Summary of Contents for Baoli KBE35

- Page 1 1-3.5T Electric Forklift Truck Operator manual Suit model: 1-3.5T Electric Forklift Truck KION Baoli ( Jiangsu) Forklift Co.,Ltd...

-

Page 2: Table Of Contents

CONTENTS Introduction……………………………………………………………………………………1 Ⅰ.Parts name and function…………………………………………………………………3 1. Liquid crystal displayer………………………………………………………………………3 2. Controls & switches…………………………………………………………………………4 Ⅱ.Safety operation……………………………………………………………………………9 1. Information of safety operation……………………………………………………………9 2. Information of driving………………………………………………………………………13 3. Information of driving………………………………………………………………………18 4. Information of after finished working……………………………………………………24 Ⅲ.Driving and operation……………………………………………………………………27 1. Preparation for start………………………………………………………………………27 2. -

Page 3: Introduction

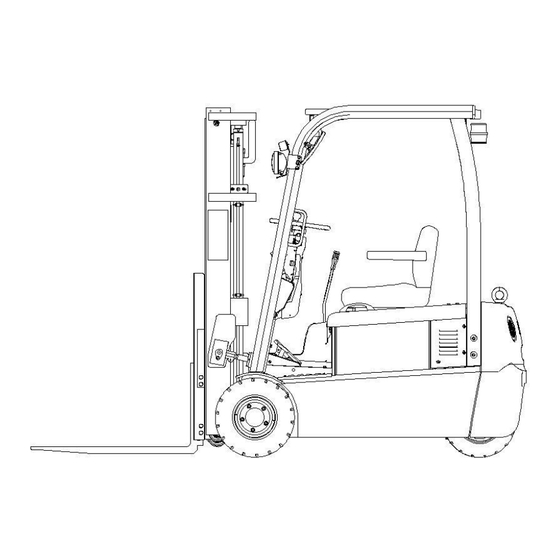

Introduction This manual should be kept by operator and read it repeatedly. This operator’s manual provides the paper operation, easy maintenance and routine inspection. Prior to operation, read this carefully to secure safe and efficient materials handing by proper driving and maintenance. This manual content might not correspond with the actual condition because of ... - Page 4 1.Overhead guard 2. Rear combination lamp 3.Seat 4. Rear view mirror(L) 5. Balance weight 6. Rear board 7. Draw bar pin 8. Battery cover 9. Side board 10. Rear wheel 11. Floor 12. Floor 13. Tilt cylinder 14. Front wheel 15 .Fork 16.Lift chain 17.

-

Page 5: Ⅰ.parts Name And Function

Ⅰ. Parts name and function 1. Liquid crystal displayer switch to “ON”, (1) Turn the key the electric control circuit is on. After the screen of the liquid crystal displayers flashes four times, the signals display. (2) Battery capacity indicator The indicator is displayed as follows when the electrolyte level is at the highest mark. -

Page 6: Controls & Switches

The displayer is used to record the working time accumulated. Letter length is sex bits, within the range of 0 to 99999.9 hours. 2. Controls & Switches ①Steering handle and ②Steering handle knob When steering, grasp the wheel knob by the left hand, while the right hand is put either on the valve lever or the steering wheel lightly. - Page 7 ④Horn button Horn buttons are supplied on the center of the steering wheel and left side of the front board. ⑤Directional switch lever Indicate the traveling direction. Forward traveling: push the lever and depress the accelerator pedal. Reverse traveling: pull the lever and depress the accelerator pedal.

- Page 8 correctly. NOTE When park the truck, take off the key switch. NOTE When operate the parking brake lever, depress the brake pedal. ⑧Lift lever Lift up the forks: Pull the lift lever backward. Left down the forks: Push the lift lever forward. NOTE Appropriate lift and lower speeds by handling are regulated by the stroke of lift lever.

- Page 9 NOTE Appropriate tilting speeds by handling are regulated by the stroke of tilt lever. NOTE When turn the key switch on with pulling or pushing the tilt lever, the tilting movement will not work. ⑩Seat Seat is adjustable for best position in front and in the rear.

- Page 10 Operation T×2 Lamp × × ○ ○ Width lamp × × × ○ Head lamp ○ × × × steering lamp left × ○ × × steering lamp right ○: lamp on ×:lamp off...

-

Page 11: Ⅱ.safety Operation

Ⅱ.Safety operation 1. Information of safety operation (1) Operation training CAUTION The characteristic of brake, accelerator and hydraulic control levers are different and every truck which has same specification. After getting accustomed to operation, operate the forklift truck. (2) Clothing of forklift truck working CAUTION Wear a helmet, safety shoes and working clothes. - Page 12 (5) Keep clean condition of operator’s compartment CAUTION Operator’s compartment shall be kept in a clean condition at all times. CAUTION Do not operate forklifts with oily hands or wet hands. When having slippery oily hands or muddy hands, this condition will lead a ...

