Table of Contents

Advertisement

Quick Links

Technical Manual

SPIRIT II 150

Register your equipment:

www.lincolnelectric.com/register

Save for future reference

Date Purchased:

Model Number:

Serial Number:

BK8053-000093 Rev C |

Issue Date: 23-May-2018

© Lincoln Global, Inc. All Rights Reserved

This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to

non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

®

Manual Plasma Cutting System

with FineLine High Definition Technology

™

THE LINCOLN ELECTRIC COMPANY

4130 Carolina Commerce Pkwy

Phone: +1.843.695.4000

Ladson, SC 29456

U.S.A.

www.lincolnelectric.com

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Lincoln Electric SPIRIT II 150

- Page 1 Technical Manual SPIRIT II 150 Manual Plasma Cutting System ® with FineLine High Definition Technology ™ Register your equipment: www.lincolnelectric.com/register Save for future reference Date Purchased: Model Number: Serial Number: THE LINCOLN ELECTRIC COMPANY BK8053-000093 Rev C | 4130 Carolina Commerce Pkwy Ladson, SC 29456 U.S.A.

- Page 2 This documentation may not be copied, photocopied, reproduced, translated, or reduced to any electronic medium or machine-readable format without explicit written permission from Lincoln Electric. This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to...

-

Page 3: Table Of Contents

Spirit II User’s Manual Prologue Table of Contents Section 1: Safety General Precautions ................. 1-1 Ultraviolet Radiation Protection ............1-1 Noise Protection................. 1-1 Toxic Fume Prevention ..............1-2 Electric Shock Prevention ..............1-2 Fire Prevention................... 1-3 Explosion Prevention ................. 1-3 Health Support Equipment .............. - Page 4 Prologue Spirit II User’s Manual Section 4: Operation Operating the Manual Gas Console (MGC) ........4-1 Setting up to Cut ................4-2 Setting up to Mark ................4-3 Verifying Input Gas Pressures ............4-4 Input Gas Pressure Error Messages ..........4-4 Making a Cut or Mark .................

- Page 5 Spirit II User’s Manual Prologue H17 Supply Gas Hose (Optional) ............. 7-13 Supply Gas Hose Fittings Kit, BK300624 (Optional) ......7-14 "CII" Cable (for Optional External Inova) .......... 7-15 "FII" Cable (for Optional Internal Inova) ........... 7-16 "JII" Cable (for Optional Internal Inova) ..........7-17 PCB Assemblies –...

- Page 6 Contacter le 1-800-787-9707. • Poussoirs magnétiques main (5) Lincoln Electric n’est pas responsable de l’usure des câbles ni des dom- • All torch valve assemblies mages résultant de l’usure des câbles suite à des courbures et à l’abra- 90 Jours sion.

- Page 7 Poussoirs magnétiques main • Todos los sistemas de control de altura de la antorcha y (5) Lincoln Electric n’est pas responsable de l’usure des câbles ni des dom- los sensores de colisión mages résultant de l’usure des câbles suite à des courbures et à l’abra- 90 Jours sion.

- Page 8 DASS DIESE LÖSUNG NICHT DEN WESENTLICHEN ZWECK ERFÜLLTE • Poussoirs magnétiques main (5) Lincoln Electric n’est pas responsable de l’usure des câbles ni des dom- • Alle Brennerventilbaugruppen mages résultant de l’usure des câbles suite à des courbures et à l’abra- 90 Jours sion.

- Page 9 • Tous les systèmes de contrôle de hauteur de chalumeau et • Poussoirs magnétiques main (5) Lincoln Electric n’est pas responsable de l’usure des câbles ni des dom- les capteurs de collision mages résultant de l’usure des câbles suite à des courbures et à l’abra- 90 Jours sion.

- Page 10 Contacter le 1-800-787-9707. 工服务 - 仅适用于美国 • Poussoirs magnétiques main (5) Lincoln Electric n’est pas responsable de l’usure des câbles ni des dom- mages résultant de l’usure des câbles suite à des courbures et à l’abra- 90 Jours 备件 (所有维修零件)...

-

Page 11: Section 1: Safety General Precautions

Spirit II User’s Manual Section 1: Safety Section 1: Safety General Precautions Whereas plasma cutting has been used safely for years, it does require certain precautions to ensure the safety of the operator and other people around the equipment. The following safety information must be provided to each person who will operate, observe, perform maintenance, or work in close proximity to this piece of equipment. -

Page 12: Toxic Fume Prevention

Section 1: Safety Spirit II User’s Manual Toxic Fume Prevention Care should be taken to ensure adequate ventilation in the cutting area. Some materials give off toxic fumes that can be harmful or fatal to people in the vicinity of the cutting area. -

Page 13: Fire Prevention

Spirit II User’s Manual Section 1: Safety • Never change torch consumable parts unless the system is switched off at the wall disconnect. • Do not attempt to remove any parts from beneath the torch when cutting. Remember that the workpiece forms the current path back to the power supply. •... -

Page 14: Health Support Equipment

Section 1: Safety Spirit II User’s Manual • Never operate the system in the presence of explosive gases or other explosive materials. • Never cut pressurized cylinders or any closed container. • When using a water table and cutting aluminum under water or with water touching the underside of the aluminum plate, hydrogen gas is produced. -

Page 15: Safety Standards Booklet Index

Spirit II User’s Manual Section 1: Safety Safety Standards Booklet Index For further information concerning safety practices to be exercised with plasma arc cutting equipment, please refer to the following publications: 1. AWS Standard AWN, Arc Welding and Cutting Noise, obtainable from the American Welding Society, 550 NW LeJeune Road, Miami, FL 33126. - Page 16 Section 1: Safety Spirit II User’s Manual 12. NFPA Standard 51, Oxygen - Fuel Gas Systems for Welding, Cutting, and Allied Processes, obtainable from the National Fire Protection Association, 1 Batterymarch Park, Quincy, MA 02269. 13. NFPA Standard 51B, Cutting and Welding Processes, obtainable from the National Fire Protection Association, 1 Batterymarch Park, Quincy, MA 02269.

