Table of Contents

Advertisement

Quick Links

654

WELLS BLOOMFIELD, LLC

2 ERIK CIRCLE, P. O. Box 280 Verdi, NV 89439

fax: 888-492-2783

telephone: 888-492-2782

www.wellsbloomfield.com

PROGRAMMING MANUAL

for

E-MAX™ COFFEE AND TEA BREWERS

E-Max BREWERS are covered under

U. S. Patents #5704275, 5862738 & 6,095,031.

Other U.S. Patents and Canadian Patents Pending

PRINTED IN UNITED STATES OF AMERICA

73674

07

p/n

Rev. I ECN-13315

M654

0718 cps

Advertisement

Table of Contents

Summary of Contents for Bloomfield E-MAX

- Page 1 2 ERIK CIRCLE, P. O. Box 280 Verdi, NV 89439 fax: 888-492-2783 telephone: 888-492-2782 www.wellsbloomfield.com PROGRAMMING MANUAL E-MAX™ COFFEE AND TEA BREWERS E-Max BREWERS are covered under U. S. Patents #5704275, 5862738 & 6,095,031. Other U.S. Patents and Canadian Patents Pending PRINTED IN UNITED STATES OF AMERICA 73674 Rev.

-

Page 2: Table Of Contents

CALIBRATION PULSE BREW AND PRE-INFUSION TEST PROGRAM E-MAX™ ADDENDUM Extract of Service Bulletin APPLICATION Proper setup is essential to This manual applies to the following E-Max™ brewers: achieving the optimum performance this appliance Decanter Brewer Models can provide. 2012 2015... -

Page 3: Precautions & General Information

PRECAUTIONS AND GENERAL INFORMATION WARNING: Electric Shock Hazard All servicing requiring access to non-insulated components must be performed by qualified service personnel. Do not open any access panels which require the use of tools. Failure to heed this warning can result in electrical shock. WARNING: Injury Hazard All installation procedures must be performed by qualified personnel with full knowledge of all applicable electrical and plumbing codes. -

Page 4: Operation

BREW 4. Normal Operation (Non Brewing): When the unit is not brewing, switch will be ignored, the E-Max™ maintains the water temperature at the Precise (there will be a beep each Temperature for Brewing™ (PTB™). The heating element will time it is pressed). - Page 5 USER’S GUIDE WARNING: 1. Remove the brew chamber from under the spray head. Burn Hazard. Place one (1) genuine Bloomfield paper filter into the brew This appliance chamber. Add your choice of pre-measured ground coffee. dispenses very hot liquid. Shake the brew chamber gently to level the coffee.

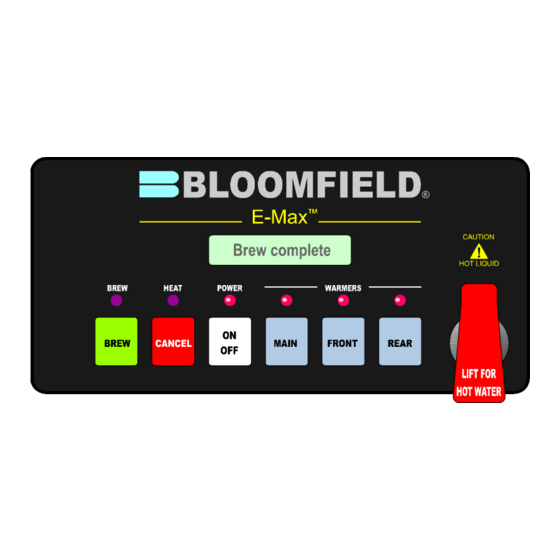

- Page 6 PROGRAMMING - CONTROL PANEL CONFIGURATIONS DECANTER BREWERS 1 BREW Key 1 2 BREW CANCEL Key 2 3 POWER Key 3 4 MAIN WARMER Key 4 5 FRONT WARMER Key 5 6 REAR WARMER Key 6 AIRPOT & THERMAL BREWERS TEA BREWERS WITH VOLUME KEY 1 BREW Key 1...

- Page 7 PROGRAMMING - OPERATOR LEVEL PROGRAMMING FEATURES AND OPTIONS 1. View Water Temperature in Tank: To view the water temperature on the screen, the brewer brewer must be ON, and not brewing or in the filling mode. Press and hold the 4th key, and depress the 6th key.

- Page 8 After Hours™ mode turned OFF. The After Hours™ can be programmed to come on from 1 to 6 hours after the last brew. When the E-Max™ goes into the After Hours™ mode, any warmer plates left on will be turned off (on decanter brewers), the water in the tank will be allowed to drop from the normal brewing temperature and will re heat less frequently –...

- Page 9 4¼ minutes, (the screen will read “filling…”). If water is not detected at the end of this time the E-Max™ will shut down with the message “no water sensed”. The valves and all elements are turned off, and the Brew and Power light flash alternately with the Heat light, until the brewer is reset.

- Page 10 On Tea brewers without volume keys, the 4th key is hidden under the “E”, and the 6th key is hidden under the “T” in E-Max T. The LCD will show “BREW SETTINGS” indicating that you are at the first menu item as outlined on page 12, Once in the programming mode the keys on the front panel can be used to perform the functions outlined.

- Page 11 5. To Exit Programming, you can press CANCEL (EXIT) at any time. While in the programming mode, if no entries are made for 2 minutes the E-Max will automatically exit programming. 6. To re-enter programming, ensure brewer is off, then press and hold the 4th and 6th keys for 3 seconds, until “Brew...

- Page 12 PROGRAMMING - TABLE...

