Dunkirk XEB-3 Installation, Operation & Maintenance Manual

Xeb series gas-fired hot water induced draft boilers

Hide thumbs

Also See for XEB-3:

- Installation, operation & maintenance manual (40 pages) ,

- Installation manual (37 pages) ,

- Installation instructions manual (33 pages)

Summary of Contents for Dunkirk XEB-3

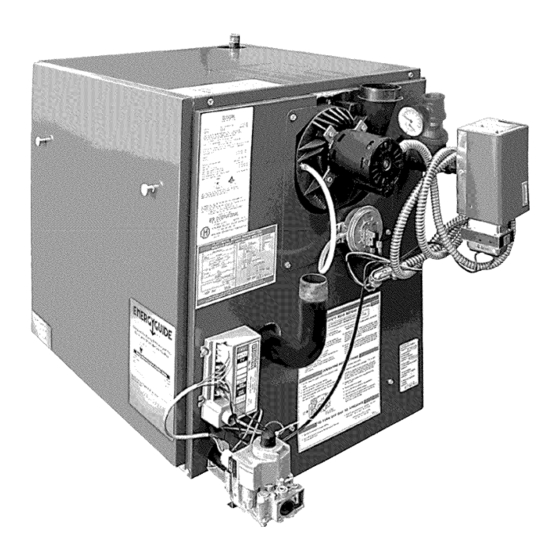

- Page 1 XEB Series Gas-FiredHot Water Induced Draft Boilers INSTALLATION, OPERATION & MAINTENANCE MANUAL DUNKIRK BOILERS 85 Middle Dunkirk, NY 14048 www. dunkirk, corn P/N 14683001 Rev. B [11/09]...

- Page 2 Safety Symbols ................................ Installation Instructions ............................Boiler Ratings And Capacities ..........................Before You Start ..............................Locating The Boiler ..............................Fresh Air For Combustion ............................Installation System Piping ..........................Chimney & Vent Pipe Connection ........................Horizontal Venting Instructions ........................Optional Horizontal Venting Instruction ......................

- Page 3 ASME R_LIEF VALVE \,® VALVE DESIGN CERTIFIED NATURAt AND PROPANE LeR Si_e Fro_t Right Side XEB-2 42.5 XEB-3 75.0 14-1/4 XEB-4 112.5 17-1/2 XEB-5 150.0 20-3/4 XEB-6 187.5 XEB-7 225.0 27-1/4 * MBH = f,O00 Btuh = British Thermal Unit Per Hou_ Boilers are equipped for altitudes up to 2,000 feet on!_ U.S.A. Only - For altitudes above 2,000 feet, ratings should be reduced at the rate of 4% for each f,O00 feet above sea level.

-

Page 4: Table Of Contents

iiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii iiii iiiiiiiiiiii... - Page 5 If the boiler is part of a planned heating system, locate it where Figure 2 - Minimum Clearances To Combustible shown on your plan. If boiler is to be part of an existing system,it is usually best to put it where the old one was. Ifyou plan to change location, you will need additional materials as wellas an adequate Construction i8,,...

- Page 6 Sizing Air/Ventilation Openings Provision forcombustion and ventilation airmust be in accordance withtheNational Fuel G as C ode, ANSI Z223.1- latest revision, orapplicable provisions ofthelocal Air openings must be sized to handle all appliances and building codes. air movers (exhaust fans,etc.) using the air supply.For air openings into spaces containing other appliancesin addition to the boiler refer to the National Fuel Gas Code, ANSIZ223.1 for sizing.

- Page 7 EXAMPLE 1: Boiler Located In Unconfined Space An unconfined space is defined as a space whose volume is not less than 50 cubic feet per 1,000 Btu per hour of the total input rating of all appliances installed in that space. If your boiler is in an open area (non-partitioned basement) in a conventional house, the air that leaks through the cracks around doors and windows will usually be adequate to provide air for combustion.

- Page 8 All Air from Outdoors: The confined space shall communicate with the outdoors in accordance with Methods A or B below. The minimum dimension of air openings shall not be less than 3 in. Where ducts are used, they shall be of the same cross-sectional area as the free area of the openings to which they connect.

- Page 9 2. Where c ommunicating withtheoutdoors through h orizontal ducts (see Figure 3D), each opening shall have a minimum free area of 1 area ofsq. in. per 2000 Btu per hour of total rating of all equipment in the enclosure. Figure 3D - Horizontal Ducts Communicating to the Outdoors Louver Allowance...