-

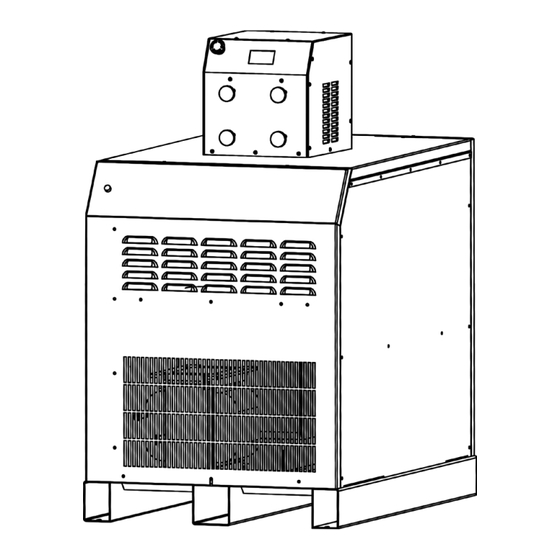

Page 17: Section 2: Specifications System Description

Section 2: Specifications System Description The Spirit II 150 is a 150 amp microprocessor controlled, 100% duty cycle high current density plasma cutting and marking system. It utilizes a precision, dual gas torch that is capable of cutting mild steel up to 1-1/2" thick and stainless steel up to 3/4” thick. -

Page 18: System Components

Section 2: Specifications Spirit II User’s Manual System Components The Spirit II 150 System consists of the following components: Standard Components • Power Supply • Manual Gas Console • CAN Cable • Arc Starting Console (ASC) with Remote High Frequency (RHF) - or - ™... -

Page 19: Power Supply Specifications

Spirit II User’s Manual Section 2: Specifications Power Supply Specifications Input Current at Power Supply Description Part Number Maximum Output 208 VAC, 3Ø, 60Hz BK300211 99 amps 220 VAC, 3Ø, 60Hz BK300212 94 amps 240 VAC, 3Ø, 60Hz BK300213 86 amps 380 VAC, 3Ø, 50/60Hz BK300214 54 amps... -

Page 20: Torch Coolant Specifications

Section 2: Specifications Spirit II User’s Manual Torch Coolant Specifications Note: Refer to the supplier’s most current Material Safety Data Sheet for information regarding safety, handling, and storage of torch coolant. The Spirit system is shipped without torch coolant in the reservoir. Coolant must be added before applying power to the system. -

Page 21: Manual Gas Console (Mgc) Specifications

Spirit II User’s Manual Section 2: Specifications Manual Gas Console (MGC) Specifications Part Number ............ BK300610 Weight .............. 43 lbs (19.5 kg) 12.4" [315] 2.4 [315] 13.6" [348] 12.0" [305] 12.0 [305] 13.7 [348] (4) Ø .300 [7.6] .300 [7.6] 10.9"... -

Page 22: Gas Supply Requirements

Section 2: Specifications Spirit II User’s Manual Gas Supply Requirements Plasma gas types: Mild Steel ............. Oxygen Stainless Steel ..........Air or H17 Aluminum ............ Air Shield gas types: Mild Steel ............. Oxygen or Air Stainless Steel ..........Air or Nitrogen Aluminum ............ - Page 23 Spirit II User’s Manual Section 2: Specifications Arc Starting Console (ASC) Specifications with Remote High Frequency (RHF) Part Number ............. BK300510 Weight .............. 24 lbs (10.9 kg) Spark gap distance .......... 0.015 in (0.381 mm) Note: The Spirit II system requires either an ASC with RHF or an ASC with ™...

-

Page 24: Arc Starting Console (Asc) Specifications With Cleanstrike

Section 2: Specifications Spirit II User’s Manual Arc Starting Console (ASC) Specifications ™ with CleanStrike Technology Part Number ............ BK300500 Weight ............... 22 lbs (10 kg) Note: The Spirit II system requires either an ASC with RHF or an ASC with ™... -

Page 25: Torch And 2-Gang Manifold Specifications

Spirit II User’s Manual Section 2: Specifications Torch and 2-Gang Manifold Specifications Part Number: 2-Gang Manifold Assembly ..........BK284214 Torch Handle (standard) ............BK278001 Torch Handle (short) ............BK278018 Torch Base................BK279000 Torch Head (Copper Electrode) ........... BK279100 Torch Head (Silver Electrode) ..........BK279060 Max Weight: Manifold/Bracket, Handle (BK278001), Base and Head .. -

Page 26: 5-Gang Manifold Specifications

Section 2: Specifications Spirit II User’s Manual 5-Gang Manifold Specifications Part Number ............ BK300075 Weight .............. 6 lbs (2.7 kg) 6.18" [157] 0.327" [8.3] 0.25" [6.4] (4) 0.187" [4.8] Mounting Holes 1.18" [30] 3.80" 4.20" ... -

Page 27: Airborne Noise Emissions

Spirit II User’s Manual Section 2: Specifications Airborne Noise Emissions The system generates high noise levels while cutting. Depending on the size of the cutting area, distance from the cutting torch, and arc current cutting level, acceptable noise levels may be exceeded. Proper ear protection should be used as defined by local or national codes. - Page 28 Section 2: Specifications Spirit II User’s Manual BLANK This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR. 2-12...

-

Page 29: Section 3: Installation Initial Inspection

Spirit II User’s Manual Section 3: Installation Section 3: Installation Initial Inspection All systems undergo full testing before being shipped from the factory. In the unlikely event that one of the components is defective or missing, please contact customer service so that a replacement can be sent. Also, special care has been taken in the packaging of the system. -

Page 30: System Interconnection

Section 3: Installation Spirit II User’s Manual 2-Gang Manifold The 2-gang manifold assembly must be mounted to the torch. See Section 2 for mounting dimensions. Torch The torch must be installed on the positioner of an arc voltage control (height control) capable of maintaining the cutting arc voltage within 1 arc volt. - Page 31 Spirit II User’s Manual Section 3: Installation Figure 1a: Spirit II System (MGC, Internal Inova, ASC with RHF) This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

- Page 32 Section 3: Installation Spirit II User’s Manual Figure 1b: Spirit II System (MGC, External Inova, ASC with RHF) This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

- Page 33 Spirit II User’s Manual Section 3: Installation ™ Figure 1c: Spirit II System (MGC, Internal Inova, ASC with CleanStrike Technology) This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S.

- Page 34 Section 3: Installation Spirit II User’s Manual ™ Figure 1d: Spirit II System (MGC, External Inova, ASC with CleanStrike Technology) This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S.

