Table of Contents

Advertisement

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

Indoor unit

[Model names]

SEZ-KD25VAQ

SEZ-KD35VAQ

SEZ-KD50VAQ

SEZ-KD60VAQ

SEZ-KD71VAQ

INDOOR UNIT

WIRED REMOTE

CONTROLLER

[Service Ref.]

SEZ-KD25VAQ.TH

SEZ-KD35VAQ.TH

SEZ-KD50VAQ.TH

SEZ-KD60VAQ.TH

SEZ-KD71VAQ.TH

Model name

indication

TEMP.

ON/OFF

(option)

December 2010

REVISED EDITION-B

CONTENTS

1. PART NAMES AND FUNCTIONS ········2

2. SPECIFICATIONS·································4

3. OUTLINES AND DIMENSIONS··········17

4. WIRING DIAGRAM ·····························18

5. REFRIGERANT SYSTEM DIAGRAM·······19

6. TROUBLESHOOTING·························20

7. DISASSEMBLY PROCEDURE ···········32

No.HWE10080

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Mitsubishi Electric SEZ-KD25VAQ.TH

-

Page 1: Table Of Contents

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS December 2010 No.HWE10080 REVISED EDITION-B TECHNICAL & SERVICE MANUAL Indoor unit [Model names] [Service Ref.] SEZ-KD25VAQ.TH SEZ-KD25VAQ SEZ-KD35VAQ.TH SEZ-KD35VAQ SEZ-KD50VAQ.TH SEZ-KD50VAQ SEZ-KD60VAQ.TH SEZ-KD60VAQ SEZ-KD71VAQ.TH SEZ-KD71VAQ CONTENTS 1. PART NAMES AND FUNCTIONS ········2 2. SPECIFICATIONS·································4 3. OUTLINES AND DIMENSIONS··········17 4. -

Page 2: Part Names And Functions

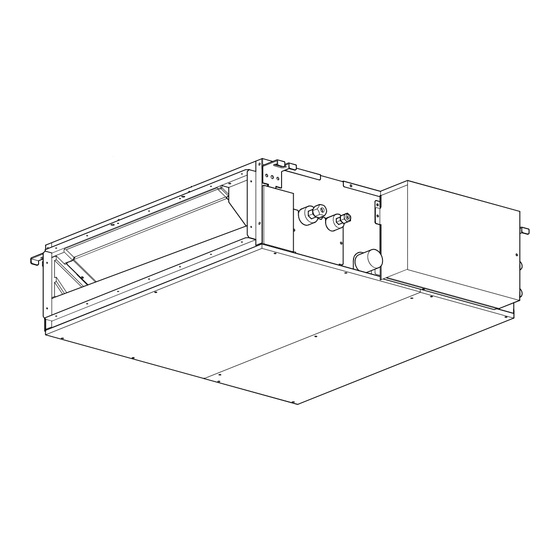

PART NAMES AND FUNCTIONS Indoor Unit Air outlet Air outlet duct flange Air inlet Wired remote controller (option) Once the controls are set, the same operation mode can be repeated by simply pressing the ON/OFF button. ● Operation buttons Start/Stop button Set Temperature buttons Down Fan Speed button... - Page 3 ● Display “Sensor” indication Displayed when the remote controller sensor is used. Day-of-Week For purposes of this explanation, Shows the current day of the week. all parts of the display are shown as lit. During actual operation, only Time/Timer Display the relevant items will be lit.

-

Page 4: Specifications

SPECIFICATIONS SEZ-KD25VAQ SEZ-KD35VAQ Model Name Capacity Cooling Heating Cooling Heating Power source 230V (50Hz) 230V (50Hz) Power input 0.04 0.04 0.05 0.05 Current 0.39 0.39 0.46 0.46 Temperature set range Remote controller ˚ C( ˚ F) 19 to 30 (67 to 86) 17 to 28 (63 to 83) 19 to 30 (67 to 86) 17 to 28 (63 to 83) - Page 5 SEZ-KD50VAQ SEZ-KD60VAQ Model Name Capacity Cooling Heating Cooling Heating Power source 230V (50Hz) 230V (50Hz) Power input 0.07 0.07 0.07 0.07 Current 0.63 0.63 0.63 0.63 Temperature set range Remote controller ˚ C( ˚ F) 19 to 30 (67 to 86) 17 to 28 (63 to 83) 19 to 30 (67 to 86) 17 to 28 (63 to 83)

- Page 6 SEZ-KD71VAQ Model Name Capacity Cooling Heating Power source 230V (50Hz) Power input 0.10 0.10 Current 0.84 0.84 Temperature set range Remote controller ˚ C( ˚ F) 19 to 30 (67 to 86) 17 to 28 (63 to 83) Airflow direction Sirocco fan x 4 Type x Quantity External static press...

