Table of Contents

Advertisement

Available languages

Available languages

Operator's Manual

®

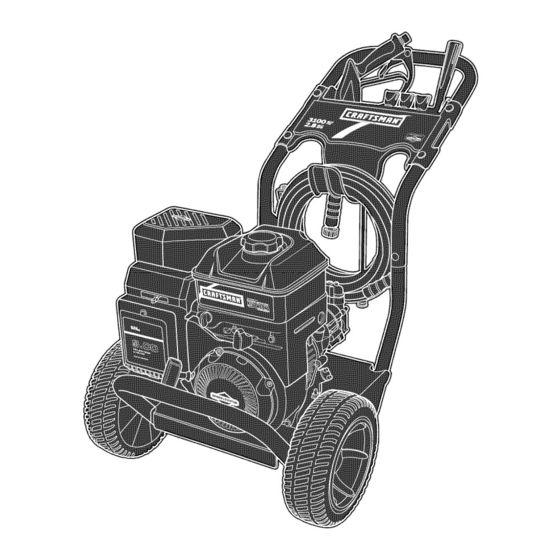

3100 PSi MAX

2.8 GPM MAX

Model No. 580.752080

wAReeeG

Before using this product, read this

manual and follow atI Safety Rutes

and Operating Instructions.

ADVER'rENCmA

Antes de utiiizar el producto, Iea este

manuai y siga todas Ias Reglas de

Seguridad e Instrucciones de Uso.

Sears, Roebuck and Co., Hoffman Estates, [L 68179 U.S.A.

Visit our Craftsman website: www.craftsman.eom

Part No. 203794GS Draft - (04/02/2007)

®Safety

®AssembJy

®Operation

,, Maintenance

®Parts

,, Espa_oi, p. 34

o J!

Advertisement

Table of Contents

Summary of Contents for Craftsman 580.752080

- Page 1 Ias Reglas de and Operating Instructions. Seguridad e Instrucciones de Uso. ,, Espa_oi, p. 34 o J! Sears, Roebuck and Co., Hoffman Estates, [L 68179 U.S.A. Visit our Craftsman website: www.craftsman.eom Part No. 203794GS Draft - (04/02/2007)

-

Page 2: Table Of Contents

If this pressure washer faiis due to a defect in materiai or workmanship within one year from the date of purchase, return it to any Searsstore, other Craftsman outlet, or Sears Parts & Repair Center in the United States or Canadafor free repair (or replacementif repair proves impossible). - Page 3 WARNING Fuel and its vapors are extremely flammable and explosive. death. Fire or explosion can cause severe burns or Contents areharmful orfatal i f swailowed. Avoid WHEN ADDmNG OR DRAiNiNG FUEL contact toeyes, skinorclothing. DO NOT t ake • Turn pressure washer OFFand let it cool at least 2 minutes internaiiy.

- Page 4 WARNING WARNING Starter cord kickback (rapid retraction) can result The high pressure stream of water that thb bodily injury. pulI Kickback will hand and arm equipment produces can cut through skin and its toward engine faster than you can Iet go. underlying tissues, ieading to serious injury and amputation.

- Page 5 WARNING High pressure spray may damage fragiie items inciuding Starter and other rotating parts can entangie lass. hands, hair, clothing, or accessories. DONOTpointspraygun at glasswhen usingMAX(0°) nozzle. NEVER aim spraygun at plants. • NEVER operatepressurewasherwithoutprotectivehousingor covers. • DONOT wea! looseclothing jewelryor anything that may be caughtin the starteror other rotati_gparts.

- Page 6 KNOWYOURPRESSURE WASHER ,r' F I-_ Read the Operator's ManuaJ and safety rubs before operating your pressure washer..Compare the illustrations with your pressure washer to familiarize yourself with the locations of various controls and adjustments. Savethis manual for future reference. _1=Throttle Lever-- Sets engine in starting mode for recoil A - HydroFoam Launcher-- Use to apply HydroFoam...

- Page 7 6. if any parts are missing or damaged, calI the pressure washer helpline at 1=81}1}=222=3136. ASSEMBLING PRESSURE WASHER Your Craftsman pressure washer wJflneed assembly before Insert multi-colored ProjectPro nozzlesand other operation: suppiied accessories in spaces provided in accessory Fiii out and send in registration card.

