Table of Contents

Advertisement

Quick Links

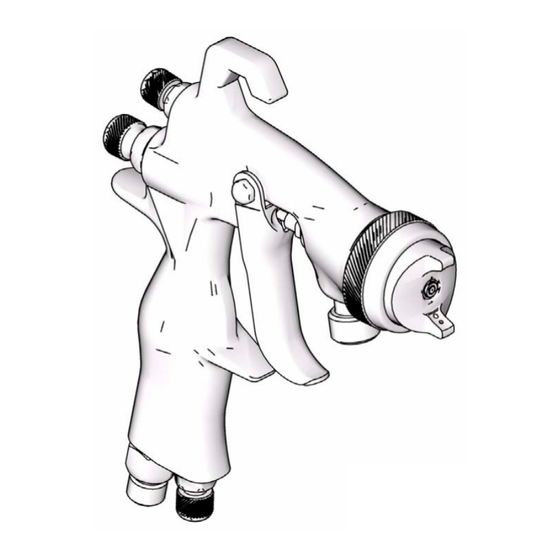

Instructions-Parts

AirPro

Feed Airspray Gun

Conventional, HVLP, and compliant guns for specialty industrial applications.

100 psi (0.7 MPa, 7 bar) Maximum Air Inlet Pressure

300 psi (2.1 MPa, 21 bar) Maximum Fluid Inlet Pressure

Important Safety Instructions

Read all warnings and instructions in

this manual. Save these instructions.

See page

2

for model information.

™

Pressure

312414D

ti1109

ll 2 G

Advertisement

Table of Contents

Summary of Contents for Graco AIRPRO 312414D

- Page 1 Instructions-Parts ™ AirPro Feed Airspray Gun Conventional, HVLP, and compliant guns for specialty industrial applications. 100 psi (0.7 MPa, 7 bar) Maximum Air Inlet Pressure 300 psi (2.1 MPa, 21 bar) Maximum Fluid Inlet Pressure Important Safety Instructions Read all warnings and instructions in this manual.

-

Page 2: Table Of Contents

Graco Standard Warranty ....24 Graco Information ......24... -

Page 3: Models

Models General Metal Spray Guns Conventional Orifice HVLP/Compliant Size Air Pressure in. (mm) Model Series psi (MPa, bar) 0.020 (0.5) 288726 0.030 (0.8) 288929 0.042 (1.1) 288930 0.055 (1.4) 288931 0.070 (1.8) 288932 0.086 (2.2) 288933 0.110 (2.8) 288934 General Metal with Stainless Steel Tip Conventional Orifice HVLP/Compliant... -

Page 4: Stain

Models Stain Conventional Orifice HVLP/Compliant Size Air Pressure in. (mm) Model Series psi (MPa, bar) 0.020 (0.5) 288958 0.030 (0.8) 288959 0.040 (1.0) 289109 Waterborne Conventional Orifice HVLP/Compliant Size Air Pressure in. (mm) Model Series psi (MPa, bar) 0.030 (0.8) 288964 0.042 (1.1) 288965 0.055 (1.4) 288966 High Wear... -

Page 5: Warnings

Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equip- ment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where applicable. -

Page 6: Gun Selection

HVLP guns. The Graco compliant guns have no restrictions on air cap pressures, but the gun inlet pres- sure must remain under the maximum compli- ant pressure shown on pages 3-4 to remain in compliance. -

Page 7: Setup

Ground the Gun Check your local electrical code and pump manual for detailed grounding instructions. Ground the spray gun through connection to a Graco-approved grounded fluid or air supply hose. Flush Before Using Equipment The equipment was tested with lightweight oil, which is left in the fluid passages to protect parts. -

Page 8: Adjust Spray Pattern

Setup Adjust Spray Pattern 1. Rotate the air cap to achieve desired spray pattern. See ti4839a 2. To achieve full fan pattern, open the air control valve by turning the knob fully coun- terclockwise. See 3. To create a round pattern, turn the pattern air off by turning the air control valve fully clockwise. -

Page 9: Operation

Operation Pressure Relief Procedure Trapped air can cause the pump to cycle unexpectedly, which could result in serious injury from splashing or moving parts. 1. Turn off air and fluid supply. 2. Hold a metal part of the gun firmly to a grounded metal pail. -

Page 10: Daily Gun Maintenance

Daily Gun Maintenance Daily Gun Maintenance Follow Pressure Relief Procedure, page 9, when you stop spraying and before cleaning, checking, servicing, or transporting equip- ment. Read Warnings, page 5. General Tasks • Frequently lubricate the gun moving parts with a drop of non-silicone oil. •... -

