Table of Contents

Advertisement

Quick Links

www.mkdiamond.com

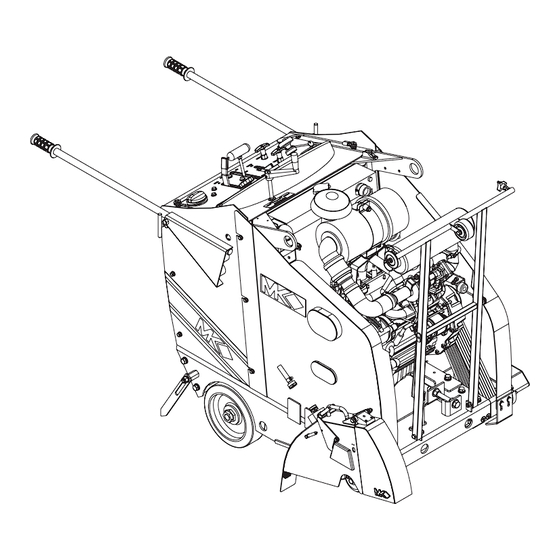

MK-4018KB

Kubota

Diesel Engine

Revision 100

Manual Part No. 168118

Caution: Read all safety and operating instructions before

using this equipment. This parts list MUST accompany the

equipment at all times.

01.2010

MK-4000 SERIES

CONCRETE SAW

OPERATOR'S MANUAL

MODELS: MK-4018KB, MK-4018HY

MK-4024KB, MK-4024HY

MK-4030KB, MK-4030HY

MK-4036KB, MK-4036HY

MK-4036HY

Hyundai

Gas Engine

MK Diamond Products, Inc.

Advertisement

Table of Contents

Summary of Contents for MK Diamond Products MK-4018KB

- Page 1 MK-4000 SERIES CONCRETE SAW OPERATOR’S MANUAL MODELS: MK-4018KB, MK-4018HY MK-4024KB, MK-4024HY MK-4030KB, MK-4030HY MK-4036KB, MK-4036HY MK-4018KB Kubota Diesel Engine MK-4036HY Revision 100 01.2010 Hyundai Gas Engine Manual Part No. 168118 Caution: Read all safety and operating instructions before using this equipment. This parts list MUST accompany the equipment at all times.

-

Page 2: Model Number

INTRODUCTION Congratulations on your purchase of a MK-4000 Concrete Saw. We are certain that you will be pleased with your purchase. MK Diamond takes pride in producing the finest construction power tools and diamond blades in the industry. Operated correctly, your MK-4000 Concrete Saw should provide you with years of service. In order to help you, we have included this manual. -

Page 3: Table Of Contents

MK-4000 SERIES TABLE OF CONTENTS MK-4000 CONCRETE SAW SAFETY PAGE NO. Safety Message/Alert Symbols Safety Warnings Rules for Safe Operation Operation & Safety Decals Safety Decal Locations Console Controls Console Control Descriptions PRODUCT SPECIFICATIONS Saw Features Engine Specifications Saw Dimensions Model Specifications Instructions for Changing Blade Speed INSPECTION &... - Page 4 MK-4000 SERIES NOTES...

-

Page 5: Safety Message/Alert Symbols

MK-4000 SERIES SAFETY Safety precautions should be followed at all times when operating this equipment. Failure to read and understand the Safety Precaution and Operating Instructions could result in injury to yourself and others. This Operator’s Manual has been developed to provide complete instructions for the safe and efficient operation of the MK-4000 Concrete Saw. -

Page 6: Safety Warnings

MK-4000 SERIES SAFETY SAFETY WARNINGS SILICA DUST WARNING: Grinding/cutting/drilling of masonry, concrete, metal and other materials with silica in their composition may give off dust or mists containing crystalline silica. Silica is a basic component of sand, quartz, brick clay, granite and numerous other minerals and rocks. -

Page 7: Rules For Safe Operation

MK-4000 SERIES SAFETY RULES FOR SAFE OPERATION DANGER Failure to follow instructions in this manual may lead to serious injury or even death! This equipment is to be operated by trained and qualified personnel only! This equipment is for industrial use only. The following safety guidelines should always be used when operating the MK-4000 Concrete Saw. -

Page 8: Saw Blade Safety

MK-4000 SERIES SAFETY • NEVER leave the machine unattended. Turn off machine when unattended. Know how to stop the ON / OFF machine quickly in case of emergency. • NEVER try to stop a moving blade with your hand. • NEVER use a wet blade without adequate water supply to the blade. •... - Page 9 MK-4000 SERIES SAFETY • Make sure the blade is not contacting anything before starting the engine. • ALWAYS cut in a straight line. DO NOT cut deeper than 1” per pass with a dry blade. Step cut to achieve deeper cuts. NEVER cock, jam wedge or twist the blade in a cut. DO NOT grind on the side of the blade.