-

Page 8: Warranty

Add Engine OiJ WARNING Place pressure washer on a fiat, bvei surface. Cleanarea around oii fiii and remove yeiiow oii fiii FueIand its vapors are extremely fiammabb and cap/dipstick. explosive. NOTE:See Oil Recommendations in Maintenancesection. death. Verify provided oii bottle is the correct viscosity for current Fire or explosion can cause severe burns or ambient temperature. - Page 9 FreshStart Fuel Cap tti!lh llllitude Adding fue! preserver helps keepfuei fresh and carburetors At altitudes over 5,000 feet (1524 meters), a minimum clean for easier starting, ati season iong. This new fue! cap 85 octane / 85 AKi (89 RON)gasoiine is acceptable. To automatically drips concentrated fuel preserver into your fuel remain emissions compiiant, high aititude adjustment is tank.

-

Page 10: Safety Rules

Before connecting garden hose to water inlet, inspect 6, Turn ONttle water, press red button on the gun and inlet screen. Cleanscreen (A) if it contains debris or have squeezethe trigger to purge the pump system of air and it replacedif damaged, DO NOTranpressurewasher if impurities. - Page 11 To Start Your Pressure Washer HOWTO USEYOUR PRESSURE WASHER To start your engine=poweredpressure washer for the first If you haveany problems operating your pressure washer, time, foiiow these instructions step=by=step. T his information please call the pressure washer helpline at 1-800-222-3136. also applies whenever you start the engine after you have let Pressure Washer Lecatien the pressure washer sit idle for at bast a day.

- Page 12 Move throttie lever (A) to "Fast" position, shown here as IIVAIIIIIIIIII a rabbit. Starter cord kickback (rapid retraction) can result in bodily injury. Kickback will pull hand and arm toward engine faster than you can iet go. Broken bones, fractures, bruises, or sprains could resuit.

- Page 13 How te Use Accessory Tray WARNING The unit is equipped with an accessorytray with piacesto store your ProjectPro nozzles, HydroFoam iauncher, spray Contact with muffler area can result in serious gun and nozzleextension. There is aiso a hook at the front of burns.

- Page 14 FoJJow t hese in_rucflons to changeProjectPro nozzJes: For maximum rinsing (higiler pressure and lower flow), for stubborn or hard to reachsurface such as PulI back collar on quick-connect and pulI current second story surfaces, paint removal, oii stains, rust ProjectPro nozzle off.

- Page 15 To apply detergent follow these dope: Keepspray gun a safe distance from spray surface. 1. Review P rojectPro nozzleand HydroFoam launcheruse. WARNING Prepare HydroFoam wash according to instructions on the bottb or prepare detergentsolution as required by job. Kickback from spray gun can cause you to fail. Mace smaii fiiter end of detergent siphoning tube into detergent container.

- Page 16 ENGINETECHNICALiNFORMATiON PRODUCTSPECiFiCATiONS This is a single cylinder, overhead valve (OHV), air cooled PressureWasher Specifications engine, it is a iow emissions engine. Max Outbt Pressure ....... 3,100 PSi In the State of California, Model Series 120000 engines are Max Ftow Rate ......2.8 GPM certified by the California Air Resources Board to meet Chemicat Mix......

-

Page 17: Assembly

OWNER'SRESPONSiBiLiTIES Follow the hourly or calendar intervals, whichever occurs first. More frequent service is required when operating in adverse conditions noted below. MABNTENANCE SCHEBULE OPERATINGINTERVALS SERVICEDATES Every 1O0 FILL IN DATESAS YOU COMPLETE Before MABNTENANCE TASK Hours or Hours or Hours or REGULARSERVICE Each Use... - Page 18 WARNING NOTICE j Improper treatment of pressure washer can damage it and The high pressure stream of water that this _tsq_fe, equipment produces can cut through skin and its W_orten ..DONOT insert anyobjectsthroughcoolingslots. )ossibie amputation. ° Usea vacuumcleanerto pick up loose dirt and debris. nderiying tissues, ieading to serious injury and Spray gun traps Ngh water pressure, even when Check and Cmean[n_et Screen...