- Page 7 NOISE CRITERION CURVES <50/60Hz> <50/60Hz> SEZ-KD25VAQ.TH SEZ-KD25VAQ.TH NOTCH LINE NOTCH LINE SPL(dB) SPL(dB) High High External static pressure: 5Pa External static pressure: 15Pa Middle Middle NC-70 NC-70 NC-60 NC-60 NC-50 NC-50 NC-40 NC-40 NC-30 NC-30 APPROXIMATE APPROXIMATE TERESHOLD OF TERESHOLD OF...

- Page 8 <50/60Hz> <50/60Hz> SEZ-KD35VAQ.TH SEZ-KD35VAQ.TH NOTCH SPL(dB) LINE NOTCH SPL(dB) LINE High High External static pressure: 5Pa External static pressure: 15Pa Middle Middle NC-70 NC-70 NC-60 NC-60 NC-50 NC-50 NC-40 NC-40 NC-30 NC-30 APPROXIMATE APPROXIMATE TERESHOLD OF TERESHOLD OF HEARING FOR HEARING FOR NC-20 NC-20...

- Page 9 <50/60Hz> <50/60Hz> SEZ-KD50VAQ.TH SEZ-KD50VAQ.TH NOTCH SPL(dB) LINE NOTCH SPL(dB) LINE High High External static pressure: 5Pa External static pressure: 15Pa Middle Middle NC-70 NC-70 NC-60 NC-60 NC-50 NC-50 NC-40 NC-40 NC-30 NC-30 APPROXIMATE APPROXIMATE TERESHOLD OF TERESHOLD OF HEARING FOR HEARING FOR NC-20 NC-20...

- Page 10 <50/60Hz> <50/60Hz> SEZ-KD60VAQ.TH SEZ-KD60VAQ.TH NOTCH SPL(dB) LINE NOTCH SPL(dB) LINE High High External static pressure: 5Pa External static pressure: 15Pa Middle Middle NC-70 NC-70 NC-60 NC-60 NC-50 NC-50 NC-40 NC-40 NC-30 NC-30 APPROXIMATE APPROXIMATE TERESHOLD OF TERESHOLD OF HEARING FOR HEARING FOR NC-20 NC-20...

- Page 11 <50/60Hz> <50/60Hz> SEZ-KD71VAQ.TH SEZ-KD71VAQ.TH NOTCH SPL(dB) LINE NOTCH SPL(dB) LINE High High External static pressure: 5Pa External static pressure: 15Pa Middle Middle NC-70 NC-70 NC-60 NC-60 NC-50 NC-50 NC-40 NC-40 NC-30 NC-30 APPROXIMATE APPROXIMATE TERESHOLD OF TERESHOLD OF HEARING FOR HEARING FOR NC-20 NC-20...

-

Page 12: Middle

INDOOR FAN PERFORMANCE AND CORRECTED AIR FLOW SEZ-KD25VAQ SEZ-KD25VAQ (External static pressure 5Pa) 220-240V 50/60Hz (External static pressure 15Pa) 220-240V 50/60Hz Limit Limit High Middle High Rated point Middle Rated point Airflow rate(m /min) Airflow rate(m /min) SEZ-KD25VAQ SEZ-KD25VAQ (External static pressure 35Pa) 220-240V 50/60Hz (External static pressure 50Pa) 220-240V 50/60Hz Limit Limit... -

Page 13: 50/60Hz

SEZ-KD35VAQ SEZ-KD35VAQ (External static pressure 5Pa) 220-240V 50/60Hz (External static pressure 15Pa) 220-240V 50/60Hz Limit Limit High High Middle Rated point Middle Rated point Airflow rate(m /min) Airflow rate(m /min) SEZ-KD35VAQ SEZ-KD35VAQ (External static pressure 35Pa) 220-240V 50/60Hz (External static pressure 50Pa) 220-240V 50/60Hz Limit Limit Rated point... -

Page 14: 50/60Hz

SEZ-KD50VAQ SEZ-KD50VAQ (External static pressure 5Pa) 220-240V 50/60Hz (External static pressure 15Pa) 220-240V 50/60Hz Limit Limit High High Middle Middle Rated point Rated point Airflow rate(m /min) Airflow rate(m /min) SEZ-KD50VAQ SEZ-KD50VAQ (External static pressure 35Pa) 220-240V 50/60Hz (External static pressure 50Pa) 220-240V 50/60Hz Limit Limit High... -

