Subscribe to Our Youtube Channel

Summary of Contents for Whip Mix Pro Press 200

- Page 1 Pro 200 Series Furnace Operators Manual Pro 200 Pro Press 200 Whip Mix Corporation 361 Farmington Ave. P.O. Box 17183 Louisville, KY 40217-0183 USA • • • 502-637-1451 800-626-5651 Fax 502-634-4512 www.whipmix.com • • •...

-

Page 2: Intended Use

Note: During shipping the muffle might absorb moisture from the air. So, it is recommended you heat the muffle Whip Mix Corporation warrants the Pro 200 and Pro Press to dry the moisture before firing any porcelain. To dry the 200 to the original purchaser against defective workmanship muffle, set the idle temperature to 400°... -

Page 3: Table Of Contents

External Component Locator ..........4 Look at a Program ...............17 Before Unpacking ..............5 Add/Edit a Program .............18 Unpacking ................5 Press Firing Cycle Program (Pro Press 200 only)....20 Press Version ................5 Copy/Change a Program .............22 Press Regulator Set-Up ............5 Move a Program ..............22 Installing the Vacuum Pump ..........5... -

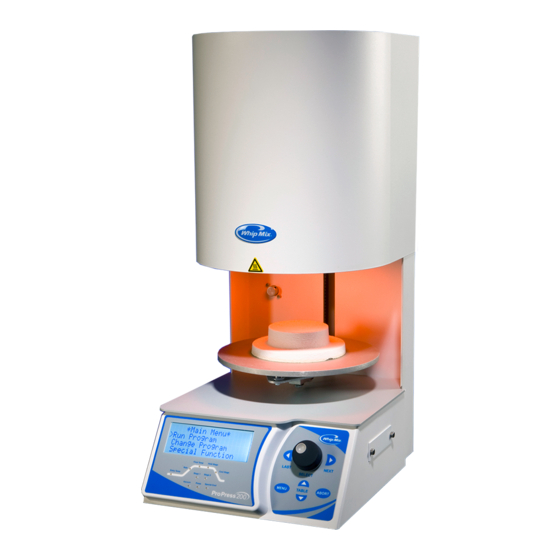

Page 4: External Component Locator

Pro 200 Series Furnace Operations Manual External Component Locator Top Muffle Cover Press Regulator Attachment Lift Table Calibration Port Selector Knob Keyboard Back Cover Quick Cool Jet Hose Barb Power Switch USB Port Vacuum Pump Power Inlet Plug Power Outlet Fuses Vacuum Pump Hose Barb... -

Page 5: Before Unpacking

Press Regulator Set-Up • With the clear plastic portion The Pro Press 200 requires compressed air to run a press facing down, push the regulator cycle. Generally minimum air pressure of 63 psi/4.25 onto the quick connect fitting at BAR and a maximum of 150 psi/10 BAR. -

Page 6: Quick-Cool Jet Installation For Pro 200 Furnaces With Air Cool Jet

Pro 200 Series Furnace Operations Manual Quick-Cool Jet Installation for Pro 200 Furnaces with Air Cool Jet This side goes to the Quick Cool Jet Preparation: 1. Remove the vacuum pump from its box. 2. Remove the brass hose barb from the Furnace accessory box. -

Page 7: Power

Be sure to have Ver XX.XX.XX at least 8 inches on all sides of the furnace to allow By Whip Mix sufficient airflow to keep the electronics of the furnace cool. Do not place anything flammable NOTE: THE ACTUAL VERSION NUMBER OF YOUR near the furnace. -

Page 8: Menu Selection Buttons

Pro 200 Series Furnace Operations Manual Menu Selection Buttons The three menu selection items (Run Program, Change Special Functions — press the Selector Knob and turn the Selector Knob to one of the following actions: Program and Special Functions) will display different options. -

Page 9: Information Display And Entry

Pro 200 Series Furnace Operations Manual Information Display and Entry DISPLAY — All information and user prompts will be TABLE UP — Press the up arrow button to manually shown on the display (four lines, twenty characters each). raise the table. Press the up arrow button a second time and the table will stop. -

Page 10: Using The Furnace

Pro 200 Series Furnace Operations Manual Using the Furnace After the furnace has completed the self-test at power up, 1. Set up the operating features of the furnace by reading and following the instructions in the Firmware Version appears on the screen, then the Chapter 2 —... -

Page 11: Chapter Two - Special Functions

Pro 200 Series Furnace Operations Manual Chapter Two — Special Functions Most Special Functions can be performed while a To look at or change a function, press the Special program is running, however this is not recommended Functions item from the Main Menu. Turn the Selector because changing the operating features could affect Knob clockwise or counterclockwise until the desired how the current program runs. -

Page 12: Set Vacuum Level

Pro 200 Series Furnace Operations Manual Set Vacuum Level To set the vacuum level for all programs do the following: The factory setting for vacuum is 71 cm of mercury. The acceptable range is from 22 cm to 74–75 cm of mercury 1. -

Page 13: Set Program Start Delay

Pro 200 Series Furnace Operations Manual Set Program Start Delay The furnace has a unique feature that allows the operator 6. Push the Selector Knob OR press the Next button to save your selection. You will be returned to the to program a delay to occur before the start of all programs. -

Page 14: Saving Programs To A Flash Drive (Exporting)

Pro 200 Series Furnace Operations Manual Saving Programs to a Flash Drive (Exporting) 1. Place the Flash Drive in the USB slot on the left side of the furnace with the shiny metal contact facing upward. 2. Select the Special Functions item from the Main Menu. 3. -

