Subscribe to Our Youtube Channel

Summary of Contents for Chromalox 1601

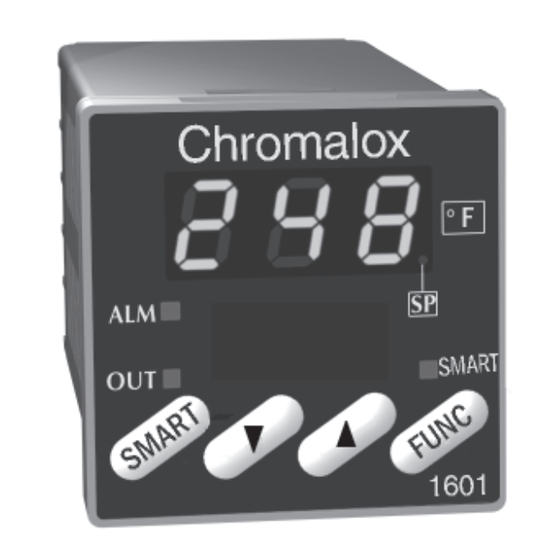

- Page 1 1601 Temperature Controller r USER'S MANUAL Issue date March 2000 0037 - 75236 1601-0-0C.p65 5/2/00, 1:45 PM...

-

Page 2: Table Of Contents

Direct access to the set point ..... 12 Display of the set point value ..... 12 Bargraph operating ........13 Lamp test ........... 13 OPERATOR PARAMETERS ......13 ERROR MESSAGES ........15 GENERAL INFORMATIONS ......17 MAINTENANCE ..........18 DEFAULT PARAMETERS ....... A.1 1601-0-0C.p65 5/2/00, 1:45 PM... - Page 3 Output 2 - Alarm Relay, 1 Amp at 250 Vac (Resistive load) Code Add to complete model number Code Instrument Power 100 - 240 Vac 24 Vac/dc Code Add to complete model number 1601 6 Typical Model Number 1601-0-0C.p65 5/2/00, 1:45 PM...

-

Page 4: Outline And Cut Out Dimensions

OUTLINE AND CUT OUT DIMENSIONS 1601-0-0C.p65 5/2/00, 1:45 PM... - Page 5 1601-0-0C.p65 5/2/00, 1:45 PM...

-

Page 6: Mounting Requirements

2) insert the instrument in the panel cutout; 3) pushing the instrument against the panel, insert Gasket the mounting bracket; 4) with a screwdriver, turn the screws with a Fig. 1 torque between 2.7 to 3.5 in-lb (0.3 and 0.4 Nm). 1601-1-0C.p65 5/2/00, 1:45 PM... -

Page 7: Connection Diagrams

2) For TC wiring use proper compensating cable (for example, J TC extension wire for J TC) preferable shielded. 3) when a shielded cable is used, it should be connected at one point only. Fig. 2 REAR TERMINAL BLOCK 1601-1-0C.p65 5/2/00, 1:45 PM... - Page 8 75 °C (167°F). 3) Use copper conductors only. 4) Don’t run input wires together with power cables. The following recommendations avoid serious problems which may occur, when using relay output for driving inductive loads. 1601-1-0C.p65 5/2/00, 1:45 PM...

- Page 9 THE INTERNAL CONTACT In this cases it is recommended to install an additional RC network across the external contact as show in Fig. 7 (Chromalox snubber PN 0149- 01305 is recommended). The value of capacitor (C) and resistor (R) are shown in the following table.

-

Page 10: General Operation

A) POWER LINE WIRING GENERAL OPERATION Theree are two setup modes for the 1601 - Configuration mode - Operator mode POWER LINE In general the configuration mode is the initial 100 V to 240 V AC (50/60Hz) setup of the controller when first installed. Input... -

Page 11: Configuration Parameters

600 °F for TC input and 100 °C or 200 °F for parameter. RTD input. 2) Changing P2 and/or P3 parameters, the rL and rH parameters will be realligned to it. 1601-1-0C.p65 5/2/00, 1:45 PM... - Page 12 L.L= low alarm (inside band) with manual reset (latching) Input When P5 = 4 the selections H.A and L.A show an instrument failure indicator with automatic reset while the H.L and L.L selections show an instrument failure indicator with manual reset. 1601-1-0C.p65 5/2/00, 1:45 PM...

- Page 13 500 to 999 = when selecting a security code between these two numbers, the operation is identical to a selection from "2 to 499" except that both the set point and the alarm set point can be modi- fied. 1601-1-0C.p65 5/2/00, 1:45 PM...

- Page 14 P18 value to 99.9. P17 - Minimum value of the proportional band settable by the SMART function in heating control only. It may be programmed from 1.0% to P16 value. P18 - Not Available P19 - Not Available 1601-1-0C.p65 5/2/00, 1:45 PM...

