 115V duplex and one 230V grounding type receptacle are provided. The circuit is protected with circuit breakers. - Page 16 IMPORTANT: 1/2” clearance between the FLEXIBLE HOSE and the fuel tank edge is required. Also 2” clearance between FLEXIBLE HOSE and roof. 4. Reconnect negative battery cable. FIGURE 2 A. FLEXIBLE HOSE B. HEAT COLLECTOR SHIELD C. AIR FILTER NOTE: On welders received directly from the factory, the “Deicing”...

-

Page 17: Accessories

OPTIONAL FEATURES (Field Installed) Accessory Set (K703) - Includes electrode and work cables, headshield, work clamp and electrode holder. Hi-Freq ™ (K799) - Provides high frequency plus gas valve for DC TIG welding. Linc-Thaw™ (L2964-1) - Includes meter and fuses to protect welder when thawing frozen water pipes. -

Page 18: Maintenance

MAINTENANCE WARNING Have qualified personnel do the maintenance work. Turn the engine off before working inside the machine. In some cases, it may be neces- sary to remove safety guards to perform required maintenance. Remove guards only when necessary and replace them when the maintenance requiring their removal is com- plete. -

Page 19: Idler Maintenance

Replace brushes when they wear within 1/4” of the pigtail. A complete set of replacement brushes should be kept on hand. Lincoln brushes have a curved face to fit the commutator. Have an experienced mainte- nance man seat these brushes by lightly stoning the commutator as the armature rotates at full speed until contact is made across the full face of the brushes. -

Page 20: Engine Service

Hours Between Servicing Daily C or R I = Inspect NOTES: Consult Engine Operators Manual for oil recommendations. Or equivalent. First inspection after 50 hours; every 500 thereafter. Gasoline engine only. Diesel engine only. (Welder Code Numbers 10061 and below) Diesel engine only. -

Page 21: Troubleshooting

TROUBLESHOOTING WARNING Have qualified personnel do the troubleshooting work. Turn the engine off before working inside the machine. In some cases, it may be neces- sary to remove safety guards to perform required maintenance. Remove guards only when necessary and replace them when the maintenance requiring their removal is com- plete. -

Page 22: Welder Troubleshooting

WELDER TROUBLESHOOTING TROUBLE Machine fails to hold the heat consistently. Welder starts but fails to generate current. FLASHING THE FIELDS: Stop the engine welder and remove the cover from the exciter. Turn the “Fine Adjustment Control” (rheostat) to “100” on the dial. Using a 12 volt automotive battery, connect it’s negative terminal to the negative brushholder. -

Page 23: Electronic Idler Troubleshooting Guide

ELECTRONIC IDLER TROUBLESHOOTING GUIDE Continuity Good Reed Switch in Weld Circuit May be Closed. Check Continuity of Idler Solenoid Coil (8.5 - 9.0 ohms) & Leads. Check Ground Connections in Idle Circuit. Replace P.C. Board. The Arc is Struck Reed Switch in Weld Circuit Defective -- Will Not Close To Check: Short the Red Lead on P.C. -

Page 24: Engine Troubleshooting

ENGINE TROUBLESHOOTING - TROUBLE Engine fails to start Low oil pressure. Light not lit when engine is running. Lack of power. Overheating. Knocking. Surging. See engine manual. If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. - Page 25 ENGINE TROUBLESHOOTING - TROUBLE Large decrease in speed. Unable to strike an arc. Engine runs irregularly. b. Carburetor Deicing Kit in wrong configuration. Engine fails to pick up speed when arc is struck. See engine manual. If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

-

Page 26: Diagrams

PLUGS PLUGS DIAGRAMS CLASSIC III AND IIID... - Page 27 DIAGRAMS CLASSIC III AND IIID...

- Page 28 DIAGRAMS CLASSIC III AND IIID...

- Page 29 NOTES CLASSIC III AND IIID...

- Page 30 NOTES CLASSIC III AND IIID...

- Page 31 Address: Telephone: _______________________________________________ |_|_| |_|_| Exp Date Month BOOK DIVISION, The Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199 for fastest service, FAX this completed form to: 216-361-5901 Telephone: 216-383-2211 or, Titles: Price New Lessons in Arc Welding $5.00...

- Page 32 ● WARNING ● Spanish ● AVISO DE PRECAUCION ● French ● ATTENTION ● ● German WARNUNG ● Portuguese ● ATENÇÃO ● Japanese Chinese Korean Arabic READ AND UNDERSTAND THE MANUFACTURER’S INSTRUCTION FOR THIS EQUIPMENT AND THE CONSUMABLES TO BE USED AND FOLLOW YOUR EMPLOYER’S SAFETY PRACTICES. SE RECOMIENDA LEER Y ENTENDER LAS INSTRUCCIONES DEL FABRICANTE PARA EL USO DE ESTE EQUIPO Y LOS CONSUMIBLES QUE VA A UTILIZAR, SIGA LAS MEDIDAS DE SEGURIDAD DE SU SUPERVISOR.

- Page 33 ● ● Keep your head out of fumes. Turn power off before servicing. ● Use ventilation or exhaust to remove fumes from breathing zone. ● Los humos fuera de la zona de res- ● Desconectar el cable de ali- piración. mentación de poder de la máquina ●...

- Page 34 • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com...

Need help?

Do you have a question about the CLASSIC III 10033 and is the answer not in the manual?

Questions and answers