Page 15: Low Fusing Adjust

Pro 200 Series Furnace Operations Manual Low Fusing Adjust Calibration (800° C/1470° F or below) Example: If your porcelain appears to be overfired by 25°, you would enter a negative (-25) twenty-five degree value to 1. Select the Special Functions item from the Main Menu. lower the effective firing temperature of ALL the Low Fusing 2. -

Page 16: Testing Your Furnace

Push the Selector Knob OR press the Next button. Enter Mix TOPS Technicians.) the password and access the selected function. • On Pro Press 200; use Timed Press; Yes/No Changes preference between Re-Press and Timed Press, press programs are factory set and include vacuum. -

Page 17: Chapter Three - Change Program Menu

All of the features described here may be performed while examples show how a user could make program a program is running. Both the Pro 200 and Pro Press 200 identification easy: furnaces use a unique method of numbering and naming... -

Page 18: Add/Edit A Program

Pro 200 Series Furnace Operations Manual Normal Porcelain Add/Edit a Program Add/Edit a Program is used The ^ symbol under the line identifies the current HOLD TIME character position being entered. Rotate the Selector to enter a new program or HEAT RISE Knob to bring up the desired character, then push the Edit a pre-existing program. - Page 19 Pro 200 Series Furnace Operations Manual 11. Hold Temperature All furnaces have individual firing characteristics, even with identical settings. The Special Functions Hold Temperature or the top temperature is the final, High/Low Fusing Adjustment features are useful for highest temperature in a 1-Stage Program, and an matching the firing characteristics of two furnaces intermediate stopover temperature in a 2-Stage so that they fire identically.

-

Page 20: Press Firing Cycle Program (Pro Press 200 Only)

Selector Knob as in the example below. The range will automatically be returned to the Main Menu. Press Firing Cycle Program (Pro Press 200 only) The following procedures describe how to enter a If the program you wish to Add requires only a single Rate Rise and Hold Temperature, select 1-Stage. - Page 21 Pro 200 Series Furnace Operations Manual 8. Entry Temperature Why do you need fusing adjustments? Entry Temperature is the temperature at which the The Program Level Fusing Adjust is useful for making table will close completely. minor adjustments to a single, specific Program without The range of values is 25°...

-

Page 22: Copy/Change A Program

Pro 200 Series Furnace Operations Manual Copy/Change a Program 5. COPY TO: is displayed. Turn the Selector Knob to The Copy/Change a program feature allows a program to select a location for the copied program. If a program be copied from one program number to another and then that is already entered is selected, you will write over changed. -

Page 23: Chapter Four - Run Program Menu

Pro 200 Series Furnace Operations Manual Chapter Four — Run Program Menu Turn the Selector Knob until the desired program is The Run Program mode allows you to run programs and displayed. If the table has not been lowered, do so now. to view programs as they are running. -

Page 24: The Led Graph

LEDs on a 1-Stage Program: >Pre Dry segment: >First Rise segment: *Argon feature is only available on Pro 200 **Press function is only available on Pro Press 200 >Rate Rise segment: >First Hold segment >Hold Temp segment: >Second Rise segment: >Closed Cool segment:... -

Page 25: Running A Pressing Program

Running a Pressing Program (Pro Press 200 only) The Pro Press 200 can press into a 100 or 200 gram investment mold. Configure the firing tray and press insert as show below for each size mold. 1. If the muffle temperature is below the entry 3. -

Page 26: Chapter Five - Maintenance

THE CHASSIS BEFORE FIRST REMOVING THE AC NOTE: IF HAZARDOUS MATERIAL IS SPILLED ON OR ELECTRICAL POWER CORD. THERE ARE DEADLY INSIDE THE FURNACE, CONTACT WHIP MIX TECHNICAL VOLTAGES INSIDE. SUPPORT IF THERE IS ANY DOUBT AS HOW TO SAFELY REMOVE THE MATERIAL. -

Page 27: Purge/Decontamination

Purge/Decontamination Trouble Shooting Guide Moisture removal must be done first: The Pro 200 and Pro Press 200 furnaces offer a number of self checks and warning messages that are designed to When the furnace is unused for prolonged periods of identify problems. -

Page 28: Vacuum Test

> Test Furnace if you have questions about the furnace not covered in the manual, contact your dealer or Whip Mix at: 4. Turn the Selector Knob to Vacuum Test. Press the Next button. The vacuum test will automatically begin. -

Page 29: Replacement Parts

Maximum Temperature 2200°F 96094 Lift Limit Sensor Dimensions Pro 200 11" W x 16"D x 21"H 96021 Lift Belt Pro Press 200 11"W x 16" D x 25"H 96025 Table 96309 Press Regulator with Quick disconnect 96012 Press Insert Trays 96013... -

Page 30: Pro Series Accessories

Pro 200 Series Furnace Operations Manual Pro Series Accessories High-Efficiency Vacuum Pump ProCal... -

Page 31: Fahrenheit To Centigrade

Pro 200 Series Furnace Operations Manual Fahrenheit to Centigrade Centigrade to Fahrenheit ° F ° C ° F ° C ° F ° C ° F ° C ° C ° F ° C ° F ° C ° F °... - Page 32 IT 11522 10/13...

Need help?

Do you have a question about the Pro Press 200 and is the answer not in the manual?

Questions and answers