Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Magnum MLT 4250

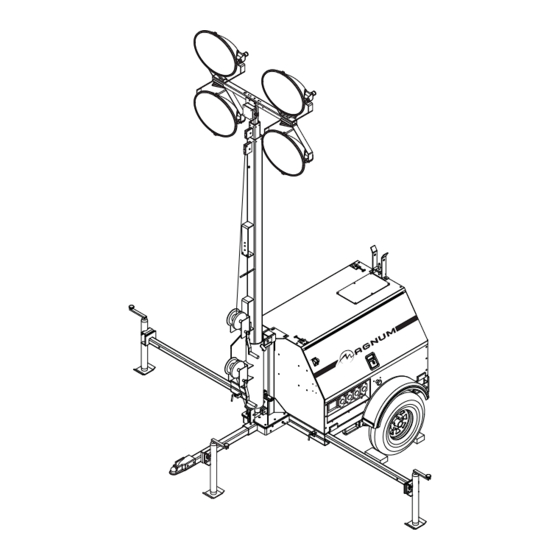

- Page 1 MLT 4250 OPERATING/PARTS MANUAL...

-

Page 2: Introduction

Occupational Safety and Health Association (OSHA) guidelines. Keep a copy of this manual with the unit at all times. Additional copies are available from Magnum Products LLC, or can be found at www.m-p-llc.com. An engine operators manual was also supplied with the unit at the time of shipment from the factory. -

Page 3: Table Of Contents

SAFETY SYMBOL SUMMARY ..................7 SPECIFICATIONS ......................8 - 9 EXTERIOR LOCATIONS ....................10 MAIN CONTROL PANEL COMPONENTS ................ 11 MAGNUM DIGITAL CONTROLLER (MDC) ..............12 - 13 GENERATOR MONITORING .................... 13 ENGINE MONITORING .................... 14 - 15 FINE VOLTAGE ADJUSTMENT ..................15 MDC CONTROLLER INFORMATION DISPLAYS, FUNCTIONS AND RESET .... -

Page 4: Safety Notes

SAFETY NOTES This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death. This manual contains DANGERS, WARNINGS, CAUTIONS, NOTICES and NOTES which must be followed to prevent the possibility of improper service, damage to the equipment, personal injury or death. -

Page 5: Engine Safety

ENGINE SAFETY Internal combustion engines present special hazards during operation and fueling! Failure to follow the safety guidelines described below could result in severe injury or death. Also read and follow all safety warnings described in the Engine Operator's Manual. A copy of this manual was supplied with unit when it was shipped from the factory. -

Page 6: Towing Safety

If you believe your trailer has a defect which could cause a crash or could cause injury or death, you should immedi- ately inform the National Highway Traffic Safety Administration (NHTSA) in addition to notifying Magnum Products LLC. If NHTSA receives similar complaints, it may open an investigation; and if it finds that a safety defect exists in a group of vehicles, it may order a recall and remedy campaign. -

Page 7: Safety Symbol Summary

SAFETY SYMBOL SUMMARY This equipment has been supplied with numerous safety and operating decals. These decals provide important operating instructions and warn of dangers and hazards. Replace any missing or hard-to-read decals and use care when washing or cleaning the unit. Decal placement and part numbers can be found in the beginning of the parts section of this manual. - Page 8 Read all of the manuals included with this unit. Each manual details specific information regarding items such as set up, use and service requirements. Specifications are subject to change without notice. MAGNUM MODEL MLT 4250 Engine Make/Brand ............Isuzu Model ..............4LE1-NYGV-01 Type ..............

-

Page 9: Specifications ........................................................................................................ 8

SPECIFICATIONS Read this manual carefully before attempting to use this light tower. The potential for property damage, personal injury or death exists if this equipment is misused or installed incorrectly. Read all of the manuals included with this unit. Each manual details specific information regarding items such as set up, use and service requirements. Specifications are subject to change without notice. -

Page 10: Exterior Locations

EXTERIOR LOCATIONS 1. FUEL FILLER LOCATION (under door): Use clean DIESEL FUEL ONLY. 2. RADIATOR ACCESS PANEL: Remove this panel for engine coolant service. 3. CONTROL PANEL LOCATION (under door): Engine/generator controls and all circuit breakers. 4. EMERGENCY STOP SWITCH: For emergency shutdown; stops engine and trips main circuit breaker. 5. -

