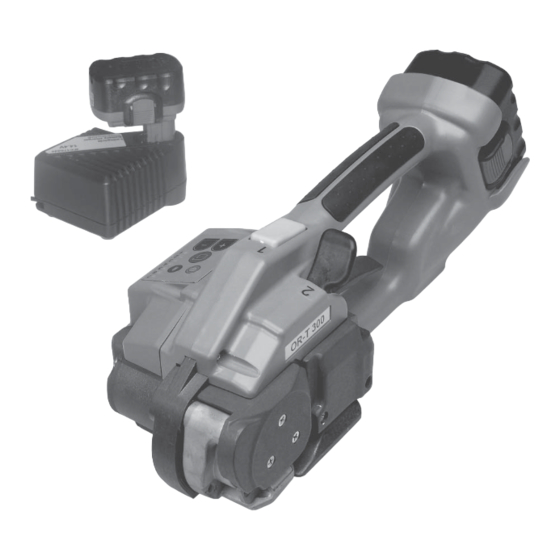

Orgapack OR-T 300 Operating And Safety Instructions Manual

Battery-hand tool for plastic strapping

Hide thumbs

Also See for OR-T 300:

- Short instruction: operating and maintenance (8 pages) ,

- Operating instructions manual (12 pages)

Table of Contents

Advertisement

DEUTSCH

ENGLISH

14

FRANÇAIS

25

ITALIANO

36

Ab Serie-Nr. 3/63500

From serie no 3/63500

A partir du no de série 3/63500

A partire dal no di serie 3/63500

Vor dem Gebrauch des

Gerätes die Betriebs-

anleitung aufmerksam

lesen.

Before using the tool,

read the operating

instructions carefully.

Avant l'utilisation de

l'appareil, consultez

soigneusement le

mode d'emploi.

Prima d'utilizzare

l'apparecchio, leggere

attentamante le istruzi-

oni per l'uso.

11.06/WE

BETRIEBSANLEITUNG UND SICHERHEITSVORSCHRIFTEN

3

OPERATING AND SAFETY INSTRUCTIONS

MODE D'EMPLOI ET DE SÉCURITÉ

ISTRUZIONI PER L'USO E DI SICUREZZA

OR-T 300

Akku-Handgerät zum Umreifen mit Kunststoffband

Battery-hand tool for plastic strapping

Appareil sur accu pour le cerclage par bande plastique

Apparecchio da batteria per reggiare con reggetta di plastica

Advertisement

Table of Contents

Summary of Contents for Orgapack OR-T 300

- Page 1 ENGLISH MODE D‘EMPLOI ET DE SÉCURITÉ FRANÇAIS ISTRUZIONI PER L‘USO E DI SICUREZZA ITALIANO OR-T 300 Akku-Handgerät zum Umreifen mit Kunststoffband Ab Serie-Nr. 3/63500 Battery-hand tool for plastic strapping From serie no 3/63500 Appareil sur accu pour le cerclage par bande plastique A partir du no de série 3/63500...

-

Page 2: Table Of Contents

DECLARATION OF AGREEMENT We take sole responsibility for declaring that the According to norm: tool OR-T 300, to which this declaration refers, is EN ISO 12100-1, EN ISO 12100-2, EN 349, in full compliance with the current requirements of EN 1050, EN 61000-6-1, EN 61000-6-3 the guidelines laid down by the council on 22th CH-8953 Dietikon, 11.10.2005... -

Page 3: General Information

ORGAPACK OR-T 300 GENERAL INFORMATION These operating instructions are intended to simplify familiarisation with the strapping tool and its proper CAUTION! use for the intended purpose. The operating instruc- tions contain important information concerning the Used where there is dan- safe, proper and effi... -

Page 4: Safety Instructions

ORGAPACK OR-T 300 SAFETY INSTRUCTIONS Inform yourself! Original ORGAPACK spare Original Read the operating instructions parts must be used exclusi- carefully. vely! jklsfjklsdjš lksdfjkl Preventive and corrective main- Not using original spare parts jkljsdllkjjkljsd ORGAPACK fkljjklkjkljsdafj asdfjklkjjkljklj ksldafkjkljklš jkljklkljsdafjlkj tenance on the tool may only... -

Page 5: Description

ORGAPACK OR-T 300 DESCRIPTION 4.1 CONSTRUCTION 1 Operating panel 2 Strap tensioning push button 3 Handle 4 Battery 5 Rocker lever 6 Welding/cutting button 7 Welding/Cutting 8 Tensioning 9 Battery charger (refer to chapter 4.4) Note on performance In order to achieve peak performance, only original batteries and charger may be used. -

Page 6: Battery Charger

ORGAPACK OR-T 300 4.4 BATTERY CHARGER The battery charger (IFC1702dx) is a special device with both charging and discharging functions for maxi- mum battery power and life. – When a battery is placed in the charger, the remai- ning charge level is tested fi rst. If the battery is not completely discharged, the charger will fi... -

Page 7: Initial Operation

ORGAPACK OR-T 300 INITIAL OPERATION 5.1 BATTERY CHARGER Input 90-135VAC, 170-264VAC / 47...65 Hz The mains supply must comply with the specifi cations on the rating plate (Fig. 5). Battery Type: Bosch NTC-Battery 14,4V The battery charger is suitable only for charging batteries from the Bosch range of tools (NiCd/ Fig. -

Page 8: Operating Instructions

ORGAPACK OR-T 300 OPERATING INSTRUCTIONS 6.1 OPERATING THE TOOL – Insert charged battery (7/1) into strapping tool. – Place strap round goods to be packaged, so that the straps lie one above the other on top of package. The beginning of the strap is underneath. -

Page 9: Checking The Seal

ORGAPACK OR-T 300 – Depress button (10/1) completely to the stop. The straps are welded together and the upper strap is cut off. The LED indicator (10/2) indicates the cooling time of the sealing: LED fl ashing After fi nishing the friction wel- ding, the green LED fl... -

Page 10: Operating Panel

ORGAPACK OR-T 300 6.3 OPERATING PANEL a) Standard indication max. min. a) Standard indication (green) The current strap tension setting is monitored with inserted and charged battery. green 1 = minimum strap tension (approx. 400 N) 7 = maximum strap tension (approx. 1400/3300 N*) -

Page 11: Setting Strap Tension Range

ORGAPACK OR-T 300 6.3.4 SETTING STRAP TENSION RANGE The following two strap tension ranges can be set on the tool: A = 400–3300 N (standard, PET straps) B = 400–1400 N (recommended for Polypro- pylene (PP) straps) Check strap tension range –... -

Page 12: Preventive And Corrective Maintenance

The tension wheel must not be cleaned while it is rotating. There is a risk of breaking teeth! Fig. 20 (3 = Tension wheel type for OR-T 300) Installation – Install the parts in reverse order. – Grease gear teeth of tension wheel lightly with Klüber grease GBU Y 131 (Microlube).

Need help?

Do you have a question about the OR-T 300 and is the answer not in the manual?

Questions and answers