Bunn DUAL068000 Installation & Operating Manual

Dual sh dbc with smart funnel dual068000 & up

Hide thumbs

Also See for DUAL068000:

- Installation and operating manual (8 pages) ,

- Programming manual (36 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Programming Manual

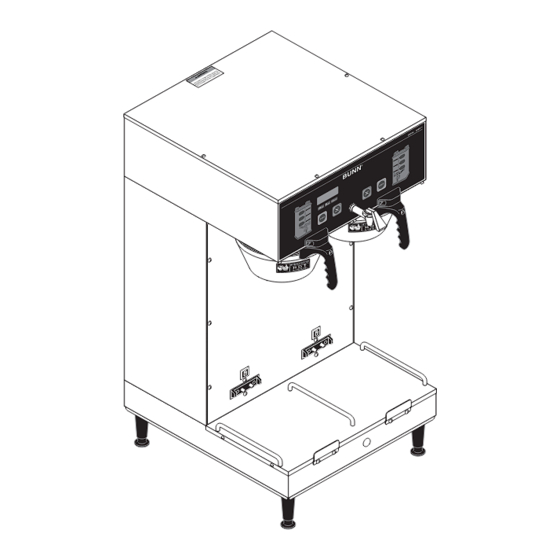

DUAL

SH DBC

®

®

WITH SMART FUNNEL

®

S/N DUAL068000 & UP

N

U T

IO

C A

!

INSTALLATION & OPERATING MANUAL

BUNN-O-MATIC CORPORATION

POST OFFICE BOX 3227

SPRINGFIELD, ILLINOIS 62708-3227

PHONE: (217) 529-6601 FAX: (217) 529-6644

To obtain the Illustrated Parts Catalog, visit the Bunn-O-Matic website, at www.bunn.com. This is absolutely FREE, and the

quickest way to obtain the catalog. Contact Bunn-O-Matic Corporation at 1-800-286-6070 to obtain a paper copy of the

required Illustrated Parts Catalog mailed via U.S. Postal Service

www.bunn.com

29877.0003 01/08 ©2005 Bunn-O-Matic Corporation

Advertisement

Table of Contents

Summary of Contents for Bunn DUAL068000

- Page 1 PHONE: (217) 529-6601 FAX: (217) 529-6644 To obtain the Illustrated Parts Catalog, visit the Bunn-O-Matic website, at www.bunn.com. This is absolutely FREE, and the quickest way to obtain the catalog. Contact Bunn-O-Matic Corporation at 1-800-286-6070 to obtain a paper copy of the required Illustrated Parts Catalog mailed via U.S.

- Page 2 This warranty is conditioned on the Buyer 1) giving BUNN prompt notice of any claim to be made under this warranty by telephone at (217) 529-6601 or by writing to Post Office Box 3227, Springfield, Illinois 62708-3227; 2) if requested by BUNN, shipping the defective equipment prepaid to an authorized BUNN service location;...

-

Page 3: Table Of Contents

TABLE OF CONTENTS User Notices ..........................4 Electrical Requirements ......................5 Plumbing Requirements ......................6 Operating Controls ........................7 Initial Setup and Coffee Brewing ....................8 Cleaning ............................9 Glossary ............................10 PROGRAMMING ........................11 Programming Switches ......................11 Programming the Brewer ......................12 PROGRAM FUNCTIONS (LEVEL 1) Brew Lockout .........................12 Recipe Programing Methods ....................13 Flow Diagram ..........................14 PROGRAM FUNCTIONS (LEVEL 2) -

Page 4: User Notices

USER NOTICES The notices on this brewer should be kept in good condition. Replace unreadable or damaged labels. 00658.0000 This equipment must be installed to comply 00831.0000 with the International Plumbing Code of the International Code Council and the Food Code Manual of the Food and Drug Adminis- tration (FDA). -

Page 5: Electrical Requirements

ELECTRICAL REQUIREMENTS WARNING - The brewer must be disconnected from the power source until specified in Initial Set-Up. Refer to Data Plate on the Brewer, and local/national electrical codes to determine circuit requirements. L2 RED L2 RED L2 RED L2 RED WHITE WHITE L1 BLACK... -

Page 6: Plumbing Requirements

" water supply line. A tight coil of copper tubing in the water line will facilitate moving the brewer to clean the counter top. Bunn-O-Matic does not recommend the use of a saddle valve to install the brewer. The size and shape of the hole made in the supply line by this type of device may restrict water flow. -

