Summary of Contents for Isuzu AU-4LE1T

- Page 1 CALIFORNIA Proposition 65 Warning Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm.

- Page 2 He knows your engine best and is ready to meet your satisfaction. All information, illustrations, and specifications contained in this Manual are based on the latest product information available at the time of publication. ISUZU reserves the right to make changes in this Manual at any time without prior notice.

- Page 3 WARNING AND CAUTION SAFETY WARNINGS WARNING: These mean there is something that could hurt you or other people. In the warning area, we tell you what the hazard is. Then we tell you what to do to help avoid or reduce the hazard. Please read these warnings. If you don’t, you or others could be hurt.

-

Page 4: Table Of Contents

EPA AND CARB CERTIFIED ENGINE DATA AND SPECIFICATIONS ................ EC EMISSION CONTROL LABLE: ENGINE LABEL (ONLY EC TYPE) ................. 18 ENGINE IDENTIFICATION............19 ISUZU ENGINE AFTER SERVICE..........21 FUEL, LUBRICANT, AND COOLANT..........22 FUEL .................... 22 LUBRICANT................. 27 COOLANT ..................30 ENGINE OPERATION ................. -

Page 5: Table Of Contents

ENGINE CARE FOR OVER-COOLING ........52 OPERATION AND CARE FOR TURBOCHARGED ENGINE ..53 STARTING THE ENGINE AFTER BEING LEFT UNUSED FOR A LONG PERIOD OF TIME ..........54 PERIODICAL INSPECTION AND MAINTENANCE ......55 LUBRICATING SYSTEM.............. 55 COOLING SYSTEM ..............64 FUEL SYSTEM................ -

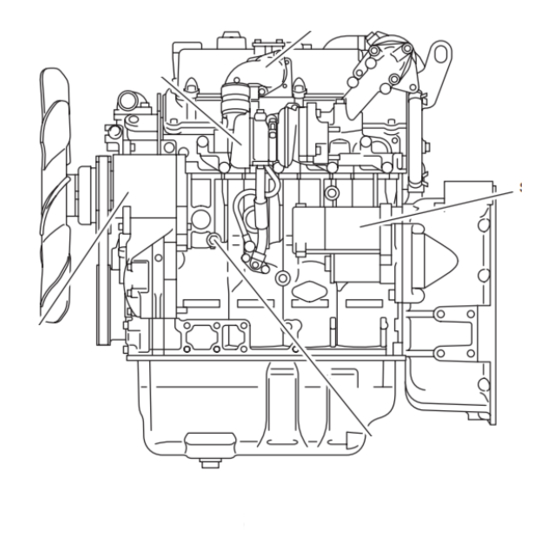

Page 6: Engine External Views

ENGINE EXTERNAL VIEWS 1. MODEL 4LE1T Air inlet Turbocharger Starter Generator Note: Engine details may vary depending on the Water drain plug specifications. IMLE0085... - Page 7 Nozzle holder Thermostat housing Solenoid stopper Water pump Oil cooler Oil filler cap Note: Engine details may From oil filter vary depending on the Oil drain plug specifications. To oil filter IMLE0086...

-

Page 8: Model 4Le1Na

2. MODEL 4LE1NA Air inlet Starter Generator Note: Engine details may vary depending on the Water drain plug specifications. IMLE0087... - Page 9 Nozzle holder Thermostat housing Water pump Solenoid stopper Oil filler cap Note: Engine details may Oil filter Fuel filter vary depending on the Oil drain plug specifications. IMLE0088...

-

Page 10: General Information

GENERAL INFORMATION 1. EPA AND CARB CERTIFIED ENGINE DATA AND SPECIFICATIONS Se rapporter à la fin de ce document pour les informations EPA en français. Model AU-4LE1T ISUZU engine model name AU-4LE1T Engine family *SZXL02.2UTA Engine code 4LE1XXXXX-XX Engine type... - Page 11 ISUZU engine model name AU-4LE1T Injection nozzles Throttle type Specified fuel Diesel fuel (ASTM D975 No.2-D) *2 Starter (V-kW) 12 – 2.2 *2 Alternator (V-A) 12 – 50 Specified engine oil (API grade) Refer to 3.LUBRICANT, Engine Oil Selection. *2 Lub. oil volume L(qts) 7.6 (8.0) –...

- Page 12 Model BV-4LE1T ISUZU engine model name BV-4LE1T Engine family *SZXL02.2VTB Engine code 4LE1XXXXX-XX Engine type Water-Cooled, four cycle, in-line overhead valve type Combustion type Swirl chamber type No. of cylinders – bore × stroke mm(in) 4 – 85 × 96 (3.35 ×...

- Page 13 ISUZU engine model name BV-4LE1T Injection nozzles Throttle type Specified fuel Diesel fuel (ASTM D975 No.2-D) *2 Starter (V-kW) 12 – 2.0 *2 Alternator (V-A) 12 – 35 Specified engine oil (API grade) Refer to 3.LUBRICANT, Engine Oil Selection. *2 Lub. oil volume L(qts) 7.6 (8.0) –...

- Page 14 Model AV-4LE1N ISUZU engine model name AV-4LE1N Engine family *SZXL02.2VNA Engine code 4LE1XXXXX-XX Engine type Water-Cooled, four cycle, in-line overhead valve type Combustion type Swirl chamber type No. of cylinders – bore × stroke mm(in) 4 – 85 × 96 (3.35 ×...