Page 11: Main Control Panel Components

MAIN CONTROL PANEL COMPONENTS 1. MAIN CIRCUIT BREAKER (90A): This breaker will disconnect power to the connection lugs. 2. LUG DOOR SAFETY SWITCHES: These switches will shut the generator down if the lug door is opened when the generator is running. 3. -

Page 12: Magnum Digital Controller (Mdc)

MAGNUM DIGITAL CONTROLLER (MDC) The Magnum Digital Controller (MDC) is an enhanced digital generator controller used to start, stop and monitor the operation of the generator and the engine. The controller constantly monitors vital generator and engine functions for a number of pre-programmed alarm and fault conditions. When a fault condition occurs, the engine will shut down automatically and the Liquid Crystal Display (LCD) window will display the fault that caused the shutdown;... -

Page 13: Generator Monitoring

• “ALARM CANCEL” Button When an alarm is activated, either visually or audibly, press this button to silence or cancel the alarm. • “FAULT RESET” Button Press this button to clear the fault from the LCD window after the fault has been corrected. Press “FAULT RESET”... -

Page 14: Engine Monitoring

ENGINE MONITORING Engine information is shown on the Liquid Crystal Display (LCD) window in a toggling manner with the Generator information after the first 60 seconds of operation and then every 5 seconds thereafter. The engine display screen will show oil pressure, engine coolant temperature, fuel level and battery voltage. •... -

Page 15: Fine Voltage Adjustment

These codes will not be lost when the control power toggle switch is powered off. FINE VOLTAGE ADJUSTMENT Upon start-up of the generator, the “Running” screen of the Magnum Digital VOLTAGE CONTROL Controller (MDC) will display “SENSING” and will countdown from 45 seconds ADJUSTMENT to “0”... -

Page 16: Mdc Controller Information Displays, Functions And Reset

MAGNUM DIGITAL CONTROLLER (MDC) INFORMATION DISPLAYS, FUNCTIONS AND RESET The Magnum Digital Controller (MDC) constantly monitors vital generator and engine functions for a number of operation, alarm and fault conditions. When a fault condition occurs, the engine will shut down automatically and the Liquid Crystal Display (LCD) window will show the fault that has caused the shut down. -

Page 17: Mdc Controller List Of Possible Alarms With Descriptions

MAGNUM DIGITAL CONTROLLER (MDC) - LIST OF POSSIBLE ALARMS/DESCRIPTIONS Shut down and warning fault conditions and the displayed message are described in the following table: Information on Binary Events Protection Output Specification Type Available Description 1 AnInIOM Sd Shutdown alarm configurable on the input of IG-IOM/IGS-PTM. -

Page 18: Mdc Controller - History

MAGNUM DIGITAL CONTROLLER (MDC) – HISTORY The Magnum Digital Controller (MDC) controller stores a record of each important event into the history file of the controller. The history file seats 118 records. When the history file is full, the oldest records are removed. -

Page 19: Adjusting The Display Backlighting

RESETTING OF THE “TIME TO SERVICE” REMINDER The Magnum Digital Controller (MDC) will display the message “ WrnServiceTime” when the unit is due for mainte- nance or service. The maintenance or service interval is set at 250 hours of engine running time. Once the unit has been serviced, the “ServiceTime”... -

Page 20: Generator Output Connection Lugs

GENERATOR OUTPUT CONNECTION LUGS The generator is equipped with connection lugs behind a door below the controller face. The lugs provide connection points for attachment of external loads to the generator. A large decal on the inside of the connection lug door details the proper connections for selected voltages. -

Page 21: Voltage Selector Switch

VOLTAGE SELECTOR SWITCH The voltage selector switch is located behind the lug door, underneath the engine controller panel. The selector switch is a three position switch that mechanically changes the connections between the generator output leads and the connection lugs. Voltage ranges are selected by rotating the handle on the switch to the desired voltage. NOTICE Never change the voltage selector switch while the engine is running! This will cause sever arcing and damage to the switch and generator windings. -

Page 22: Auxiliary Outlets

The regulator has three screwdriver adjustable potentiometers that may be adjusted for voltage, stability and under frequency (U/F). The voltage regulator on your unit is adjusted before shipment from the factory. Contact Magnum Products LLC for additional information before attempting to adjust the voltage regulator. -

