Summarization of Contents

General Information

Use of the manual

This manual is integral to the appliance and should be kept for future reference before installing or using.

Delivery

Appliance delivered partially assembled in a box, with documentation including manual, safety instructions, and declaration of conformity.

Disposing of packaging

Packaging materials are not pollutants but must be recycled or disposed of according to relevant legislation.

Safety signs

Comply with instructions from safety signs. Check they are present and legible; fit replacements if necessary.

Technical Information

Envisaged use

Designed for individual use cleaning vehicles, machines, boats, masonry, removing stubborn dirt with water and detergents.

Operator

The symbol identifies the appliance's intended operator: professional or non-professional.

Improper use

Forbidden to use by unskilled persons, or with inflammable, explosive, toxic liquids, or in explosive atmospheres.

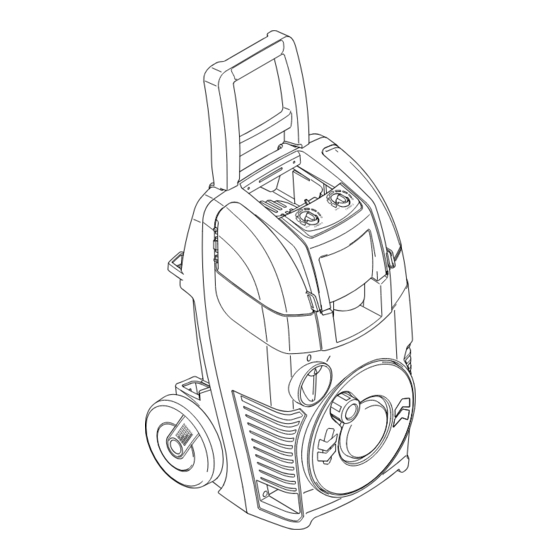

Main components

Lists main components like spray nozzle, lance, gun, hoses, and detergent tank.

Safety devices

Includes safety valve and pressure limiting valve. Safety catch prevents accidental spraying.

Installation

Assembly

All installation and assembly operations must be performed with the appliance disconnected from the mains power supply.

Assembling the rotating nozzle

For models with this feature, the rotating nozzle kit delivers greater washing power.

Electrical connection

Check voltage/frequency, connect to earthed supply with a 30 mA differential security breaker.

Water supply connection

Use clean/filtered water. Ensure supply hose is connected properly and is adequate.

Adjustment Information

Adjusting the spray nozzle

Water flow is adjusted by regulating the nozzle (E).

Adjusting the detergent

Detergent flow is adjusted using the regulator (F).

Adjusting the detergent pressure

Set the adjustable nozzle to deliver detergent at the correct pressure.

Adjusting the pressure

The regulator (G) adjusts working pressure, shown on the pressure gauge.

Information on Use of the Appliance

Controls

Details on starter device (ON/1, OFF/0) and water jet control lever (I).

Start-up

Procedure for starting the appliance, including water supply, safety catch release, and trigger operation.

Stopping the appliance

Steps to stop the appliance, including switching off, discharging residual pressure, and engaging the safety catch.

Restarting

Procedure for restarting the appliance after it has been stopped.

Storage

Instructions for storing the appliance, including switching off, disconnecting, and draining.

Refilling and using detergent

Guidelines for refilling and using detergent, including setting the nozzle and using degradable detergents.

Recommended cleaning procedure

Procedure for dissolving dirt with detergent and high-pressure jet, working from bottom to top.

Maintenance

Cleaning the nozzle

Instructions for cleaning the nozzle, including removing dirt deposits with the provided tool.

Cleaning the filter

Procedure for cleaning the suction filter and detergent filter after 50 hours of operation.

Unjamming the motor

How to unjam the motor if it seizes due to limescale sediments, by turning the drive shaft.

End-of-season storage

Treat the appliance with non-corrosive antifreeze before storing for winter.

Troubleshooting

Pump does not reach working pressure

Lists possible causes like worn nozzle, fouled filter, low water pressure, or air in pump.

Pressure drops during use

Possible causes include nozzle position, external tank use, or hot intake water.

Motor 'sounds' but fails to start

Potential issues include insufficient power supply, voltage loss from extension cables, or long periods of disuse.

Motor fails to start

Covers problems with TSS device, no electrical power, or long periods of disuse.

Water leakage

Possible causes are worn seals, water too hot, or oil leakage.

Appliance noisy

Identifies worn seals or clogged nozzles as potential causes for noise.

TSS versions only: motor starts even with gun trigger is released

Addresses issues where the motor starts unexpectedly in TSS models.

TSS versions only: no water delivery when gun trigger is depressed (with supply hose connected)

Troubleshooting for no water delivery in TSS models when the gun trigger is depressed.

Need help?

Do you have a question about the 440 and is the answer not in the manual?

Questions and answers