Table of Contents

Advertisement

Published 07/18

This Operator's Manual is an

integral part of the safe operation

of this machine and must be

maintained with the unit at all

times. READ, UNDERSTAND, and

FOLLOW

Operation Instructions contained

in this manual before operating

the equipment. C01-Cover_R

®

RHINO

1020 S. Sangamon Ave.

Gibson City, IL 60936

800-446-5158

Email: parts@rhinoag.com

OPERATOR'S MANUAL

the

Safety

© 2018 Alamo Group Inc.

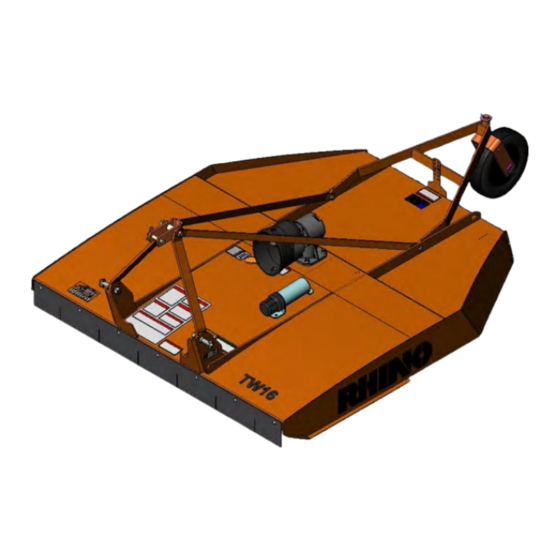

TWISTER 10

Models TW14, TW15, TW16

Important Operating

and

Safety

Instructions

found in the Mower

and

Safety

Video

can

be

instantly

accessed

on

SERIES

ROTARY MOWER

Part No. 00792245C

are

that

the

$0.00

Advertisement

Chapters

Table of Contents

Summarization of Contents

Operator's Manual

TWISTER 10 SERIES

Product name for the mower series.

Models TW14, TW15, TW16

Specific model variants covered by the manual.

Rotary Mower

Type of equipment covered in the manual.

Important Operating and Safety Instructions

Crucial instructions for safe operation and maintenance of the equipment.

Safety

General safety information and guidelines.

Safety Training Makes the Difference

Emphasis on the importance of safety training for mower operation.

OSHA TRAINING REQUIREMENTS

Information regarding OSHA requirements for operator training.

To the Owner/Operator/Dealer

Introduction for the manual's intended audience.

Before You Start!

Key preliminary steps and warnings before operating the equipment.

Safety First.

Prioritizing safety in all aspects of equipment use.

Parts Information

Details about available replacement parts for the mower.

General Safety Instructions and Practices

Fundamental safety rules for operating the mower.

Safety Alert Symbol

Explanation of the safety alert symbol and its meaning.

Signal Words

Explanation of signal words used to indicate hazard severity.

Operator Safety

Specific safety measures for the equipment operator.

General Operating Safety

Broad safety guidelines for operating the mower.

Connection or Disconnecting Implement Safety

Safety procedures for connecting and disconnecting the mower.

Crushing Hazards

Hazards related to crushing injuries from equipment.

Thrown Objects Hazards

Hazards associated with objects being thrown by the mower.

Run Over Hazards

Hazards related to being run over by the tractor or mower.

PTO Entanglement Hazards

Hazards associated with entanglement with the PTO.

Mower Blade Contact Hazards

Hazards related to contact with mower blades.

High Pressure Oil Leak Hazards

Hazards associated with high-pressure hydraulic oil leaks.

Electrical & Fire Hazards

Hazards related to electrical contact and fire.

Transporting Hazards

Hazards associated with transporting the mower.

Hazards with Maintenance of Implement

Hazards encountered during maintenance of the mower.

Parts Information

Information regarding mower parts and their specifications.

Decal Location

Diagram showing the location of safety decals on the mower.

Decal Description

Description and meaning of various safety decals.

