Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

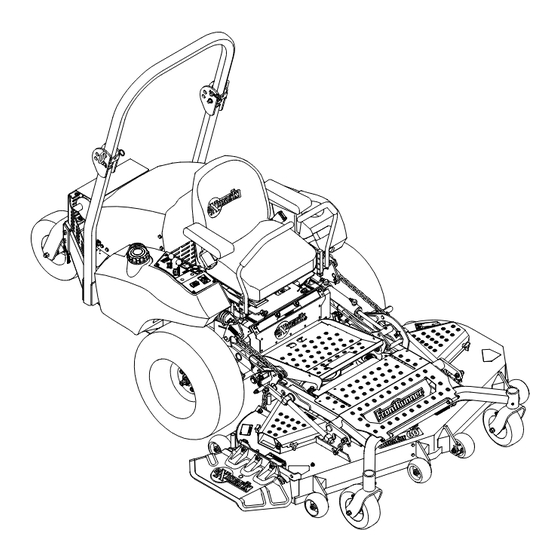

Summary of Contents for Exmark Frontrunner FR20KC

- Page 1 For Serial Nos. 600,000 & Higher Part No. 109-4288 Rev. A...

- Page 2 POTENTIAL HAZARD ♦ This product is a piece of power equipment. WHAT CAN HAPPEN ♦ Failure to follow safe operating practices can result in serious operator injury or even death. HOW TO AVOID THE HAZARD ♦ Keep all shields, guards, and safety devices (especially the grass discharge system) in place and in proper working condition.

- Page 3 3. Exmark being unable to ship the part and the Exmark parts order is received by 3:00 p.m., central time, Exmark pays for the part and freight. 4. If the part does not arrive overnight due to the shipper (UPS), the shipper pays for the freight and Exmark pays for the part.

- Page 4 If additional information is needed, or should you require trained mechanic service, contact your authorized Exmark equipment dealer or distributor. All Exmark equipment dealers and distributors are kept informed of the latest methods of servicing and are equipped to provide prompt and efficient service in the field or at their service stations.

-

Page 5: Table Of Contents

1. SAFETY Safety Alert Symbol ... 1 Training ... 1 Preparation... 1-5 Operation ... 5-9 Maintenance & Storage ... 9-10 Safety Signs ... 10-12 2. SPECIFICATIONS Model Number ... 12 Engine ... 12 Fuel System ... 12 Electrical System ... 12-13 Operator Controls... -

Page 6: Safety Alert Symbol

MAY result in minor or moderate injury. 1.2 TRAINING 1.2.1 Regard the Exmark mower as a piece of power equipment and teach this regard to all who operate this unit. 1.2.2 Read the instructions carefully. Familiarize yourself with the controls and the proper use of the equipment. - Page 7 POTENTIAL HAZARD ♦ This machine produces sound levels in excess of 85 dBA at the operator’s ear when in operation. WHAT CAN HAPPEN ♦ Exposure to sound levels of 85 dBA or above for extended periods of time can cause hearing loss. HOW TO AVOID THE HAZARD ♦...

- Page 8 DANGER POTENTIAL HAZARD ♦ In certain conditions gasoline is extremely flammable and highly explosive. WHAT CAN HAPPEN ♦ A fire or explosion from gasoline can burn you, others, and cause property damage. HOW TO AVOID THE HAZARD ♦ DO NOT smoke while refueling, and stay away from an open flame or where gasoline fumes may be ignited by spark.

- Page 9 DANGER POTENTIAL HAZARD ♦ In certain conditions gasoline is extremely flammable and highly explosive. WHAT CAN HAPPEN ♦ A static charge can ignite gasoline vapors. A fire or explosion from gasoline can burn you, others, and cause property damage. HOW TO AVOID THE HAZARD ♦...

-

Page 10: Operation

POTENTIAL HAZARD ♦ Gasoline vapor can collect inside enclosed trailers and may be ignited by electrical sparks or hot engine/exhaust components. WHAT CAN HAPPEN ♦ Explosion and fire may occur, resulting in property damage, personal injury, and/or death. HOW TO AVOID THE HAZARD ♦... - Page 11 ♦ Tip-over could cause serious injury or death. HOW TO AVOID THE HAZARD ♦ When operating a FrontRunner tractor without an approved Exmark front mount attachment, observe the following: Limit operation to minimum required to install a different front mount attachment.

- Page 12 1.4.4 Use EXTREME caution when mowing and/or turning on slopes as loss of traction and/or tip-over could occur. The operator is responsible for safe operation on slopes. POTENTIAL HAZARD ♦ Mowing on wet grass or steep slopes can cause sliding and loss of control. WHAT CAN HAPPEN ♦...

- Page 13 • Remove or mark obstacles such as rocks, tree limbs, etc. from the mowing area. Tall grass can hide obstacles. • Use extreme care with attachments. These can change the stability of the machine and cause loss of control. • Follow the manufacturer’s recommendations for wheel weights or counterweights to improve stability.

