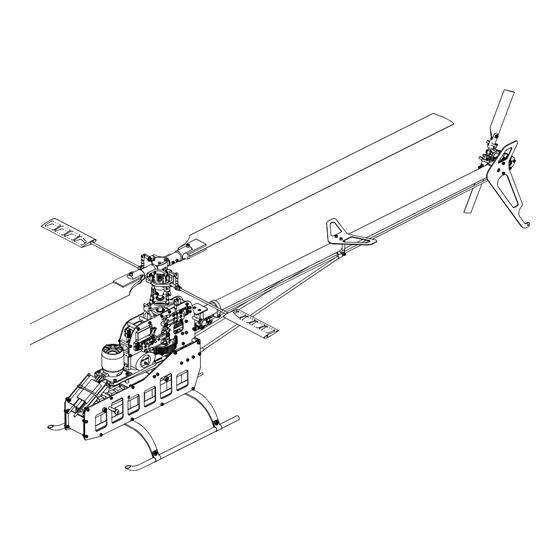

Summary of Contents for minicopter Maxi-Joker 2

- Page 1 Ord.-No.: 2600 manual Dipl.Ing. Gerd Guzicki Rheinstahlring 47 34246 Vellmar Fon: +49 561 9882800 Fax: +49 561 9882801 Version 3 www.minicopter.de / info@minicopter.de Date: july 4th 2007...

- Page 2 Congratulations on the purchase of your Maxi-Joker 2 - helicopter. The successor of our popular Joker-series has got some new features to increase its span of usage. From beginners training over usage in scale bodies, as photo helicopter to 3D extrem flight is everything possible without modifications.

- Page 3 Safety rules: Radio controlled helicopters are no toys. A wrong use of such models can cause accidents with heavy injuries. Therefore please bear following rules in your mind: For engine running tests on your workbench remove the complete mainrotor including all rods and the tailrotor blades. Consider that nothing can come in the tailrotor.

- Page 4 (2x) (4x) (bore Ø1.8mm) (4x) (4x) (4x) (2x) 187.5 = use Loctite ® manual...

- Page 5 (8x) (2x) (2x) (8x) (2x) 8 = lock nut M3 14 = hexagon socket screw M3 x 8 = use Loctite ® manual...

- Page 6 (2x) (2x) (2x) (2x) (4x) 8 = lock nut M3 471 = hexagon flat head screw M3 x 16 771 = hexagon flat head screw M3 x 25 = use Loctite ® manual...

- Page 7 (16x) (2x) (14x) Tighten pos. 16 later! 8 = lock nut M3 14 = hexagon socket screw M3 x 8 16 = hexagon socket screw M3 x 12 = use Loctite ® manual...

- Page 8 Do not tighten Part.-No. 15 yet! (4x) 15 = hexagon socket screw M3 x 10 = use Loctite ® manual...

- Page 9 ® manual...

- Page 10 Vertiefung nach unten! (feststehend) 18.0x10.2 (drehend) 17.8x10.0 (4x) Erst Welle in Getriebe- block einfügen! 4 = U-Scheibe M3 groß 8 = Stopmutter M3 (4x) 15 = Inbusschraube M3 x 10 16 = Inbusschraube M3 x 12 (5x) 72 = Flanschkugellager 10x19x7 ®...

- Page 11 (2x) (2x) (4x) (5x) 8 = lock nut M3 18 = hexagon socket screw M3 x 20 19 = hexagon socket screw M3 x 25 41 = ball joint 2.5 51 = shim 3 x 6 x 1 63 = ball bearing with flange F3 x 8 x 4 76 = joint bolt M3 x 4 469 = hexagon socket screw M2.5 x 12 = use Loctite...

- Page 12 (2x) (2x) (3x) (6x) (2x) Bearing carrier should be tightened up after the belt is fitted! Use shims 3x6x0.1 for the right distance to the belt! Distance between bearing and belt about 0.2-0.3mm! Bearing may NOT run with the belt during normal usage!! 8 = lock nut M3 14 = hexagon socket screw M3 x 8 17 = hexagon socket screw M3 x 16...