- Page 15 ISUZU engine model name AV-4LE1N Injection nozzles Throttle type Specified fuel Diesel fuel (ASTM D975 No.2-D) *2 Starter (V-kW) 12 – 2.0 *2 Alternator (V-A) 12 – 35 Specified engine oil (API grade) Refer to 3.LUBRICANT, Engine Oil Selection. *2 Lub. oil volume L(qts) 5.9 (6.2) –...

- Page 16 Model BV-4LE1N ISUZU engine model name BV-4LE1N Engine family *SZXL02.2VNC Engine code 4LE1XXXXX-XX Engine type Water-Cooled, four cycle, in-line overhead valve type Combustion type Swirl chamber type No. of cylinders – bore × stroke mm(in) 4 – 85 × 96 (3.35 ×...

- Page 17 ISUZU engine model name BV-4LE1N Injection nozzles Throttle type Specified fuel Diesel fuel (ASTM D975 No.2-D) *2 Starter (V-kW) 12 – 2.0 *2 Alternator (V-A) 12 – 20 Specified engine oil (API grade) Refer to 3.LUBRICANT, Engine Oil Selection. *2 Lub. oil volume L(qts) 5.9 (6.2) –...

- Page 18 Engine family index Injection nozzle Injection timing Engine Engine family Engine code opening pressure B.T.D.C. MPa(psi) (Static) 4LE1T *SZXL02.2UTA –– –– 4LE1T *SZXL02.2VTB –– –– 4LE1N *SZXL02.2VNA –– –– 4LE1N *SZXL02.2VNC –– –– * Mark ; Put a letter codes for model year on the top of the letters. Y : 2000, 1 : 2001, 2 : 2002, 3 : 2003, 4 : 2004, 5 : 2005, 6 : 2006, 7 : 2007, 8 : 2008, 9 : 2009, Model Year...

- Page 19 The following is the sample of a label required for engine emission control information, along with location. 4LE1T EMISSION CONTROL INFORMATION ISUZU MOTORS LTD. MADE IN JAPAN THIS ENGINE COMPLIES WITH U.S. EPA REGULATIONS FOR XX MY NONROAD DIESEL ENGINES AND CALIFORNIA REGULATIONS FOR XX MY OFF-ROAD DIESEL ENGINES.

- Page 20 4LE1NA EMISSION CONTROL INFORMATION ISUZU MOTORS LTD. MADE IN JAPAN THIS ENGINE COMPLIES WITH U.S. EPA REGULATIONS FOR XX MY NONROAD DIESEL ENGINES AND CALIFORNIA REGULATIONS FOR XX MY OFF-ROAD DIESEL ENGINES. SEE SERVICE MANUAL FOR ENGINE FAMILY : XXXXXXX.XXXX MODEL SPECIFICATIONS.

- Page 21 EMISSION CONTROL LABEL: ENGINE LABEL (ONLY EPA TYPE) Emission control label is attached at a visible point on the equipment. EMISSION CONTROL INFORMATION ISUZU MOTORS LTD. MADE IN JAPAN THIS ENGINE COMPLIES WITH U.S. EPA REGULATIONS FOR XX MY NONROAD DIESEL ENGINES AND CALIFORNIA REGULATIONS FOR XX MY OFF-ROAD DIESEL ENGINES.

- Page 22 FUEL TYPE IN USE LIMITATION LABEL (FOR EPA) The fuel type in use limitation label is attached on the filler neck of the fuel tank. Contents of the label: LOW SULFUR OR ULTRA LOW SULFUR DIESEL FUEL ONLY IMLE0066...

- Page 23 The following is the detail of a label required for engine emission control information, along with location. EMISSION CONTROL INFORMATION ISUZU MOTORS LTD. MADE IN JAPAN THIS ENGINE IS CONFORMED 97/68/EC DIRECTIVE. ENGINE FAMILY : XXXXXXXXXX ENGINE TYPE : XXXXXXXXXX TYPE APPROVAL NUMBER : XXXXXXXXXXXXXXXXXX ENGINE I.D.NUMBER : XXXX-XXXX...

-

Page 24: Engine Identification

3. ENGINE IDENTIFICATION Position of Display The engine serial number is stamped on the front upper right side of the cylinder body, and the engine model is cast on the rear lower right side of cylinder body just above the oil cooler. Further, engine model is described also on an ID label on the top of the cylinder head cover. - Page 25 Engine model Serial number 4LE1 000000 IMLE0092...

-

Page 26: Isuzu Engine After Service

Please feel free to contact your ISUZU dealer for periodical inspection and maintenance. Isuzu Genuine Parts The ISUZU genuine parts are identical with those of used in the engine production, and accordingly, they are warranted by ISUZU MOTORS LIMITED. The ISUZU genuine parts are supplied by the ISUZU distributors or the authorized parts suppliers. -

Page 27: Fuel, Lubricant, And Coolant

FUEL, LUBRICANT, AND COOLANT 1. FUEL Fuel Selection The following specific advantages are required for the diesel fuel. Must be free from minute dust particles. Must have adequate viscosity. Must have high cetane value. Must have high fluidity at low temperature. *Low sulfur or ultra low sulfur diesel fuel only. - Page 28 Isuzu. Such damage is not Isuzu’s responsibility, and is not covered by the Warranty. To help avoid fuel system or engine damage, please heed the following: •...