- Page 13 Do not install any parts blocking visibility from operating position. (7) working program for safety operation NOTE Make a working program prior operation, arrange for safety thoroughly. (8) Prohibition of operation with not in safe operating condition CAUTION Carry out daily servicing and periodic servicing. Carry out daily servicing before operation.

- Page 14 CAUTION Make sure the weight of load and the center of gravity at the load position. (11)Using a proper pallet CAUTION Use a pallet which is suitable Size and strength for a load. (12)Check of loading CAUTION Make sure palletized load is in proper shape and securely palletized.

-

Page 15: Information Of Driving

2. Information of Driving (1) Check for safety around the truck NOTE Make sure no person is around truck before starting the truck. NOTE When carrying the large load and visibility is poor, make a drive backward or someone should induce the truck. NOTE When driving to backward, make sure no person is around the truck. - Page 16 NOTE Do not look aside. NOTE A forklift truck is rear wheel steering which is different from a car. Slow down the traveling speed and approach to a turning corner then operate steering wheel with taking care of a turn at the truck back.

- Page 17 A sudden start and braking can cause a falling of load. A sharp turn on traveling can cause an overturn of truck and may relate to a serious accident. Slow down traveling speed and make a turn carefully. NOTE Do not run over bumps and obstacles scattered on the road.

- Page 18 (3) Prohibition of driving with forks lifted up the air. CAUTION Do not drive with forks lifted up. When traveling with lifted forks, this could cause an unstable condition and a turn over of the truck. (4) Prohibition of fork tip working CAUTION Do not push a load or lift up by the tip of forks.

- Page 19 (7) Stabilized load CAUTION Drive the truck with mast tilting back for stabilizing the load. When traveling with or without load, raise the forks for 150-200mm from the floor. (8) Prohibition of sideway driving CAUTION Make sure the safety distance from sideways or platform’s edges.

-

Page 20: Information Of Driving

CAUTION Driving, turning and loading shall not be taken on a slope. It could cause turning sideways of the truck, it is very dangerous. 3. Information of operation (1) Prohibition of overload CAUTION Handle only loads within the allowable capacity of the truck. To handle a load shall be based on the load ... - Page 21 (3) Prohibition of permitting passengers to ride WARNING Do not permit passenger to ride on the forks or a pallet. CAUTION Do not ride people on the truck except driver. CAUTION Do not ride people on the truck as a counterbalance.

- Page 22 There is a danger if hitting a rack or a post. (5) Prohibition of operating levers suddenly CAUTION Operate hydraulic control levers slowly when loading and unloading. CAUTION There is a danger of falling load or overturning the truck when operating the levers suddenly ay high height position of forks.

- Page 23 (7) Driving into trailer CAUTION Operate the truck at the place where has holding means of a trailer at docks. CAUTION Before starting operation of truck, fix a deck board and inspect its strength. When getting into or off the trailer, drive carefully and slowly across the deck board or bridge plate.

- Page 24 Loaded load should be contacting with a load backrest. When making a double stack loading, fasten the loads with rope to prevent falling of loads. When loads go over a load backrest, there is a danger of load’s falling against operator.

- Page 25 (13) Adjustment of forks CAUTION Adjust the spreading of forks in accordance with a pallet size. CAUTION Take care your fingers when adjust the fork spread. When adjusting the width of forks, making sure that the setting pin of forks are fixed. ...

-

Page 26: Information Of After Finished Working

(15) Prohibition of holding down loads by hands CAUTION Do not hold down the loads by hands. There is a danger of load’s falling. (16) Prohibition of no pallet using NOTE When operating, the loads must be positioned on pallet. (17) Parking of disabled forklift truck NOTE When park the off road forklift truck,... - Page 27 (2) Parking at reserved place CAUTION Park at reserved place. Parking place should be hard sufficiently. Park a place which does not disturb traffic. Do not park on or near an inflammable object. (3) Prohibition of parking on a slope CAUTION Do not park trucks on a slope.

- Page 28 CAUTION Indicate what the battery on the truck is charging.