- Page 13 1616 actro 24-5 heli 1618 actro 32-4 heli (4x) (4x) (2x) (4x) (4x) (2x) (2x) 764 14Z i=11,6:1 765 15Z i=10,8:1 2 = washer M3 8 = Lock nut M3 14 = hexagon socket screw M3 x 8 16 = hexagon socket screw M3 x 12 18 = hexagon socket screw M3 x 20 = use Loctite 35 = grub screw M4 x 5...

- Page 14 1620 HP 370/40/A2S (4x) (4x) (2x) (4x) (4x) (2x) 768 18Z i= 9,0:1 (2x) 2 = washer M3 8 = Lock nut M3 14 = hexagon socket screw M3 x 8 16 = hexagon socket screw M3 x 12 18 = hexagon socket screw M3 x 20 35 = grub screw M4 x 5 = use Loctite 760 = hexagon lense screw M4 x 8...

- Page 15 Mainshaft may not have any endplay! Justate with collar ring! (16x) (2x) (2x) in bag 8! No screw in this hole! (15x) 8 = lock nut M3 21 = hexagon socket screw M3 x 35 709 = hexagon socket screw M3 x 45 ®...

- Page 16 After mounting of upper and lower frame remove screws from bearing plate 421 and check concentricity of holes in lower frame to threads holes in bearing plate, eventually file nacharbeiten. holes in frame a little bit. (2x) (2x) (4x) (2x) file fillet rectangular! (2x) (2x)

- Page 17 (4x) (2x) (4x) (4x) (2x) (4x) 46 mm long (2x) ca.77.5 2 = washer M3 7 = lock nut M2 8 = lock nut M3 16 = hexagon socket screw M3 x 12 41 = ball joint 2.5 ® manual...

- Page 18 (4x) (2x) 26 mm long (2x) (2x) (2x) (2x) (4x) (4x) 2 = washer M3 ca 58.5 7 = lock nut M2 8 = lock nut M3 16 = hexagon socket screw M3 x 12 41 = ball joint 2.5 494 = hexagon lense screw M3 x 16 ®...

- Page 19 (4x) (2x) 26 mm long (2x) (2x) (2x) (2x) (4x) (4x) (4x) 2 = washer M3 ca. 57 7 = lock nut M2 8 = lock nut M3 16 = hexagon socket screw M3 x 12 41 = ball joint 2.5 494 = hexagon lense screw M3 x 16 ®...

- Page 20 (2x) (2x) 1210 (3x) 120°-mode (recommended) 140°-mode Screw the jount balls 480 with care! 51 = washer 3 x 6 x 1 76 = joint bolt M 3 x 4 77 = joint bolt M 3 x 6 78 = joint bolt M 3 x 9 = use Loctite ®...

- Page 21 (4x) (2x) 31 mm long links are in bag 11! ca. 59 41 = ball joint 2.5 ® manual...

- Page 22 ® manual...

- Page 23 ® manual...

- Page 24 (2x) ® manual...

- Page 25 (6x) (4x) (2x) (4x) (2x) 50-55 2 = washer M3 8 = lock nut M3 16 = hexagon socket screw M3 x 12 21 = hexagon socket screw M3 x 35 25 = hexagon flat head screw M3 x 8 ®...

- Page 26 (2x) (4x) (2x) Epoxy (4x) Tip: Pull belt with a cranked steel wire thru the tube! 14 = hexagon socket screw M3 x 8 21 = hexagon socket screw M3 x 35 ® manual...

- Page 27 (2x) (2x) 8 = lock nut M3 23 = hexagon lense screw M3x6 ® manual...

- Page 28 adjust for no end play using 5x10x0.1 shims (2x) (2x) (3x) (2x) (2x) (2x) (2x) (2x) (2x) (2x) distance of ball bearing 441 to toothed belt: 0.2-0.3 mm (5x) (standing, does NOT run with the belt!) 8 = lock nut M3 14 = hexagon socket screw M3x8 Turn belt 90 degree to the 19 = hexagon socket screw M3 x 25...

- Page 29 (2x) (2x) (2x) (2x) Oil bearings frequently! Tip: Don´t screw in by hand, but press bridge on in a vice 66 = ball bearing 6 x 10 x 2,5 (check for squareness)! ® manual...