- Page 29 Your engine is designed to use either Number 1-D or Number 2-D diesel fuel. However, for better fuel economy, use Number 2-D diesel fuel whenever possible. At temperatures less than -7°C, (20°F), Number 2-D fuel may pose operating problems (see "Cold Weather Operation" which follows). At colder temperatures, use Number 1-D fuel (if available) or use a "winterized"...

- Page 30 Handling of the Fuel The fuel containing dust particles or water will cause engine failure. Therefore, the following notice must be observed. Take care to prevent the fuel from entry of dust particles or water when filling the fuel tank. When fueling is done from an oil drum directly, keep the drum stationary over a long time so that clean fuel can be used after the dust particles or water is completely sedimented.

- Page 31 (Refer to Filter Replacement or Cleaning) When the filter exchange of this pump is necessary, please inquire at your machine supply source or contact ISUZU dealer. Biocides In warm or humid weather, fungus and/or bacteria may form in diesel...

- Page 32 CAUTION: Fungus or bacteria can cause fuel system damage by plugging the fuel lines, fuel filters or injector. They can also cause fuel system corrosion. If fungus or bacteria has caused fuel system problems, you should have your authorized dealer correct these problems. Then, use a diesel fuel biocide to sterilize the fuel system (follow the biocide manufacturer’s instructions).

- Page 33 API or ACEA grade above. Their qualities are guaranteed by ISUZU. GRADE LUBRICATION MAKER BRAND/TYPE ACEA JASO ISUZU GENUINE BESCO MULTI-Z TYPE CE (10W-30) ISUZU GENUINE *BESCO MULTI-Z (10W-30) CD/CF/CF-4 ISUZU GENUINE BESCO S-3 (10W, 20W, 30, 40) Caltex/Chevron...

- Page 34 (2) Oil Viscosity Engine oil viscosity largely affect engine startability, performance, oil consumption, speed of wearing and occurrence of seizure, etc. Using lubricants whose viscosity selected according to the atmospheric temperature is important. CAUTION: 1. Using a mixture of different brand or quality oils will adversely affect the original oil quality;...

- Page 35 CAUTION: 1. Supplement inhibitors or additives claiming to provide increases cooling capability that have not been specifically approved by Isuzu are not recommended for addition to the cooling system. 2. When supplying or replacing coolant, do not use water of...

-

Page 36: Engine Operation

ENGINE OPERATION Engine Exhaust Gas Caution (Carbon Monoxide) WARNING: Do not breathe exhaust gas because it contains carbon monoxide, which by itself has no color or odor. Carbon monoxide is a dangerous gas. It can cause unconsciousness and can be lethal. We recommend that the exhaust system be inspected by competent technician: •... -

Page 37: Check Before Operation

1. CHECK BEFORE OPERATION WARNING: For Safety’s sake, conduct the inspection before start-up with the engine stopped. Without turbocharger CAUTION: As the remote filter is used, the engine oil is filled above the Dipstick specified level. (Turbocharged engine only) Adjust the engine oil level as required. Engine Oil Level Place the engine on a level surface. - Page 38 Check the oil level by the level marks on the dipstick. The oil level Dipstick must be between the "Max" level mark and the "Min" level mark as illustrated. Take care not to add too much engine oil. • Drain oil to the max. oil level if oil level is above the max. level Max.

- Page 39 WARNING: 1. In adding oil, take care not to spill it. If you spill oil on engine or equipment, wipe it properly, or this could lead to a fire and the risk of personal injury and/or equipment damage. 2. For model that employs the closed PCV, excessive oil may cause hunting in oil pressure, increase in the oil temperature, oil seepage from the intake system and engine oil intrusion into the combustion chamber, resulting...

- Page 40 This will prevent you from getting burnt with hot steam spouted out from the filler port. CAUTION: Use Isuzu genuine anti-freeze (ethylene-glycol based) or equivalent with the specified mixing ratio.

- Page 41 Radiator Cap Condition After the replenishment of the coolant, install the radiator cap. Make sure the cap is securely installed. Battery Cable Connection Check the battery cable connections for looseness or corrosion. The loosened cable connection will result in hard engine starting or insufficient battery charge.

- Page 42 Battery Electrolyte Level Regular position The amount of electrolyte in the batteries will be reduced after repeated discharge and recharge. Shortage Check the electrolyte for the level in the batteries, replenish with a commercially available electrolyte such as distilled water, if necessary. The battery electrolyte level checking procedure will vary with battery type.

-

Page 43: Engine Starting

2. ENGINE STARTING In case of the type with QOS system Pre-starting Preparation Make sure that all hydraulic control levers etc. on the equipment are in DRIVE the NEUTRAL position. START Set the engine stop knob in the START position. (It is unnecessary for AUTO RETURN the engine equipped with the engine shutdown switch.) Switch ON the battery switch (if so equipped). - Page 44 Pre-heating Procedures As an engine starting aid, pre-heating is required in a cold engine starting. The type with QOS system: This pre-heating uses "QOS," a quick pre-heating system which automatically controls pre-heating time utilizing coolant temperature to conduct the irreducible minimum of pre-heating. Turn the key to the DRIVE position, and the glow plugs built in the engine will grow red-hot to pre-heat the engine.

- Page 45 WARNING: Make sure that there is no flammable near outlet port of exhaust gas at engine starting. It is very dangerous due to deformation, discoloration or a fire. Engine Starting Depress the engine throttle lever or throttle pedal and turn the starter switch key clockwise to START position.