Entanglement Hazard

Hazards related to entanglement with rotating parts.

Crushing Hazard - Injury or Death

Hazards related to crushing injuries from equipment.

Non-genuine parts can fail catastrophically.

Warning about the failure of non-genuine replacement parts.

IMPORTANT

Key information for safe operation before starting.

Federal Laws and Regulations

Explanation of relevant federal laws and regulations.

Employer Responsibilities:

Responsibilities of the employer for ensuring operator safety.

Acknowledgment

Recognition of contributions to the safety manual.

Foreword

Introduction and purpose of the safety manual.

Safety Alerts

Information on safety symbols and signal words.

A Word To The User/Operator

Emphasis on operator responsibility for safety.

The Industrial/Agricultural Mower

Overview of different types of industrial and agricultural mowers.

Follow A Safety Program

Guidelines for establishing and following a safety program.

Protect Yourself

Recommendations for personal protective equipment (PPE).

Follow A Safety Program

Guidelines for establishing and following a safety program.

Follow A Safety Program

Guidelines for establishing and following a safety program.

Follow A Safety Program

Guidelines for establishing and following a safety program.

Follow A Safety Program

Guidelines for establishing and following a safety program.

Prepare For Safe Operation

Steps to prepare the mower and tractor for safe operation.

Check The Mower And Tractor Equipment

Procedures for inspecting the mower and tractor before use.

Prepare For Safe Operation

Steps to prepare the mower and tractor for safe operation.

Prepare For Safe Operation

Steps to prepare the mower and tractor for safe operation.

Know The Work Area

Instructions for inspecting and understanding the work area.

Look Out For Others

Safety precautions when other people are present.

Mount And Dismount Tractor Properly

Safe procedures for mounting and dismounting the tractor.

Prepare For Safe Operation

Steps to prepare the mower and tractor for safe operation.

Tractor And Mower Controls Safety Test

Testing tractor and mower controls before starting.

Power Takeoff System

Information and safety precautions for the PTO system.

Prepare For Safe Operation

Steps to prepare the mower and tractor for safe operation.

Hitching Mower To Tractor

Procedures for safely hitching the mower to the tractor.

Pull-type hitch-mounted mowers:

Specific hitching procedures for pull-type mowers.

Start Safely

Procedures for safely starting the tractor and mower.

Make The Right Start

Key steps for a safe start to mowing operations.

Mower-Thrown Objects

Explanation of hazards related to thrown objects.

Operate Safely

Guidelines for safe mower operation.

Mower shielding is designed to reduce the risk of thrown objects...

Importance of mower shielding for reducing thrown object risks.

The risk of serious injury or death from thrown objects can be significantly reduced by following three rules.

Three essential rules to reduce thrown object risks.

Operate Safely

Guidelines for safe mower operation.

Mower-Thrown Objects (continued)

Further details on hazards from thrown objects.

Mowing In Reverse

Safety precautions when mowing in reverse.

Mowing Ground Speed

Guidelines for selecting appropriate mowing ground speed.

Operate Safely

Guidelines for safe mower operation.

Extremely Tall Grass Mowing

Procedures for mowing extremely tall grass.

Watch Equipment Clearances

Ensuring adequate clearance for mower swing.

Operate Safely

Guidelines for safe mower operation.

Under Mount Mower Safety Practices

Safety practices for under-mount mower operation.

Wing Or Boom Mower Overhead Obstruction Hazards And Risks

Hazards related to overhead obstructions with wing/boom mowers.

DANGER! Avoid electrocution or serious injury from contact with or inadequate clearance to energized power lines or apparatus.

Warning about electrocution risk from power lines.

Operate Safely

Guidelines for safe mower operation.

Wing And Side Mount Mowers Safety Practices

Safety practices for side-mount mowers.

Ditch Bank Mowing Safety Practices

Safety practices for mowing ditch banks.

Operate Safely

Guidelines for safe mower operation.

Uneven Terrain Mowing Safety Practices

Safety practices for mowing on uneven terrain.