- Page 30 (4x) (2x) 17 = hexagon socket screw M3 x 16 51 = shim 3 x 6 x 1 63 = ball bearing with flange F3 x 8 x 4 76 = joint bolt M3 x 4 = use Loctite 92 = hexagon lense screw M3 x 8 Spezial ®...

- Page 31 (4x) (4x) (2x) (2x) (2x) Chamfer to the inner side! (2x) (2x) (2x) (2x) 4.2x10.0 4.0x9.8 4.0x9.8 (blue painted) 1036 (2x) (4x) (2x) Before mounting the bladegrips check the easy running of each bearing unit, eventually shorten bush 711 a little bit (remove from side with chamfer with sandpaper)! 8 = lock nut M3...

- Page 32 ground strap (2x) (2x) wire (2x) ca. 882 mm (2x) Epoxy Epoxy Inner side! 397 silicone tube! Oil frequently! bore Ø3.0 (2x) (2x) O-Rings! Don´t forget! belt should not touch other side of belt (press with thumb) Silicone tube! Don´t forget! 2 = washer M3 4 = washer M3 large 6 = clevis 2.5 PA...

- Page 33 (2x) (2x) 53 = shim 4x8x0.1 67 = ball bearing 4x12x4 ® manual...

- Page 34 Do not oil or lubricate piston! Keep dry and clean! (2x) (2x) (2x) 95 = hexagon socket screw M3 x 10 alloy steel 32 = hexagon grub screw with cone point M4x5 alloy steel = use Loctite ® manual...

- Page 35 (4x) (2x) (2x) (2x) (4x) (2x) If necessary! (2x) (4x) (2x) 8.2x16! Blade grips must rotate freely but 8x15.8! without any end play! (4x) (2x) Lubricate O-Rings! assembly may require the blade grips to be heated to 150°C/300°F 11 = shim 8x14x0.2 34 = hexagon socket screw M5x12 12.9 46 = shim 8x14x0.1 47 = shim 8x14x0.5...

- Page 36 Note: Steering arm 503 is on the backside of the rotorblade! (4x) (4x) (2x) (4x) (2x) (6x) (4x) Justate coupling 506 parallel to the hub or vertical (2x) axis, eventually remove (4x) one shim #51. (2x) (2x) (2x) (2x) (2x) = use Loctite = do not use Loctite 13 = hexagon socket screw M3 x 5...

- Page 37 (4x) (2x) (2x) Screw the jount balls 526 with care! (2x) 35 = grub screw M4 x 5 43 = shim 4 x 8 x 1 = use Loctite 57 = teflon bearing ® manual...

- Page 38 (2x) (2x) screw depth of paddles: 35 - 36 mm screw both paddles at the same length! (2x) (2x) (2x) (2x) (2x) (2x) (2x) (4x) (2x) (2x) Oil brass weight and Cut the shrink tube with 8 mm overlap at insert with a hammer each end and then use a hair dry to shrink Normally do not insert weight!

- Page 39 (4x) (2x) Use oil for the first mounting of the rotorhead. DO NOT TURN, push only straight!If the hub jams, then remove, clean and try again! 8 = lock nut M3 89 = hexagon socket screw M3 x19 Spezial 97 = rubber grommet 3 mm ®...

- Page 40 1. All servo arms and bellcranks must be vertical or horizontal. 2. Adjust pushrods (1) to level the swashplate. 3. Adjust pushrods (2) to the Hiller bridge until the antorotation ball bearing is centered in its brass lined slot. 4. Double ball links (3) between flybar and mixer arm are 42 mm long. 5.

- Page 41 Pitch gauge +10° +8° +6° 0° -2° -6° -10° Minimum Maximum middle stick hovering Recommended rotorspeed: 1200 - 1300 1/min Highest allowed rotorspeed: 1400 1/min Do not exceed! Deflections: Elevator: Hovering 1350 1/min: 10° 25% Exponential Forward flight 1350 1/min: 15° 20% Exponential Roll: Hovering 1350 1/min: 10°...

Need help?

Do you have a question about the Maxi-Joker 2 and is the answer not in the manual?

Questions and answers