Page 7: Operating Controls

OPERATING CONTROLS I T C OPERATING CONTROLS (a) MAIN ON/OFF SWITCH This switch, located under the brewer behind the right front leg, turns power on and off to all components in the brewer. (b) BATCH SELECTOR SWITCHES Pressing the switch corresponding to the Small, Medium, or Large batch selects the amount of coffee to be brewed. -

Page 8: Cleaning

7. The brewer is now ready for use in accordance with the coffee brewing instructions. COFFEE BREWING 1. Insert a BUNN filter into the Smart Funnel. 2. If a grinder is not used to obtain the coffee grounds, pour the proper amount of fresh coffee grounds into the funnel and level by gently shaking. -

Page 9: Glossary

GLOSSARY AD CARD: An assembly consisting of a computer chip and an instruction label. Used for loading advertising messages into the brewer. BREW LOCKOUT: The inability to initiate a brew if the water temperature is less than the ready temperature programmed into the brewer. -

Page 10: Programming

This is used to access the programming mode and is also used to scroll forward through the function list. 2. Upper left corner of the "B" in the BUNN logo This is used to scroll backwards through the function list. -

Page 11: Programming The Brewer

PROGRAMMING THE BREWER The programming of the brewer is divided into two levels. There is one function in Level 1. All other functions are accessed in Level 2. The following function screens are in order of appearance. Each screen will have instructions on how to access, and the procedures to program the various functions of the brewer. -

Page 12: Recipe Programing Methods

AND NO NAME RIGHT BREW REFER TO NAME LIST SETTINGS GO TO REVIEW RECIPES IN GRINDER MANUAL AND FOLLOW INSTRUCTIONS CONTACT BUNN-O-MATIC TO VIEW A LIST OF EXISTING RECIPES, FOR ASSISTANCE GO TO REVIEW RECIPES AND FOLLOW THE INSTRUCTIONS P2369 Page 12... -

Page 13: Flow Diagram

PROGRAMMING THE BREWER (cont.) PROGRAM FLOW DIAGRAM LEVEL 1 Press upper right hidden switch for approximately 2 seconds, until the following screen appears. BREW LOCKOUT? DONE Returns to normal operating mode LEVEL 2 Press upper right hidden switch for approximately 4 seconds, until “UNITS” appears on screen. Sets unit of Sets unit of UNITS... - Page 14 PROGRAMMING THE BREWER (cont.) PROGRAM FLOW DIAGRAM (Cont.) LEFT, RIGHT, FULL FULL BYPASS EASY PULSE SETUP TRANSFER SET ALL 3 SET ALL 3 COMPLETE DONE BATCHES BATCHES ENABLE ADS? BREW TIME: X:XX 3 BATCHES DONE? DONE DONE 3 BATCHES DONE? SET TEMP: 200°F LEFT, RIGHT,...

- Page 15 PROGRAMMING THE BREWER (cont.) PROGRAM FLOW DIAGRAM (Cont.) LEFT BREW VALVE NEXT L BYPS OZ/M XX.X SPRAY HEAD CAL? DONE LEFT BYPASS NEXT R BYPS OZ/M XX.X BYPASS CAL? DONE LEFT FUNNEL LOCK NEXT CALIBRATE FLOW? CONTAINER RDY? CONTAINER RDY? QUIT QUIT LEFT SERVER...

- Page 16 PROGRAMMING THE BREWER (cont.) UNITS (SETTING UNITS OF MEASURE) 2. Press DONE to proceed. The display should now This function allows the units of measure to be read CHANGING UNITS!! WILL ERASE!! ... ALL set in English or Metric readings for all screens. The PREVIOUSLY STORED RECIPES AND ALL SETUP program is defaulted to English.