-

Page 35: Radio Frequency (Rf) And Electromagnetic Interference (Emi)

Spirit II User’s Manual Section 3: Installation Radio Frequency (RF) and Electromagnetic Interference (EMI) Overview This section describes the proper grounding of the Spirit II Plasma System components to minimize Radio Frequency (RF) and Electromagnetic Interference (EMI). The Arc Starting Console (ASC), by nature of its function in the system, is a source of RF/EMI along with other system components such as drive amplifiers. - Page 36 Section 3: Installation Spirit II User’s Manual 4. The braided shield on the torch leads must be electrically connected to the ASC console and to the torch handle. The length of the braid must be insulated from any metal contact or contact with the floor. The braid can be insulated with a plastic or leather sheath or run in a plastic track.

-

Page 37: Power Supply Primary Power Connections

Spirit II User’s Manual Section 3: Installation Power Supply Primary Power Connections ** Before connecting primary power, check the data plate on the power supply to verify the voltage required ** A primary disconnect switch, switching all ungrounded supply conductors, should be provided for each Spirit system. - Page 38 Section 3: Installation Spirit II User’s Manual TB5 is located on the rear of the power supply and is accessible with the right-side cover removed. Be sure to connect the primary ground cable to the ground stud on the input terminal block. Under no circumstances are the supply cables to be routed through the opening in the power supply cabinet without conduit or an appropriate strain relief as per local and national codes.

-

Page 39: Power Supply Output Connections

Spirit II User’s Manual Section 3: Installation Power Supply Output Connections Perform the following steps to connect the output of the power supply to the arc starting console and the work table. See Figure 4 on the next page. Power Supply Electrode Lead 1. - Page 40 Section 3: Installation Spirit II User’s Manual Strain Relief ™ ASC with RHF ASC with CleanStrike Technology Strain Relief Strain Relief Figure 4: Power Supply Output Connections This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S.

-

Page 41: Asc Control Cable And Asc Ground Connections

Spirit II User’s Manual Section 3: Installation ASC Control Cable and ASC Ground Connections Perform the following steps to connect the ASC control cable and ASC ground. See Figure 5 on the next page. ASC Control Cable 1. Connect the ASC control cable plug labeled P16 to the connector labeled P16 on the rear of the power supply. - Page 42 Section 3: Installation Spirit II User’s Manual ™ ASC with RHF ASC with CleanStrike Technology Figure 5: Cooling System Connections This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S.

-

Page 43: Torch Leads To Arc Starting Console Connections

Spirit II User’s Manual Section 3: Installation Torch Leads to Arc Starting Console Connections Perform the following steps to connect the torch leads to the arc starting console. See Figure 6 on the next page. Note: When making hose connections, only tighten the brass fittings enough to make water or gas seals. - Page 44 Section 3: Installation Spirit II User’s Manual ™ ASC with RHF ASC with CleanStrike Technology • Figure 6: Torch Leads to Arc Starting Console Connections This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S.

-

Page 45: Torch Leads To Torch Base Connections

Spirit II User’s Manual Section 3: Installation Torch Leads to Torch Base Connections Perform the following steps to connect the torch leads to the torch base. Note: When making hose connections, only tighten the brass fittings enough to make water or gas seals. The fittings are subject to damage if over tightened. -

Page 46: Torch Gas Connections

Section 3: Installation Spirit II User’s Manual Torch Gas Connections Perform the following steps to connect the torch gas hoses to the manual gas console, torch base, and manifold assemblies. See Figure 8. Note: When making hose connections, only tighten the brass fittings enough to make gas seals. - Page 47 Spirit II User’s Manual Section 3: Installation Postflow Gas Hose 1. Connect one end of the postflow hose to the postflow outlet on the rear of the MGC. Note that the postflow hose fittings have left hand threads. 2. Connect the other end of the postflow hose to the postflow inlet on the 5-gang manifold.

- Page 48 Section 3: Installation Spirit II User’s Manual Manual Gas Console GREEN BLUE GREEN REAR PORT REAR PORT BLUE Figure 8: Torch Gas Connections This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S.

-

Page 49: Gas Supply Connections

Spirit II User’s Manual Section 3: Installation Gas Supply Connections Perform the following steps to connect the gas supply lines to the MGC. See Section 2 for gas supply requirements. Mating hose barbs should be sized for 3/8 inch inside diameter hose. -

Page 50: Can Communication Connections

Section 3: Installation Spirit II User’s Manual CAN Communication Connections Perform the following steps to connect the plasma power supply to the MGC. CAN Cable • Connect the male end of the CAN cable to the connector labeled P4 on the rear of the plasma power supply. -

Page 51: Cnc Machine Interface Connections

Spirit II User’s Manual Section 3: Installation CNC Machine Interface Connections Perform the following steps to properly interface the Spirit system with a CNC cutting machine. See the system schematic for additional information. Plasma Start Input The power supply requires a contact closure between P8 pins 3 and 4 to commence the cutting or marking sequence. -

Page 52: Filling The Cooling System

Section 3: Installation Spirit II User’s Manual Filling the Cooling System WARNING: Do not touch the fans inside the power supply. Important: Never turn on the system when the coolant reservoir is empty. Important: When handling coolant, wear nitrile gloves and safety glasses. Important: Only use approved coolant. -

Page 53: Section 4: Operation

Spirit II User’s Manual Section 4: Operation with Manual Gas Console Section 4: Operation Operating the Manual Gas Console (MGC) The Manual Gas Console (MGC) is the interface to the entire Spirit II system. It includes a display to access all settings as well as the adjustment regulator knobs used to manually adjust the gas pressures necessary for cutting and marking. -

Page 54: Setting Up To Cut

Section 4: Operation with Manual Gas Console Spirit II User’s Manual Setting up to Cut The following procedure uses the information from the cutting charts in Section 5 to prepare the system to cut. Always verify the correct gases are connected to the proper input gas connections on the MGC in case marking was previously performed. -

Page 55: Setting Up To Mark

Spirit II User’s Manual Section 4: Operation with Manual Gas Console Setting up to Mark The system can mark with the same consumables that are used to cut. Refer to the cutting charts in Section 5 for the correct settings. Connect nitrogen gas to the plasma and shield inputs on the MGC (preflow and postflow inputs are not used for marking) and then follow the steps below. -

Page 56: Verifying Input Gas Pressures

Section 4: Operation with Manual Gas Console Spirit II User’s Manual Verifying Input Gas Pressures For the system to work properly the input gas pressures must be within an acceptable range. To check the input pressures, follow the steps below. On the main menu, move the pointer to Input Gas. -

Page 57: Making A Cut Or Mark

Spirit II User’s Manual Section 4: Operation with Manual Gas Console Making a Cut or Mark Once the process type, gas types and gas pressures have been set in the MGC, the correct torch parts (consumables) installed, and the X/Y controller and torch height control are properly configured, the system is ready to cut or mark. -

