Subscribe to Our Youtube Channel

Summary of Contents for Hotsy DBA-252739

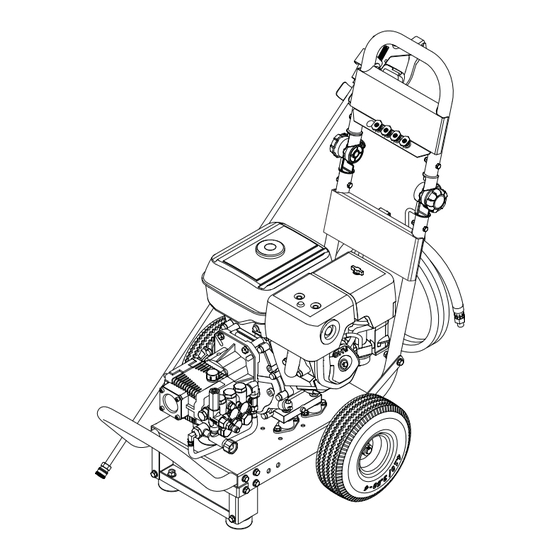

- Page 1 OPERATOR’S MAN U AL MODEL # ORDER # DBA-252739 1.107-117.0 DBA-303039 1.107-118.0 DBA-383539 1.107-119.0 To locate your local Hotsy Commercial Pressure Washer Dealer nearest you, visit www.hotsy.com 8.917-986.0...

-

Page 2: Table Of Contents

CONTENTS Important Safety Information ..............4-6 Component Identifi cation ................. 7 Assembly Instructions ................8 Operating Instructions.................9-10 Detergent and General Operating Techniques ........11 Shut Down and Clean-Up ..............12 Storage ....................12 Troubleshooting ................13-14 Preventive Maintenance ................ 15 Oil Change Record ................17 Warranty .................... -

Page 3: Important Safety Information

INTRODUCTION & IMPORTANT SAFETY INFORMATION WARNING: Keep wand, hose, and WARNING water spray away from electric Thank you for purchasing this Pressure Washer. wiring or fatal electric shock may We reserve the right to make changes at any time result. without incurring any obligation. -

Page 4: Important Safety Information

IMPORTANT SAFETY INFORMATION 12. Never make adjustments on machine while in op- WARNING: This product contains chemicals known eration. to the state of California to cause cancer and birth defects or other reproductive harm. Operation of 13. Be certain all quick coupler fi ttings are secured this equipment may create sparks that can start before using pressure washer. - Page 5 IMPORTANT SAFETY INFORMATION 20. Never run pump dry or leave spray gun closed longer than 1-2 minutes. 21. Machines with shut-off spray gun should not be operated with the spray gun in the off position for extensive periods of time as this may cause dam- age to the pump.

-

Page 6: Component Identifi Cation

COMPONENT IDENTIFICATION Pressure Spray Gun Nozzle Straight Through Wand Detergent Bucket (not included) Pump Trigger ENGINE Unloader Pump Protector High Pressure Inlet Hose Screen Hose Detergent Starter Grip Detergent Garden Hose Injector PUMP (not included) (Not Included) Pump — Develops high pressure. High Pressure Hose —... -

Page 7: Assembly Instructions

ASSEMBLY INSTRUCTIONS Rotary Tube-Joint Handle Bolt Bolt Knob Frame Bolt Assy. Holder STEP 1: Insert rotary joints into STEP 2: Attach the handle to the STEP 3: Use the carriage bolts to handle and frame tubes so that frame. Align holes, insert one 3/8" attach the wand holder. -

Page 8: Operating Instructions

OPERATING INSTRUCTIONS Dipstick Oil Dipstick Oil Window STEP 1: Check engine oil level. Oil level should be level with the bottom STEP 2: Remove shipping cap and of the oil fi ller neck. Be sure the machine is level when checking the oil install oil dipstick. -

Page 9: Operating Instructions

OPERATING INSTRUCTIONS On-Off Switch STEP 8: Turn the engine switch to "On" position. STEP 9: Pull the starter grip. If the engine fails to start after 2 pulls, squeeze the trigger gun to release pres- On Vanguard engines, move the throttle lever to sure and repeat step. -

Page 10: Cleaning Tips

DETERGENT AND GENERAL CLEANING TECHNIQUES WARNING: Some detergents THERMAL PUMP PROTECTION WARNING may be harmful if inhaled or If you run the engine on your pressure washer for 1-2 ingested, causing severe nau- minutes without pressing the trigger on the spray gun, sea, fainting or poisoning. -

Page 11: Storage

SHUTTING DOWN AND CLEAN-UP On-Off Switch STEP 1: Remove detergent suc- STEP 2: Turn off the engine. STEP 3: Turn off water tion tube from container and insert supply. into one gallon of fresh water. Slide nozzle forward for low pressure or to connect black detergent nozzle. -

Page 12: Troubleshooting

TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION LOW OPERATING Insuffi cient water supply. Closed Use larger garden hose; clean inlet water PRESSURE faucet. Inlet hose kinked screen. Open faucet. Clogged inlet hose strainer Check plumbing system for leaks. Retape leaks with tefl on tape. Faulty or mis-adjusted unloader Adjust unloader for proper pressure. - Page 13 TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION ENGINE OPERATES Not enough gas or engine oil Fill tank with gas. Check oil level. FOR 15 MINUTES Vapor lock developed by heat of day Keep gas tank full to avoid vapor locking. THEN STOPS Obstruction in fuel fi...

-

Page 14: Preventative Maintenance

PREVENTATIVE MAINTENANCE This pressure washer was produced with the best available materials and quality craftsmanship. However, you as the owner have certain responsibilities for the correct care of the equipment. Attention to regular preventa- tive maintenance procedures will assist in preserving the performance of your equipment. Contact your dealer for maintenance. -

Page 15: Oil Change Record

OIL CHANGE RECORD Check pump oil and engine oil level before fi rst use of your new pressure washer. Estimated Operating Estimated Operating Date Oil Changed Hours Since Last Date Oil Changed Hours Since Last Month/Day/Year Oil Change Month/Day/Year Oil Change 8.917-986.0 •... -

Page 16: Warranty

Hotsy does not authorize any other party, including authorized Hotsy Distributors, to make any representation or promise on behalf of Hotsy, or to modify the terms, conditions, or limitations in any way. It is the buyer’s responsibility to ensure that the installation and use of Hotsy products conforms to local codes. - Page 18 If you are looking for replacement parts for your Hotsy, please contact your local dealer. You can find a dealer by calling Hotsy at 800-525-1976 or by visiting www.hotsy.com.

- Page 19 Form #8.917-986.0 • DBA • Revised 12/10 • Printed in U.S.A. or Mexico...

Need help?

Do you have a question about the DBA-252739 and is the answer not in the manual?

Questions and answers