-

Page 29: Ⅲ.driving And Operation

Ⅲ . Driving and operation NOTE Do not operate the truck prior to daily check and not approving a periodical servicing. Make sure safety around the truck before taking a seat. 1. Preparation for start (1) Check the directional switch lever position Put the directional switch lever to the neutral position. -

Page 30: Driving

(5)Taking off the parking brake Depress the brake pedal. Push the parking brake lever forward fully. Grasp the steering wheel by left hand, put right hand lightly on the steering wheel. 2. Driving (1) Start Take off your foot from the brake pedal and depress the accelerator pedal gradually, then the truck will begin to move. -

Page 31: Stacking Operation

(4) Stop Slow down and apply the brake slowly. CAUTION Do not apply brake suddenly. A sudden stop causes a lode falling. When apply brakes suddenly on a full traveling speed, it makes the driver bend forward and hitting to the steering wheel. - Page 32 (5) Tilt the mast to vertical position and lift up the forks above the stacking position. (6) Check the stacking position and move forward and stop slowly at the proper position. (7) Make sure the load is just above the stacking position and lower the forks slowly. Make sure the load stacked correctly.

-

Page 33: Picking Operation

4. Picking operation When picking up the loads, observe following procedures. (1) Slow down the traveling speed when approaching a load to be picked up. (2) Stop the truck in front of the load(about 30cm between the load and the fork tips). - Page 34 (7) After inserting the forks, lift up the pallet(50-100mm). (8) Check the clearance and move the truck backward until the load is lowered. (9) Lower the load up to 150-200mm above the floor. (10) Tilt the mast backward for stabilizing the load. (11) Carry the load to its destination.

-

Page 35: Ⅳ.battery And Charger

Ⅳ .Battery and charger When the truck is equipped local supply battery and charger, please follow the instructions of manufacturer. 1. Precaution in handling of the battery CAUTION When making a wrong use of battery, it causes damage of an ignite explosion or injuries. - Page 36 Do not operate the truck until it does not move. The battery life will be shortened. When the battery capacity warning flushes, charge the battery. (6) Keep clean (Static electricity is dangerous.) CAUTION Keep the upper surface of the battery clean. ...

- Page 37 (9) Emergency first aid NOTE When an accident is occurred, take the emergency first aid as following and consult a physician immediately. Spilled on the skin: It should be washed off with water for 10-15 minutes. Splashed in eyes: ...

-

Page 38: Precaution On Charging

It causes a damage of battery or fire. (13) Abnormal battery CAUTION When the battery shows the following condition, contact the sale apartment of our company. The battery stinks. The electrolyte becomes muddy. The temperature of electrolyte is high. ... - Page 39 When the electrolyte of battery is in short supply, its life will be shorten. Check the electrolyte once a week. (2) Replenishment of refined water or distilled water Refer to Operation & Service Manual of Battery. (3) Prohibition of overcharging (4) Being well ventilated place CAUTION Charge the battery at a place where is well ventilates and does not get wet...

-

Page 40: Charging

(8) Check for specific gravity Measure the specific gravity of all cells before charging. Any abnormality within the battery could be found and an accident prevented by knowing the specific gravity before and after charging. (9) Pulling out or putting on the plug should be done by holding plug itself not cable CAUTION Do not pull cables. - Page 41 working or a turnover of truck under traveling. When truck operates continuously over a working shift and battery power is consumed, change the battery with another battery which is charged fully at the time of shift and then charge the dismounted battery fully. CAUTION Exchanging battery should be done on a flat floor.

-

Page 42: Ⅴ.inspection Prior To Operation

Ⅴ .Inspection prior to operation Inspection the truck prior to operation should be done for safety operation and keep good condition of the truck. This is a duty in low. When revealed fault, contact the sale apartment of our company. CAUTION A small fault could cause a serious accident. -

Page 43: Check Points And Contents

1. Check points and contents Check points Contents Brake pedal Depth of foot brake pedal and braking force Braking Brake oil Quantity and stain system Parking brake Pulling depth of lever and operation force Play of steering Loosened, play and/or vertical movement Steering wheel system... -

Page 44: Inspection Procedures

2. Inspection procedure (1) Check of foot brake pedal Check performance of brake and make sure that it is over 50mm from the floor plate when depressing the brake pedal fully. Proper braking distance without a local is about 2.5mm. (2) Check of brake oil CAUTION Remove the cap of brake oil tank and... - Page 45 (4) Check of play of steering wheel Turn the steering wheel clockwise and counterclockwise lightly and check to see if there is play. Appropriate play is 50-100m. The steering wheel moves forward and backward by about 7°, this is normal play. (5) Check of power steering function Turn the steering wheel to clockwise and counterclockwise, check the power steering operation.

- Page 46 Models KBE15/18 23 L(6.1 Gal) 21 L(5.5 Gal) KBET15/18 24 L(6.3 Gal) 21 L(5.5 Gal) KBE20/25 27 L(7.1 Gal) 25 L(6.6 Gal) KBE30/35 31 L(8.0 Gal) 29 L(7.7 Gal) (9) Check of lift chains Lift up forks by 200-300mm above the floor, and make sure lift chains are equivalent in tension.