Page 58: Piercing Thick Materials

Section 4: Operation with Manual Gas Console Spirit II User’s Manual Piercing Thick Materials Care must be taken when piercing thick materials in order to prevent damage to the shield cap and nozzle. As with all thicknesses, the pierce height must be set high enough so the metal ejected while piercing does not come into contact with the shield cap. -

Page 59: Cut Quality

Spirit II User’s Manual Section 4: Operation with Manual Gas Console Cut Quality Before the optimum cutting condition can be achieved on a particular material type and thickness, the machine operator must have a thorough understanding of the cutting characteristics of the Spirit II system. When the cut quality is not satisfactory, the cutting speed, torch height, or gas pressures may need to be adjusted in small increments until the proper cutting condition is obtained. -

Page 60: Checking Errors

Section 4: Operation with Manual Gas Console Spirit II User’s Manual Checking Errors The last ten (10) system errors are available through the MGC as described below. On the main menu, move the pointer to Errors. Press the select button. Press the select ... -

Page 61: Changing The Language

Spirit II User’s Manual Section 4: Operation with Manual Gas Console Changing the Language The language displayed on the MGC can be changed as described below. On the main menu, move the pointer to Configure. Press the select button. Press the select ... - Page 62 Section 4: Operation with Manual Gas Console Spirit II User’s Manual BLANK This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR. 4-10...

-

Page 63: Section 5: Torch Consumables And Cutting Charts Installing / Removing The Torch Head

Spirit II User’s Manual Section 5: Torch Consumables and Cutting Charts Section 5: Torch Consumables and Cutting Charts Installing / Removing the Torch Head DANGER! Electric Shock Can Kill. • Remove primary power from the Spirit system before installing or removing the torch head. - Page 64 Section 5: Torch Consumables and Cutting Charts Spirit II User’s Manual O-ring O-ring Torch Base Torch Head Gap is visible There is no gap between between o-ring and o-ring and attachment attachment ring ring To remove the torch head, turn the attachment ring to the LEFT. This information is subject to the controls of the Export Administration Regulations [EAR].

-

Page 65: Installing / Replacing Consumables

Spirit II User’s Manual Section 5: Torch Consumables and Cutting Charts Installing / Replacing Consumables DANGER! Electric Shock Can Kill. • Remove primary power from the Spirit system before installing or removing the torch head. WARNING! Hot Parts Can Burn Skin. •... - Page 66 Section 5: Torch Consumables and Cutting Charts Spirit II User’s Manual PULL PULL 6. Use the swirl ring removal tool (P/N BK260105) to remove the swirl ring from the nozzle. 7. Remove the electrode from the torch head using the appropriate tool: •...

-

Page 67: Maximizing Consumable Life

Spirit II User’s Manual Section 5: Torch Consumables and Cutting Charts Maximizing Consumable Life Use the following guidelines to maximize consumable parts life: 1. The Spirit system utilizes the latest advancement in technology for extending the life of the torch consumable parts. To maximize the life of the consumable parts, it is imperative that the shutdown procedure of the arc is carried out properly. -

Page 68: Inspecting For Damage

Section 5: Torch Consumables and Cutting Charts Spirit II User’s Manual Inspecting for Damage When the cut quality is not satisfactory, use the following guidelines for determining which consumable parts need to be changed. Inspect all parts for dirt, debris, and excess o-ring lubricant and clean as necessary. Part Inspect For Corrective Action... -

Page 69: Selecting Consumables

Spirit II User’s Manual Section 5: Torch Consumables and Cutting Charts Selecting Consumables Mild Steel Copper Electrode Inner Outer Shield Swirl Copper Torch Retaining Nozzle Retaining Cap Ring Electrode Head BK284150 BK277145 BK277153 BK277120 BK277140 BK277130 BK279100 BK277140/ BK284150 BK277115 BK277153 BK277122 BK277142 BK277131... - Page 70 Section 5: Torch Consumables and Cutting Charts Spirit II User’s Manual Mild Steel Silver Electrode Inner Outer Shield Swirl Silver Torch Retaining Nozzle Retaining Cap Ring Electrode Head BK279410 BK284150 BK277286 BK277151 BK279484 BK279483 BK279060 (brown o-ring) 100A BK277151/ BK279420 BK284150 BK277117 BK277152...

- Page 71 Spirit II User’s Manual Section 5: Torch Consumables and Cutting Charts Stainless Steel - H17 Plasma Copper Electrode Outer Shield Inner Swirl Copper Torch Nozzle Retaining Cap Retaining Cap Ring Electrode Head BK284150 BK277150 BK277113 BK277124 BK277140 BK277132 BK279100 BK284150 BK277146 BK277113 BK277126 BK277141 BK277133...

- Page 72 Section 5: Torch Consumables and Cutting Charts Spirit II User’s Manual Stainless Steel - Air or Nitrogen Plasma Copper Electrode Outer Shield Inner Swirl Copper Torch Nozzle Retaining Cap Retaining Cap Ring Electrode Head BK284150 BK277144 BK277110 BK277121 BK277138 BK277137 BK279100 BK284150 BK277149...

- Page 73 Spirit II User’s Manual Section 5: Torch Consumables and Cutting Charts Stainless Steel - Air or Nitrogen Plasma Silver Electrode Outer Shield Inner Swirl Silver Torch Nozzle Retaining Cap Retaining Cap Ring Electrode Head BK279410 BK284150 BK277286 BK277151 BK279484 BK279483 BK279060 (brown o-ring) 100A...

- Page 74 Section 5: Torch Consumables and Cutting Charts Spirit II User’s Manual Aluminum Copper Electrode Outer Shield Inner Swirl Copper Torch Nozzle Retaining Cap Retaining Cap Ring Electrode Head BK284150 BK277145 BK277153 BK277120 BK277140 BK277130 BK279100 BK284150 BK277150 BK277153 BK277122 BK277142 BK277131 BK279100 BK284150 BK277150...

- Page 75 Spirit II User’s Manual Section 5: Torch Consumables and Cutting Charts Aluminum Silver Electrode Outer Shield Inner Swirl Silver Torch Nozzle Retaining Cap Retaining Cap Ring Electrode Head BK279410 BK284150 BK277286 BK277151 BK279484 BK279483 BK279060 (brown o-ring) 100A BK279420 BK284150 BK277117 BK277152 BK279493 BK279439...