- Page 46 When repeating starting operation, return the key to the OFF position and then pre-heat and start the engine once again. If the engine still remains unstarted, something may be wrong with the engine. Check the repeated parts to locate the cause. CAUTION: Do not use starting "aids"...

- Page 47 3. CHECK AND OPERATION AFTER THE ENGINE START-UP Warming-up Operation Do the warming-up operation at 1000 min about ten minutes after the engine has started. As the lubrication for the entire engine systems will be done in this warming-up, do not speed up and load it abruptly. Particularly, observe this in cold season operation.

- Page 48 Engine noise and exhaust smoke color Pay attention to engine noise and, if any abnormal noise is heard, check the engine to detect the cause. Check the fuel combustion condition by exhaust smoke color. The exhaust smoke color after engine warming-up and at no-load operation.

- Page 49 Check the following items: • Lube oil leakage Check both sides and bottom of the engine assembly for lube oil leaks, paying particular attention to the lube oil pressure gauge pipe joint, lube oil filter and lube oil pipe joints. •...

-

Page 50: Care In The Engine Operation

4. CARE IN THE ENGINE OPERATION In the engine operation, always pay attention to the following items if the engine indicates any sign of abnormalities. Engine Oil Pressure Engine oil pressure is normal when the oil pressure gauge shows the values of the following in the engine warmed-up condition. - Page 51 Coolant Temperature The engine performance will be adversely affected if engine coolant temperature is too hot or too cold. The normal coolant temperature is 75 to 90°C (167 to 194°F). Overheating WARNING: If the Engine Coolant Temperature Gage shows an overheat condition or you have other reason to suspect the engine may be overheating, continued operation of the engine (other than as spelled out here) even for a short period of time may result...

- Page 52 If the Engine Coolant Temperature gage shows an overheat condition, or you have reason to suspect the engine may be overheating, take the following step: • If your air conditioner (if equipped) is on, turn it off. And turn on the heater.

- Page 53 If no steam or engine coolant can be seen or heard, open the engine access cover. If the engine coolant is boiling, wait until it stops before proceeding. Look at the see-through reserve tank. The engine coolant level should be between the "MAX" and "MIN" marks on the reserve tank.

- Page 54 If the engine coolant level in the reserve tank is at the correct level but there is still an indication on the instrument panel of an overheat condition: • YOU MUST LET ENGINE COOL FIRST. You may then add engine coolant directly to the radiator. Once the Engine Coolant Temperature Gage no longer signals an overheat condition, you can resume operating at a reduced speed.

- Page 55 Engine Hourmeter (Engine Operation Hour Indicating) (If so equipped) This meter indicates the engine operation hours. Make sure that the meter is always working during engine operation. Periodical engine maintenance is scheduled on the operation hours indicated on the hourmeter. Liquid and Exhaust Smoke Leakage Be careful with lubricant, fuel, coolant and exhaust smoke leakage.

-

Page 56: Engine Stopping

5. ENGINE STOPPING Make sure that all of the control levers on the equipment are in NEUTRAL position. Before stopping the engine, cool down the engine by operating it at low idle speed about three minutes. In this operation, check the engine noise and the engine oil pressure for abnormalities. -

Page 57: Engine Care For Over-Cooling

6. OPERATION AND CARE FOR NEW ENGINE Your ISUZU engine is carefully tested and adjusted in the factory, however, further, thorough run-in (i.e. break-in) operation is necessary. If the new engine is harshly operated, lubricating oil film will be reduced leading to abnormal wear or seizure. - Page 58 8. OPERATION AND CARE FOR TURBOCHARGED ENGINE Engine Starting The warming-up operation of the engine should be done in the way separately described. In addition, ensure the bearings supporting the rotating parts of the turbocharger are sufficiently lubricated. Do not race cold engine. When starting the engine after a long period (more than one month) of standing, proceed as follows: Pour engine oil into the turbocharger through the oil inlet port with the...

- Page 59 9. STARTING THE ENGINE AFTER BEING LEFT UNUSED FOR A LONG PERIOD OF TIME When the machine or equipment is left unused for "more than three months" without running the engine (warming up), conduct a thorough inspection of the machine before starting the engine. Crank the engine for 10 seconds and then stop it for 30 seconds with the fuel cut.

-

Page 60: Lubricating System

PERIODICAL INSPECTION AND MAINTENANCE 1. LUBRICATING SYSTEM WARNING: 1. During inspection and service, a burn injury may occur due to hot engine body, coolant or engine oil. For the sake of safety, conduct service work after the engine is stopped and cools down sufficiently. - Page 61 Engine oil draining Oil filler cap WARNING: To help avoid the damage of being burned, do not drain oil while the engine is still hot. One-touch type Wipe clean around the oil filler cap taking care so that no foreign particles entry.

- Page 62 Drain plug type Wipe clean around the oil filler cap taking care so that no foreign Oil filler cap particles entry. Remove the filler cap. Remove the drain plug by loosening it, and then drain oil. After oil has been drained completely, replace the packing of the drain plug with a new one, and then install the plug.

- Page 63 4LE1T Oil filler cap Oil level gauge Oil filler cap Oil drain plug IMLE0094...

- Page 64 4LE1NA Oil filler cap Oil level gauge Oil filler cap Oil drain plug IMLE0095...

