Summarization of Contents

Safety Instructions

Intended Use

Defines the specific purpose for which the welding device is designed and operated.

Safety Symbols

Explains the meaning of various icons and symbols used throughout the manual for safety warnings.

Operational Guidelines

Environmental Conditions

Specifies the permissible ambient conditions for device operation, transport, and storage.

Grid Connection

Discusses the impact of high-output devices on grid energy quality and connection requirements.

Hazard Warnings

Personal Protection and Protection of Others

Outlines necessary protective measures and clothing for welders and bystanders.

Danger from toxic gases and vapors

Warns about hazardous fumes produced during welding and necessary ventilation precautions.

Electrical Hazards

Danger from Flying Sparks

Warns about the risks associated with flying sparks causing fires and explosions.

Risks from grid current and welding current

Highlights the dangers of electric shock from grid and welding currents.

EMC and EMF Measures

EMC Device Classifications and Measures

Classifies devices based on emissions and provides measures to mitigate electromagnetic interference.

EMF Measures and Hazard Areas

Discusses EMF health effects, precautions, and identifies specific hazard areas related to moving parts.

Shielding Gas and Safety Measures

Shielding Gas Requirements and Cylinder Dangers

Specifies shielding gas quality and warns about dangers associated with compressed gas cylinders.

Gas Leak and Setup Safety

Addresses risks from gas leaks, secure setup, and safe transport measures for the device.

Disposal and Data Management

Disposal Guidelines

Instructs on the proper disposal of electrical equipment according to regulations to protect the environment and health.

Data Backup Responsibility

States user responsibility for backing up factory settings and manufacturer's non-liability for lost personal settings.

Duty Cycle and Operation Parameters

Duty Cycle Explanation

Defines duty cycle as the percentage of time a unit can weld at rated load without overheating.

Overheating and Distance Selection

Explains actions to take if the unit overheats and how to select appropriate operating distances.

Connecting Input Power

Safety and Mains Cable Connection

Details connecting to mains power, including safety precautions and cable connection instructions.

Generator-Powered Operation

Explains how to select and connect a generator for powering the welding machine, including receptacle information.

Commissioning and MIG/MAG Welding

Commissioning Steps

Guides through initial setup, component connection, and system checks before operation.

MIG/MAG Welding Overview

Introduces MIG/MAG welding, its overview, and synergic welding procedures.

Advanced MIG/MAG Processes

Pulsed, Duo Pulse, and Gouging Processes

Describes pulsed synergic, Duo Pulse/Position, and Arc Air Gouging processes for enhanced welding and cutting.

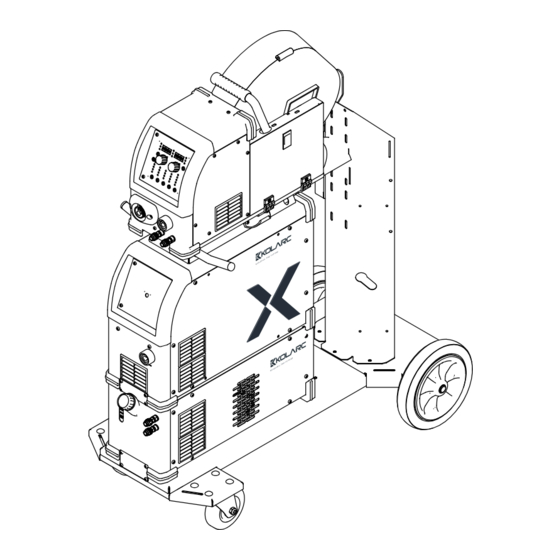

System Components

Identifies system components and refers to their operating instructions, including safety aspects.

Control Panel Functions

Control Panel Overview

Identifies and explains the functions of various buttons, knobs, and displays on the welding machine's control panel.

Parameter Selection and Adjustment

Covers selecting material, wire, gas, process parameters, and making corrections during welding.

Connections and Mechanical Components

Side view of Components

Illustrates the side view of mechanical components like the wire spool holder and roller drive.

Minimum Equipment for Welding

MIG/MAG and MMA Equipment

Lists minimum equipment required for gas-cooled/water-cooled MIG/MAG and manual metal arc welding.

Arc Air Gauging Equipment

Specifies the essential equipment needed for performing arc air gouging operations.

Before Installation and Initial Operation

Safety and Intended Use

Provides crucial safety guidelines and defines the intended use of the welding equipment.

Setup Regulations

Outlines regulations for device setup, including protection against foreign bodies and spraywater.

System Component Connections

Wirefeeder, Hosepack, and Grounding

Details placing the wirefeeder, connecting the hosepack, and establishing a ground earth connection.

Brake Cylinder and Wire Feeding Reel

Brake Cylinder Components

Illustrates the components of the brake cylinder and their correct assembly.

MIG/MAG Welding Safety and Operation

MIG/MAG Safety Precautions

Emphasizes safety precautions and warnings specific to MIG/MAG welding operations.

MIG/MAG Welding Preparation

Outlines the steps for preparing the welding torch, inserting the plug, and checking the cooling unit.

Manual Metal Arc (MMA) Welding

MMA Safety, Preparation, and Operation

Covers MMA safety, preparation, and operational steps, including electrode selection and voltage application.

MMA Welding Functions

Explains specific features like HotStart and Anti-Stick that enhance MMA welding performance and prevent issues.

Arc Air Gauging

Arc Air Gauging Safety and Preparation

Details safety precautions, preparation steps, and connections required for arc air gauging.

Source Circuit Inductance

Hose Package Positioning

Explains the effect of hose package placement on welding circuit inductance and how to position it correctly.

Troubleshooting

Troubleshooting Guide

Offers general advice and safety precautions for diagnosing and resolving potential issues with the welding equipment.

Error Resolution Table

Lists common error codes, their causes, and recommended solutions for diagnosing machine faults.

Need help?

Do you have a question about the MX270 and is the answer not in the manual?

Questions and answers