- Page 13 PROGRAMMING - TABLE (continued)

-

Page 14: Brew Settings

PROGRAMMING - PROCEDURES Brew Settings · “Water Temp:” is actual water temperature in the tank. · “Brew Temp:” is desired brew temperature. The brew temperature cannot Temperature +/-1ºF will be maintained in the tank. be set any higher than 5ºF Adjust by pressing 5th or 6th keys (on Tea Brewers without below the Maximum Water Volume Keys: the “a”... -

Page 15: Time Functions

When using the automatic timer be sure to allow 20-30 power outages. The E-Max™ minutes for the E-Max™ to reach proper temperature from battery backup system the time it is turned on. maintains the proper time except while in the Time ·... -

Page 16: Machine Settings

5º below the maximum temperature. Maximum temperature should be set at least 2ºF degrees below the boiling point. The E-Max™ will go into the “overheat error” if the water temperature in the tank is sensed to be at or above the Maximum Water Temperature level. -

Page 17: Programming Table

“Brew Wait:” The Precise Temperature for Brewing™ feature can be overridden by setting Brew Wait to “N” for No. By doing this, the E-Max™ will start a brew whenever the brew switch is depressed. There will be no delay to heat to the proper temperature. -

Page 18: Time Functions

PROGRAMMING - PROCEDURES (continued) Factory Settings · “InflRate:” – Inflow Rate. The inflow rate is factory set at 0.70 gallons per minute. This value is required to calculate The factory settings menu can the water volume. Generally the 0.70 setting will be quite only be accessed by going into accurate unless there is unusually low or high water pressure the programming mode:... - Page 19 PROGRAMMING - PROCEDURES (continued) 1. Remove the top cover of the brewer. Identify and locate the Adjust Inlet Valve Time vent, or overflow tube. 2. Access the programming mode, go to Factory Settings and Determining Pressure then to “InletValvTime:” setting. Set to 25 seconds, press 3rd and Flow key to register change in memory, then 2nd key to exit programming mode.

- Page 20 Once this has been completed the E-Max™ will maintain the calibrated setting. 7. Once calibrated press the 3rd key to continue in the Factory Settings menu, press the 1st key to return to Brew Settings...

-

Page 21: Pulse Brew And Pre-Infusion

The pulse feature allows the delivery time of the water to be extended. Overflow problems can also be experienced if particularly find grind coffee is used. The E-Max™ can be programmed to extend the delivery of the water over a longer period of time, thus preventing any overflow problems. - Page 22 Valve) will be repeated continuously until the brew valve has been opened for the “Total Valve” Time. The E-Max™ will calculate the number of seconds for the full brew and display it on the LCD to begin the brew and it will also calculate how many pulse cycles are required to complete the brew.

- Page 23 PULSE BREW AND PRE-INFUSION (continued) Pulse Feature Examples DECANTER, THERMAL and AIRPOT MODELS #1 PRE-INFUSION One Pulse Cycle 152 sec. 20 sec. OFF - DRIP OUT 30 sec. 60 sec. 1. Pre-Infuse Standard 64 oz. Brew. Total valve time of 172 seconds required for 64 oz. ·...

- Page 24 PULSE BREW AND PRE-INFUSION (continued) #3 PREVENT BREW BASKET OVERFLOW 1st pulse 2nd pulse 3rd pulse 62 sec. 58 sec. 58 sec. 58 sec. OFF - DRIP OUT 36 sec. 36 sec. 36 sec. 60 sec. Prevent Brew Basket Overflow on 85 oz. Brew, 4 oz. of Ground Coffee. Total valve time of 236 seconds required for 85 oz.

- Page 25 PULSE BREW AND PRE-INFUSION (continued) #2 EXTENDED CONTACT TIME 1st Pulse 2nd Pulse 3rd Pulse 4th Pulse Drip Out 64 sec 64 sec 63 sec 64 sec 64 sec 20 sec 20 sec 60 sec 20 sec 20 sec 2. Extend Contact Time on Standard 3 gal. Brew. Total valve time of 319 seconds required for 128 oz.

- Page 26 Exiting Test Program except during the key switch tests, numbers 4 through 9 below. Mode: Or - complete the full test and the E-Max will return to the off mode. Software (Firmware) Revision will be displayed (i.e. Test Program Mode MFW275 Rev3.4).

- Page 27 155 indicate a defective probe.) ≥ 155 Probe Press ON/OFF to proceed to next item. Test Done. Indicates completion, press ON/OFF to reset controller. The controller should restart with the message “BLOOMFIELD”, then return to the off mode.

- Page 28 Note the altered flow rates for E-Max™ when the new spray head is installed: Before – Embossed spray disk and flat band gasket Now –...

- Page 29 Total Valve (sec.) Brew Vol 2 (volume) Initial Valve (sec.) Pulse Delay (sec.) Pulse Valve (sec.) Total Valve (sec.) Bypass Delay (E-Max-T™) Bypass Valve (E-Max-T™) After Hours (0 to 6 hr) QualityTime Timer Weekday ON (hr : min) Weekday OFF (hr : min)

- Page 30 Commercial Food Equipment Service Association Wells Bloomfield proudly supports CFESA Commercial Food Equipment Service Association SERVICE TRAINING - QUALITY SERVICE SERVICE TRAINING - QUALITY SERVICE Genuine Parts Protect - YOU - All - Ways CUSTOMER SATISFACTION CUSTOMER SATISFACTION WELLS BLOOMFIELD, LLC 2 ERIK CIRCLE, P.

Need help?

Do you have a question about the E-MAX and is the answer not in the manual?

Questions and answers