- Page 65 Oil filter element removal Use a filter wrench to remove the cartridge type oil filter element. There may remain the used engine oil in the cartridge, and care should be taken not to spill it when removing the filter. Discard the used filter. Cartridge type Remote filter type Cartridge...

- Page 66 Oil filter element installation Apply lightly engine oil to the O-ring. Turn in new cartridge until its sealed face comes in contact with the O-ring. Use a filter wrench to further turn in the cartridge. Oil filter element tightening torque : 14.7 – 20.6 Nm (1.5 – 2.1 kgm) IMWG0034 Engine oil refilling Disconnect the oil drain hose and reinstall the cap of drain cock.

- Page 67 CAUTION: 1. Prevent dust particles from entering through filler port at replenishment. Be careful, entry of dust particles may cause engine damage or accident. 2. Replenishment of oil above "Max" level or below "Min" level may cause engine damage or accident. Drain oil to the "Max"...

- Page 68 Engine Oil Additives Engine oils contain a variety of additives. Your engine should not need any extra additives if you use the recommended oil quality and change intervals. Used Oil Disposal Do not dispose of used engine oil (or any other oil) in a careless manner such as pouring it on the ground, into sewers, or into streams or bodies of water.

-

Page 69: Cooling System

2. COOLING SYSTEM Fan Belt Tension Adjustment Adjust fan belt tension when belt slackness is greater than the specified amount and when the belts are replaced. WARNING: To help avoid being injury, check and adjust fan belt tension with engine stopped. Belt tension Belt tension is normal when it is depressed with the thumb at the midway between the fan pulley and alternator pulley. - Page 70 Use of fan belt with poor quality will result in premature belt wear or belt elongation leading to engine damage such as overheat. Therefore use of the ISUZU genuine fan belts are highly recommended. When you check the belt and find the following condition, replace the belt with new one.

- Page 71 CAUTION: Use Isuzu genuine anti-freeze (ethylene-glycol based) or equivalent with the specified mixing ratio. If oil is in coolant, contact "ISUZU Distributor" as soon as possible. CAUTION: The coolant must be changed at intervals of 12 months. If the coolant is being fouled greatly, it will lead to engine overheat or coolant blow-off from the radiator and cause a burn.

- Page 72 Drain away the coolant from the engine by loosening the water drain plug at the rear of alternator on the left side of cylinder body. IMLE0021 Filling with coolant Close or tighten the coolant drain plug. Fill up the radiator with the coolant until the level comes up to the filler port neck.

- Page 73 Tighten the plug when the coolant spills over from the air bleeder plug. (Turbocharged engine only) CAUTION: 1. Take care to prevent the spilt coolant from getting the exhaust system parts wet. 2. If you spill coolant, wipe it properly, or this could lead to a fire.

- Page 74 Cooling System Circuit Cleaning When the cooling system circuit is fouled with water scales or sludge particles, cooling efficiency will be lowered. Periodically clean the circuit interior with a cleaner. Cooling system cleaning interval : Every 12 months or 1000 operation hours.

-

Page 75: Fuel System

3. FUEL SYSTEM The fuel injection pump and fuel injection nozzle are precisely manufactured, and therefore, using the fuel which contains water or dust particles will result in either injection pump plunger seizure or injection nozzle seizure, and the fouled fuel filter element with sludge or dust particles lead to decreased engine output. - Page 76 CAUTION: 1. If the cup is removed without turning the fuel filter lever just above, the fuel may flow out. 2. The cartridge and cup contain fuel. Take care not to spill it during disassembly. 3. Perform the "fuel system air bleeding" after the water in the fuel is drained.

- Page 77 Fuel Filter Element Change Change interval Fuel filter element change inerval:Every 500 operating hours CAUTION: The fuel filter element may be clogged faster depending on the amount of dust particles in the fuel. Therefore, the element may need to change more often than Change interval above. If the low engine output or engine stall is found, the change of fuel filter element may recover them.

- Page 78 Cleaning procedure Turn the water sedimenter lever to the closed position. CAUTION: If the cup is removed without turning the lever as instructed, the fuel may flow out. Loosen the ring nut, remove the cup, and take out the element. Clean the cup and element, install new packing on the ring nut.

- Page 79 CLOSE Air bleeder plug OPEN Lever Ring nut Element Drain plug IMLE0059...

- Page 80 Filter Replacement or Cleaning Depending on the machine, the electromagnetic type fuel pump is Electromagnetic pump equipped in this engine. Filters inside of the pump consist of paper type and steel mesh type. Gasket Replace the paper-type filter at intervals of 500 operating hours. Clean Filter the steel mesh-type filter at intervals of 500 operating hours.

- Page 81 Install the cover. When installing, use a wrench and fully tighten it to the end. After installing the cover, be sure to check airtightness. CAUTION: Governor Control Seals As the governor (timing gear case) is precisely adjusted, most of the controls are sealed, please do not break them.

-

Page 82: Air Intake System

4. AIR INTAKE SYSTEM Air Cleaner Engine performance and life vary with the air intake conditions. A dirty air cleaner element reduces the amount of intake air, causing reduced engine output or disordered engine. Also, a damaged element leads to abrasion of cylinders and valves, resulting in increased oil consumption, reduced output and shortened engine life. - Page 83 Air Cleaner with Dust Indicator This indicator is attached to the air cleaner. When the air cleaner element is clogged, air intake resistance becomes greater and the dust indicator signal turns into red indicating the element change timing. When the signal turns into red, clean the air cleaner or replace the element.