Page 11: Clean Gun

Clean Gun CAUTION • Do not submerge gun in solvent. Solvent dissolves lubricant, dries out packings, and clogs air passages. • Do not use metal tools to clean air cap holes as this may scratch them and distort the spray pattern. •... -

Page 12: Troubleshooting

Troubleshooting Troubleshooting Problem Spray Pattern Right Spray Pattern Wrong Heavy top or bottom Spray Pattern Wrong Split pattern Spray Pattern Wrong Cause Normal pattern. Dirty or damaged air cap or fluid nozzle. Pressure too high for viscosity of material being sprayed. Dirty or distorted air horn holes. - Page 13 Problem Gun spitting. Will not spray. Excessive air blowing back. Gun fluid pressure is too high with gun triggered (cannot achieve desired flow rate). Using a low fluid pressure set- ting, the fluid flow is too high, making it necessary to restrict needle travel to reduce fluid flow.

-

Page 14: Repair

Repair Repair Follow Pressure Relief Procedure, page 9. See Parts, page 16, for callout references. Disassembly 1. Unscrew retaining ring (14) to remove air cap (13b). Check o-rings (13a and 13c) and replace if necessary. 2. Trigger gun while unscrewing nozzle (11) to prevent needle damage. -

Page 15: Reassembly

Reassembly 1. Install air control valve assembly (5) with valve turned fully counterclockwise to out- ermost position. Torque to 85-90 in-lb (9.6-10.2 N•m). 2. Install air inlet valve assembly (27) with valve turned fully counterclockwise to out- ermost position. Torque to 85-90 in-lb (9.6-10.2 N•m). -

Page 16: Parts

Parts Parts Pull trigger before installing nozzle (11). Insert spreader (15) with tapered end facing rear of gun. Insert u-cup (16) with open end facing front of gun. Apply lubricant. Apply low strength thread retainer. Apply thread sealant. Torque to 85-90 in-lbs (9.6-10.2 N•m). Torque to 15-20 in-lbs (1.7-2.2 N•m). - Page 17 Ref. Part Description 1❖ 289016 BODY, gun 289796 VALVE, air control assembly 6★* 289038 VALVE, air, assembly 1 289052 NUT, air valve, u-cup assembly 289097 VALVE, fluid control NEEDLE, assembly p. 20-22 (includes 9a-9c) NUT, needle NEEDLE TIP, needle p. 20-22 289140 TRIGGER, gun NOZZLE, fluid, p.

- Page 18 Parts 312414D...

-

Page 19: Accessories

Accessories Repair Kits Part No. Description 289455 Needle Packing Repair Kit 289399 Gun Repair Kit 289791 Air Cap Seal Kit 289143 Trigger Repair Kit 289407 Air Valve Repair Kit 289079 Retaining Ring Kit 289016 Gun Handle Replacement Kit 288986 Gun without needle, nozzle, or air cap, with 3/8 npsm (R3/8-19) fluid inlet 289419... -

Page 20: Repair Kits

Repair Kits Repair Kits General Metal Spray Guns Nozzle Size Model Spray Type in. (mm) 288726 Conventional 0.020 (0.5) 288929 Conventional 0.030 (0.8) 288930 Conventional 0.042 (1.1) 288931 Conventional 0.055 (1.4) 288932 Conventional 0.070 (1.8) 288933 Conventional 0.086 (2.2) 288934 Conventional 0.110 (2.8) 288935 HVLP 0.020 (0.5) - Page 21 General Metal with Stainless Steel Tip Nozzle Size Model Spray Type in. (mm) 288955 Compliant 0.042 (1.1) 288956 Compliant 0.055 (1.4) 288957 Compliant 0.070 (1.8) Automotive Nozzle Size Model Spray Type in. (mm) 288929 Conventional 0.030 (0.8) 288930 Conventional 0.042 (1.1) 288931 Conventional 0.055 (1.4) 289034 HVLP...

- Page 22 Repair Kits Adhesives Nozzle Size Model Spray Type in. (mm) 288982 Conventional 0.051 (1.3) 288983 Conventional 0.070 (1.8) Spatter Nozzle Size Model Spray Type in. (mm) 288985 HVLP 0.042 (1.1) Waterborne Nozzle Size Model Spray Type in. (mm) 288964 Conventional 0.030 (0.8) 288965 Conventional 0.042 (1.1) 288966 Conventional 0.055 (1.4) 288967...

-

Page 23: Technical Data

Technical Data Maximum Air Inlet Pressure ....100 psi (0.7 MPa, 7 bar) Maximum Fluid Inlet Pressure ....300 psi (2.1 MPa, 21 bar) Maximum HVLP*/Compliant Inbound Air Pressure Printed on air cap. -

Page 24: Graco Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the AIRPRO 312414D and is the answer not in the manual?

Questions and answers