Table of Contents

Advertisement

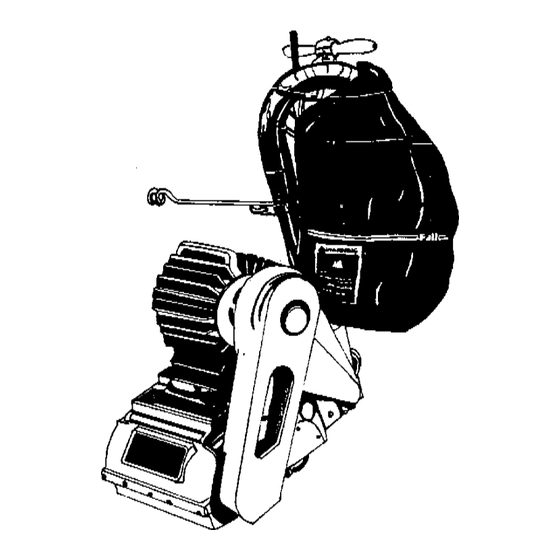

American 12

Operator's Manual

Models: 07044C, 07108A, 07120A, 07049C, 07109A

READ THIS BOOK

This book has important information for the use and safe operation of this machine. Failure to read this

book prior to operating or attempting any service or maintenance procedure to your Clarke American

Sanders machine could result in injury to you or to other personnel; damage to the machine or to

other property could occur as well. You must have training in the operation of this machine before

using it. If operator(s) cannot read this manual, have it explained fully before attempting to operate

this machine.

Si Ud. o sus operadores no pueden leer el Inglés, se hagan explicar este manual completamente

antes de tratar el manejo o servicio de esta máquina.

All directions given in this book are as seen from the operator's position at the rear of the machine.

Form No. 78150D

5/06 revised 3/10

Advertisement

Table of Contents

Summary of Contents for American Sanders American 12 07044C

- Page 1 American 12 Operator's Manual Models: 07044C, 07108A, 07120A, 07049C, 07109A READ THIS BOOK This book has important information for the use and safe operation of this machine. Failure to read this book prior to operating or attempting any service or maintenance procedure to your Clarke American Sanders machine could result in injury to you or to other personnel;...

-

Page 2: Table Of Contents

Contents of this Book Operator Safety Instructions ............3 Introduction and Machine Specifi cations ........5 230V Electrical Connection Instructions ........6 How to Transport the Machine............. 7 Machine Set-Up ................8 How to Operate the Machine ............. 10 Sanding Cuts and Sandpaper ........... 12 Sander Adjustment Procedures .......... -

Page 3: Operator Safety Instructions

OPERATOR SAFETY INSTRUCTIONS WARNING AVERTISSEMENT ADVERTENCIA DANGER means: Severe bodily injury or death can occur to you or other personnel if the DANGER statements found on this machine or in this Operator's Manual are ignored or are not adhered to. Read and observe all DANGER statements found in this Operator's Manual and on your machine. - Page 4 DANGER: Operating partially assembled sanding equipment could result in injury to the operator or by- stander and could cause damage to the equipment or to other property. • Do not operate this equipment unless it it fully assembled and all guards, doors and covers are secured.

-

Page 5: Introduction And Machine Specifi Cations

Operating Controls Introduction and Machine Specifi cations Operating Controls Motor Starter / Protector Sanding Pressure Adjustment Tool Storage Tray Leveling Adjustment MODEL 07108A / (07044C) 07109A / (07049C) 07120A Electrical Requirements ~208-240V 60 Hz ~220-240V 50 Hz ~220-240V 50 Hz Amperage 15.7 11.8... -

Page 6: 230V Electrical Connection Instructions

230V Electrical Connection Instructions CAUTION: This machine will operate only on AC frequency and on electrical voltage shown on the equipment nameplate. Make sure you have the correct frequency and voltage before connecting the power cord to an outlet. See the example in fi... -