Operate Safely

Guidelines for safe mower operation.

Uneven Terrain Mowing Safety Practices (continued)

Continued safety practices for uneven terrain mowing.

Road Transport Safety Practices

Safety practices for transporting the mower on roads.

Before operating on public roads:

Key steps before operating on public roads.

Before transporting on public roads:

Key steps before transporting on public roads.

While transporting on public roads:

Key steps while transporting on public roads.

Park Safely

Procedures for safely parking the tractor and mower.

Parking Safety Practices

Specific practices for safe parking.

Shut Down Safely

Procedures for safely shutting down the tractor and mower.

Proper Equipment Shut Down Practices

Habits for properly shutting down equipment.

Shut Down Safely

Procedures for safely shutting down the tractor and mower.

Dismounting Properly

Safe procedures for dismounting the tractor.

Perform Maintenance Safely

Guidelines for performing maintenance safely.

Maintain Your Equipment

Instructions for maintaining the equipment.

WARNING! Do not modify equipment or add components not approved by the manufacturer.

Warning against using unapproved parts or modifications.

Mower Parts And Your Safety

Importance of using correct mower parts for safety.

Perform Maintenance Safely

Guidelines for performing maintenance safely.

Prepare Yourself

Recommendations for operator preparation before maintenance.

WARNING! Prevent death or serious injury from entanglement.

Warning about entanglement risks during maintenance.

Perform Maintenance Safely

Guidelines for performing maintenance safely.

Prepare The Work Area

Steps for preparing the work area for maintenance.

Perform Maintenance Safely

Guidelines for performing maintenance safely.

Prepare The Machine

Procedures for preparing the machine for maintenance.

Safety practices to prevent potential injuries from energy-releasing sources:

Practices to prevent injuries from energy sources.

Perform Maintenance Safely

Guidelines for performing maintenance safely.

Attach a “DO NOT OPERATE” warning tag...

Procedure for tagging equipment that should not be operated.

Install approved support device(s) when working under or near raised equipment.

Importance of using support devices for raised equipment.

WARNING! Unsupported raised mowers or other equipment may drop unexpectedly.

Warning about the risk of falling raised equipment.

Perform Maintenance Safely

Guidelines for performing maintenance safely.

Use Proper Ventilation

Importance of proper ventilation during engine operation.

WARNING! Prevent possible injury. Never work on machinery with the engine running...

Warning against working on machinery with a running engine.

WARNING! Never operate any type of engine without proper ventilation—EXHAUST FUMES CAN KILL.

Warning about the danger of exhaust fumes.

Use Jacks And Hoists Carefully

Safety precautions when using jacks and hoists.

Common Maintenance Safety Practices

General safety practices for maintenance.

Fuel Hazards

Hazards associated with fuel.

WARNING! Always use approved fuel containers and/or dispensing equipment.

Warning about using approved fuel containers.

Fuels are flammable, so observe these practices to reduce the possibility of a serious accident.

Practices to reduce accident risk when handling flammable fuels.

Engine Coolant Hazards

Hazards associated with engine coolant.

Liquid cooling systems build up pressure as the engine gets hot, so use extreme caution before removing the radiator cap.

Caution when removing the radiator cap due to system pressure.

Perform Maintenance Safely

Guidelines for performing maintenance safely.

Hydraulic System Hazards

Hazards associated with the hydraulic system.

The hydraulic system is under pressure whenever the engine is operating...

Information on hydraulic system pressure after engine shutdown.

During inspection of the hydraulic system:

Inspection procedures for the hydraulic system.

Hot hydraulic fluid can cause SEVERE BURNS.

Warning about severe burns from hot hydraulic fluid.

WARNING! Hydraulic fluid under pressure can penetrate the skin or eyes and cause serious injury, blindness or death.

Warning about high-pressure fluid injection hazards.

Electrical System Hazards

Hazards associated with the electrical system.

Before working on the electrical system, disconnect the battery cable(s).