Page 15: Middle

SEZ-KD60VAQ SEZ-KD60VAQ (External static pressure 5Pa) 220-240V 50/60Hz (External static pressure 15Pa) 220-240V 50/60Hz Limit Limit High Middle High Middle Rated point Rated point Airflow rate(m /min) Airflow rate(m /min) SEZ-KD60VAQ SEZ-KD60VAQ (External static pressure 35Pa) 220-240V 50/60Hz (External static pressure 50Pa) 220-240V 50/60Hz Limit Limit High... -

Page 16: Middle

SEZ-KD71VAQ SEZ-KD71VAQ (External static pressure 5Pa) 220-240V 50/60Hz (External static pressure 15Pa) 220-240V 50/60Hz Limit Limit High Rated point High Middle Middle Rated point Airflow rate(m /min) Airflow rate(m /min) SEZ-KD71VAQ SEZ-KD71VAQ (External static pressure 35Pa) 220-240V 50/60Hz (External static pressure 50Pa) 220-240V 50/60Hz Limit High Limit... -

Page 17: Outlines And Dimensions

OUTLINES AND DIMENSIONS Unit : mm 157.5 37 100 outlet inlet L-{2.9 2XE-{2.9 Air filter 625 (Suspension bolt pitch) Knockout hole {27 Suspension bolt hole (Remote controller transmission line) 4-14X30 Slot 2 Refrigerant piping flare connection (liquid) Knockout hole {27 Control box (Indoor/outdoor connecting line) Terminal block... -

Page 18: Wiring Diagram

WIRING DIAGRAM INSIDE SECTION OF CONTROL BOX R.B. TB15 I.B. CN01 (BLACK) CN3C(BLUE) CN32 CN51 CN41 ZNR02 L1:ONLY CN2L CN22(BLUE) ON OFF DC310~340V FUSE ZNR01 SEZ-KD71VAQ RECTIFY CIRCUIT LED2 LED3 LED1 CN4F CN44 CN20(RED) CNMF (BLUE) CN4F OUTDOOR UNIT t˚ t˚... -

Page 19: Refrigerant System Diagram

REFRIGERANT SYSTEM DIAGRAM Strainer Heat exchanger Refrigerant GAS pipe connection (Flare) Condenser/evaporator temperature thermistor (TH5) Refrigerant flow in cooling Refrigerant flow in heating Refrigerant LIQUID pipe connection (Flare) Pipe temperature thermistor/liquid Room temperature (TH2) thermistor (TH1) Strainer Distributor... -

Page 20: Troubleshooting

TROUBLESHOOTING 6-1. CAUTIONS ON TROUBLESHOOTING (1) Before troubleshooting, check the followings: 1 Check the power supply voltage. 2 Check the indoor/outdoor connecting wire for mis-wiring. (2) Take care the followings during servicing. 1 Before servicing the air conditioner, be sure to turn off the remote controller first to stop the main unit, and then turn off the breaker. - Page 21 • If the unit cannot be operated properly after the test run has been performed, refer to the following table to remove the cause. Symptom Cause Wired remote controller LED 1, 2 (PCB in outdoor unit) For about 2 •For about 2 minutes after power-on,op- After LED 1, 2 are lighted, LED 2 is PLEASE WAIT minutes after...

- Page 22 [Output pattern A] Errors detected by indoor unit Wired remote Wireless remote controller controller Symptom Remark Beeper sounds/OPERATION INDICATOR lamp flashes Check code (Number of times) Intake sensor error Pipe (Liquid or 2-phase pipe) sensor error P2, P9 Indoor/outdoor unit communication error E6, E7 Drain sensor error Drain pump error...

-

Page 23: Auto Restart Function

For description of each LED (LED1, 2, 3) provided on the indoor controller, refer to the following table. LED 1 (power for microcomputer) Indicates whether control power is supplied. Make sure that this LED is always lit. LED 2 (power for remote controller) Indicates whether power is supplied to the remote controller. -

Page 24: Self-Diagnosis Action Table

Note: Refer to the manual of outdoor unit for the details of display 6-3. SELF-DIAGNOSIS ACTION TABLE such as F, U, and other E. Abnormal point and detection method Countermeasure Error Code Cause Room temperature 1 Defective thermistor 1–3 Check resistance value of thermistor. thermistor (TH1) characteristics 0: ······15.0k"... - Page 25 Abnormal point and detection method Countermeasure Error Code Cause Freezing/overheating protection is (Cooling or drying mode) (Cooling or drying mode) working 1 Clogged filter (reduced airflow) 1 Check clogging of the filter. 1 Freezing protection (Cooling mode) 2 Short cycle of air path 2 Remove shields.