-

Page 76: Cutting Charts

Section 5: Torch Consumables and Cutting Charts Spirit II User’s Manual Cutting Charts The cutting charts shown on the following pages are intended to give the operator the best starting point to use when making a cut on a particular material type and thickness. - Page 77 Spirit II User’s Manual Section 5: Torch Consumables and Cutting Charts Mild Steel - 30 Amps - Copper Electrode Oxygen Plasma / Oxygen Shield / Air Preflow & Postflow Shield Cap Nozzle Electrode BK277145 BK277120 BK277130 Outer Cap Retaining Cap Swirl Ring Torch Head BK284150...

- Page 78 Section 5: Torch Consumables and Cutting Charts Spirit II User’s Manual Mild Steel - 50 Amps - Copper Electrode Oxygen Plasma / Oxygen or Air Shield / Air Preflow & Postflow Shield Cap Nozzle Electrode BK277115 BK277122 BK277131 Outer Cap Retaining Cap Swirl Ring Torch Head...

- Page 79 Spirit II User’s Manual Section 5: Torch Consumables and Cutting Charts Mild Steel - 70 Amps - Copper Electrode Oxygen Plasma / Air Shield / Air Preflow & Postflow Shield Cap Nozzle Electrode BK277150 BK277125 BK277131 Outer Cap Retaining Cap Swirl Ring Torch Head BK284150...

- Page 80 Section 5: Torch Consumables and Cutting Charts Spirit II User’s Manual Mild Steel - 100 Amps - Copper Electrode Oxygen Plasma / Air Shield / Air Preflow & Postflow Shield Cap Nozzle Electrode BK277286 BK277284 BK277282 Outer Cap Retaining Cap Swirl Ring Torch Head BK284150...

- Page 81 Spirit II User’s Manual Section 5: Torch Consumables and Cutting Charts Mild Steel - 150 Amps - Copper Electrode Oxygen Plasma / Air Shield / Air Preflow & Postflow Shield Cap Nozzle Electrode BK277117 BK277293 BK277292 Outer Cap Retaining Cap Swirl Ring Torch Head BK284150...

- Page 82 Section 5: Torch Consumables and Cutting Charts Spirit II User’s Manual Stainless Steel - 30 Amps - Copper Electrode Air Plasma / Air Shield / Air Preflow & Postflow Shield Cap Nozzle Electrode BK277144 BK277121 BK277137 Outer Cap Retaining Cap Swirl Ring Torch Head BK284150...

- Page 83 Spirit II User’s Manual Section 5: Torch Consumables and Cutting Charts Stainless Steel - 50 Amps - Copper Electrode Air Plasma / Nitrogen Shield / Air Preflow & Postflow Shield Cap Nozzle Electrode BK277149 BK277123 BK277137 Outer Cap Retaining Cap Swirl Ring Torch Head BK284150...

- Page 84 Section 5: Torch Consumables and Cutting Charts Spirit II User’s Manual Stainless Steel - 70 Amps - Copper Electrode H17 Plasma / Nitrogen Shield / Nitrogen Preflow & Postflow (H17 = 17.5% Hydrogen / 32.5% Argon / 50% Nitrogen) This gas combination gives the best cut quality and minimum dross levels Shield Cap Nozzle Electrode...

- Page 85 Spirit II User’s Manual Section 5: Torch Consumables and Cutting Charts Stainless Steel - 70 Amps - Copper Electrode Air Plasma / Nitrogen Shield / Air Preflow & Postflow This gas combination gives medium cut quality and minimum dross levels Shield Cap Nozzle Electrode...

- Page 86 Section 5: Torch Consumables and Cutting Charts Spirit II User’s Manual Stainless Steel - 100 Amps - Copper Electrode H17 Plasma / Nitrogen Shield / Nitrogen Preflow & Postflow (H17 = 17.5% Hydrogen / 32.5% Argon / 50% Nitrogen) This gas combination gives the best cut quality and minimum dross levels Shield Cap Nozzle Electrode...

- Page 87 Spirit II User’s Manual Section 5: Torch Consumables and Cutting Charts Stainless Steel - 100 Amps - Copper Electrode Air Plasma / Nitrogen Shield / Air Preflow & Postflow This gas combination gives medium cut quality and minimum dross levels Shield Cap Nozzle Electrode...

- Page 88 Section 5: Torch Consumables and Cutting Charts Spirit II User’s Manual Stainless Steel - 150 Amps - Copper Electrode H17 Plasma / Nitrogen Shield / Nitrogen Preflow & Postflow (H17 = 17.5% Hydrogen / 32.5% Argon / 50% Nitrogen) This gas combination gives the best cut quality and minimum dross levels Shield Cap Nozzle Electrode...

- Page 89 Spirit II User’s Manual Section 5: Torch Consumables and Cutting Charts Stainless Steel - 150 Amps - Copper Electrode Air Plasma / Nitrogen Shield / Air Preflow & Postflow This gas combination gives medium cut quality and minimum dross levels Shield Cap Nozzle Electrode...

- Page 90 Section 5: Torch Consumables and Cutting Charts Spirit II User’s Manual Aluminum - 30 Amps - Copper Electrode Air Plasma / Nitrogen Shield / Air Preflow & Postflow Shield Cap Nozzle Electrode BK277145 BK277120 BK277130 Outer Cap Retaining Cap Swirl Ring Torch Head BK284150 BK277153...

- Page 91 Spirit II User’s Manual Section 5: Torch Consumables and Cutting Charts Aluminum - 50 Amps - Copper Electrode Air Plasma / Nitrogen Shield / Air Preflow & Postflow Shield Cap Nozzle Electrode BK277150 BK277122 BK277131 Outer Cap Retaining Cap Swirl Ring Torch Head BK284150 BK277153...

- Page 92 Section 5: Torch Consumables and Cutting Charts Spirit II User’s Manual Aluminum - 70 Amps - Copper Electrode Air Plasma / Nitrogen Shield / Air Preflow & Postflow Shield Cap Nozzle Electrode BK277150 BK277125 BK277131 Outer Cap Retaining Cap Swirl Ring Torch Head BK284150 BK277153...

- Page 93 Spirit II User’s Manual Section 5: Torch Consumables and Cutting Charts Aluminum - 100 Amps - Copper Electrode Air Plasma / Nitrogen Shield / Air Preflow & Postflow Shield Cap Nozzle Electrode BK277286 BK277284 BK277282 Outer Cap Retaining Cap Swirl Ring Torch Head BK284150 BK277151...