-

Page 10: Operation & Safety Decals

MK-4000 SERIES SAFETY OPERATION & SAFETY DECALS The MK-4000 is equipped with a number of safety decals provided for operator safety and maintenance infor- mation. Should any of these decals become unreadable, replacements can be obtained by calling (800) 262- 1575. -

Page 11: Safety Decal Locations

MK-4000 SERIES SAFETY SAFETY DECAL LOCATIONS Decal J Decal I Decal B, C, D Decal E Decal A Decal F Decal G, H MK-4000 Safety Decal Locations Decal Location Description Machine Front Caution Keep Hands and Feet Clear Top of Belt Guard Caution Do Not Overtension Belts Top of Belt Guard Caution Do Not Touch Hot Surface... -

Page 12: Console Controls

MK-4000 SERIES CONSOLE CONTROLS CONSOLE CONTROLS The following is a list of console controls elements: AA BB EE Kubota and Hyundai Hyundai Only... -

Page 13: Console Control Descriptions

MK-4000 SERIES CONSOLE CONTROL DESCRIPTIONS CONSOLE CONTROL DESCRIPTIONS Hyundai & Kubota Console Decal Name Function Ignition Switch Use to start engine (Glow-OFF-ON-START). Engine Throttle Controls engine speed. Engine Temp Gauge Shows temperature of engine. Lifting Points Used to lift saw. Engine Tachometer Shows the engine RPM’s. -

Page 14: Engine Specifications

167420-36 *Engine power ratings are calculated by the individual engine manufacturer and the rating method may vary among engine manufacturers. MK Diamond Products makes no claim, representation or warranty as to the power rating of the engine on this equipment and disclaims any responsibility or liability of any kind whatsoever with respect to the accuracy or the engine power rating. Users are advised to consult the engine manufacturer’s owners manual and website for specific information regarding the engine power rating. -

Page 15: Saw Dimensions

MK-4000 SERIES PRODUCT SPECIFICATIONS SAW DIMENSIONS Item Description Inches (mm) Height 47-1/4" (1,200) Minimum Saw Length 64-1/4" (1,632) Maximum Overall Length 107-1/2" (2,731) Handle Extension 22" (559) Maximum Pointer Extension 21-1/4" (540) Frame Width 27" (686) Frame Length 42" (1,067) Depth of Cut Saw Width 34-3/4"... -

Page 16: Model Specifications

MK-4000 SERIES PRODUCT SPECIFICATIONS INSTRUCTIONS FOR CHANGING BLADE SPEED WARNING Do not exceed blade shaft speed shown for each blade size. Excessive blade speed could result in blade failure and serious personal injury. NOTICE Changing Blade Guard size MUST be accompanied by changing Pulleys to achieve the correct blade speed. Blade Blade Shaft Speed P/N for... -

Page 17: Instructions For Changing Blade Speed

MK-4000 SERIES INSPECTION & START-UP PRE-OPERATION CHECKLIST WARNING Before leaving our factory, every machine is thoroughly tested. Follow instructions strictly and your machine will give you long service in normal operating conditions. Before starting up the machine, make sure you read this entire Operation Manual and are familiar with the operation of the machine. -

Page 18: Blade Mounting Instructions

MK-4000 SERIES OPERATION NOTICE Before mounting the blade, machine should be turned “OFF”. Clean the blade collars and stub shaft. BLADE MOUNTING INSTRUCTIONS 1. Remove Blade Guard. A. Unscrew the hose fitting to disconnect hose. B. Hold the Blade Guard by the handle. Release the inner latch. C. -

Page 19: Blade Mounting Instructions

MK-4000 SERIES OPERATION BLADE MOUNTING INSTRUCTIONS CONTINUED Tighten the arbor bolt. Install the blade guard in place. Make sure that the guard locks in place and connect the hose. Install Blade Guard Tighten Arbor Bolt WARNING Observe the rotation arrow on blade and DO NOT exceed maximum RPM stamped on the blade. To set proper RPM, consult the Blade Guards and Blade Sizes Table on page 16. -