-

Page 15: Operator Mode

NOTE: 1) If, during parameter modification, no pushbutton is pressed for more than 10 seconds, the instrument reverts automatically to the “normal display mode” and the new setting of the last parameter will be lost. 1601-1-0C.p65 5/2/00, 1:45 PM... -

Page 16: Pushbutton Function

"n.rS" parameter (the display will show "n.rS" and "OFF"). Using the s and t pushbuttons select "ON" and push the FUNC pushbutton again. The alarm cannot be reset until the alarm condition has disappeared. 1601-1-0C.p65 5/2/00, 1:45 PM... -

Page 17: Output Power Off

With the output off the 1601 can be used as an indicator. DIRECT ACCESS TO THE SET POINT To turn OFF the output signal, hold the s MODIFICATION pushbutton first and then push FUNC pushbutton. -

Page 18: Bargraph Operating

To turn off the Lamp Test, press t and FUNC Push the FUNC pushbutton, the 1601 will together. alternately show the parameter and its value or the status (ON or OFF) of the selected parameter. - Page 19 Derivative time (in minutes and seconds enabled independently from P10 [mm.ss]). This parameter is skipped if parameter value. Pb=0 (ON/OFF action). Note: The tOL can be modified but the new value will become operative only at 1601-1-0C.p65 5/2/00, 1:45 PM...

-

Page 20: Error Messages

The sensor leads break can be signalled as: - for TC input : OVERRANGE or UNDERRANGE If required see Chromalox for set up. - for RTD input : OVERRANGE Sensor leads short circuit detection: On RTD input, a special test is provided to signal OVERRANGE when input resistance is less than 15 ohm (Short circuit sensor detection). - Page 21 2 seconds. Set the switch V2 in open condition. Switch on the controller. Set the switch V2 in closed condition and power the controller. 201 - 219 Configuration parameter error (2xx. where xx is the Configuration code). 1601-1-0C.p65 5/2/00, 1:45 PM...

-

Page 22: General Informations

CALIBRATION PROCEDURE All 1601 are calibrated at the manufacturing Calibration parameters are logically divided in plan. It is not necessary to calibrate the 1601 groups of two parameter each (initial and final on receipt. scale value). After each group, the calibration... - Page 23 At the end of this calibration routine, the controller will go to the next step. controller under test as shown in fig. 12. 2) The display will show "tL.F" (where "F" means "OFF"). 2) Set calibrator to 0.000 mV. 1601-1-0C.p65 5/2/00, 1:45 PM...

- Page 24 At the end of this calibration routine, the 3) If linearity is incorrect, repeat thermocouple controller will go to the next calibration step. calibration. 4) Push FUNC pushbutton, the instrument will go to the next calibration group. 1601-1-0C.p65 5/2/00, 1:45 PM...

- Page 25 Check symbol MSD (in counts) Resistor Box remaining three digits Fig.14 2) Set 0.00 W on the resistor box. 3) Push L or M pushbutton, the display will change to "PL.n" (where "n" means "On"). 1601-1-0C.p65 5/2/00, 1:45 PM...

- Page 26 L pushbutton and the display will show "CnF" and the controller is in configuration mode. If the previous configuration is correct, switch the controller OFF and set the switch V2. 1601-1-0C.p65 5/2/00, 1:45 PM...

- Page 27 89/336/EEC (reference harmonized standard EN-50081-2 and EN-50082-2) and to council 0 - +999 °C 0 - +999 °F directives 73/23/EEC and 93/68/EEC (reference 0 - + 400 °C 0 - +752 °F harmonized standard EN 61010-1). 1601-1-0C.p65 5/2/00, 1:45 PM...

-

Page 28: Maintenance

6) Before re-inserting the instrument in its case, be NOTE: the PB, TI and TD parameters may be sure that it is perfectly dry. limited when the SMART function is enabled. 7) re-insert the instrument and turn it ON. 1601-1-0C.p65 5/2/00, 1:45 PM... -

Page 29: Default Parameters

Within 10 seconds press s or t pushbutton. = initial scale value The display will show: = full scale value = 100 % = infinite d.O n g) Press FUNC pushbutton; the display will show: L. d t. A. 1 1601-A-0C.p65 5/2/00, 1:45 PM... - Page 30 The instrument will show d.F F e) Press s pushbutton to select between table 1 30.0 30.0 (european) or table 2 (american) default parameter set. The display will show: t b. 1 00.3 00.3 A. 2 1601-A-0C.p65 5/2/00, 1:45 PM...

- Page 31 Not withstanding the provisions of this WARRANTY AND LIMITATIONS Clause it is specifically understood that Products and parts not manufactured and work not performed by Chromalox are warranted only to the extent and in the manner that the same are warranted to Chromalox by Chromalox’s vendors, and then only to the extent that Chromalox is reasonably able to enforce such a warranty, it being understood Chromalox shall have no obligation to initiate litigation unless buyer undertakes to pay all cost and expenses therefore including but not limited to attorney’s fees and indemnifies Chromalox against any liability to...

- Page 32 170.IU0.160.100 ® Chromalox INSTRUMENTS AND CONTROLS 1382 HEIL QUAKER BOULEVARD LAVERGNE, TN 37086-3536 PHONE (615) 793-3900 FAX (615) 793-3563 EMERSON ELECTRIC CO. 1601-A-0C.p65 5/2/00, 3:37 PM...

Need help?

Do you have a question about the 1601 and is the answer not in the manual?

Questions and answers