- Page 94 Section 5: Torch Consumables and Cutting Charts Spirit II User’s Manual Aluminum - 150 Amps - Copper Electrode Air Plasma / Nitrogen Shield / Air Preflow & Postflow Shield Cap Nozzle Electrode BK277117 BK277293 BK277292 Outer Cap Retaining Cap Swirl Ring Torch Head BK284150 BK277152...

- Page 95 Spirit II User’s Manual Section 5: Torch Consumables and Cutting Charts Mild Steel - 100 Amps - Silver Electrode Oxygen Plasma / Air Shield / Air Preflow & Postflow Shield Cap Nozzle Electrode BK277286 BK279484 BK279410 (brown o-ring) Outer Cap Retaining Cap Swirl Ring Torch Head...

- Page 96 Section 5: Torch Consumables and Cutting Charts Spirit II User’s Manual Mild Steel - 150 Amps - Silver Electrode Oxygen Plasma / Air Shield / Air Preflow & Postflow Shield Cap Nozzle Electrode BK277117 BK279493 BK279420 (green o-ring) Outer Cap Retaining Cap Swirl Ring Torch Head...

- Page 97 Spirit II User’s Manual Section 5: Torch Consumables and Cutting Charts Stainless Steel - 100 Amps - Silver Electrode Air Plasma / Nitrogen Shield / Air Preflow & Postflow Shield Cap Nozzle Electrode BK277286 BK279484 BK279410 (brown o-ring) Outer Cap Retaining Cap Swirl Ring Torch Head...

- Page 98 Section 5: Torch Consumables and Cutting Charts Spirit II User’s Manual Stainless Steel - 150 Amps - Silver Electrode Air Plasma / Nitrogen Shield / Air Preflow & Postflow Shield Cap Nozzle Electrode BK277117 BK279493 BK279420 (green o-ring) Outer Cap Retaining Cap Swirl Ring Torch Head...

- Page 99 Spirit II User’s Manual Section 5: Torch Consumables and Cutting Charts Aluminum - 100 Amps - Silver Electrode Air Plasma / Nitrogen Shield / Air Preflow & Postflow Shield Cap Nozzle Electrode BK277286 BK279484 BK279410 (brown o-ring) Outer Cap Retaining Cap Swirl Ring Torch Head BK284150...

- Page 100 Section 5: Torch Consumables and Cutting Charts Spirit II User’s Manual Aluminum - 150 Amps - Silver Electrode Air Plasma / Nitrogen Shield / Air Preflow & Postflow Shield Cap Nozzle Electrode BK277117 BK279493 BK279420 (green o-ring) Outer Cap Retaining Cap Swirl Ring Torch Head BK284150...

-

Page 101: Section 6: Maintenance And Troubleshooting

Spirit II User’s Manual Section 6: Maintenance &Troubleshooting Section 6: Maintenance & Troubleshooting WARNING: Only qualified maintenance personnel should perform maintenance on the Spirit system. The system utilizes potentially fatal A.C. and D.C. voltages. All maintenance should be performed with safety in mind. Use extreme caution when working near the power conversion module (i.e., chopper). - Page 102 Section 6: Maintenance &Troubleshooting Spirit II User’s Manual Manual Gas Console (MGC) 1. Remove the cover of the manual gas console. Using clean, dry, compressed air (30 psi maximum), blow out all accumulated dust inside the unit. In an excessively dirty environment, blow out the unit on a weekly basis.

- Page 103 Spirit II User’s Manual Section 6: Maintenance &Troubleshooting Arc Starting Console (ASC) 1. Open the cover (door) of the arc starting console and verify that all leads and hoses are tightened securely. Only tighten the fittings enough to make a coolant or gas seal.

-

Page 104: Replacing The Torch Coolant And Filter

Section 6: Maintenance &Troubleshooting Spirit II User’s Manual Replacing the Torch Coolant and Filter WARNING: Do not touch the fans inside the power supply. Important: Never turn on the system when the coolant reservoir is empty. Important: When handling coolant, wear nitrile gloves and safety glasses. Important: Only use approved coolant. -

Page 105: Power Supply Microprocessor (Dsp) Status Indicators

Spirit II User’s Manual Section 6: Maintenance &Troubleshooting Power Supply Microprocessor (DSP) Status Indicators The microprocessor DSP board controls all of the functions of the Spirit power supply. It contains diagnostic LEDs and OPTO LEDs which aid in troubleshooting the system. These indicators illuminate when a particular event occurs. -

Page 106: Power Supply Microprocessor (Dsp) Sequence Of Operation

Section 6: Maintenance &Troubleshooting Spirit II User’s Manual Power Supply Microprocessor (DSP) Sequence of Operation The following DSP Indicators should illuminate after primary power is applied: D77 ........3.3V Supply D78 ........1.8V Supply D50 ........ASC (Door) ... -

Page 107: Error Codes

Spirit II User’s Manual Section 6: Maintenance &Troubleshooting Error Codes The following is a comprehensive list of error codes for the Spirit system. When the system uses a Manual Gas Console, only the numeric error code is displayed. When an Automatic Gas Console is used, the text description is also displayed. - Page 108 Section 6: Maintenance &Troubleshooting Spirit II User’s Manual Gas Console Code Short Description Long Description 20200 Low Plasma Input Pressure is low 20210 Shield Low Input Pressure is low 20230 Low Pre/Post Input Pressure is low This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S.

-

Page 109: General Troubleshooting

Spirit II User’s Manual Section 6: Maintenance &Troubleshooting General Troubleshooting The following contains general troubleshooting guidelines for the Spirit system. Please contact technical support for any issues not covered in this section. Before any tests are performed, make sure that all system fuses are good; remove top cover of power supply to check these fuses. - Page 110 Section 6: Maintenance &Troubleshooting Spirit II User’s Manual Problem Possible Cause Primary power has been 1. Check power/communications CAN cable applied to the system, but connection on back of manual gas console. the manual gas console 2. Check for blown DIN rail fuse. screen is blank 3.

-

Page 111: Chopper Test Procedure

Spirit II User’s Manual Section 6: Maintenance &Troubleshooting Chopper Test Procedure WARNING: Only qualified maintenance personnel should perform the chopper test procedure. The system utilizes potentially fatal A.C. and D.C. voltages. All maintenance should be performed with safety in mind. Use extreme caution when working near the power conversion module (i.e., chopper). - Page 112 Section 6: Maintenance &Troubleshooting Spirit II User’s Manual 4. Remove the Electrode, Work and Nozzle leads from the output terminal block, which is located on the left side of the unit. 5. Ensure the torch head (with a full set of consumables) is properly installed onto the torch base.