Page 20: Starting Engine, Starting Instructions

MK-4000 SERIES OPERATION STARTING ENGINE NOTICE Read the engine instructions manual before starting. WARNING Be sure blade is unobstructed and not resting on ground. WARNING Be sure hands and feet are clear of blade. 1. Check engine oil. Add oil if low. 2. -

Page 21: Saw Guide Alignment And Adjustment, Pointer Alignment

MK-4000 SERIES OPERATION SAW GUIDE ALIGNMENT AND ADJUSTMENT WARNING This operation is performed with the engine “OFF”! The front and rear pointers are set in line at the factory. However, the pointers should be checked for proper alignment with the blade after every use. The following are the procedures for aligning the pointers with the blade, with the engine shut off. -

Page 22: Maneuvering The Saw, Dry Cutting, Wet Cutting, Speed Control-Lever Use And Adjustment

MK-4000 SERIES OPERATION MANEUVERING THE SAW WARNING The blade is spinning whenever the saw is running. Raise the blade as high as possible when maneuvering so that the blade will not strike the pavement. DRY CUTTING Dry cutting blades have been specially designed for use with concrete saws. Ensure that the blade you are using is clearly marked for dry cutting. -

Page 23: Engaging The Drive Unit, Water Hook Up

MK-4000 SERIES OPERATION ENGAGING THE DRIVE UNIT This saw is driven by a hydrostatic transmission. To engage the transmission, PULL the Neutral Engagement Handle up and turn to either direction to lock. NOTICE DO NOT engage the unit unless FNR Handle (Figure 18) is on NEUTRAL. Neutal Engagement FNR Handle... -

Page 24: Depth Indicator And Depth Stop

MK-4000 SERIES OPERATION DEPTH INDICATOR AND DEPTH STOP The saw is equipped with a Depth Indicator and a Depth Stop. The Depth Indicator tells you approximately how deep you are in the cut. To set the indicator, you need to first lower the blade until it is just touching the ground and then rotate the Depth Indicator knob to 0. -

Page 25: Engine, Hydrostatic Drive Unit

MK-4000 SERIES MAINTENANCE ENGINE The operation and life of the engine depends on proper maintenance. Do not start engine until engine pre- check is complete. The engine pre-check consists of checking the oil, fuel level, air filter and greasing the wheel, axle, drive unit and arbor bearings. -

Page 26: Maintenance Schedule

MK-4000 SERIES MAINTENANCE MAINTENANCE SCHEDULE MAINTENANCE SCHEDULE DAILY HOURS HOURS HOURS • Check Oil Level • Check Air Filter • Check Air Intake, Clean if Necessary • Grease Rear Wheel Pillow Blocks • Grease Front Wheel Bearings • Check Transmission Fluid, Add if Low •... -

Page 27: Troubleshooting

MK-4000 SERIES MAINTENANCE TROUBLESHOOTING When trouble occurs, be sure to check the simple causes which, at first, may seem too obvious to be considered. Refer to the table below for problems and their possible causes. Cause Loose Water in Dirty Loose Cooling Transmission... -

Page 28: Theory Of Diamond Blades

MK-4000 SERIES GENERAL PRODUCT INFORMATION THEORY OF DIAMOND BLADES Diamond blades do not really cut; they grind the material through friction. Diamond crystals, often visible at the leading edge and sides of the rim/segment, remove material by scratching out particles of hard, dense materials, or by knocking out larger particles of loosely bonded abrasive material. - Page 29 MK-4000 SERIES NOTES...

-

Page 30: Accessories, Ordering And Return Information

ACCESSORIES, ORDERING AND RETURN INFORMATION Ordering Information You may order MK Diamond products through your local MK Diamond distributor or, you may order direct from MK Diamond. NOTE: There is a $25.00 minimum order when ordering direct from MK Diamond. All purchases must be made using VISA or MasterCard. -

Page 31: Contact Information And Limited Warranty

© COPYRIGHT 2010, MK DIAMOND PRODUCTS, INC. ALL RIGHTS RESERVED. The MK Diamond logo is a registered trademark of MK Diamond Products, Inc. and may not be used, reproduced, or altered without written permission. All other trademarks are the property of their respective owners and used with permission. - Page 32 MODEL MK-4000 SERIES OPERATOR’S MANUAL DOCUMENT NO. 168118 MK Diamond Products, Inc. 1315 Storm Parkway Torrance, CA 90501 Toll-Free: (800) 421-5830 Phone: (310) 539-5221 Fax: (310) 539-5158 www.mkdiamond.com...

Need help?

Do you have a question about the MK-4018KB and is the answer not in the manual?

Questions and answers