-

Page 19: Operation

Pump OiJMaintenance SAE30: 40°F and higher (5°C and higher) is good for aii purpose use above 40%, use below 40°F will cause hard DONOTattempt any oil maintenanceon this pump. This starting. model does not require any pump oii maintenance. The pump 10W-31_: O to IO0°F (=18to 38°C) is better for varying is pre=iubricatedand sealed from the factory, requiring no temperature conditions. - Page 20 Service Air gleaner Changing EngineOil Changeengine oii after the first 5 hours and every 50 hours Your engine wiii not run properly and may be damaged if you thereafter, if you are using your pressure washer under run it with a dirty air cleaner. extremely dirty or dusty conditions, or in extremely hot Service the air cleaner once every 25 hours of operation or weather, change oil more often.

-

Page 21: Storage

AFTEREACHUSE Spark Attester Service Your engine is not factory-equipped with a spark arrester. In Water should not remain in the unit for iong periods of time. some areas, it is iliegai to operate an engine without a spark Sediments or minerats can deposit on pump parts and arrester. - Page 22 WINTERSTORAGE Change eiJ While engine is still warm, drain oii from crankcase. Refill with recommended grade. See ChangingEngine 0//'. You must protect your unit from freezing temperatures. eiJ CylinderBere Faik_re to do so will permanently damage your pumpa_d ° Removespark plug and pour about 1/2 ounce (15 rot) of renderyour unit inoperable.

- Page 23 Replace HydroFoam launcher with high pressure nozzb. Water inlet is blocked. Clearinlet. Inadequate water suppiy. Provide adequatewater flow. Inlet hose is kinked or baking. Straighten inlet hose, patch ieak. Pump has followingproblems: Checkand clean inlet hose strainer. Clogged inbt hose strainer. failure to producepressure, erratic pressure, chattering, loss Water suppiy is over IO0°F.

- Page 24 CRAFTSMAN3100 PSi Pressure Washer 580,752080 Main Unit _ ExpJodedView --iO --11 @@@@ @@@@...

- Page 25 CRAFTSMAN3188 PSi Pressure Washer 58&752888 Main Unit _ Parts List item Part # Description 202974GS ASSY, Base B201499GS HANDLE 202975GS ASSY, Biilboard w/Decals & Clips 195964GS Ctips, Tree 30809GS Grommet 192131GS KiT, Pump Mounting Hardware 202978GS KIT, Wheel 200517GS Hubcap 192050GS E-Ring 202634GS...

- Page 26 CRAFTSMAN3100 PSi Pressure Washer 580_752080 Pump -- Expi0ded View...

- Page 27 CRAFTSMAN3188 PSi Pressure Washer 58&752888 Pump _ Parts List item Part # Description 190571GS CAP,Oil MANIFOLD 198102GS 190578GS 190581GS CAP,!/8 THERMAL RELIEF 19429BGS KIT,UNLOADER 190594GS KIT,WATER INLET 19067BGS 190669GS KIT,BREATHER T UBE 193BBBGS KIT,HEAD BRASS 193806GS KIT,CHECK VALVES KIT,INLET CHECK 190592GS KIT,CHEMICAL I NJECTION 190593GS...

- Page 28 ENGINE, B riggs and $tratton, 121012 - Exploded View 1022 619 _@ 3s _ _38 0 1034 36q_ 868 _o@ _" 914A _@ 337_ 9!4 d@ 14B d@ 415 @ 22d_ 21 _o...

- Page 29 ENGINE, Briggs and Stratten, 121012 - Exploded View 633 (@ 633A @ 95 _ 276 _o=} 425_ 977 CARBURET633A @ORGASKET SET5_633 @163 _ !21 CARBURET OROVERHAUL 633A @ 633 @ 358 ENGINE GASKET SET 1022 993 _o_ sss_...

- Page 30 ENGINE, Briggs and $tratten, 121012 - Exploded View 209A 427 ® 773 __ 188 1' 836 ? 613 _' 356 _<_1_% 883 _ 836A 4566899_45 5s L_j I211 1095 VALVE GASKET SET 993 _86851 10701005_ 455_ 332 @...