-

Page 10: Iiii Iiiiiiiiiiii Iiii Iiiiiiiiiiii Iiii Iiiiiiiiiiii Iiii Iiiiiiiiiiii Iiii Iiiiiiiiiiii Iiii Iiiiiiiiiiii Iiii Iiiiiiiiiiii Iiii Iiiiiiiiiiii Iii_ ¸I

To avoid burns, scalding, or water damage due to discharge of steam and/or hot water during operation, a discharge line shall be installed to relief valve outlet connection. The discharge line shall: •connect to relief valve outlet and piped down to safe point of disposal. •be of pipe size equal to or greater than that of the relief valve outlet over the entire length of discharge line;... - Page 11 Figure 4 - Relief Valve Discharge Piping RELIEF VALVE DISCHARGE PIPING Check local code_ Figure 6 - Forced Hot Water Typical Piping With Zone for maximum Control Valve distance from floor or other al- lowable safe point ZONE VALVE o, of discharge MAiN Figure 5 - Forced Hot Water Typical Piping...

- Page 12 If you are installing an entire new heating system,first install all of Low Design Water Temperature Systems (Below 140 ° F) your radiation units (panels, radiators or cabinets) and the Supply And Large Water Content Systems: and Return Mains - then make the connections at the boiler. In connecting the cold water supply to the water vane, make sure that a clean water supply is available.

- Page 13 7. Where possible,it is recommended to common vent the water heater and boiler. Consult the appropriate Vent SizingTables in iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_ iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_ either the National Fuel Gas Code, or the Canadian Installation For boilers for connection to gas vents or chimneys, vent Codes for specificrequirements of multiple appliance venting.

-

Page 14: I_Ii_Ii_ I_Ii_Ii

Figure 9 - Type B Gas Vent Liner Chimney Sheet Metal Vent System Cleanout CHECK YOUR CHIMNEY This is a very important part of your heating system. It must be clean, the right size, properly constructed and in GOOD CONDITION. No boiler can function properly with a bad chimney. - Page 15 nected to the common venting systemproperlyventswhen tested zontal pitch and determine there is no blockage or restriction, asoutlined above,return doors, windows,exhaustfans,fireplace leakage, corrosion and other deficiencies which could cause an unsafe condition. dampers and any other gas-burningapplianceto their previous conditionsof use. Insofar as is practical, close all building doors and windows and alldoors between the space in which the appliancesremaining Any improper operation of the common venting system should...

- Page 16 INDUCED DRAFT HIGH EFFICIENCY BOILERS Maximum Horizontal Vent Length For StainlessSteelVentPipe - 30' CHOICE OF VENT PIPE MATERIAL Plus One 90° Elbow PlusVent Terminal. 1. U.L. ListedZ-FlexZ-Vent Stainless SteelVent Pipe. Minimum Horizontal Vent Length - 2' Plus One 90° ElbowVent 2.

- Page 17 These boilers may be vented horizontally as shown in Vent Termination Fitting: For all vent pipe materials, you may use either: Figure 10. The vent pipe is pitched down from the boiler to the vent termination. Do not connect other appliances to this A.

- Page 18 Figure 11 - Horizontal Venting Clearances NOTE: THERE POTENTIAL EXCES:S_VE WINDS, SPECIAL CONSIDERATION _NOULD GIVEN LOCATE VENT TERMINATION AWAY FROM WINDWARD Si:DE BUILD_NG, LOCATE VENT ALLOW _2" ABOVE: ORADE Locate or guard the vent to prevent accidental contact with ing system shall terminate at least 4 feet below, 4 feet people or pets.

- Page 19 For 3" vent pipe runs begin with the male end of the vent to which an even bead of high temperature siliconesealant pipe over the boilers induced draft blower outlet. For 4" should be applied. Then continue the 4" Saf-T-Ventpipe vent pipe runs begin with a 6"...

- Page 20 Applyhigh temperature siliconein an even ¼" bead ap- all vent pipe seams and orient upward in allhorizontal proximately 1/4" f rom the end of the vent hood's connecting applications. Adjustablevent lengths are availablefor 4" vent pipe. Also,run a similar sizebead of siliconesealant diameter vent piping.