-

Page 14: Maintenance & Storage

connect the negative or ground cable (-) from the negative post on the booster battery to the engine block as far away from the battery as possible. disconnect battery cables in the reverse order after starting. 1.5 MAINTENANCE AND STORAGE 1.5.1 For engine maintenance, follow the engine manufacturer’s recommendations precisely as stated in the engine manual. -

Page 15: Safety Signs

When new components are installed, be sure that current safety signs are affixed to the replaced components. 1.6.4 New safety signs may be obtained from Exmark Mfg. Co. Inc. 1.6.5 Safety signs may be affixed by peeling off the backing to expose the adhesive surface. - Page 16 PART NO. 1-523552 LOCATION: Top Surface of Hydraulic Tank PART NO. 103-5881 LOCATION: Inside Surface of Hood Support – Each Side PART NO. 107-2112 LOCATION: Top of Floor Pan PART NO. 109-2356 PART NO. 109-2358 LOCATION: Top of LOCATION: On Control Console, RH Side PART NO.

-

Page 17: Specifications 2.1 Model Number

2.4 ELECTRICAL SYSTEM 2.4.1 Charging System: 2.4.2 Charging Capacity: 2.4.3 Battery Type: BCI Group U1 2.4.4 Battery Voltage: 12 Volt 2.4.5 Polarity: Negative Ground FR20KC; FR23KC; FR27KC Flywheel Alternator 15 amps PART NO. 98-5954 LOCATION: Top Surface of Hood Support PART NO. -

Page 18: Operator Controls

2.4.6 Safety Interlock System: PTO must be disengaged, brake engaged, and speed control lever in neutral position to start engine. (It is not necessary for the operator to be in the seat to start the engine.) Operator must be in seat when PTO is engaged, brake is disengaged, or speed control lever is moved out of neutral or engine will stop. -

Page 19: Tires

2.8 TIRES Pneumatic (Air-Filled) Quantity Tread Size Ply Rating Pressure 13 psi (90 kPa) Pneumatic (Air-Filled) Quantity Tread Size Ply Rating Pressure 2.9 MOWER DECK (Sold Separately) 2.9.1 Models Discharge Cutting Width 2.10 DIMENSIONS 2.10.1 Overall Width: without deck deflector up deflector down 2.10.2 Overall Length: without deck &... -

Page 20: Torque Requirements

2.11 TORQUE REQUIREMENTS Bolt Location Cutter Housing Spindle Nut (secured with threadlocker) 160-185 ft-lbs. (217-251 N-m) Blade Mounting Bolt... 55-60 ft-lbs. (75-81 N-m) Sheave Mounting Nut ... 90-110 ft-lbs. (122-149 N-m) Engine Deck/Front Frame Mount Bolts ... 30-35 ft-lbs. (41-47 N-m) Anti-Scalp Roller (See Figure 7) Nyloc Nut ... - Page 21 To make a zero turn to the left, pull the left lever back beyond neutral while holding the right lever slightly ahead of neutral. To make a zero turn to the right, pull the right lever back beyond neutral while holding the left lever slightly ahead of neutral.

-

Page 22: Pre-Start

3.1.8 Hour Meter: Located on the right fuel tank console. The hour meter is connected to a pressure switch installed in the engine block and it records the number of hours that the engine has run. If the ignition switch is left on without engine running, hour meter will not run. - Page 23 3.3.3 Starting Engine: Brake must be engaged, speed control lever in neutral position and PTO switch “OFF” to start engine. (It is not necessary for the operator to be in the seat to start the engine.) On a cold engine, place the throttle midway between the “SLOW” and “FAST” positions and push choke lever forward into the “ON”...

-

Page 24: Transporting

Close fuel shut-off valve when machine will not be used for a few days, when transporting, and when the unit is parked inside a building. 3.4 TRANSPORTING IMPORTANT: Do not transport FrontRunner tractor without an approved Exmark front mount attachment. 3.4.1 Transporting a Unit: Use a heavy-duty trailer or truck to transport the machine. - Page 25 POTENTIAL HAZARD ♦ Loading a unit on a trailer or truck increases the possibility of tip-over. WHAT CAN HAPPEN ♦ Tip-over of the unit could cause serious injury or death. HOW TO AVOID THE HAZARD ♦ Use extreme caution when operating a unit on a ramp.

-

Page 26: Maintenance And Adjustments

4. MAINTENANCE & ADJUSTMENTS POTENTIAL HAZARD ♦ While maintenance or adjustments are being made, someone could start the engine. WHAT CAN HAPPEN ♦ Accidental starting of the engine could seriously injure you or other bystanders. HOW TO AVOID THE HAZARD ♦... - Page 27 4.1.2 Check battery charge: Service Interval: Monthly Allowing batteries to stand for an extended period of time without recharging them will result in reduced performance and service life. To preserve optimum battery performance and life, recharge batteries in storage when the open circuit voltage drops to 12.4 volts.

- Page 28 4.1.4 Check safety interlock system. Service Interval: Daily Check starting circuit: Starter should crank with, parking brake engaged, PTO disengaged and motion control levers moved out in the neutral lock position. The operator does not need to be in the seat to start the engine. Try to start with operator in seat, parking brake disengaged, PTO disengaged and motion control levers in the neutral lock position - starter must not crank.