- Page 113 Spirit II User’s Manual Section 6: Maintenance &Troubleshooting 9. With a start signal applied, check for the proper DC voltage (refer to TABLE 1) at the output terminal block between Electrode and Work, which is located on the left side of the unit.

- Page 114 Section 6: Maintenance &Troubleshooting Spirit II User’s Manual 13. Remove primary power from the Spirit system. Check cable continuity between the chopper PCB and DSP PCB. Use a digital voltmeter set up to read resistance (ohms) and make the following measurements: Chopper (1) J1-1 to DSP J7-1 Chopper (1) J1-2 to DSP J7-2 Chopper (1) J1-3 to DSP J7-3...

-

Page 115: Section 7: Parts List

Spirit II User’s Manual Section 7: Parts List Section 7: Parts List Power Supply (BK300211 - BK300219) Right Side View Item Part Number Quantity Description BK707155 L1 Inductor BK709105 Strain Relief BK708121 CON 1 Contactor BK702048 EMI Filter, 380/400/415 V units only BK709376 TB5 3 Phase Input Power Terminal Block BK300250... - Page 116 Section 7: Parts List Spirit II User’s Manual Power Supply (BK300211 - BK300219) Left Side View Item Part Number Quantity Description BK300101 Printed Circuit Board (PCB), Microprocessor (DSP) BK300112 Printed Circuit Board (PCB), A.C. Detect BK708118 CR3/PAR Relay BK705011 PAT IGBT BK702075 PAT IGBT Filter Capacitor BK300108...

- Page 117 Spirit II User’s Manual Section 7: Parts List Power Supply (BK300211 - BK300219) Top View Item Part Number Quantity Description BK501163 Light Housing BK501164 Bulb BK501162 White Lens BK709359 F3 Fuse, 5A, Slow Blow BK709358 F4 Fuse, 5A, Medium Blow BK709358 F5 Fuse, 5A, Medium Blow BK709360...

- Page 118 Section 7: Parts List Spirit II User’s Manual Power Supply (BK300211 - BK300219) Cooling Section View Item Part Number Quantity Description BK709105 Strain Relief BK200092 Coolant Reservoir, without Fittings or Cap BK500518 Coolant Reservoir Cap/Level Gauge BK300135 Coolant Level Switch BK505024 Coolant Temperature Switch BK500059...

-

Page 119: Manual Gas Console (Bk300610)

Spirit II User’s Manual Section 7: Parts List Manual Gas Console (BK300610) Right Side View Item Part Number Quantity Description BK300613 Power Supply, 24VDC, 1.04A BK300301-PMGC Printed Circuit Board (PCB), Gas Console DSP BK300606 Keypad Membrane BK300604 LCD Display Assembly BK708111 Switch, Pushbutton (OFF Button) BK500570... - Page 120 Section 7: Parts List Spirit II User’s Manual Manual Gas Console (BK300610) Left Side View Item Part Number Quantity Description BK300613 Power Supply, 24VDC, 1.04A BK300301-PMGC Printed Circuit Board (PCB), Gas Console DSP BK708111 Switch, Pushbutton (OFF Button) BK500570 Postflow Regulator, 0-125 PSI BK500562 Preflow Regulator, 0-60 PSI BK300618...

- Page 121 Spirit II User’s Manual Section 7: Parts List Arc Starting Console (BK300510) with Remote High Frequency (RHF) Item Part Number Quantity Description BK715051 Coolant return fitting (left hand) BK715050 Coolant supply fitting (right hand) BK709227 Strain relief BK709001 4 pin receptacle BK707001 Line filter BK706109...

-

Page 122: Arc Starting Console (Bk300500) With Cleanstrike

Section 7: Parts List Spirit II User’s Manual Arc Starting Console (BK300500) ™ with CleanStrike Technology Item Part Number Quantity Description BK715051 Coolant Return Fitting (left hand) BK715050 Coolant Supply Fitting (right hand) BK715021 Coolant Supply Fitting (right hand) BK709001 4 Pin Receptacle BK708057 Door Interlock Switch... -

Page 123: Torch And Manifold Assemblies

Spirit II User’s Manual Section 7: Parts List Torch and Manifold Assemblies Item Part Number Quantity Description BK284214 2-Gang Manifold (includes Bracket) BK277195 2-Gang Manifold Bracket BK278001 Torch Handle – Standard BK278018 Torch Handle – Short BK279000 Torch Base BK279100 Torch Head (Copper Electrode) BK279060 Torch Head (Silver Electrode) -

Page 124: Shielded Torch Leads

Section 7: Parts List Spirit II User’s Manual Shielded Torch Leads Part Number Length BK284304-XX Where -XX is the length in feet. 4-10 ft lengths available in 1 ft increments. 15-50 ft lengths available in 5 ft increments. CAN Communication Cable and Termination Plug Item Part Number Length... -

Page 125: Gas Hose Package With Mgc

Spirit II User’s Manual Section 7: Parts List Gas Hose Package with MGC Part Number Length* BK300086-XX Where -XX is the length in feet. 10-150 ft lengths available in 10 ft increments. *Custom lengths are available. Contact factory. ... -

Page 126: Coolant And Power Leads

Section 7: Parts List Spirit II User’s Manual Coolant and Power Leads Part Number Part Number Length (Non-CSA Systems) (CSA Systems) BK300306-XX BK388306-XX Where -XX is the length in feet. 10-150 ft lengths available in 10 ft increments. ... -

Page 127: Oxygen Supply Gas Hose (Optional)

Spirit II User’s Manual Section 7: Parts List Oxygen Supply Gas Hose (Optional) Part Number Length BK200362-XX Where -XX is the length in feet. 25-100 ft lengths available in 25 ft increments. BLUE BLUE Nitrogen Supply Gas Hose (Optional) Part Number Length BK200365-XX Where -XX is the length in feet. -

Page 128: Supply Gas Hose Fittings Kit, Bk300624 (Optional)

Section 7: Parts List Spirit II User’s Manual Supply Gas Hose Fittings Kit, BK300624 (Optional) This kit contains the components shown below. Hose and ferrule/clamp are not supplied. Supply Gas Hose Assembled Fittings Barbed Nipple for 3/8” ID Hose Oxygen 9/16”... -

Page 129: Cii" Cable (For Optional External Inova)