-

Page 84: Engine Electrical

5. ENGINE ELECTRICAL The ISUZU engines uses a 24 volt or 12 volt system and a negative grounding type for the electrical system. CAUTION: 1. Take care not to connect reversely the polarity of battery terminal. Reverse connection damage the electrical parts, causing a fire or accident. - Page 85 Battery Servicing Battery maintenance schedules will vary with equipment and battery types. Follow the equipment manufacturer’s instructions. Gravity of the batteries The battery charge condition is judged by the electrolyte gravity measurement. Periodically measure the electrolyte gravity of the batteries. Eye level For the internal check follow the equipment manufacturer’s standard.

- Page 86 Gravity conversion The specified electrolyte temperature for the gravity measurement is 20°C (68°F). Measure the electrolyte temperature and do the conversion in accordance with the following formula when the temperature does not fall to the specified temperature. = St + 0.0007 (t – 20) ;...

- Page 87 Alternator Servicing The polarity of the alternator is negative grounding type. When an inverted circuit connection takes place, the circuit will be in short circuit instantaneously resulting the alternator failure. Do not put water directly on the alternator. Entry of water into the alternator leads an electrolyte corrosion causing an alternator failure.

-

Page 88: Engine Assembly And Others

Further, it causes a piston seizure or piston damage etc. In such cases, contact ISUZU dealer or Bosch dealer to adjust the injection starting pressure or replace the nozzle. IMLE0071 Injection starting pressure Refer to the Engine Family Index. - Page 89 Valve Clearance Adjustment The valve clearance must be adjusted every 1000 operating hours, or whenever the tappet is abnormally noisy, or in an engine malfunction though the fuel system is properly working. Valve clearance : 0.40 mm (0.0157 in) (When the engine is cold.) The model 4LE1 engine has two types of the valve clearance adjusting method.

- Page 90 Cylinder No. Valve arrangement When No. 1 cylinder is at TDC in the compression stroke When No. 4 cylinder is at TDC in the compression stroke I: Intake E: Exhaust On completion of the valve clearance adjustment in 3) above, make mark alignment as in 1) above by giving a turn to the crankshaft in normal direction.

- Page 91 Adjustment Procedure Turn the crankshaft clockwise so that the TDC mark groove (1) on the crank pulley is aligned with the TDC mark (cast out) on the timing gear case cover. Remove the cylinder head cover and check that the cylinder No. 1 is at TDC in the compression stroke or at TDC in the exhaust stroke.

- Page 92 Cylinder No. Valve arrangement Step 1: Aligning mark groove (1) with TDC mark Step 2: Aligning mark groove (2) with TDC mark Step 3: Aligning mark groove (1) with TDC mark Step 4: Aligning mark groove (2) with TDC mark I: Intake E: Exhaust Adjustment of Injection Timing The injection timing may not be readjusted.

- Page 93 Starter and Alternator Servicing Do the starter and the alternator servicing every 1000 operating hours on the following items. • Starter commutator cleaning. • Alternator slip ring cleaning. • Carbon brushes and the brush contact check. Radiator Pressurization Valve Check A pressurization valve is incorporated in the radiator cap assembly.

-

Page 94: Engine Care In Cold Season

ENGINE CARE IN COLD SEASON 1. FUEL Fuel Selection In the cold zone, the fuel might be frozen resulting in hard engine starting; therefore, select a suitable fuel for such engine operation. Use ASTM 975 No. 2-D fuel if you expect temperature above –7°C (20°F). - Page 95 A 50/50 mix Ethylene glycol base antifreeze/tap water (soft water), distilled water or demineralized water. (which provides protection to –37°C (–34°F) is recommended for use in these ISUZU diesel engines). Concentrations over 65% adversely affect freeze protection, heat transfer rates, and silicate stability which may cause water pump leakage.

- Page 96 CAUTION: 1. Methyl alcohol base antifreeze is not recommended because of its effect on the non-metallic components of the cooling system and because of its low boiling point. 2. High silicate antifreeze is not recommended because of causing serious silica gelation problems. 3.

-

Page 97: Engine Oil

3. ENGINE OIL Engine oil viscosity largely affects engine startability, so the use of lubricant with selected viscosity according to the atmospheric temperature is important. (Refer to 3.2 LUBRICANT.) At low atmospheric temperature, engine oil viscosity will increase to cause hard engine starting. - Page 98 5. ENGINE STARTING In cold engine starting at atmospheric temperature of below 0°C (32°F), pay attention to the following items: Do the preheating operation before cranking the engine with the starter. Set the engine throttle lever or pedal to the 1/3 position of the full lever or pedal stroke.

-

Page 99: Engine Maintenance Schedule

This is a recommended maintenance. The failure to perform this maintenance item will nullify the emission warranty or limit recall liability prior to the completion engine useful life. Isuzu, however, urges that recommended maintenance service is performed at the indicated intervals. - Page 100 This is a recommended maintenance. The failure to perform this maintenance item will nullify the emission warranty or limit recall liability prior to the completion engine useful life. Isuzu, however, urges that recommended maintenance service is performed at the indicated intervals.

- Page 101 (operation hours) Description of check Daily Remark and maintenance 1000 1250 1500 23. Electrolyte level check 24. Battery cleaning Ammeter registration Battery charge condition Charge warning lamp 26. Electrolyte gravity check See "EXPLANATION OF Starter and alternator check and MAINTENANCE cleaning (*) SCHEDULE"...