Page 23: Main Circuit Breaker

MAIN CIRCUIT BREAKER The main circuit breaker is located on the main control panel. When the breaker is in the OFF “O” position, power is interrupted between the customer connection lugs and the generator. Once the connections have been made to the connection lugs and the generator has been started and allowed to reach normal operating temperature, the breaker may be switched to the ON “I”... -

Page 24: Transfer Switch

Installation of a transfer switch or other type of remote starting device is the responsibility of the generator user. Installation of such devices must be performed by following all directions supplied by the manufacturer of the switch. If attaching generator to a power supply normally serviced by a utility company, notify the utility company and check local and state regulations. -

Page 25: Light Tower Set-Up

LIGHT TOWER SET-UP 1. For maximum light coverage locate tower at ground level or in a spot higher than the area being illuminated by the lamps. WARNING Check for any overhead obstructions such as utility lines or vegetation as the tower extends up to 30 ft. -

Page 26: Raising The Tower

RAISING THE TOWER WARNING The trailer must be leveled with the outriggers extended before raising the tower. The outriggers must remain extended while the tower is up. Failure to level the trailer or extend the outriggers will severely reduce the stability of the unit and could allow the tower to tip and fall. 1. -

Page 27: Raising The Tower With Optional Electric Winch

RAISING THE TOWER WITH THE OPTIONAL ELECTRIC WINCH 1. Set up and level the trailer as described on page 25, and follow steps 1-3 on page 26. 2. Remove the safety pin from the mast lock bar (R). 3. Press the lower winch control toggle switch upward to raise mast into the vertical position (S). -

Page 28: Light Tower Start Up

LIGHT TOWER START UP Before starting the light tower, carefully read the pre-start check list. Make sure that all of the items are checked before trying to start the light tower. This check list applies for both manual and remote starting. PRE- START CHECK LIST Make sure the control ON/OFF toggle switch is in the OFF “O”... - Page 29 4. Press the green “ENGINE START” button. The Prestart (Preheat) screen will be displayed (if equipped) and a countdown will begin from 20 seconds to 0. 5. The Starting screen will be displayed. The engine will crank and start running. 6.

-

Page 30: Auto (Remote) Starting Of The Generator

Attach a jumper wire (minimum 16 gauge) across the two terminals on the remote start terminal block. This applies a ground to the Magnum Digital Controller (MDC) to close the starting circuit contacts. The engine should crank, start and run. -

Page 31: Light Operation

LIGHT OPERATION 1. Once the engine is up to temperature and running smoothly, switch main circuit breaker to the ON “I” position. 2. With main circuit breaker on, switch each individual circuit breaker for the lights to ON “I”, one at a time. 3. -

Page 32: Lowering The Tower

5. After the mast is completely down, insert the cradle lock pin and secure it with the safety pin. 6. If the trailer is going to be moved, Magnum Products LLC strongly recommends that the lights be removed from the mast and stowed for transportation. See REMOVING THE LIGHTS FOR TRANSPORTATION section on page 33. -

Page 33: Removing The Lights For Transportation

REMOVING THE LIGHTS FOR TRANSPORTATION 1. On units equipped with quick disconnect fittings for the lights, disconnect the power cords from the junction box at the top of the mast. Replace the dust caps on the junction box. On other units, remove the junction box cover on the top of the mast and disconnect ONLY the mast light wires from the terminal blocks. -

Page 34: Lifting The Trailer

LIFTING THE TRAILER When lifting the light tower and trailer, attach any slings, chains or hooks directly to the central lifting eye. The lifting eye is located on the mast between the two forklift pockets. 1. Make sure the equipment being used to lift the light tower has sufficient capacity. Note: See the unit specifica- tions on pages 8 - 9 for approximate weights. -

Page 35: Engine Maintenance

ENGINE MAINTENANCE Note: During the first 50 hours of operation, avoid long periods of no load or sustained maximum load operation. If the light tower is to run for longer than five minutes without a load, shut the engine down. The engine is supplied with engine break-in oil from the factory. -

Page 36: Derating For Altitude

DERATING FOR ALTITUDE All light towers are subject to derating for altitude and temperature; this will reduce the available power for operating to tools and accessories connected to the auxiliary outlets. Typical reductions in performance are 2-4% for every 1000 ft. (305 meters) of elevation and 1% per 10º F (3-5º C) increase in ambient air temperature over 72º F (22.2º C). TROUBLESHOOTING SHUTDOWN CONDITIONS LOW OIL PRESSURE SHUTDOWN 1. -

