Summary of Contents for Northern Lights Lugger 0844K

- Page 1 O844K For Models: M844K, M844LK, M20CL, and M20CR OPERATOR’S MANUAL Marine Generators | Marine Diesel Engines | Land-Based Generators...

- Page 2 4420 14th Avenue N.W. Seattle, WA 98107 Tel: (206) 789-3880 Fax: (206) 782-5455 Copyright ©2009 Northern Lights, Inc. All rights reserved. Northern Lights™, and the Northern Lights logo are trademarks of Northern Lights, Inc. Printed in U.S.A. PART NO.: O844K 10/09...

-

Page 3: Table Of Contents

This publication is the property of Northern Lights, Inc. It may not be reproduced in whole or in part without the written permission of Northern Lights, Inc. © Northern Lights, Inc. All rights reserved. Litho U.S.A. Publication number O844K 10/09... -

Page 4: Introduction

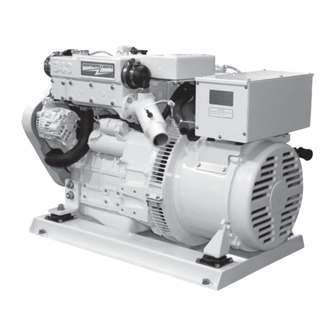

Cylinders 84 mm C - Commercial version Northern Lights marine diesel generator set with Northern Lights 20 kW (@ 60 Hz) commercial grade M844 M20CL an 844 engine and a PX-300K generator end. marine generator set with a special generator end. -

Page 5: Serial Numbers

The generator set plate is found on the service side of the generator and resembles the drawing in Figure 1. Fill in the serial number of My Northern Lights generator set SERIAL number is: your unit in the box provided. Figure 1: Generator set serial number plate. -

Page 6: Component Locations M844 K And M844L K Marine Generators

Marine generator Component Locations Non-Service Side Optional PTO Service Side Figure 2A and 2B: M844K and M844LK with PXK generator ends. Coolant Fill Belt Guard Oil Fill (Top) Oil Dipstick Expansion Tank/Exhaust Raw Water Pump Fresh Water Pump Oil Filter Manifold/Heat Exch.Tank Alternator Injection Pump... -

Page 7: M20Cl Marine Generators

Commercial generator Set Component Locations Non-Service Side Service Side Figure 3A and 3B: M20CL with special generator end. Air Filter Vibration Mount Injection Pump Generator End Coolant Thermostat (behind) DC Alternator Oil Fill (Side) DC Circuit Breaker Expansion Tank/Manifold/ Keel Cooler Return Freshwater Block Drain Secondary Fuel Filter Heat Exchanger Tank... -

Page 8: Control Panels

Control Panels 1. ShUTdOWN byPASS-PREhEAT SWITCh Two functions are built into this switch: the preheat- ing of the engine, and bypassing of the engine safety shutdown circuit. Hold switch in the ON position 10 - 20 seconds before starting the engine, and continue holding on during engine cranking. - Page 9 Notes O844K 10/09...

-

Page 10: Operating Procedures

Operating Procedures bREAK-IN PERIOd STARTINg 1. The first 100 hours on a new or reconditioned 1. Hold the Shutdown Bypass-Preheat switch in the ON engine are critical to its life and performance. position for 10 to 20 seconds before starting a cold 2. -

Page 11: Shutdowns And Alarms

ShUTdOWNS ANd ALARMS SPARE PARTS 1. Your unit is fitted with a system to protect it from 1. Northern Lights recommends that you keep the high water temperature or low oil pressure. following spare parts on hand for field service. The a. -

Page 12: Servicing Schedule Chart

Servicing Schedule Chart The Servicing Schedule Chart below shows the service schedule required for proper maintenance of your generator set. More detailed coverage of each Service Point (SP) is listed on the page noted in the ‘page’ column. dAILy: EvERy 500 hOURS: Check oil level in engine Change primary fuel filter element Check V-belt tension... - Page 13 Service Record Notes O844K 10/09...