- Page 29 The PTO must not engage. NOTE: If machine does not pass any of these tests, do not operate. Contact your authorized EXMARK SERVICE DEALER. IMPORTANT: It is essential that operator safety mechanisms be connected and in proper operating condition prior to use for mowing.

- Page 30 drain, then close the valve by pushing inward and rotating 1/4 turn clockwise. Remove and retain the hose for future use. Replace the oil filter every other oil change. Clean around oil filter and unscrew filter to remove. Before reinstalling new filter, apply a thin coating of oil on the surface of the rubber seal.

-

Page 31: Lubrication Chart

4.1.10 Check tire pressures: Service Interval: 40 hrs. Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake. Check tire pressure in drive tires. For 20 and 23 HP Kohler Units: The drive tires should be inflated to 13 psi (90 kpa). - Page 32 Pack the bearings with a NGLI grade #1 multi-purpose grease. g) Insert (1) bearing, (1) new seal into the wheel. NOTE: Seals (Exmark PN 103-0063) must be replaced. h) If the axle assembly has had both spacer nuts removed (or broken loose), apply a thread locking adhesive to (1) spacer nut and thread onto the axle with the wrench flats facing outward.

- Page 33 4.1.15 Lubricate the brake rod bushings: Service Interval: 160 hrs. Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake. Tilt seat forward and raise hood. Lubricate bronze bushings on each end of the brake rod shaft with a spray type lubricant or light oil (bushings are located to the inside of the flange bearings).

- Page 34 4.1.22 Change hydraulic system filter: Service Interval: After First 250 hrs. NOTE: Use only Exmark Part No.103-2146 Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake. Carefully clean area around filter. It is important that no dirt or contamination enter hydraulic system.

-

Page 35: Adjustments

4.1.23 Wheel Hub – lock nut torque specification Service Interval: 500 hrs When tightening the lock nut on the wheel motor tapered shaft: Torque the lock nut to 125 ft-lbs (169 N-m). NOTE: Do not use antisieze on wheel hub. 4.1.24 Fuel Tank –... - Page 36 d) Locate the park brake spring assembly. See Figure 7. There should be a gap of 1/8” (3 mm) between the yoke and thin nyloc nut on the brake bolt. If necessary, rotate the thin nyloc nut to obtain the 1/8” gap. e) If park brake does not fully disengage when the lever is disengaged check the brake rod linkage assembly.

- Page 37 4.2.5 Motion control linkage adjustment POTENTIAL HAZARD ♦ Engine must be running and drive wheels must be turning so motion control adjustment can be performed. WHAT CAN HAPPEN ♦ Contact with moving parts or hot surfaces may cause personal injury. HOW TO AVOID THE HAZARD ♦...

- Page 38 h) Move the motion control levers to the reverse position. Return the motion control levers to neutral. The wheels must stop turning (or slightly creep in reverse). Stop engine and wait for all moving parts to stop. Remove jumper wire from wire harness connector and plug connector into seat switch.

-

Page 39: Adjustments

POTENTIAL HAZARD ♦ Weight transfer springs may have stored energy. WHAT CAN HAPPEN ♦ Removing the weight transfer springs without releasing the stored energy can cause serious injury HOW TO AVOID THE HAZARD ♦ Fold mower deck and front frame and lock in service position to remove spring tension and release stored energy before performing any maintenance or... -

Page 40: Waste Disposal

5. WASTE DISPOSAL 5.1 MOTOR OIL DISPOSAL Engine oil and hydraulic oil are both pollutants to the environment. Dispose of used oil at a certified recycling center or according to your state and local regulations. 5.2 BATTERY DISPOSAL POTENTIAL HAZARD ♦... -

Page 41: Troubleshooting

NOTE: After carefully checking the above steps, attempt to start the engine. If it does not start, contact your authorized Exmark service dealer. IMPORTANT: It is essential that all operator safety mechanisms be connected and in proper operating condition prior to mower use. -

Page 42: Electrical Diagram

7. ELECTRICAL DIAGRAM... -

Page 43: Hydraulic Diagram

8. HYDRAULIC DIAGRAM... -

Page 44: Warranty

Company, pursuant to an agreement between them, jointly warrant on the terms and conditions herein, that we will repair, replace or adjust any part manufactured by Exmark and found by us (in the exercise of our reasonable discretion) to be defective in factory materials or workmanship for a period of two years. -

Page 45: Evaporative Emission Control Warranty

Manufacturing Company cannot deny warranty solely for the lack of receipts. As the equipment owner, you should however be aware that Exmark Manufacturing Company may deny you warranty coverage if your emission warranty parts have failed due to abuse, neglect, or improper maintenance or unapproved modifications. - Page 46 NOTES...

- Page 48 The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm. ©2005-2006 EXMARK MFG. CO. INC. INDUSTRIAL PARK BOX 808 BEATRICE, NE 68310 ALL RIGHTS RESERVED LINE OF ACCESSORIES...

Need help?

Do you have a question about the Frontrunner FR20KC and is the answer not in the manual?

Questions and answers