Page 7: How To Transport The Machine

How to Transport the Machine WARNING: The machine is heavy. Remove the motor from the machine before transporting. Get help loading the machine and motor. To transport the machine, follow this procedure: 1. Make sure the power cable is disconnected from the electrical outlet. -

Page 8: Machine Set-Up

Machine Set-Up To set-up your machine follow this procedure: 1. Familiarize yourself with the machine and read all danger, warning and caution statements. Make sure all operators of this machine have read this Owner's Manual. If they cannot read English, have the manual explained fully before allowing anyone to operate the sander. - Page 9 8. Put the smooth side of the abrasive against the sanding drum. 9. Put one end of the abrasive against the sand- ing drum slot (1). See fi gure 3. 10. Turn the drum one revolution. Put the other end of the abrasive in the drum slot (2). See fi...

-

Page 10: How To Operate The Machine

How to Operate the Machine DANGER: Sanding/fi nishing wood fl oors can create an environment that can be explosive. Cigarette lighters, pilot lights and any other source of ignition can create an explosion when active during a sanding session. All sources of ignition should be extinguished or removed en- tirely if possible from the work... - Page 11 To operate the machine follow this procedure: 1. Install the operator's belt as follows: a. Position the operator's belt around waist. b. Cross the straps at the waist. See fi gure 5. c. Slide the belt loop end over the handle on the control lever side.

- Page 12 A. First pass forward, right to left. B. First pass reverse, retrace same path. C. Second pass forward, overlap ½ the drum width. Second pass reverse, retrace second path forward, etc..for the entire room E. Work the remaining unsanded fl oor in the same fashion, right to left.

-

Page 13: Sanding Cuts And Sandpaper

Sanding Cuts and Sandpaper Initial Cut The purpose of the initial cut is to remove old fi nish and gross imperfections on the fl oor surface. The sand- ing equipment should be adjusted to heavy sanding pressure setting and a coarse abrasive should be used. If the surface is severely damaged by deep scratches, pre-existing dwell marks, uneven planks, etc., it may be necessary to sand across or diagonally to the grain to restore evenness to the surface. -

Page 14: Sander Adjustment Procedures

Sander Adjustment Procedures DANGER: Electrocution could occur if main- tenance and repairs are performed on a unit that is not properly dis- connected from the power source. Disconnect the power supply be- fore attempting any maintenance or service. DANGER: Moving parts of this machine can cause serious injury and/or dam- age. - Page 15 Leveling If the sanding drum is out of adjustment, follow this procedure: 1. Remove the belt cover. 2. Loosen the eccentric lock screw. Using the 7/16" wrench, turn the eccentric lock screw (1) counter- clockwise. See fi gure 7. 3. To raise or lower the drum, turn the eccentric (2). See fi...

-

Page 16: Routine Maintenance

Routine Maintenance The following items need to be periodically inspected and maintained to keep your sander in good working condition. Wheels Periodically remove the debris from the truck and caster wheels. Debris can cause waves on a sanded surface. Lubricate truck mechanism every 25 hours of use. -

Page 17: Troubleshooting

Troubleshooting ROBLEM CTION AUSE Drive belts slip. Insuffi cient tension. Tension drive belt. (Squeaking or squealing sound) Worn belts. Replace belts. Squealing, growling or grinding Damaged and/or worn bearing. Remove drive belts, rotate arbor noise coming from machine. motor, fan, shafts and idler pulley to locate dragging or rough bearing. - Page 18 NOTES ® Page 18 FORM NO. 78150D American Sanders - American 12 Floor Sander Owner's Manual Clarke...

- Page 19 American Section II Parts and Service Manual (78150D) ® American Sanders - American 12 Floor Sander Operator's Manual FORM NO. 78150D Page 19 Clarke...

