Janome Sewing Machine Instruction Book

Hide thumbs

Also See for Sewing Machine:

- Instruction book (138 pages) ,

- Getting started manual (112 pages) ,

- Instruction manual (92 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Janome Sewing Machine

- Page 1 INSTRUCTION BOOK...

-

Page 2: Important Safety Instructions

Use only attachments recommended by the manufacturer as contained in this owner’s manual. 3. Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been dropped or damaged, or dropped into water. -

Page 3: Table Of Contents

SECTION II. GETTING READY TO SEW Patchwork Piecing ............39 Connecting the Power Supply ........4 Quilting ................ 40 Before Using Your Sewing Machine ......4 Fagoting ..............40 Speed Control Slider ............. 5 Satin Stitches .............. 40 Controlling Sewing Speed ..........5 Cross Stitch .............. -

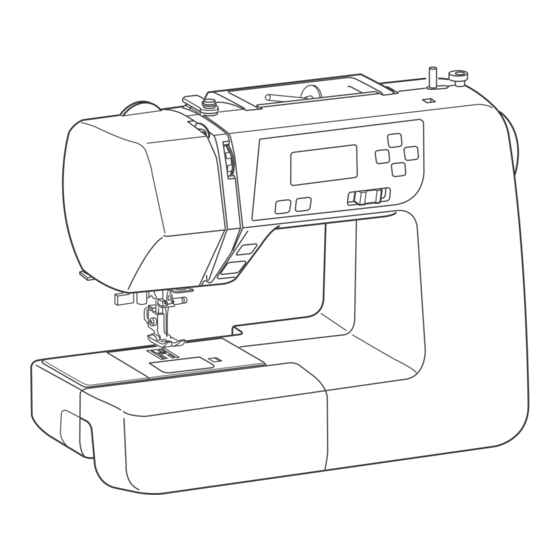

Page 4: Section I. Names Of Parts Names Of Parts

Power inlet Foot control jack Power switch Handwheel Carrying handle Upper thread guide Presser foot lifter Buttonhole lever Free-arm Drop feed lever Foot control Power supply cord NOTE: Sewing machine design and specifications are subject to change without prior notice. -

Page 5: Standard Accessories

Standard Accessories Bobbin Spool pin felt Needle set Additional spool pin Satin stitch foot F Zipper foot E Automatic buttonhole foot R Overedge foot C Blind hem foot G Seam ripper (Buttonhole opener) Screwdriver key Lint brush Small spool holder Large spool holder Spool stand Extension Table... -

Page 6: Section Ii. Getting Ready To Sew Connecting The Power Supply

Before Using Your Sewing Machine plug is intended to fit in a polarized outlet only one way. Before using your sewing machine for the first time, If it still does not fit, contact a qualified electrician to place a scrap of fabric under the presser foot and run install the proper outlet. -

Page 7: Speed Control Slider

Speed Control Slider Sewing speed can be varied by the speed control slider according to your sewing needs. To increase sewing speed, slide the slider to the right. To decrease sewing speed, slide the slider to the left. Controlling Sewing Speed Depress the foot control to start the machine. -

Page 8: Machine Operating Buttons

Machine Operating Buttons q q q q q Start/Stop Button Lower the presser foot lifter. Press the start/stop button q to start the machine. The machine starts running slowly for the first few stitches; it then runs at the speed set by the speed control slider. - Page 9 t t t t t Cursor Buttons Use these buttons to move the cursor u. Press button to move the cursor to right. Press button to move the cursor to left. y y y y y Value Set Buttons Use these buttons to change the set value. Move the cursor under the digit you would like to change.