- Page 21 10. If the horizontal vent must go through a crawl space or other required to prevent freezing of liquid condensate. Consult the unheated space, the cool temperatures will likely cause the flue vent pipe manufacturer's instructions for specific guidelines. gases to continuously condense inside the vent pipe. Do not 11.

- Page 22 Connecting The Gas Piping Refer to Figure 12 for the general layout at the boiler. It shows the basic fittings you will need. The gas line enters the boiler from the Never use a match or open flame to test for leaks. right side.

- Page 23 All electrical work must conform to local codes as well as the Na- tional Electrical Code, ANSI/NFPA-70, latest revision. In Canada, electrical wiring shall comply with the Canadian Electrical Code, Label all wires prior to disconnection when servicing iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii CSA-C22.1. iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii controls.

- Page 24 Figure #13 -Intermittent Ignition 120/60/1 LINE VOLTAGE WIRING POWER SUPPLY LOW VOLTAGE WIRING NEUT LOW VOLTAGE FIELD WIRING HOT_ THERMOSTAT ,Ol w7: BLACK DISCONNEC 1 BLACK WITH TRACER ;1)/L. <T_ WHITE \_>' GREEN L8148A AQUASTAT BLUE INDUCER DRAFT AT 140C TRANSFORMER CIRCULATOR INTERMITTENT PILOT CONTROL...

- Page 25 Relief Valve Air Eliminating Fitting (Air Purger) Youmust have a reliefvalve on your boiler. Water expands as it is An Air Purger is used to remove excessair from the system. It is in- heated. If there is no place for the water to expand into, water pres- stalledin the supply line.

- Page 26 Rollout Switch Blower (Draft Inducer) The blower provides a means for pulling air through the boiler and (Flame Rollout Safety Shutoff) exhausting the flue gasses into the vent system. The blower shuts off The rollout switch is a temperature-sensitive fuse link device. It is lo- when the burners are not firing.

-

Page 27: Ii ¸_I Iiiii

A Hot Water System Operates Your entire heating system (boiler, piping and radiation units) is Never run water into a hot empty boiler. filled with water. As the water in the boiler is heated, it is pumped from the top of the boiler through the supply main to the radia- tion units. -

Page 28: I I¸_ Iiiiii ¸_ I I

Operating Instructions. 1. Set the thermostat to lowestsetting. Waitfive (5) minutes to allowany gas in the combustion 2. Turn off allelectric power to the appliance. chamber to vent. If you then smell gas in the appliance 3. This appliance is equipped with an ignition devicewhich auto- area or near the floor, do not touch any electrical switch, maticallylights the burner. - Page 29 Adjust Limit Controls Figure 15 - PILOT FLAME ADJUSTMENT Instructions for each control are included with the controls. Recommended Boiler Water Temperatures 3i8 '!tO 112" Type of Heating Unit Limit Control Setting Flame Standing Radiators ......... 180° F Sensor Baseboard and Convector Radiators ..... 180° F These settings can be changed after you have had some idea how the system works.

- Page 30 XEB Series Cast Iron Gas-Fired Cast Iron Boilers Check off each step as completed. Verify base insulation is securely fastened to base panels. Verify air purged from hydronic heating system. Purge air from gas piping; check gas piping for leaks. Verify proper orifices have been installed.

- Page 31 Boiler Manufacturer: Model #: Dunkirk Boilers Serial #: 85 Middle Road Dunkirk, NY 14048 Measured BTUH input: Operational Test Date: Installation Instructions in the XEBInstallation,Operation and MaintenanceManual have been followed. Initial Operational BoilerTestCheck-Out Procedure has been performed. Information on this form is certifiedto be correct.

- Page 32 Relief Valve Vent Pipe This valveshould open automaticallyif the system pressure exceeds The venting of this unit is very important and the piping should be the pressure rating (usually 30psi) of the reliefvaNe. Should it ever checked at least once a month. If the vent piping shows any sign of fail to open under this condition, shut down your system.

- Page 33 WHAT TODOIFYOU SMELL G AS DoNottrytolightanyappliance. Do not touch any electricswitch, do not use the phone or any mobile electronics. These actions may create a spark and cause igni- tion. Leavethe building immediately,then callyour gas supplier. If you cannot reach the gas supplier, call the fire department. Thermostat is not set correctly Reset thermostat Check flame.

- Page 36 Dmi'_i__ 85 Middle Rd. Dunkirk, NY 14048...

Need help?

Do you have a question about the XEB-3 and is the answer not in the manual?

Questions and answers