-

Page 14: Servicing

Servicing LUbRICATION - gENERAL SP2. OIL ChANgES 1. Use only clean, high quality lubricants stored in 1. The set is delivered with special break-in oil. clean containers in a protected area. Change the engine oil and oil filter after 50 hours 2. -

Page 15: Air Filter

Servicing SP4. AIR CLEANER 1. Inspect air cleaner every 250 hours. In dusty condi- tions, check more often. 2. Marine sets: if dirty, wash element in soapy water. Rinse and dry thoroughly before re-installing. Replace if necessary. Part numbers are: M844 and M844L –... -

Page 16: Fuels - General

Servicing fUELS - gENERAL SP7-9. fUEL fILTERS 1. Use only clean, high quality fuels of the following Primary specifications, as defined by ASTM designation Fuel Filter D975 for diesel fuels: a. Use grade no. 2 diesel at ambient temperatures above freezing 32°F (0°C). b. -

Page 17: Bleeding The Fuel System

Servicing SP10. bLEEdINg ThE fUEL SySTEM CAUTIoN: escaping diesel fuel under pressure can penetrate skin causing serious personal injury. Before disconnecting lines be sure to relieve all pressure. Before applying pressure, be sure all connections are tight and lines, pipes and hoses are not damaged. Fuel escaping from a very small hole can be almost invisible. Use a piece of cardboard or wood, rather than hands, to search for suspected leaks. - Page 18 Servicing Figure 11: Remove delivery line flare nuts. Figure 15: Remove return line. Figure 12: Remove delivery lines. Figure 16: Unscrew injector. Figure 13: Cover lines, inlets and injection pump outlets. Figure 17: Remove and replace copper sealing washer. Figure 14: Remove return line nuts. Figure 18: Reinstall injector.

-

Page 19: Injector Service

1. Injectors should be checked every 1000 hours. 1. Since operating conditions may vary considerably, it Check should be made by a Northern Lights dealer is difficult to give a definite interval for checking the or local injection repair station. -

Page 20: Cooling System Flushing

4. Clean the inside of exchanger core tubes using Manual. If you do not have one of these manuals, a metal rod. Flush, inspect and clean again if neces- contact your local Northern Lights dealer. sary. 5. Reassemble. Fill the cooling system, start the engine ELECTRICAL SySTEM - gENERAL and check for leaks. -

Page 21: Glow Plugs

Servicing gLOW PLUgS SP 18-19. bATTERy CARE 1. Each cylinder is supplied with a glow plug which 1. Check electrolyte level daily. Add distilled water to serves to heat the combustion chamber. manufacturer’s recommended level. 2. To check the glow plugs, loosen the current 2. -

Page 22: Troubleshooting

Faulty connection • Clean and tighten battery and harness plug connections. Sulfated or worn out batteries • Check specific gravity and electrolyte level of each battery. If you cannot correct problems with these procedures, see your Northern Lights dealer. O844K 10/09... - Page 23 Troubleshooting ENgINE PRObLEM POSSIbLE CAUSE RECOMMENdATION(S) Engine hard to Start Improper starting procedure • See starting section of this manual. Take or Will Not Start special note of Bypass Switch operation. No fuel • Check level of fuel in fuel tank. Low battery output •...

- Page 24 • Oil consumption decreases after break in. Crankcase oil too light • Use proper viscosity oil. Oil leaks • Check for leaks in lines around gaskets and drain plug. If you cannot correct problems with these procedures, see your Northern Lights dealer. O844K 10/09...

- Page 25 White Smoke Cold engine • Warm up engine to normal operating temperature. Defective thermostat • Remove and check thermostat. Engine timing off • See your dealer. If you cannot correct problems with these procedures, see your Northern Lights dealer. O844K 10/09...

-

Page 26: Engine

M844 data Kilowatt Rating Prime 16 kW 12 kW Rated RPM/frequency 1800/ 60hz 1500/ 50hz general Information Engine Type Lugger 4 cycle, swirl chamber diesel Lugger 4 cycle, swirl chamber diesel Cylinders Inline 4 Inline 4 Displacement 121in (1.995 liters) 121in (1.995 liters) Cycles... -

Page 27: M844L K

M844L data Kilowatt Rating Prime 20 kW 16 kW Rated RPM/frequency 1800/ 60hz 1500/ 50hz general Information Engine Type Lugger 4 cycle, swirl chamber diesel Lugger 4 cycle, swirl chamber diesel Cylinders Inline 4 Inline 4 Displacement 135 in (2.216 L) 135 in (2.216 L) Cycles... -

Page 28: M20Cl

M20CL data Kilowatt Rating Prime 20 kW 16 kW Rated RPM/frequency 1800/60hz 1500/50hz general Information Engine Type Lugger 4 cycle, swirl chamber diesel Lugger 4 cycle, swirl chamber diesel Cylinders Inline 4 Inline 4 Displacement 135 in (2.216 L) 135 in (2.216 L) Cycles Bore x Stroke... -

Page 29: Wiring Diagrams

Wiring diagrams O844K 10/09... - Page 30 Notes O844K 10/09...

Need help?

Do you have a question about the Lugger 0844K and is the answer not in the manual?

Questions and answers