Procedure for disconnecting battery cables.

The liquid in batteries contains acid, which is a POISON and can cause SEVERE CHEMICAL BURNS.

Warning about battery acid hazards.

Avoid Injury

General injury avoidance during electrical system work.

Perform Maintenance Safely

Guidelines for performing maintenance safely.

Avoid Explosion

Hazards related to battery explosion.

WARNING! Avoid possible serious injury from explosion.

Warning about the risk of battery explosion.

Safety rules during battery boost starting:

Rules for safely performing battery boost starting.

Tire And Wheel Maintenance

Procedures for tire and wheel maintenance.

Check your tires and wheels daily because the stability of the tractor and mower can be dramatically affected by tire pressure or damage to tires or wheels.

Importance of daily tire and wheel checks for stability.

Check tires for:

Items to check on the tires.

Check wheels for:

Items to check on the wheels.

All tire service should be performed by a qualified tire service center or by an authorized service person...

Recommendations for professional tire service.

Perform Maintenance Safely

Guidelines for performing maintenance safely.

Tire And Wheel Maintenance (continued)

Continued tire and wheel maintenance information.

WARNING! The types of wheels and tires usually found on this equipment require special care when servicing to prevent death or serious injury.

Warning about special care needed when servicing wheels and tires.

Do not inflate the tires above the recommended pressure.

Warning against over-inflating tires.

Keep wheel lug nuts tightened to manufacturer’s recommendations.

Importance of properly tightening wheel lug nuts.

Never reinflate a tire that has been run flat or seriously underinflated without removing the tire from the wheel.

Procedure for reinflating flat or underinflated tires.

Complete Service And Repairs Before Machine Is Released

Procedures before releasing the machine after service.

Tighten all bolts, fittings, and connections to torques specified by the manufacturer.

Importance of proper torque for fasteners.

Install all guards, covers, and shields after servicing.

Ensuring guards and shields are replaced after service.

Replace or repair any damaged parts.

Importance of replacing damaged parts.

Start the engine and check for leaks.

Checking for leaks after starting the engine.

Operate all controls to make sure the tractor and mower are functioning properly.

Verifying proper operation of tractor and mower controls.

All parts should be inspected during repair and replaced if worn, cracked or damaged.

Inspection and replacement of worn or damaged parts.

Excessively worn or damaged parts can fail and cause injury or death.

Consequences of using excessively worn or damaged parts.

Replace any damaged or illegible safety signs.

Importance of replacing damaged safety signs.

Mower Blade Maintenance

Maintenance procedures for mower blades.

Do not take chances using damaged or bent blades.

Warning against using damaged or bent mower blades.

The mower manufacturers from the Association of Equipment Manufacturers (AEM) and the Farm Equipment Manufacturers Association (FEMA) advocate that you DO NOT reuse, straighten, hard face or weld mower blades.

Manufacturer recommendations against reusing, straightening, or welding mower blades.

Death or serious injury could result if a broken blade is thrown from a mower.

Consequences of a broken blade being thrown from the mower.

Perform Maintenance Safely

Guidelines for performing maintenance safely.

Mower Blade Maintenance (continued)

Continued information on mower blade maintenance.

How are mower blades made?

Description of mower blade construction and materials.

What happens when a mower blade bends?

Explanation of what occurs when a mower blade bends.

Avoid bending blades.

Instructions to prevent mower blades from bending or cracking.

Replace damaged blades!

Procedure for replacing damaged mower blades.

Final Word To The User

Concluding remarks and safety advice to the user.

Assembly Section

DEALER SETUP INSTRUCTIONS

Instructions for dealer setup of the mower.

SHIELD ASSEMBLY

Procedure for assembling the mower's shields.

A-FRAME AND TAILWHEEL INSTALLATION

Instructions for installing the A-frame and tailwheel.

SHEAR BOLT or SLIP CLUTCH DRIVELINE INSTALLATION

Instructions for installing the driveline with shear bolt or slip clutch.