Page 37: Troubleshooting The Lights

2. Generator output incorrect. Check the incoming voltage to the ballast by checking the available voltage on the duplex receptacle. Incoming voltage should be 120V +/- 5V. If voltage is incorrect engine speed may need to be adjusted or generator may require service. Contact Magnum Products Technical Service Department for more information. -

Page 38: Unit Decals

EN DES ACCIDENTS DE PERSONNE. DECONNECTER BATTERIE AVANT TOUT ENTRETIEN. ITEM NO. PART NO. DESCRIPTION 12141 Decal set, LT eng/safety 4-lang 12140 Decal set, common mast 4-lang 12142 Decal, ground 16488 Decal, Magnum logo with red stripe 12191 Decal, label set - MLG25... - Page 39 UNIT DECALS WARNING SECURE MAST IN TRANSPORT LOCK BEFORE LIFTING OR TOWING! WARNUNG DEN MAST VOR DEM ANHEBEN ODER ABSCHLEPPEN IN DER TRANSPORTHALTERUNG SICHERN! ADVERTENCIA FIJE EL MASTIL EN LA TRABA DE TRANSPORTE ANTES DE REMOLCAR O LEVANTAR EL MISMO. ADVERTISSEMENT VERROUILLEZ SOLIDEMENT LE MAT POUR LE TRANSPORT AVANT DE...

- Page 40 DESCRIPTION 12141 Decal set, LT eng/safety 4-lang 12140 Decal set, common mast 4-lang 11275 Decal, Magnum logo w/web, red vinyl 12262 Decal, 4000/5000 set up 4-lang (manual winch) 12880 Decal, instruction 4000/5000 4-lang (electric winch) 13614 Decal, mast junction box wiring - 4 light...

- Page 41 UNIT DECALS NEUTRAL BONDED TO FRAME NULL-LEITER AM RAHMEN ANGESCHLOSSEN LIGHTS AND CONDUCTOR NEUTRO CONECTADO AL CHASIS CONDUCTEUR NEUTRE MIS A LA MASSE DU CHASSIS EQUIPMENT OUTLETS GENERATOR MAIN MAIN CIRCUIT BREAKER CIRCUIT BREAKER STARTING THE GENERATOR DAS STARTEN DES GENERATORS COMIENZO DEL GENERADOR COMMENCEMENT DU GÉNÉRATEUR 1.

-

Page 42: Manual Winch Mast Assembly

MANUAL WINCH MAST ASSEMBLY... - Page 43 ITEM NO. PART NO. DESCRIPTION 11954 Coil cord, mast 16600 Winch, manual 60584 Nut, .750-10 nylock G5 yellow zinc 11902B Weldment, mast tube 11649Z Weldment, t-bolt 15292 Screw, .750-10X6.500 hx hd SS 15380 Pin, cotter - .125X1.250 14262 Sheave, 3 in. 60247 Washer, flat .750 14234...

-

Page 44: Electric Winch Mast Assembly

ELECTRIC WINCH MAST ASSEMBLY... - Page 45 ITEM NO. PART NO. DESCRIPTION 11954 Coil cord 12875B Cover, winch contactor 11293 Contactor, electric winch - warn 65049 Relay, 12V 30/40A N.O. w/diode 65707 Switch, toggle - SPDT spring weatherproof 12872B Bracket, winch mounting 12874 Winch, electric - 770 lb. hoist 15380 Pin, cotter - .125X1.250 15006...

-

Page 46: Frame And Components

FRAME AND COMPONENTS 6, 69 14, 70... - Page 47 ITEM NO. PART NO. DESCRIPTION 16270 Fitting, .375MNPT to .250 FNPT straight 16271 Fitting, 90-.250NPTX.188 barb 15142 Fitting, strt-.250NPTX.312 barb 12259 Fuel pick up tube - 24.00 in. 12361B Weldment, fuel tank strap 12080 Cap, fuel tank - vented, 3.5 dia. grn diesel only 12162 Tank, fuel - 56 gallon poly 11735B...

- Page 48 ITEM NO. PART NO. DESCRIPTION 16830 Coupler - 2.00 ball/2.50 channel 23367 Chain, safety - 7,800 lbs. rated 12420B Weldment, removable tongue 13300 Cam, transformer - ballast box (5.5” height) 13299 Transf. & base brkt w/str relief-60Hz MH cyl bal OPTIONAL FEATURES: 12235B Weldment, spare tire holder...

