Table of Contents

Summary of Contents for Heiniger XTRA VS84-S

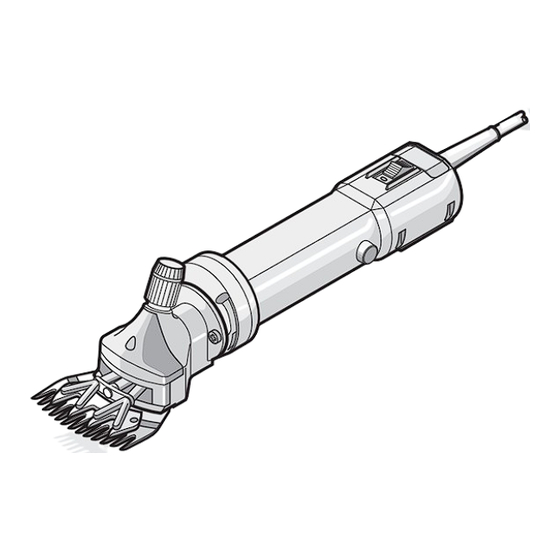

- Page 1 swiss made Betriebsanleitung Instruction manual Mode d’emploi Istruzioni d’uso Manual de Instrucciones Bedieningshandleiding Instruktionsbog Instruktionsbok Instruksjonsbok Käyttöohjekirja Manual de instruções δηγίες ρήσης Ausgabe/Index: XTRA/I 09-11...

-

Page 2: Table Of Contents

Contents 1 Proper Use 1.1 Overall View / Controls 1.2 Intended Use 1.3 Technical Data 1.4 Equipment Items 2 Safety Regulations 2.1 Introduction 2.2 Symbols and Warning Signs 2.3 Proper Use 2.4 Safety Principles 2.4.1 Power Connections 2.4.2 Servicing and Checking Requirement 2.4.3 Noise Emission / Personal Protective Equipment 2.4.4 Other Dangers 2.5 Essential Operator Skills... -

Page 3: Proper Use

45 Stator XTRA 240V 10 Gauge plate 2.5“ XTRA/12V option 45 Stator XTRA 120V 11 Gauge plate 3“ XTRA/12V 46 Motor housing XTRA Heiniger grey 12 Crankshaft XTRA/12V 47 Carbon brushes with spring + protection cap XTRA/HANDY 13 Ball XTRA/12V... -

Page 4: Intended Use

1.2 Intended Use The shearing machine is intended exclusively for use on sheep and goats, as well as llamas, alpacas and other members of the camel family. Its use can also be extended to cattle and horses by changing the standard shearing head. Other uses, in particular using the machine on people, are expressly prohibited. -

Page 5: Proper Use

Danger Symbols Warning indicates a potentially dangerous situation. If preventive action is not taken, death or very serious injury could result. Caution indicates a potentially dangerous situation. If preventive action is not taken, the conse- quences could be slight or minor injuries. Information Symbols Note Note, non-compliance with which can lead to operating malfunctions or damage. -

Page 6: Other Dangers

Wear Protective Goggles and Gloves! For your personal protection we recommend that you wear protective goggles and gloves. Personal protective equipment is to be provided by the operator. 2.4.4 Other Dangers Should evidence of dangers or potential dangers, not directly related to the shearing of animals, occur during operation, we would ask you to inform us. -

Page 7: Shearing Adjustment Using The Tension Nut

• Only use original shearing blades. Do not use damaged shearing blades with blunt, missing or broken off teeth. Only work using sharp shearing blades, ground in a specialist workshop. • We recommend you use a comb for no longer than an hour and a cutter for no longer than 15 minutes before you change them for a sharp comb and cutter. -

Page 8: Lubrication

Hair may collect between the shear blades, if the tension nut is insufficiently tightened at the start of shearing. This will have an adverse effect on further shearing progress or make it quite impossible. If this happens, the shear blades must be disassembled, cleaned, oiled and re-fitted as described at 4.2. -

Page 9: Servicing

4 Servicing Before starting any servicing work, disconnect the power supply; pull the plug out. Even with the machine switched off, do not handle the area round the shearing blades as long as the machine is still connected to a power source. Whenever working on the shearing blades/shearing head, always first disconnect the power supply. -

Page 10: Resharpening The Shearing Blades

It is designed to give longevity and high performance. If spare parts are used during the life of this product, please ensure that they are genuine Heiniger parts. Failure to use genuine Heiniger spares may reduce the performance of this precision engineered product and will void any warranty claim. - Page 11 Sheep Shearing Head MALFUNCTION CAUSE RECTIFICATION Tension link broken Have tension link replaced Crank spindle and/or crank Have crank spindle and/or Cutter does not move across its roller and/or swiveling fork crank roller and/or swiveling whole running surface worn out fork replaced Bearings badly worn Have bearings replaced...

- Page 12 Sheep Shearing Head MALFUNCTION CAUSE RECTIFICATION Comb plate wrongly fitted Readjust the upper blade 1.5 mm backwards in relation to the comb plate (Illustration 11) Crank roller missing Have crank roller replaced (Illustration 1, Item 25) Does not cut Cogwheel and/or reducing Replace cogwheel gear faulty (Illustration 1, Item 8)

- Page 13 Motor Section MALFUNCTION CAUSE RECTIFICATION No power Check lead and fuse Faulty cable Have it checked and changed by service centre Motor does not run Faulty switch or motor Have it repaired by service centre Overload protection switch Push in (Illustration 5) tripped out Blades jammed (Illustration 6) Remove jam...

-

Page 14: Environmental Protection And Disposal

6 Environmental Protection and Disposal 6.1 Introduction The owner has a duty to dispose of the shearing blades as well as of the shearing machine properly at the end of its service life. Please observe your relevant national regulations. 6.2 Material Categories Please hand the machine to a service centre or to a specialist electrical dealer in your vicinity for disassembly. - Page 15 XTRA...

- Page 16 14 15 16 17 20 21 24 25 XTRA...

- Page 17 1,5–2,0 mm XTRA...

- Page 18 Item Artikel Artículo Artikel Article Artikel Artikel Artikkel Articolo Tuote Προϊόν Artico Serial no. Serie nr. No. de serie Serie Nr. No. de série Serienr. Seriennummer Serie nummer No. di serie Sarjanro Αρ. σειράς No. de série Date of purchase Datum van aankoop Fecha de compra Købsdato...

Need help?

Do you have a question about the XTRA VS84-S and is the answer not in the manual?

Questions and answers