Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Graco Hydra-Clean 800-094

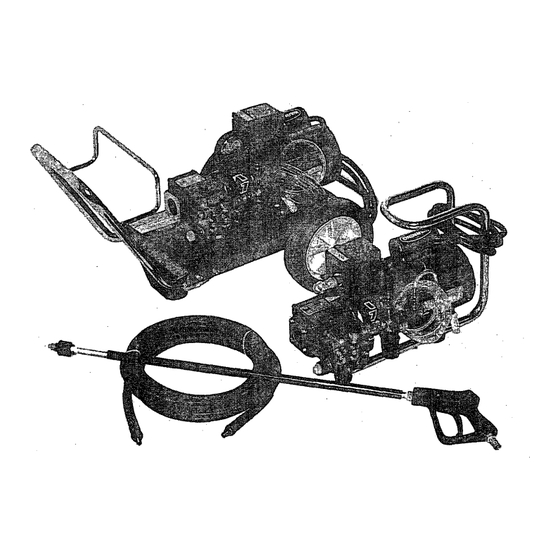

- Page 1 This IMPORTANT manual contains WARNINGS and INSTRUCTIONS RETAlN REFERENCE READ AND P/N 800-093 SERIES "A" CART MODEL P/N 800-094 SERIES "A" HANDLE MODEL OPERATING PRESSURE bar) 1 100 M A X I M U M WORKING PRESSURE bar)

- Page 2 UNJECTUON HAZARD Fluids under high pressure from spray penetrate the skin and cause extremely serious injury. including the need for amputation. NEVER point the spray gun at anyone or any part of the body. NEVER put hand or fingers over t h e spray tip. NEVER try to stop or deflect leaks with your hand or body.

- Page 3 .. . POWER COR0 HANDLE MODEL 3/4" GARDEN HOSE THREAD PRESSURE AOJUSTMENT KNOB Check For Damage Check unit for any damage that may have occurred in shipping. Any damage should be noted and the carrier notified immediately. Check unit' and accessories to be sure that all components were included.

-

Page 4: Operation

Costly damage in use. Be gun is in the Pressure Adjustment The pressure washer has been factory adjusted to 800 k25 deliver This the maximum pressure that this unit designed for. However, this pressure of the switch, if... - Page 5 Turn control ring on adjustable nozzle clockwise to cause a drop in pressure. Start pressure washer unit and trigger spray gun. The. injector may draw momentarily as system is filling but normally will stop as system builds up to full pressure.

-

Page 6: Troubleshooting

SERVICE Troubleshooting PROBLEM CAUSE Low.Pressure Worn nozzle. Coupling slippage. Air leak in inlet plumbing. Relief valve stuck, partially plugged or improperly adjusted; valve seat worn. Inlet suction strainer clogged or improper size. Worn packing. Abrasives pumped fluid or severe cavita: tion. - Page 7 BARBS DRAWING Pressure Washer A WIRING DIAGRAM 801-888...

-

Page 8: Parts List

PARTS LIST 800-093. Pressure Washer Assembly, REF. PART NO. NO. DESCRIPTION PRESSURE WASHER ASSY.. 800-093 Cart Model (Includes items 1-52, 61, 62 PRESSURE WASHER ASSY., 800-094 Handle Model (Includes 1-35, 53-60 items 8 0 0 . 1 5 4 PUMP/MOTOR ASSY., see parts drawing, pg. -

Page 9: Parts Drawing

PARTS DRAWING Pump/Motcr Asse PARTS LIST Pump/Motor Assembly, REF. PART NO. NO. DESCRIPTION 801-862 MOTOR, 1.5 801-864 PUMP, T-9791, see parts drawing, page 11 3 801-870 COUPLER HOUSING 801-871 COUPLER HOSE, By-Pass 801-866 801-890 COUPLING,3/8NPTMx3/8NPSF 801.891 COUPLING,3/8NPTMx3/8NPSM 8 801-881 COUPLING, 9 801-178 ELBOW, Street, 1/2 NPT 801-709... - Page 10 SERVICE Pump (Refer to Parts Drawing, Page 11) MOTE: Three sizes of metric wrenches necessary for servicing the. pump; M30, M17, and M6 Allen wrench. Valves: Remove the hex plug from manifold (6) using M30 wrench. 2. Examineo-ring(4)underplugandreplace'ifcutsor distortion exist. Remove valve~unit and O-ring (3) from NOTE: Valve...

- Page 11 PARTS DRAWING 8pl-864 Pump, " **PACKING & RETAINER KIT 801 -664 Includes: REF. QTY. REF. PART NO. NO. DESCRIPTION 800-651 SCREW, M8 2 801-652 WASHER, 8.4 3 801-472 VALVE UNIT 4 801-470 O-RING 5 801-471 HEX PLUG, M24 6 801-889 MANIFOLD WASHER 801-485...

- Page 12 This spring can be removed if the injector needs t o be taken apart for cleaning. Be sure to spring place whenever the pressure washer is being used. Removal of spring chemical flow but could cause chemical injector to quit working.

- Page 13 SERVICE Cartridge Gun, Replacement 1. Press access pin (1 access plate (14) by sliding plate backwards. Remove cartridge 19 mm socket wrench. Check inside housing to be sure all out when cartridge was removed. If O-ring can be seen inside the housing, remove not to damage internal threads in housing.

-

Page 14: Technical Data

ACCESSORIES (Must be purchased separately) CHEMICAL CLEANING COMPOUNDS: General Purpose Cleaner 800-1 06 Heavy Duty Degreaser 800-1 07 Vehicle Wash 800-108 Metal Pretreatment, Phosphatizer 800-109 Paintable Rust Inhibitor 800- 1 1 0 WATER PUMP: BOO WETTED PARTS: Stainless Steel, Aluminum. UNIT WEIGHT: OVERALL DIMENSION: Length: MAX. - Page 15 Graco Inc. warrants all equipment manufactured by material and workmanship under normal use and service. This warranty extends to the original purchaser for a p e r i d of 12 months from the date installed and operated in accordance with written factory recommendations. This warranty does not cover damage or wear which, in the reasonable judgment of Graco.

Need help?

Do you have a question about the Hydra-Clean 800-094 and is the answer not in the manual?

Questions and answers