Spirit II User’s Manual Section 7: Parts List “CII” Cable (for Optional External Inova) Part Number Length BK300902-XX Where -XX is the length in feet. 5-150 ft lengths available in 5 ft increments. STRAIN RELIEF BK709015 CABLE BK711001 PLUG BK709016 PLUG BK709364 STRAIN RELIEF BK709025 BK709365 PIN... -

Page 130: Fii" Cable (For Optional Internal Inova)

Section 7: Parts List Spirit II User’s Manual “FII” Cable (for Optional Internal Inova) Part Number Length BK300903-XX Where -XX is the length in feet. 5-150 ft lengths available in 5 ft increments. CABLE BK711002 PLUG BK709364 PLUG BK709095 STRAIN RELIEF BK709025 STRAIN RELIEF BK709021 BK709018 SOCKET BK709365 PINS... -

Page 131: Jii" Cable (For Optional Internal Inova)

Spirit II User’s Manual Section 7: Parts List “JII” Cable (for Optional Internal Inova) Part Number Length BK300904-XX Where -XX is the length in feet. 5-50 ft lengths available in 5 ft increments. STRAIN RELIEF BK709025 STRAIN RELIEF BK709021 PLUG BK709364 PLUG BK709020 CABLE BK711049 BK709365 PIN... -

Page 132: Pcb Assemblies - Component Reference Locations

Section 7: Parts List Spirit II User’s Manual PCB Assemblies – Component Reference Locations Power Supply, Microprocessor DSP (BK300101) – Quadrant 1 PCB Quadrant Map U37 - RHF U36 – Impulse Start U32 - Marking U31 – Postflow U30 - Vent U29 - Shield This information is subject to the controls of the Export Administration Regulations [EAR]. - Page 133 Spirit II User’s Manual Section 7: Parts List Power Supply, Microprocessor DSP (BK300101) – Quadrant 2 PCB Quadrant Map U28 - Plasma U27 - Preflow U19 – Solenoid (not used) U21 – Mtr / Sol U22 - PAR U24 - Surge U26 - Fan U23 - Con This information is subject to the controls of the Export Administration Regulations [EAR].

- Page 134 Section 7: Parts List Spirit II User’s Manual Power Supply, Microprocessor DSP (BK300101) – Quadrant 3 PCB Quadrant Map This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR. 7-20...

- Page 135 Spirit II User’s Manual Section 7: Parts List Power Supply, Microprocessor DSP (BK300101) – Quadrant 4 PCB Quadrant Map J4-1 J4-2 This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S.

- Page 136 Section 7: Parts List Spirit II User’s Manual Power Supply, Output (BK300108) This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR. 7-22...

- Page 137 Spirit II User’s Manual Section 7: Parts List Power Supply, A.C. Detect (BK300112) This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR. 7-23...

- Page 138 Section 7: Parts List Spirit II User’s Manual Gas Console, Microprocessor DSP (BK300301-PMGC) – Quadrant 1 PCB Quadrant Map This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR. 7-24...

- Page 139 Spirit II User’s Manual Section 7: Parts List Gas Console, Microprocessor DSP (BK300301-PMGC) – Quadrant 2 PCB Quadrant Map This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR. 7-25...

- Page 140 Section 7: Parts List Spirit II User’s Manual Gas Console, Microprocessor DSP (BK300301-PMGC) – Quadrant 3 PCB Quadrant Map This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR. 7-26...

- Page 141 Spirit II User’s Manual Section 7: Parts List Gas Console, Microprocessor DSP (BK300301-PMGC) – Quadrant 4 PCB Quadrant Map This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR. 7-27...

- Page 142 Section 7: Parts List Spirit II User’s Manual Chopper, Gate Driver (BK300106) This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR. 7-28...

-

Page 143: Section 8: Internal Inova Console Option Overview

RS-422 MACHINE RS-422 IN RS-422 OUT Spirit II 150/275 Spirit II 400 Unique Interconnect Cables Two unique interconnect cables are required for this option with the Spirit II system. The FII cable is used to connect the Spirit II internal Inova console (IP4) to the X/Y Machine (CNC controller). -

Page 144: Grounding

Use a minimum of #8AWG (10 mm ) wire. Note: the customer must supply the ground cable. Direct to star ground: Ground Ground Point Point Spirit II 150/275 Spirit II 400 Jumper to the work ground lead: Ground Ground Point Point Spirit II 150/275 Spirit II 400 This information is subject to the controls of the Export Administration Regulations [EAR]. -

Page 145: Parts List

Printed Circuit Board (PCB), Voltage Divider BK709276 Power Distribution Block,1 Pole Location in Spirit II 150 & 275 (pos A) (pos B) This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to... - Page 146 Section 8: Internal Inova Console Option Spirit II User’s Manual Location in Spirit II 150 & 275 - Continued This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

- Page 147 Spirit II User’s Manual Section 8: Internal Inova Console Option Location in Spirit II 400 (pos A) (pos B) This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

- Page 148 Section 8: Internal Inova Console Option Spirit II User’s Manual Location in Spirit II 400 - Continued This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

-

Page 149: Appendix A: Electromagnetic Compatibility (Emc) Background

Spirit II User’s Manual Appendix A: Electromagnetic Compatibility (EMC) Appendix A: Electromagnetic Compatibility (EMC) Background The 380V 50/60Hz and 415V 50/60Hz CE marked Spirit plasma cutting systems are manufactured to comply with the European standard EN 60974-10 (Electromagnetic compatibility (EMC) – Product standard for arc welding equipment). The system has been tested in accordance with CISPR 11, EMC classification –... -

Page 150: Assessment Of Area

Appendix A: Electromagnetic Compatibility (EMC) Spirit II User’s Manual Assessment of Area Before installing plasma cutting equipment, the user shall make an assessment of potential electromagnetic problems in the surrounding area. The following shall be taken into account: a) other supply cables, control cables, signaling and telephone cables; above, below and adjacent to the plasma cutting equipment;... - Page 151 Spirit II User’s Manual Appendix A: Electromagnetic Compatibility (EMC) Equipotential Bonding Bonding of all metallic components in the plasma cutting installation and adjacent to it should be considered. However, metallic components bonded to the workpiece will increase the risk that the operator could receive a shock by touching these metallic components and the electrode at the same time.

- Page 152 Appendix A: Electromagnetic Compatibility (EMC) Spirit II User’s Manual BLANK This information is subject to the controls of the Export Administration Regulations [EAR]. This information shall not be provided to non-U.S. persons or transferred by any means to any location outside the United States contrary to the requirements of the EAR.

Need help?

Do you have a question about the SPIRIT II 150 and is the answer not in the manual?

Questions and answers