- Page 102 This is a required maintenance. The failure to perform this maintenance item will nullify the emission warranty or limit recall liability prior to the completion engine useful life. Isuzu, however, urges that required maintenance service is performed at the indicated intervals.

- Page 103 EXPLANATION OF MAINTENANCE SCHEDULE The following is a brief explanation of the services listed in the preceding Engine Maintenance schedule. Oil level and oil fouling Check that the oil level is between the max. level mark and the min. level mark. Drain oil to the max.

- Page 104 10. Fuel filter element Change element every 500 hours. replacement Shorten depending on fuel management. 11. Water sedimenter Clean the water sedimenter element every 500 hours. Shorten depending on fuel management. element cleaning 12. Electromagnetic pump Replace the paper-type filter at intervals of 500 operating hours. Clean the steel mesh-type filter at intervals of 500 operating hours.

- Page 105 21. Cooling system circuit Clean the cooling system circuit every 12 months or 1000 hours. cleaning 22. Radiator filler cap Check radiator pressure cap periodically for proper operation according to the equipment manufacturer’s specifications. function check 23. Electrolyte level check Replenish with distilled water if necessary. Clean the terminals.

- Page 106 32. EGR valve check and Check and clean EGR valve every 1500 hours. cleaning 33. EGR lead valve Clean EGR lead valve every 1500 hours. cleaning 34. EGR cooler cleaning Clean EGR cooler every 1500 hours. Check and replace every 24 months. 35.

-

Page 107: Simple Engine Troubleshooting

SIMPLE ENGINE TROUBLESHOOTING This section contents simple troubleshooting. Refer this section in case of engine failure. If the cause can not be identified or if it is hard to correct, contact ISUZU dealer as soon as possible. The items marked with Action are necessary to be repaired or adjusted. - Page 108 Symptom Cause Action Crack in injection pipe. Injection nozzle failure. Engine stop solenoid return failure. Uneven compression pressure between cylinders. Incorrect control lever adjustment. Governor interior malfunction. Governor spring deteriorated. Unstable engine running. Air in the fuel system. Bleed air. Clogged fuel filter element.

- Page 109 Symptom Cause Action Radiator clogging. Clean with soft brush. Engine over-loaded. Check your driving. Air cleaner element clogging. Clean or change element. Engine overheat. Insufficient ventilator. Check the ventilation. Stopped coolant flow Clean inside of radiator and change coolant. (high concentration of antifreezer, etc.). Oil leakage.

- Page 110 Symptom Cause Action Air mixing in injection pump. Bleed air. Fuel filter clogged. Change element. Overflow valve malfunction. Incorrect engine control adjustment. Deteriorated governor spring. Lack engine output. Incorrect valve clearance adjustment. Make a readjustment. Nozzle holder misalignment. Cylinder bore wear. Air cleaner clogging.

- Page 111 Symptom Cause Action Damaged packing. Change packing. Fuel leakage. Improper installation or tightening. Reinstall or retighten air bleeder plug. Excessive Too much fuel injection Injection pump misadjustment. amount. consumption. Excessive mechanical Operation Check the mechanical loads. loads. Clogged air cleaner. Clean or change element.

- Page 112 Symptom Cause Action Loose or damaged belt. Retighten or change belt. Faulty alternator. Change alternator. Charging failure. Damaged wiring or contact failure. Make an adjustment. Battery overdischarge. Low speed driving. Charge or change. Excessive electrical Insufficient battery capacity. Reduce electrical load or change battery capacity. loads.

- Page 113 INFORMATION GENERALE 1. CARACTERISTIQUES TECHNIQUES ET DONNEES DU MOTEUR CARTIFIE EPA ET CARB Modèle AU-4LE1T Désignation du modèle du moteur ISUZU AU-4LE1T Famille de moteur *SZXL02.2XXX Code de moteur 4LE1XXXXX-XX Type de soupape en tête en ligne, quatre temps, Type de moteur à...

- Page 114 Désignation du modèle du moteur ISUZU AU-4LE1T Buses à injection Type à papillon Combustible spécifié Combustible Diesel (ASTM D975 No.2-D) Démarreur (V-kW) 12 – 2,2 Alternateur (V-A) 12 – 50 Référez-vous à 3. LUBRIFIANT, Huile moteur spécifiée (API grade) choix D′Huile à moteur.

- Page 115 Modèle BV-4LE1T Désignation du modèle du moteur ISUZU BV-4LE1T Famille de moteur *SZXL02.2XXX Code de moteur 4LE1XXXXX-XX Type de soupape en tête en ligne, quatre temps, Type de moteur à refroidissement à eau. Type de combustion Swirl chambre × ×...

- Page 116 Désignation du modèle du moteur ISUZU BV-4LE1T Buses à injection Type à papillon Combustible spécifié Combustible Diesel (ASTM D975 No.2-D) Démarreur (V-kW) 12 – 2,0 Alternateur (V-A) 12 – 35 Référez-vous à 3. LUBRIFIANT, Huile moteur spécifiée (API grade) choix D′Huile à moteur.

- Page 117 Modèle AV-4LE1N Désignation du modèle du moteur ISUZU AV-4LE1N Famille de moteur *SZXL02.2XXX Code de moteur 4LE1XXXXX-XX Type de soupape en tête en ligne, quatre temps, Type de moteur à refroidissement à eau. Type de combustion Swirl chambre × ×...