- Page 31 ENGJNE_ Briggs and $tratton, 121012 - Parts List Item Part # Item Part # Description Bes_riptUon 699510 699598 Cylinder Assembly Housing-Blower 399269 699480 Kit-Bushing/Seal (Magneto Side) Screw (Blower Housing) 299819S 693610 £ Oil Seal (Magneto Side) Shield-Cylinder 699486 699483 Bead-Cylinder Screw (Cylinder Shield) 698210 792723...

-

Page 32: Replacement Parts

Sears, Roebuck and Co., &S,A, (Sears), the California Air Resources Board ICARB) and the United States Environmental Protection Agency {U,S,EPA) Emissions CentromSystem Warranty Statement ISwneCs Defect Warranty Rights and 8hmigations) The California Air Resources Board (CARB), U.S. EPA and Sears are Carburetor and hrternal parts pleased to explain the Emissions Centre[ System Warranty on your Fuel Pump... - Page 33 EmJ_ion information Certain engines wiii be certified to meet the United States Environmental Protection Agency (USEPA)Phase 2 emission Enginesthat are certified to meet the California Air Resources standards. For phase 2 certified engines, the Emissions Board (CARB) Tier 2 Emission Standards must display Compiiance Period referred to on the Emissions Compliance information regarding the Emissions Durabiiity Period and Air label indicates the number of operating hours for which the...

- Page 34 Si la limpiadora a presiOn falls debido a defectos de materiales o rnalsode obra en el plazo de un aiio a partir de la fecha de compra, devu61vala a cualquier almac@ Sears_punto de vents de Craftsman o centro de reparaci@ y repuestos de Sears de los Estados Unidos o Canad_ pars su reparaci@ gratuita o en caso de que 6sta no sea posibb, pars su sustituci6n.

- Page 35 ADVEBTENCIA ADVERTENCiA EJescape deJ motor de este producto centJene eJementos quJmJ¢os re¢onocJdos en eJ Estado de CaJJfornJa La gasolinay susvaporessonextrernadamente pot producJr ¢;_ncer, defectos de nacJmJento inflamables y exp!osivos. u otros dafios de tJpo reprodu¢flvo, severas e inclusive la muerte. E[ fuego o una explosi6n pueden causar quernaduras PELJGRO...

- Page 36 ADVERTENCJA ADVERTENCJA El retroceso (repliegue r@ido) del cable del arrancador El cborro de agua a alta presi6n que este equipo puede producir bsiones El retroceso impedir_ que el produce puede atravesar la piel y los tejidos usuario sueIte e! cable a tiernpo y tirarA de su mano y brazo Isacia el motor.

- Page 37 AVl$O ADVERTENCJA El rociado de alta presi6n puede da_ar elementos fr_giles, incluyendo El arrancador y otras piezas que rotan pueden enredar el vidrio. pelo, las manos, el la ropa, o los accesorios. NO dirija la pistola rociadora hacia un cristal cuando utilice la boquilla MAX (punta de alfiler).

- Page 38 CONOZCA SU MAQUINA LIMPIADORAA PRE$16N 1 ] o, M anna, oo, o,orar, e,,ae ro,,as oo s o,nr,OaO antes oo , crier on m aro a so , m,,aOera a ,ros, n, ..: Compare [as ilustraciones con su [impiadoraa presi6n para famHiar[zarsecon las ubicaciones de los diferentes controles y ajustes. Guards este manual pare referencias futures.

- Page 39 Su lirnpiadora a presiOn requiere de cierto ensambIe y estar_ lista Conecte boquiHala extension al pistola rociadora. para ser usado t]nicamente despuOsde haber depositado el Selecto/conecta rdpido conecta boquilla a la extension de la combustible y el aceite recomendado. boquilla. Si tiene probRemas conem ensamhmede su m_quina Hmpiadora a Cenecte e! Manuhrie y Bandeja Acceseria presiOn,Hame a RamJnea de ayuda de mam_quina Hmpiadora a...