-

Page 17: Set New Recipe (Using A Smart Funnel And G9-2T Dbc Or Mhg Grinder)

PROGRAMMING THE BREWER (cont.) SET NEW RECIPE Procedure for Setting the Recipe: Using a Smart Funnel and a G9-2T DBC or MHG NOTE: Before beginning setup, place a server beneath Grinder: the left brew funnel. This function allows the operator to set BREW 1. -

Page 18: Set Pulse Brew Times

PROGRAMMING THE BREWER (cont.) SET NEW RECIPE (cont.) 8. Using (-) and (+), set the amount of brew water, in with the setup instructions for SETTING PULSE ounces, to be dispensed for that particular batch BREW - ENTER TIMES. SET DRIP TIME. (Refer size. -

Page 19: Set New Recipe (Using A Recipe Card)

CARD CONTAINS DRIP-OUT TIMES for that particular coffee NAME. RECIPE FOR These can all be loaded in seconds. Contact Bunn-O-Matic Corporation for the avail- ability of RECIPE CARDS. (COFFEE NAME) NOTE: Instructions to program the brewer and grinder SHOW QUIT SAVE are printed on the RECIPE CARD, along with the coffee name that is being programmed. -

Page 20: Set New Recipe (No Smart Funnel Nor G9-2T Dbc Or Mhg Grinder)

If not using a Smart Funnel (with a computer chip) and/or a G9-2T DBC or MHG Grinder, the brewer will EXIT TO function as a standard Bunn Dual Brewer: NEXT FUNCTION SCREEN It is possible to operate the brewer without using NO-NAME LEFT a Smart Funnel and/or a G9-2T DBC or MHG Grinder. -

Page 21: Review Recipes/Modify Recipes/Set Up No Name Coffee

PROGRAMMING THE BREWER (cont.) REVIEW RECIPES/MODIFY RECIPES/SET UP NO 2. Press YES to proceed. The display should now NAME COFFEE: read NO-NAME LEFT, along with MODIFY, SHOW This function has three parts. It allows the operator and NEXT. to view the brew settings for the various coffee names 3. - Page 22 PROGRAMMING THE BREWER (cont.) BREW OZ (SETTING OR ADJUSTING BREW VOL- Press and release the batch size to be modified. 5. Using (-) and (+), set the amount of brew water, UMES) This function allows adjustment of the brew vol- in ounces, to be dispensed over the grounds for umes for each batch.

- Page 23 PROGRAMMING THE BREWER (cont.) 4. Press and release MODIFY. The display should % BYPASS read BREW OZ. This function allows adjustment of the amount of 5. Press and release DONE. The display should read water that bypasses the grounds. The number signi- 3 BATCHES DONE?.

-

Page 24: Set Pulse Brew Times

PROGRAMMING THE BREWER (cont.) SET PULSE BREW: Modifying pulse brew: This function allows the operator to program the Range: 1st on time - off to 4 minutes brewer to "pulse” the sprayhead flow on and off con- Off time - off to 4 minutes tinually during a brew cycle (start and stop the flow Last on time - Preinfusion to 4 minutes of water out of the sprayhead). -

Page 25: Easy Pulse

PROGRAMMING THE BREWER (cont.) SET PULSE BREW (cont.) REVIEW RECIPES? EXIT TO NEXT FUNCTION SCREEN NO-NAME LEFT MODIFYSHOWNEXT ADVANCES TO ALL OTHER COFFEE NAMES PROGRAMMED IN THE BREWER'S MEMORY SCREEN DISPLAYED PRESS BREW OZ: XX.XX DONE 3 BATCHES DONE? % BYPASS XX.X DONE 3 BATCHES DONE? <RECIPE NAME>... - Page 26 PROGRAMMING THE BREWER (cont.) SET PULSE BREW - EASY PULSE SETUP 3. When finished, select another batch size to be set by pressing the switch next to the indicator light. Repeat step 2 for each batch size to be set. NOTE: The procedure to enter the PULSE BREW function must be performed prior to following the 4.

- Page 27 PROGRAMMING THE BREWER (cont.) SET PULSE BREW - ENTER TIMES NOTE: The procedure to enter the PULSE BREW SET PULSE BREW? function must be performed prior to following the steps listed below. 1. Press and release YES. The display should now read EASY PULSE SETUP.

-

Page 28: Set Preinfusion

PROGRAMMING THE BREWER (cont.) NOTE: Pressing the upper right hidden button before SET PREINFUSION: reaching the final setting screen exits the setup and This function sets the brewer to turn the sprayhead retains the old values. flow on for a preset time (1st ON TIME) followed by a preset spray pause (OFF TIMES) and then turn the spray on continuously until the brew volume is completed. - Page 29 PROGRAMMING THE BREWER (cont.) 11. When finished, press another batch size and repeat DRIP TIME (now displayed on "non" funnel lock step 10 until all three sizes are set. units as well) 12. When finished, press DONE. The display should This function allows the setting or modification read 3 BATCHES DONE? of the funnel locks to stay engaged after the end of...