-

Page 20: Section Ii - Parts And Service Manual Assembly Drawing #1

Model American 12 Floor Sander Drawing #1 Handle Assembly 5/06 For model #07120A only. 24 21 ® Page 20 FORM NO. 78150D American Sanders - American 12 Floor Sander Owner's Manual Clarke... -

Page 21: Assembly Parts List #1

Model American 12 Floor Sander Parts List #1 Handle Assembly 5/06 Ref No. Part No Description Ref. Cord Assembly 41706A Connector (NEMA) 962065 Screw - 8-32 x ¼ Pn St Mach 43501A Inlet - 20A, 250V 85313C Screw - 6-32 x ¼ Pn St Mach 980607 Washer - #1106 Shakeproof 962794... -

Page 22: Assembly Drawing #2

Model American 12 Floor Sander Drawing #2 5/06 For model #07120A only. ® Page 22 FORM NO. 78150D American Sanders - American 12 Floor Sander Owner's Manual Clarke... -

Page 23: Assembly Parts List #2

Model American 12 Floor Sander Parts List #2 5/06 Ref # Part No. Description Ref # Part No. Description 67815A Spacer, Idler Bearing 62800A Pipe, Ass'y 68101A Stud 85714A Screw, ½ - 13 x 2¼ Hex 67413A Shaft 87006A Washer, .56 X 1.38 X .11 Flat 38109A Seal, Dust Pipe (not illustrated) 962216... -

Page 24: Assembly Drawing #3 5/06

American 12 Floor Sander Assembly Drawing #3 5/06 For model # 07120A only. Optional Urethane Optional Caster Wheels Urethane Wheels 61 60 ® Page 24 FORM NO. 78150D American Sanders - American 12 Floor Sander Owner's Manual Clarke... -

Page 25: Assembly Parts List #3 5/06

American 12 Floor Sander Assembly Parts List #3 5/06 Ref. No Part No. Description Qty Qty Qty 88502A Screw, 10-24 x 25200C Knob, Hand 67309A Screw, Sustainer 87000A Washer 67907A Spring, Sustainer 67315A Screw 66123A Plunger, Spring 67109A Rod, Pilot 920196 Nut, ½-13 Hex Jam 87101A... -

Page 26: Accessories Drawing & Parts List

American 12 Floor Sander Accessories Drawing & Parts List #4 10/00 RefRef. # Part No. Description 60724A Belt, Operating 59810A Wrench, Paper Clamp 50842A Wrench, End 3/4 x 7/16 64415A Handle, Carrying 42201A Cord Assembly (NEMA) 42302A Cordset, 240/50 68314A Template ®... -

Page 27: Wiring Diagram

American Sander 12 Wiring Diagram 5/06 (models 07044C, 07049C, 07108A and 07109A) American Sander 12 Wiring Diagram 5/06 (model 07120A) ® American Sanders - American 12 Floor Sander Operator's Manual FORM NO. 78150D Page 27 Clarke... -

Page 28: Chatter-Wave Prevention

Chatter - Wave Prevention Clarke American Sanders Sanders are designed and manufactured to the most rigid tolerances. However, after a fi nishing cut it is possible to see “chatter” or “waves”. The best guarantee to remove the chatter is to fi nish the fl oor with a rotating horizontal sander, such as Clarke American Sanders’s Sander 16. - Page 29 Chatter - Wave Prevention (cont) 3) UNEVEN WALKING PACE..can leave lengthy “waves”. The machine cuts more material during the slower pace. Pay particular attention to a steady, even pace. 4) EXCESSIVE LIGHT CUTS..may reveal high spots on the paper/contact wheel and cause chatter. Take a heavier cut and increase the pace.

- Page 32 14600 21st Avenue North Plymouth, MN 55447-3408 www.clarkeus.com Phone: 800-253-0367 Fax: 800-825-2753 ©2010 Nilfi sk-Advance, Inc. A Nilfi sk-Advance Brand...

Need help?

Do you have a question about the American 12 07044C and is the answer not in the manual?

Questions and answers