- Page 40 Agregue Aceite de Motor ADVERTENCJA Coloque la limpiadora a presiOn eo una superficie pla!_ay nivelada. La gasolina y sus vapores son extFemadarnente Limpie la zona de ahededor del odficio de Ilenado de aceite y infiamables y explosivos. quite el tapOn amarillo. NOTA:ConsuIte la secciOn Aceite, para ver las recornendaciones severas e inclusive la rnuerte.

- Page 41 Gran aliilud Tap6n de Combustiblepara Mejorar el Arranque El uso de conservante de combus%le mantiene el combustible en En altitudes superiores a 1.524 metros (5.000 pies)_se deber_ buen estado y limpia los carburadores_Io que facilita el arranque en utilizar gaso%a con un minimo de 85 octanos / 85 AKI (89 RON). todas las estaciones del afio.

- Page 42 Abra e[grifo, pulseel bot6n rojo de la pistolarociadoray Antes de que conecte la manguera de jardin a la entrada de aprietee[gatillo paraelirninarel airey lasimpurezas del agua inspeccione el colador de la entrada.Limpie el colador (A) sistemade bombeo. si tiene residuos o solicite su remplazosi estd dafiado. NO haga fun¢ienar ma Hmpiadnra a presi6n si emflmtrode entrada famtae ADVERTENCiA est_ da_ado.

- Page 43 COMOUSARSU LJMPJADORA A PRESJ6N Para Pener en Marcha el Limpiadera a Presi_n Para dar[e arranque a su limpiadora a presiOn movido a motor por Si tiene prob[emas con el funcionamiento de su mAqui_a lirnpiadora primera vez siga estas instrucciones paso a paso. Esta informaci0n a presiOn,por favor !lame a la Iflseade ayuda de la rnAquina acerca de [a puesta en rnarcha inicial tambi6n es %]ida para cuando Iimpiadora a presiOnal 1-888-222-3136.

- Page 44 Mueva el control de la vAIvula de admisi@ (A) a la posici6n ADVERTENCIA "R@ido" ("Fast"), que se distingue con la figura de un conejo. El retroceso(repliegue r@ido)del cabledel arrancador puede producir bsioees. El retroceso impedirA qoe el usuario suelte el cable a tiernpo y tirarA de su rnano y brazo hacia el motor.

- Page 45 UtiJizaci_n de Ja Bandeja de Acceseries ADVERTENCJA La unidad est_ equipada con una bandejade accesorios con cornpartirnentos para guardar las boquillas ProiectPro el larlzador EIcontacto con la zona del sibnciador poe@ producir HydroFoam la pistola rociadora y et pro!ongador de la boquilla. La quemaduras graves.

- Page 46 Pa+'e meml+ie+' rome +++qmiHas P+'eje++P+'e+++% eiga es_as +ns++'t++:cim+nem: Paraun enjuagado de mdxirna potencia(altapresi6ny bajocaudal),parasuperficies rebeldes o de dificil acceso, Desptace haciaatr_se! alsillode+ conectorrApido y tire de las comosuperficies de plantasa[tas eliminaci6n de pintura, boquillasProjectPro GuardelasboquillasProjectPro en e! T M. mmschas d e aceite,eliminaciOn de 6xidou otras soportede la bandeia de accesorios.

- Page 47 Para apm[carem deter_ente, siva m+s s[_u[entes pas+s: Mantenga la pistola de rociado a una distancia segura del area que planea rociar. Repase el uso de la boqui% ProjectProT_' y del lanzador HydroFoarn ADVERTENCIA Prepare el detergente HydroFoam conforme alas instrucciones en la botella. El retroceso de la pistola rociadora puede provocar Coloque el pequefio extrerno final del filtro del tubo de caidas.

- Page 48 JNFORMACm6N T ECNmCA $ OBREEL MOTOR ESPECJFJCACJONE$ DEL PRODUCTO El motor es de uno cilindros, de vA[vulasen cabeza (ORV), Especificacienes de _aM_quina Limpiadora a refrigerado por aire y de baja emisiOn. Presi6n En el Estado de California, los motores de la serie 120000 han PresiOnde salida maxima 3,100 PSI obtenido la ce!tificaciOn del California Air Resources Board (Consejo...