-

Page 10: Removing And Attaching The Foot Holder

Removing and Attaching the Foot Holder CAUTION: Turn OFF the power switch before detaching or attaching foot holder. • Removing the foot holder Remove the setscrew q by turning it counterclockwise with a screwdriver. • Attaching the foot holder Match the hole in the foot holder w with the threaded hole in the presser bar e. -

Page 11: Dropping Or Raising The Feed Dog

Dropping or Raising the Feed Dog The drop feed lever is located underneath the free arm bed on the back of the machine. q To drop the feed dog, push the lever in the direction of the arrow q. w To raise the feed dog, push the lever in the direction of the arrow w, as illustrated, and turn the handwheel e toward you. -

Page 12: Bobbin Winding

Bobbin Winding • Removing the bobbin Gently slide the hook cover release button q to the right and remove the hook cover plate w. Lift out the bobbin. q Hook cover release button w Hook cover plate • Horizontal spool pin Lift up the spool pin q. - Page 13 • Winding the bobbin NOTE: Set the speed control slider at its fastest position for bobbin winding. z Draw the thread from the spool. x Guide the thread around the thread guide. c Thread through the hole in the bobbin from the inside to the outside.

- Page 14 • Inserting the bobbin z Place a bobbin in the bobbin holder with the thread running off counterclockwise. q End of thread x Guide the thread into the first notch w on the front side of the bobbin holder. w Notch c Draw the thread to the left, sliding it between the tension spring blades.

-

Page 15: Threading The Machine

Threading the Machine Raise the presser foot. Press the needle up/down button q to raise the thread take-up lever to its highest position. q Needle up/down button CAUTION: Turn OFF the power switch before threading the machine. • Threading the machine z Draw the end of the thread around the upper thread guide. -

Page 16: Needle Threader

Needle Threader CAUTION: Turn OFF the power switch when using the needle threader. z Lower the presser foot. Raise the needle to its highest position. Pull down the needle threader knob q as far as it will go. The hook comes out through the needle eye from behind. -

Page 17: Drawing Up The Bobbin Thread

Drawing up the Bobbin Thread z Raise the presser foot. Hold the needle thread lightly with your left hand. x Press the needle up/down button q twice to lower and raise the needle to pick up the bobbin thread. q Needle up/down button c Pull both threads 4˝... -

Page 18: Lcd Display

LCD Display The LCD display shows the following information when the machine is turned on. q Identification letter for recommended foot w Stitch pattern number e Cursors r Stitch width t Stitch length z Press the cursor keys to move the cursor under the stitch pattern number. -

Page 19: Adjusting The Needle Thread Tension For A Straight Stitch

Adjusting the Needle Thread Tension for a Straight Stitch • Correct tension q Needle thread (top thread) w Bobbin thread (bottom thread) e To loosen r To tighten The ideal straight stitch has threads locked between two layers of fabric, as illustrated (magnified to show detail). If you look at the top and bottom of the seam, notice that the stitches are evenly balanced. -

Page 20: Adjusting The Needle Thread Tension For A Zigzag Stitch

Adjusting the Needle Thread Tension for a Zigzag Stitch For an ideal zigzag stitch, the bobbin thread does not show on the right side (top side) of the fabric, and the needle thread shows slightly on the wrong side (bottom side) of the fabric. -

Page 21: Section Iii. Basic Sewing Straight Stitch Sewing

SECTION III. BASIC SEWING Straight Stitch Sewing q Stitch pattern: 00 or 01 w Needle thread tension: 2 to 6 e Presser foot: Zigzag foot A • Starting to sew Raise presser foot and position the fabric next to a seam guide line on the needle plate (5/8˝... -

Page 22: Needle Plate

Needle Plate The seam guides on the needle plate and the hook cover help you to measure seam allowance. The numbers on the needle plate indicate the distance between the center needle position q and the edge of the fabric w. q Center needle position w Edge of the fabric 3/8 1/2 5/8... -

Page 23: Straight Stitch

Straight Stitch q Stitch pattern: 00 or 01 w Needle thread tension: 2 to 6 e Presser foot: Zigzag foot A For seaming garments, zipper application and more. Pattern 01 is used for seaming fine fabrics. Lock-a-Matic Stitch q Stitch pattern: w Needle thread tension: 2 to 6 e Presser foot:... -