-

Page 30: Assign Recipes

PROGRAMMING THE BREWER (cont.) COPY SETTINGS (NO NAME COFFEE SETTINGS ASSIGN RECIPES ONLY) This function is used to transfer all the brew set- This function allows for assigning a coffee name tings from a NO NAME coffee flavor programmed other than NO-NAME to the BREW switch. on one side of the brewer to the other side. -

Page 31: Enable Ads

PROGRAMMING THE BREWER (cont.) 4. When finished, press and release DONE to save COPY SETTINGS (NO NAME COFFEE SETTINGS ONLY) the new setting, exit the ENABLE ADS function and (cont.) advance to the next function screen, SET TEMP. Another alternative is to press and release either 2. -

Page 32: Set Ready (Ready Temperature)

PROGRAMMING THE BREWER (cont.) SET TEMP (cont.) REFILL - Range: 20 to 230 This function allows the operator to adjust the 2. To adjust the brew temperature, press (-) to de- sensitivity of the refill circuit. This is mainly a trouble- crease or (+) to increase the brew temperature. -

Page 33: Bypass Oz/M (Read Bypass Flow Rate)

PROGRAMMING THE BREWER (cont.) SPRAY OZ/M (cont.) release DONE to advance to next function screen, Procedure to adjust the flow rate setting: CALIBRATE FLOW. Another alternative is to press 1. Press and hold upper right hidden switch until the and release either ON/OFF switch located on the display reads UNITS. - Page 34 PROGRAMMING THE BREWER (cont.) CALIBRATE FLOW (cont.) Procedures to calibrate the bypass flow rate: to advance to the next function screen, or press 1. Place a container, accurately graduated in ounces, and release either ON/OFF switch located on the and with a minimum capacity of 60 ounces, below front switch panel to exit the CALIBRATE FLOW the funnel on the brewer to be calibrated.

-

Page 35: Calibrate Bypass Flow

PROGRAMMING THE BREWER (cont.) BREW COUNTERS CALIBRATE FLOW (cont.) This function allows the operator to track the number of brew cycles completed on the left side, the CALIBRATE FLOW? right side, and the total of both combined. There are three resettable counters, and one life counter that is not resettable. - Page 36 PROGRAMMING THE BREWER (cont.) BREW COUNTERS (cont.) SERVER DETECT This function allows the operator to prevent the start 5. When finished, press NEXT to advance counter of a brew cycle if a Soft Heat server is not positioned screens until the display reads BREW COUN- correctly on the brewer.

-

Page 37: Service Tools

PROGRAMMING THE BREWER (cont.) SERVICE TOOLS The components that can be individually tested are as follows: This function allows the testing of individual com- Left Brew Valve ponents and the ability to check switches for proper Left Bypass Valve function. This function also tests the Soft Heat server's Left Funnel Lock status on the brewer (in place or removed), and the Left Server... - Page 38 PROGRAMMING THE BREWER (cont.) SERVICE TOOLS (cont.) is functional, the sound of the valve operating will be heard. Procedure to test components (outputs): 21. Press OFF to end testing of refill valve. 1. Place brew funnels into rails on both sides of 22.

- Page 39 PROGRAMMING THE BREWER (cont.) SERVICE TOOLS (cont.) Procedures to test coil frequency: 1. Place brew funnels into rails on both sides of front of the brewer except the upper right hidden brewer. switch. While the switch is pressed, the display 2.

-

Page 40: Factory Defaults (Reset)

PROGRAMMING THE BREWER (cont.) FACTORY DEFAULTS This function allows the operator to erase all of the previously entered recipes and ad messages. Factory- set default values will replace all previous settings. SEL BREWER TYPE? ThermoF SoftHeat DONE FACTORY DEFAULTS EXIT WILL REPLACE ALL BREW SETTINGS ARE YOU SURE? -

Page 41: Troubleshooting

TROUBLESHOOTING A troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the Bunn-O-Matic Technical Service Department. • Inspection, testing, and repair of electrical equipment should be performed only by qualified service personnel. - Page 42 TROUBLESHOOTING (cont.) Screen Displayed Possible Cause Troubleshooting Procedures 1. SMART FUNNEL not fully inserted Position the funnel so that the sensor NO FUNNEL into the funnel rails. is directly beneath the sensor coil on PRESENT the brewer. 2. Not using a SMART FUNNEL, Disable the FUNNEL DETECT func- and the FUNNEL DETECT function tion.