- Page 49 RESPONSABJLJDADES #EL PRSPJETARJO Siga el programa de mantenimiento seg@ e] ROrnero de I_oraso segOnel calendario, [o que suceda pr[mero. Se requbre de servicio con mayor frecuencia cuando opere la uRidad en las condiciones adversas descritas a continuaciOn TAREA DE MANTENIMIENTO INTERVALO DE OPERACIONPOR HeRA FECHAS DE SERVICIO Antes de...

- Page 50 MANTENJMJENTO DE LA MAQUJNA Mantenimiente de la BequHla LAVADORA A PRESJON Si siente una sensaciOnpuIsante al momento de apretar e! gatiI[o de la pistoIa rociadora puede que sea causada pot la presiOnexcesiva Lhnpie los Residues en la bomba. La causa principal de [a presiOn excesiva en la bomba es cuando la boquilla se encuentra atascada o tapada con materiales Lirnpie a diario, o antes de cada uso, los residuos acumulados en e[ extra_os tales como tierra, etc.

- Page 51 Manterdmiento de les Anillos '0' NOTA:Todo acedesint_tico que cumpla [asespecificaciones[LSAC GF-2,con rnarcade certificacidnAP[ y con simbo!o de servicio AP! Compre una O-Juego de ReparaciOnde Anillo en sus Sears locales con SJ/CFENERGY CONSERVING o superior es un aceiteaceptabb a o Ilamando 1-880-4d_IY-HOI_IE (469-4663) o en linea en todas Bs temperaturas.

- Page 52 Cambiode Aceite demMotor $ervieie del Depurader de Aire Cambie el aceite despu_s de las primeras 5 horas de operaciOn. Su motor no funcionar_ adecuadamentey puede da_arse si usted Io Cambie el aceite cada 50 boras de ese mornento en adelante. SiestA hacefuncionar con un depurador de aire sucio.

- Page 53 DESPUE$DE CA[}A U$i) $ervJcJodel Apagachispas EI motor de su unidad no viene equipado de f_brica con un No deber_,haber agua en la unidad pot largos periodos de tiempo. apagachispas. En ciertas _reas, es ilegal operar motores que no Los sedirnentos de minerales se pueden depositar en partes de la bombay "congelar"...

- Page 54 ALMACENAMJENTO PARAJNVJERNO Caahio de Aceite Con el motor todavia caliente drene el aceite de la caja del cigi_e_al. AVI$O Vuelva a Ilenadu con el grade de aceite recomendado. Yea Cumbio de Acdte. Usted deberb_ proteger su unidad de las temperaturas de congelamiento.

- Page 55 Prebmema Seiuci6n Causa LanzadorHydroFoam Cambie el lanzador HydroFoam pot la T M[nstaladO. boquilla de alta presi6n. La entrada de agua est_ bloqueada. Limpie la entrada. Suministro de agua [nadecuado. Proporcione fIujo de agua adecuado. La manguera de entrada est_ doblada o Estire [a rnanguera de entrada, coloque uo presenta fugas.

- Page 58 California Air Resources Board (CARB) U.S. EPAy Sears le explican a continuaci6n Carburador y partes internas la garantia del sistema de control de emisiones de su pequ@o motor para mdquinas Bomba de combustible de servicio (SORE, Small Offroad Engine). En California, los modelos de peque_os Tube de combustible, acoplamientos del tube de combustible,...

- Page 59 [nfermac[6n sehre emisiones Algunos rnotores cuentan con la certificaciOn de curnplimiento de la fase 2 de las normas sobre emisioees de la United States Los motores con certificacl6n de cumplhnieeto de la normativa Environmental Protection Agency (USEPA Ageecia estadourfideese sobre emisioees de nivel 2 del California Air Resources Board de protecciOndel medioambiente ).

- Page 60 iiiiiiiiiiiiiiiii!! Voor Home ::::::::::: For repair-in your home all major brand appliances, lawn and garden equipment, or heating and cooling systems, no matter who made it, no matter who sold it! ....For the replacement parts, accessories owner's manuals that you need to do-it-yourself....

Need help?

Do you have a question about the 580.752080 and is the answer not in the manual?

Questions and answers