Page 24: Stretch Stitch

Stretch Stitch q Stitch pattern: 05, 06 w Needle thread tension: 3 to 6 e Presser foot: Zigzag foot A This stitch is a narrow stretch stitch designed to eliminate puckering on knit fabrics and bias seams, while permitting the seam to be pressed completely open flat. Stitch pattern 06 used for seaming fine fabrics. -

Page 25: Zigzag Stitch

Zigzag Stitch q Stitch pattern: w Needle thread tension: 2 to 6 e Presser foot: Zigzag foot A The zigzag stitch is one of the most useful and versatile stitches. It is used for overcasting, mending, appliqué, and also used as a decorative stitch. NOTE: Use an interfacing when sewing on stretch fabrics such as knit, jersey or tricot. -

Page 26: Overcasting With Zigzag Stitch

Overcasting with Zigzag Stitch q Stitch pattern: w Needle thread tension: 3 to 7 e Presser foot: Overedge foot C This zigzag variation is very useful in garment construction and in finishing raw edges of any sewing project. The black ridge and the guide wires on the overedge foot keep the edge neat and the fabric straight. -

Page 27: Overedge Stitch

Overedge Stitch q Stitch pattern: w Thread tension dial: 3 to 7 e Presser foot: Overedge foot C This stitch pattern combines the straight and the zigzag stitches, using the overedge foot, to seam and overcast in one step. It is ideal for 1/4˝ (0.6 cm) seams on knits (when attaching ribbing) or on medium to heavyweight woven fabrics where you want a narrow seam. -

Page 28: Various Kinds Of Buttonholes And Their Uses

Various Kinds of Buttonholes and Their Uses q Square Buttonhole This square buttonhole is widely used on medium to heavy fabrics. The buttonhole size is automatically determined by placing a button in the foot. w Round-end Buttonhole This buttonhole is used on fine to medium weight fabrics, especially for blouses and children’s clothes. -

Page 29: Square Buttonhole

Square Buttonhole q Stitch pattern: w Thread tension dial: 1 to 5 e Presser foot: Automatic buttonhole foot R r Buttonhole lever sign • To sew z Press the needle up/down button to raise the needle. Attach the automatic buttonhole foot R snapping the pin w into the groove q of the foot holder. - Page 30 b Start the machine to sew the buttonhole. The buttonhole will be automatically sewn. The machine will sew the left row first. n The machine will sew the back bartack and the right row. m The machine will sew the front bartack, then it stops automatically.

-

Page 31: Adjusting The Stitch Width And Density For Buttonholes

Adjusting the Stitch Width and Density for Buttonholes • Adjusting the stitch width Press the cursor buttons to move the cursor under the stitch width value “5.0” q (default setting). button to decrease buttonhole width w. Press the button to increase buttonhole width e. Press the The stitch width can be varied from 2.5 to 7.0 depending on the selected buttonhole. -

Page 32: Stretch Buttonhole

Stretch Buttonhole q Stitch pattern: w Thread tension dial: 1 to 5 e Presser foot: Automatic buttonhole foot R The machine will sew the front bartack and left row first. The machine will sew the back bartack and right row, then it stops automatically. -

Page 33: Corded Buttonhole

Corded Buttonhole q Stitch pattern: w Thread tension dial: 1 to 5 e Presser foot: Automatic buttonhole foot R z Use the same procedure as the square buttonhole procedure. Set the stitch width to match the thickness of the cord used. With the buttonhole foot raised, hook the filler cord on the spur q at the back of the buttonhole foot. -

Page 34: Darning Stitch

Darning Stitch q Stitch pattern: w Thread tension dial: 3 to 6 e Presser foot: Automatic buttonhole foot R z x c v • Starting to sew z Pull the button holder q to the back. x Place the garment under the foot. Press the needle up/down button twice. -