-

Page 49: Generator Assembly

22899 Generator, 282NSL1505 Note: Engine and generator parts used in all Magnum Products LLC equipment carry the Original Equipment Manufacturer (OEM) warranty unless otherwise stated. OEM warranty parts must be purchased through an OEM dealer. Please contact Magnum Products LLC with questions. -

Page 50: Mast Junction Box Assembly - Hard Wired Lights

MAST JUNCTION BOX ASSEMBLY - HARD WIRED LIGHTS ITEM NO. PART NO. DESCRIPTION 12109 Box cover, 2-gang plastic 66100 Connector, 2 pos. Wago 66101 Connector, 3 pos. Wago 66102 Connector, 5 pos. Wago 60755 Fitting, .750MNPT x .500FNPT nylon 15864 Strain relief, .500NPT water tight 12095B Bracket, junction box... -

Page 51: Mast Junction Box Assembly - Quick Disconnect Lights

MAST JUNCTION BOX ASSEMBLY - QUICK DISCONNECT LIGHTS ITEM NO. PART NO. DESCRIPTION 12109 Box cover, 2-gang plastic 66100 Connector, 2 pos. Wago 66101 Connector, 3 pos. Wago 66102 Connector, 5 pos. Wago 60755 Fitting, .750MNPT x .500FNPT nylon 15403 Connector, quick disconnect (female) 15404 Cap, receptacle w/chain... -

Page 52: Enclosure Assembly

ENCLOSURE ASSEMBLY... - Page 53 ITEM NO. PART NO. DESCRIPTION 25333W Panel, back access 12195 Gasket, radiator access plate 11381 Fender, plastic 11507W Panel, right side sheetmetal 16591W Panel, door 16598 Hinge, door 10284W Panel, roof w/access hole 10287W Panel, rear 4000 Isuzu 10220 Light, rear tail/turn - no grommet 10221 Grommet, rear light rubber 4.5 10219...

-

Page 54: Auxiliary Outlet Panel Assembly

AUXILIARY OUTLET PANEL ASSEMBLY... - Page 55 ITEM NO. PART NO. DESCRIPTION 65535 Clamp, 90° 3/4" 2 screw 12248B Weldment, outlet cover 10081 Hinge, continuous - 11.00 in. 11484B Cover, breaker 14130 Receptacle, 120V/20A GFCI 65530 Block, terminal - 2 pole lug type, 7 pos./pole 14137 Receptacle, 240V/30A twist lock 18089 Receptacle, 120/ 240V 50A twist lock 12246B...

-

Page 56: Auxiliary Outlet Panel Options

AUXILIARY OUTLET PANEL OPTIONS PART NUMBER 12399 PART NUMBER 12402 Receptacle Panel (2x5-20R, 3xL6-30R, 1x50A) Receptacle Panel (2x5-20R, 3xL6-20R, 1x50A) PART NUMBER 12400 PART NUMBER 12401 Receptacle Panel (2x5-20R, 3xL14-30R, 1x50A) Receptacle Panel (2x5-20R, 4xL14-30R) - Page 57 PART NUMBER 13893 PART NUMBER 13540 Receptacle Panel (2x5-20R, 1xTT-30R, 1xL6-30R, 2x50A) Receptacle Panel (2x5-20R, 2xTT-30R, 2x14 - 50) ITEM NO. PART NO. DESCRIPTION 14130 Receptacle, 120V 20A GFCI 14137 Receptacle, 240V 30A twist lock 18089 Receptacle, 125/250V 50A twist lock 65488 Receptacle, 240V 30A twist lock 65849...

-

Page 58: Light Assembly

OVAL LIGHT ASSEMBLY... - Page 59 ITEM NO. PART NO. DESCRIPTION 60304 Screw, M5 x 25 pan hd phillips 60447 Nut, M5 nylock 13367 Assembly, aluminum ring 13369 Lens, glass oval 13373 Gasket, lens oval 11391 Bulb, 1000W MH short length 13399 Screw, M4 x 18 pan hd phillips 60067 Washer, #10 flat .435/.060 SS 13370...