- Page 118 Désignation du modèle du moteur ISUZU AV-4LE1N Buses à injection Type à papillon Combustible spécifié Combustible Diesel (ASTM D975 No.2-D) Démarreur (V-kW) 12 – 2,0 Alternateur (V-A) 12 – 35 Référez-vous à 3. LUBRIFIANT, Huile moteur spécifiée (API grade) choix D′Huile à moteur.

- Page 119 Modèle BV-4LE1N Désignation du modèle du moteur ISUZU BV-4LE1N Famille de moteur *SZXL02.2XXX Code de moteur 4LE1XXXXX-XX Type de soupape en tête en ligne, quatre temps, Type de moteur à refroidissement à eau. Type de combustion Swirl chambre × ×...

- Page 120 Désignation du modèle du moteur ISUZU BV-4LE1N Buses à injection Type à papillon Combustible spécifié Combustible Diesel (ASTM D975 No.2-D) Démarreur (V-kW) 12 – 2,0 Alternateur (V-A) 12 – 20 Référez-vous à 3. LUBRIFIANT, Huile moteur spécifiée (API grade) choix D′Huile à moteur.

- Page 121 Famille indice de moteur Pression d′injection Catage d′injection Moteur Famille de moteur Code de moteur d′injecteur B.T.D.C. MPa(psi) (degre) 4LE1T *SZXL02.2UTA Tout –– –– 4LE1T *SZXL02.2VTB Tout –– –– 4LE1N *SZXL02.2VNA Tout –– –– 4LE1N *SZXL02.2VNC Tout –– –– * Marque ; Placer un code de lettres pour l′année du modèle sur la partie supérieure des lattres. Année du modèle Y : 2000, 1 : 2001, 2 : 2002, 3 : 2003, 4 : 2004, 5 : 2005, 6 : 2006, 7 : 2007, 8 : 2008, 9 : 2009...

- Page 122 Ces étiquettes sont traduites de l′anglais en français. 4LE1T INFORMATIONS IMPORTANTES SUR LE MOTEUR ISUZU MOTORS LTD. FABRIQUE AU JAPON CE MOTEUR EST CERTIFIE POUR LE FONCTIONNEMENT AU CARBURANT DIESEL. CE MOTEUR EST CONFORME AUX REGLEMENTATIONS DE L'EPA AUX ETATS-UNIS POUR LES MOTEURS DIESEL DE VEHICULE HORS-ROUTE DE ANNEE AUTOMOBILE [ ], ETAUX REGLEMENTATIONS DE LA CALIFORNIE POUR LES MOTEURS A ALLUMAGE PAR COMPRESSION DE VEHICULE TOUT TERRAIN.

- Page 123 4LE1NA INFORMATIONS IMPORTANTES SUR LE MOTEUR ISUZU MOTORS LTD. FABRIQUE AU JAPON CE MOTEUR EST CERTIFIE POUR LE FONCTIONNEMENT AU CARBURANT DIESEL. CE MOTEUR EST CONFORME AUX REGLEMENTATIONS DE L'EPA AUX ETATS-UNIS POUR LES MOTEURS DIESEL DE VEHICULE HORS-ROUTE DE ANNEE AUTOMOBILE [ ], ETAUX REGLEMENTATIONS DE LA CALIFORNIE POUR LES MOTEURS A ALLUMAGE PAR COMPRESSION DE VEHICULE TOUT TERRAIN.

- Page 124 TYPE EC SEULEMENT INFORMATIONS IMPORTANTES SUR LE MOTEUR INFORMATIONS IMPORTANTES SUR LE MOTEUR ISUZU MOTORS LTD. FABRIQUE AU JAPON ISUZU MOTORS LTD. FABRIQUE AU JAPON CE MOTEUR EST CERTIFIE POUR LE FONCTIONNEMENT AU CARBURANT DIESEL. CE MOTEUR EST CONFORME AUX REGLEMENTATIONS DE L'EPA AUX ETATS-UNIS POUR LES MOTEURS DIESEL DE VEHICULE HORS-ROUTE DE ANNEE AUTOMOBILE [ ], ETAUX REGLEMENTATIONS DE LA CALIFORNIE POUR LES MOTEURS A ALLUMAGE PAR COMPRESSION DE VEHICULE TOUT TERRAIN.

- Page 125 ETIQUETTE DE RESTRICTION DE TYPE DE CARBURANT UTILISE (POUR EPA) L′étiquette de restriction du type de carburant utilisé se trouve sur le goulot de remplissage du réservoir de carburant. Contenu de l′étiquette: DIESEL A FAIBLE TENEUR EN SOUFRE OU DIESEL A TRES FAIBLE TENEUR EN SOUFRE UNIQUEMENT IMLE0066...

- Page 126 The right is reserved to make changes at any time without notice. INSTRUCTION MANUAL (INDUSTRIAL) 4LE1 INTERIM TIER4/ STAGE 3A IDE-6260 Issued by ISUZU MOTORS LIMITED Planning & Service Group Off-highway Powertrain Operations Dept. 6-26-1, Minami-oi, Shinagawa-ku, Tokyo, 140-8722, Japan TEL 03-5471-1111 10/2008...

Need help?

Do you have a question about the AU-4LE1T and is the answer not in the manual?

Questions and answers