Page 35: Tacking

Tacking q Stitch pattern: w Thread tension dial: 3 to 6 e Presser foot: Satin stitch foot F Tacking is used to reinforce pockets, crotches and belt carriers where extra strength is needed. • Start sewing Start the machine and sew until the machine stops automatically. -

Page 36: Zipper Sewing

Zipper Sewing q Stitch pattern: w Needle thread tension: 1 to 4 e Presser foot: Zigzag foot A Zipper foot E • Attaching the zipper foot Fit the pin on the zipper foot into the groove on the foot holder. •... - Page 37 Zipper Sewing (continued) x Attach the zipper foot with the pin on the right. Sew through all the layers from the end of the zipper opening, guiding the zipper teeth along the edge of the foot. c Stop the machine 2˝ (5 cm) before the foot reaches the slider on the zipper tape.

-

Page 38: Blind Hemming

Blind Hemming q Stitch pattern: 13 or 14 w Thread tension dial: 1 to 4 e Presser foot: Blind Hem stitch foot G z Fold a hem with the wrong side of the fabric up to form a 1/4˝~7/16˝ (0.4~0.7 cm) allowance. q Wrong side of fabric w 1/4˝~7/16˝... -

Page 39: Button Sewing

Button Sewing q Stitch pattern: w Needle thread tension: 3 to 7 e Presser foot: Satin stitch foot F r Feed dog: Dropped z x c v b n z Lower the feed dog. x Match the holes of button to the horizontal slot on the presser foot. -

Page 40: Applique

Applique q Stitch pattern: 17 or 18 w Needle thread tension: 1 to 4 e Presser foot: Satin stitch foot F r Presser foot pressure dial: * The stitch width of pattern 17 can be changed without changing its center needle position. * The stitch width of pattern 18 can be changed without changing its left needle position. -

Page 41: Smocking

Smocking q Stitch pattern: w Thread tension dial: 3 to 6 e Presser foot: Satin stitch foot F Smocking is a delicate decorative treatment used on children’s clothes or women’s blouses. Choose a soft and lightweight fabric such as batiste, gingham or challis. -

Page 42: Quilting

Quilting q Stitch pattern: w Thread tension dial: 3 to 6 e Presser foot: Satin stitch foot F * Stitch patterns 31, 39 or 42 can also be used. The quilt stitch adds a three dimensional effect when outlining designs. Fagoting q Stitch pattern: w Thread tension dial:... -

Page 43: Cross Stitch

Cross Stitch q Stitch Pattern: w Thread tension dial: 3 to 6 e Presser foot: Satin stitch foot F * Stitch pattern 48 can also be used. You can make cross stitch designs with these patterns, in half the time it would take if embroidered by hand. * If you press the auto-lock button before sewing, the machine will sew one unit of the cross stitch and stop automatically. -

Page 44: Decorative Stitch Combinations

Decorative Stitch Combinations q Stitch Pattern: 25 and 27 w Thread tension dial: 3 to 6 e Presser foot: Satin stitch foot F To combine two units of pattern 25 and 27. z Sew pattern 25 and press the auto-lock button while sewing the second unit. -

Page 45: Section V. Care Of Your Machine

After cleaning the machine, make sure the needle and presser foot are attached. Press the needle up/down button to raise the needle, then unplug the sewing machine. Remove the needle and presser foot. Remove the cover plate by sliding the cover plate release button to the right. -

Page 46: Problems And Warning Signs

Problems and Warning Signs Warning sign Cause Try this The machine will not sew with the start/stop button Disconnect the foot control because the foot control is connected. and start the machine. A buttonhole is sewn without lowering the Lower the buttonhole lever buttonhole lever. -

Page 47: Troubleshooting

Troubleshooting Reference Condition Cause 1. The needle thread is not threaded properly. See page 13, 14 The needle thread breaks. 2. The needle thread tension is too tight. See page 17, 18 3. The needle is bent or blunt. See page 9 4. - Page 48 808-800-109(Eng) Printed in Taiwan...

Need help?

Do you have a question about the Sewing Machine and is the answer not in the manual?

Questions and answers