-

Page 60: Engine Cooling Assembly

ENGINE COOLING ASSEMBLY LOWER RADIATOR HOSE... - Page 61 ITEM NO. PART NO. DESCRIPTION 60034 Screw, .375-16X.750 hx ser flg 60206 Washer, split lock .375 60386 Washer, flat .375 26305 Radiator, aluminum 11626B Weldment, fan shroud 15422 Clamp, hose SAE 20 11760B Panel, fan guard - right 60115 Screw, M6X1.0X12 hx ser flg 11769B Weldment, fan guard - left 11596B...

-

Page 62: Engine Assembly

ENGINE ASSEMBLY... - Page 63 26306 Fan, 15.75 in. increasing arc (not shown) Note: Engine and generator parts used in all Magnum Products LLC equipment carry the Original Equipment Manufacturer (OEM) warranty unless otherwise stated. OEM warranty parts must be purchased through an OEM dealer. Please contact Magnum Products LLC with questions.

-

Page 64: Control Panel Assembly

CONTROL PANEL ASSEMBLY... - Page 65 ITEM NO. PART NO. DESCRIPTION 60160 Screw, M8X1.25X30 hx ser flg 65287 Lug, terminal single #6-350 MCM 12065 Channel, glastic 12066 Angle, glastic 13126W Panel, control 11811W Bracket, glastic plate 60020 Nut, M8 hx ser flg lock 60062 Screw, 10-32X.750 pan hd phil 60044 Screw, M5X0.8X12 pan hd phil 60738...

-

Page 66: Control Box Assembly

CONTROL BOX ASSEMBLY... - Page 67 ITEM NO. PART NO. DESCRIPTION 12694W Panel, top control box 65619 Breaker, 90A, 3 pole 65429 Breaker, 100A, 250V, 2 pole 18556 Regulator, voltage - SE 350 60355 Screw, M4X35 pan head phil 65442 Transformer, current - 200:5A 60115 Screw, M6X1.0X12 hx ser flg 18081 Relay, ignition solenoid (12V-65 A) 60036...

-

Page 68: Lug Door Assembly

LUG DOOR ASSEMBLY ITEM NO. PART NO. DESCRIPTION 18598 Hinge, controller panel - 18.75 60156 Screw, M5X0.8X16 pan hd phil 60038 Nut, M5 hx nylock DIN985 20762 Lock, door - 1/4 turn cam 12631W Panel, lug door 15215 Bumper, rubber 18893 Handle, lug door 60043... -

Page 69: Wiring Diagrams

TRAILER LIGHTS WIRING DIAGRAM ITEM NO. PART NO. DESCRIPTION 10264 Harness, left side trailer 10261 Harness, main trailer 4000 10265 Harness, right side trailer 65465 Adapter, trailer wiring flat 4 to rnd 7 blade 65464 Adapter, trailer wiring flat 4 to rnd 7 pin 65463 Adapter, trailer wiring flat 4 to rnd 6 pin... - Page 70 AC WIRING DIAGRAM...

- Page 71 DC WIRING DIAGRAM BRN/WHT RED F+ BLK F- 50HZ 60HZ...

- Page 72 AC WIRING PANEL OPTIONS PART NUMBER 12399; Receptacle Panel (2x5-20R, 3xL6-30R, 1x50A) PART NUMBER 12402; Receptacle Panel (2x5-20R, 3xL6-20R, 1x50A) PART NUMBER 12400; Receptacle Panel (2x5-20R, 3xL14-30R, 1x50A)

- Page 73 AC WIRING PANEL OPTIONS PART NUMBER 12401; Receptacle Panel (2x5-20R, 4xL14-30R) CIRCUIT CIRCUIT CIRCUIT CIRCUIT BREAKER BREAKER BREAKER BREAKER 30 AMP 30 AMP 50 AMP 50 AMP 240 VOLT 240 VOLT 120 VOLT 240 VOLT 30 AMP 30 AMP 50 AMP 50 AMP TWIST LOCK TWIST LOCK...

- Page 74 DC CIRCUIT WIRING DIAGRAM, DUAL ELECTRIC WINCH ELECTRIC WINCH (OPTIONAL) WINCH WINCH PROX. PROX. RELAY RELAY PROX SWITCH PROX SWITCH TILT EXTEND 50 AMP CIRCUIT BREAKERS BATTERY 12V...

- Page 75 MAST JUNCTION BOX WIRING DIAGRAM...

- Page 76 REV: B PART NO: 13134 11.07.08...

Need help?

Do you have a question about the MLT 4250 and is the answer not in the manual?

Questions and answers