- Page 47 CAUTION Air pressure for forklift truck is higher than a normal car, do not raise the pressure over the appointed pressure. (11) Check of hub nuts Check the hub nuts are loosen by tightening them using a box wrench. (12) Check of charging Measure the specific gravity of battery.

-

Page 48: Ⅵ.inspection Of After Operation

on the instrument board are usually shown as following figure. (15) Check of overhead guard and load backrest Check if any fitting bolts or nuts are not loosen. (16) Others Check for any other abnormality. Check Be sure to turn off the key switch and disconnect the battery plug while checking electric system except turning on the lamps and checking operation. -

Page 49: Ⅶ.periodic Servicing

Ⅶ . Periodic servicing Complete inspection of the forklift truck prevents faults previously and extends an usable period of the truck. Hours shown at the maintenance schedule are based on eight hour operation a day and 200-hour operation a month. Make a maintenance schedule for safety operation. - Page 50 Servicing place should be a flat footing. Servicing place should be provided for adequate ventilation. Fire extinguishers shall be provided at the servicing facility. (2) Precautions of maintenance CAUTION Smoking shall be prohibited. Wear safeguard (helmet, shoes, glasses, gloves and boots) and suitable clothes. ...

- Page 51 CAUTION Prohibit putting into your hands, feet and body between the frame and mast assy positively. (4) Inspection and exchange of tyre CAUTION Leave a dismounting and mounting tyres to qualified service facility by our company. Handling a high pressure air shall be made by ...

-

Page 52: Weekly (50-Hour) Servicing

put blocks under the truck to prevent the truck falling down. Before lacking up, put wheel drags. (6)Treatment of used parts Hanging up the truck CAUTION Hang up the truck by trained person. Hook the wire at the appointed position. ... - Page 53 Measure the quantity and specific gravity of all cells. Normal: When all cell’s specific gravity are the same figure as converted figure at 30, it is normal. Abnormal: When the specific gravity is less than 0.05 from the average figure of others, it is abnormal.

-

Page 54: Monthly (200-Hour) Servicing

and then draw out the sand paper. Remove this procedure. 3. Monthly (200-hour) servicing Carry out the following service besides the weekly (50-hour) maintenance. As a result of inspection, when adjustment or replacement should be necessary, cell serviceman of our company. (Record of monthly maintenance should be kept.) system No. - Page 55 Steering wheel Play and movement Steering link Lubrication quantity, leakage Gear case abnormal noise Fitting nuts for tyres looseness Tyres Damage and wearing Lift chain Lubricant and tension Cylinder rod guide pins Looseness and damage Adjustment, lubricant, crack and Lift bracket distortion Forks Crack and transformation...

-

Page 56: Lubrication Points And Recommended Oil

Power steering function 4. Lubrication points and recommended oil (1) Lubrication point ○: Replace FO: Hydraulic oil ○: Replenishment GO: Gear oil □: Brake oil W: Chassis grease BO: Brake oil W: Refined water (2) Recommended oil Manufacture TRUCK Brand for Shell ESSO Mobile... -

Page 57: Every Three-Month (600-Hour) Servicing

GP-90 SAE80W GL-5 80W KBET15/18 KBE- Alvania 3# lithium grease2 base grease Grease Retinax (drop point 170) KBE- Shell ESSO Fluid 4604 Brake brake Mobile brake Compound (SAI70RI) fluid Fluid Brake fluid brake fluid H.D. H.D.400 5. Every three-month (600-hour) servicing At the same time with the every three month (600-hour) servicing, repeat the sequence of monthly (200-hour) servicing. -

Page 58: Replacing Parts Guidance

Oil filter Cleaning the oil filter Brake oil Strain and change of the brake oil CAUTION Be sure to turn off the key switch and disconnect the battery plug while checking electric system. ★ Inspection of carbon brush Raise up the while spring and then pull out the carbon brush to check. Check if the surface of the commutation is rough and wearing has gone over the wearing limitation. - Page 60 KION Baoli(Jiangsu)Forklift Co; Ltd · · · Add:No.8 Xinzhou Road Economic Development Zone Jingjiang Jiangsu China P.C:214500 Tel:+86 523 8016 1860 Fax:+86 523 8461 8578 URL: www.baoli-mh.com Customer Hotline: 400 828 2789 We reserve the right to make any changes or modifications in this manual without...

Need help?

Do you have a question about the KBE35 and is the answer not in the manual?

Questions and answers