- Page 26 Abnormal point and detection method Countermeasure Error Code Cause Abnormality of pipe temperature ther- 1 Defective thermistor 1–3 Check resistance value of thermistor. mistor / Condenser-Evaporator (TH5) characteristics For characteristics, refer to (P1) above. 2 Check contact failure of connector (CN44) 1 The unit is in three-minute resume pro- 2 Contact failure of connector on the indoor controller board.

- Page 27 Abnormal point and detection method Countermeasure Error Code Cause ∗ Check LED display on the outdoor control cir- Indoor/outdoor unit communication 1 Contact failure, short circuit or, error (Signal receiving error) cuit board. (Connect A-control service tool, mis-wiring (converse wiring) of 1 Abnormal if indoor controller board PAC-SK52ST.) indoor/outdoor unit connecting...

-

Page 28: Troubleshooting By Inferior Phenomena

6-4. TROUBLESHOOTING BY INFERIOR PHENOMENA Note: Refer to the manual of outdoor unit for the detail of remote controller. Phenomena Cause Countermeasure (1)LED2 on indoor controller board • When LED1 on indoor controller board is also off. is off. 1 Power supply of rated voltage is not supplied to out- 1 Check the voltage of outdoor power door unit. - Page 29 6-5. TEST POINT DIAGRAM 6-5-1. Indoor controller board Fuse(6.3A 250V) CN01 Power supply voltage (220 - 240VAC) Emergency operation Model selection Capacity setting CN01 CN32 Remote start/stop adapter CN22 For MA remote controller cable con- nection (10 - 13 VDC (Between 1 and 3.)) CN51 Centralized control CN41 JAMA standard HA terminal A CNMF...

-

Page 30: Trouble Criterion Of Main Parts

6-6. TROUBLE CRITERION OF MAIN PARTS Part name Check method and criterion Room temperature Measure the resistance with a tester. thermistor (Part temperature 10°C ~ 30°C) (TH1) Normal Abnormal Pipe temperature 8kΩ~20kΩ Opened or short-circuited thermistor/liquid (TH2) Condenser/evaporator temperature thermistor (TH5) Wiring diagram Motor... - Page 31 6-7. DC FAN MOTOR (FAN MOTOR/ INDOOR CONTROLLER BOARD) Check method of DC fan motor (fan motor / indoor controller circuit board) Notes · High voltage is applied to the connecter (CNMF) for the fan motor. Give attention to the service. ·...

-

Page 32: Disassembly Procedure

DISASSEMBLY PROCEDURE Exercise caution when removing heavy parts. 1. Control box 1. Removing the control box cover (1) Remove the two fixing screws on the cover (A) to remove it. Fig. 1 Fig. 2 2. Thermistor (Intake air) 1. Remove the control box cover according to the procedure in section [1]. - Page 33 Exercise caution when removing heavy parts. 3. Drainpan 1. Removing the filter and the bottom plate (1) Push up the tab on the filter, and pull out the filter in the direction of the arrow 1. (2) Remove the fixing screws on the bottom plate (D), (E) to remove it.

- Page 34 Exercise caution when removing heavy parts. 4. Thermistor (Condenser / evaporator) (Liquid pipe) 1. Remove the drain pan according to the proce- dure in section [3]. 2. Removing the Heat exchanger cover (1) Remove the four fixing screws on the heat exchanger cover (F) to remove it.

- Page 35 Exercise caution when removing heavy parts. 5. Fan and fan motor 1. Removing the filter and the bottom plate (1) Push down the tab on the filter, and pull out the filter in the direction of the arrow 1. (2) Remove the fixing screws on the bottom plate (J) to remove it.

- Page 36 Exercise caution when removing heavy parts. 6. Bearing [KD50·60·71VAQ model only] 1. Removing the bearing (1) Remove the two fixing screws on the bearing cover (K) to remove it. Fig. 13 (2) Remove the two bearing retainer screws to remove the bearing. Fig.

- Page 40 New publication, effective Dec. 2010 HWE10080 Specifications subject to change without notice. Printed in Japan...

Need help?

Do you have a question about the SEZ-KD25VAQ.TH and is the answer not in the manual?

Questions and answers