- Page 43 TROUBLESHOOTING (cont.) Screen Displayed Possible Cause Troubleshooting Procedures 1. Soft Heat Server was moved out To resume brewing, correctly BREW STOPPED! of position after the brew cycle was position the Soft Heat Server and SERVER REMOVED? press BREW again. The brew cycle started.

- Page 44 TROUBLESHOOTING (cont.) Possible Cause Troubleshooting Procedures Screen Displayed Check water supply shut-off 1. Water shut off to brewer FILL TIME TOO LONG Service required 2. Inlet Solenoid Valve failure Service required 3. Control Board Failure CHECK WATER SUPPLY Check wire and connection of both 1.

- Page 45 TROUBLESHOOTING (cont.) Problem Possible Cause Troubleshooting Procedure 1. No power or incorrect voltage. Measure the voltage at the terminal Equipment will not operate. block and confirm that it matches the voltage specified on the brewer data plate within +/- 10%. 1.

- Page 46 TROUBLESHOOTING (cont.) Problem Possible Cause Troubleshooting Procedure Check the sensitivity setting. Refer to 3. Refill Probe or Sensitivity Set- Automatic refill will not operate or ting Refill function. If the left three digit display shows FILL TIME TOO LONG number is less than the right number, (cont.) the machine “thinks”...

- Page 47 TROUBLESHOOTING (cont.) Power Troubleshooting Procedures Possible Cause Water flows into tank continuously 1. Refill Probe or Sensitivity Set- Check the sensitivity setting. Refer to with power applied to brewer. ting Refill function. If the left three digit number is less than the right number, the machine “thinks”...

- Page 48 TROUBLESHOOTING (cont.) Troubleshooting Procedures Problem Possible Cause Water will not heat or display shows 3. Triac Remove power from the brewer. HEATING TIME TOO LONG (cont.) Connect a voltmeter across one of the tank heaters. Reapply power to the brewer and refer to Testing Individual Components.

- Page 49 TROUBLESHOOTING (cont.) Troubleshooting Procedures Problem Possible Cause Perform the previous procedure 3. Electronic control board Spitting or unusual steaming from for testing triacs. If the voltage sprayhead or air vents. (Water too measured is very low or zero, then hot) (cont.) substitute a control board known to be in good working order.

- Page 50 Dripping from sprayhead. 1. Brew Valve Repair or replace leaky valve. Water overflows filter. BUNN paper filters should be used 1. Type of paper filters for proper extraction. 2. No sprayhead Check sprayhead Beverage overflows server.

- Page 51 Troubleshooting Procedures 6. Incorrect Recipe Consider adjusting bypass percent- Weak beverage (cont.) age, preinfusion, or pulse brew. Contact Bunn-O-Matic for sugges- tions. 1. Solenoid (Inlet) The nut on back of the solenoid Brewer is making unusual noises. must be tight or it will vibrate during operation 2.

-

Page 52: Schematic Wiring Diagram

MODELS WITH MAIN ON/OFF SWITCH ONLY BLK-14 BLK-14 BLK-14 RED-14 RED-14 RED-14 RED-14 RED-14 120/208 OR 120/240 VOLT A.C. + GND SINGLE PHASE 29876.0000D 01/07 © 2001 BUNN-O-MATIC CORPORATION White Strip-Tac Plus Black Ink Finished Size: 8.5" x 11.0" Page 52 ~77% Reduction 29877-3 051007... - Page 53 Left Small Batch LED Left On/Off LED Right On/Off LED 230 VOLTS AC Right Large Batch LED 2 WIRE Right Medium Batch LED Right Small Batch LED SINGLE PHASE 50HZ 29876.0001A 08/02 © 2002 BUNN-O-MATIC CORPORATION Page 53 29877-3 062005 White Strip-Tac Plus...

- Page 54 Left Large Batch LED Left Medium Batch LED Left Small Batch LED Left On/Off LED Right On/Off LED Right Large Batch LED Right Medium Batch LED Right Small Batch LED 29876.0003A 06/04 © 2004 BUNN-O-MATIC CORPORATION Page 54 29877-3 062005...

Need help?

Do you have a question about the DUAL068000 and is the answer not in the manual?

Questions and answers