FRONT DEFLECTORS AND REAR METAL BAND (Standard Equipment)

Installation and maintenance of front deflectors and rear metal band.

Front Deflector

Information and warnings regarding the front deflector.

Rear Metal Band

Information and warnings regarding the rear metal band.

Operation Section

OPERATION INSTRUCTIONS

Instructions for operating the Rhino rotary mower.

IMPORTANT: To avoid mower damage, retorque all bolts after the first 10 hours of operation.

Important maintenance reminder for bolts and blade carrier nut.

READ AND UNDERSTAND THE ENTIRE OPERATING INSTRUCTIONS AND SAFETY SECTION OF THIS MANUAL AND THE TRACTOR MANUAL BEFORE ATTEMPTING TO USE THE TRACTOR AND IMPLEMENT.

Crucial instruction to read and understand all manuals before use.

READ, UNDERSTAND, and FOLLOW the following Safety Messages.

Instruction to read, understand, and follow all safety messages.

1. OPERATOR REQUIREMENTS

Essential requirements for a safe mower operator.

PERSONAL PROTECTIVE EQUIPMENT (PPE)

List of required personal protective equipment for safe operation.

DO NOT use drugs or alcohol immediately before or while operating the Tractor and Implement.

Warning against operating equipment under the influence of drugs or alcohol.

2. TRACTOR REQUIREMENTS

Requirements for the tractor used to operate the mower.

Tractor Requirements and Capabilities

Specifications for tractor compatibility with the mower.

2.1 ROPS and Seat Belt

Importance of ROPS and seat belts for tractor safety.

2.2 Tractor Safety Devices

Importance of tractor safety devices for road transport.

2.3 Tractor Horsepower

Required tractor horsepower for operating the mower.

2.4 3-Point Hitch

Requirements for the tractor's 3-point hitch.

2.5 Power Take Off (PTO)

Information and requirements for the mower's PTO system.

DO NOT use a PTO adapter to attach a non-matching Implement driveline to a Tractor PTO.

Warning against using PTO adapters due to safety risks.

2.6 Tire Spacing

Recommended tractor tire spacing for stability.

3. GETTING ON AND OFF THE TRACTOR

Safe procedures for mounting and dismounting the tractor.

Do not mount or dismount the Tractor while the tractor is moving.

Warning against mounting or dismounting a moving tractor.

3.1 Boarding the Tractor

Safe procedures for boarding the tractor.

Never allow children to operate, ride on, or come close to the Tractor or Implement.

Warning against allowing children near the tractor or implement.

3.2 Dismounting the Tractor

Safe procedures for dismounting the tractor.

BEFORE leaving the tractor seat lower the implement, set the parking brake...

Crucial steps before leaving the tractor seat.

4. STARTING THE TRACTOR

Procedures for safely starting the tractor.

Essential Tractor Controls:

Identification of essential tractor controls.

Before starting the tractor ensure the following:

Pre-start checks for the tractor.

Never run the Tractor engine in a closed building or without adequate ventilation.

Warning about operating tractor engine in enclosed spaces.

Start tractor only when properly seated in the Tractor seat.

Warning about starting tractor in gear.

5. CONNECTING THE MOWER TO THE TRACTOR

Procedures for connecting the mower to the tractor.

Use extreme caution when connecting the mower to the tractor. The mower should be securely resting at ground level or setting on blocks.

Caution during mower connection; ensure secure resting.

Always shut the Tractor completely down, place the transmission in park, and set the parking brake before you or anyone else attempts to connect or disconnect the Implement and Tractor hitches.

Safety steps before connecting or disconnecting.

5.1 Connecting the Mower

Step-by-step instructions for connecting the mower.

Make sure the tractor is equipped with the correct PTO shaft.

Ensuring correct PTO shaft compatibility.

Shorten or remove the tractor drawbar to avoid interference when raising and lowering the mower.

Adjusting the tractor drawbar to prevent interference.

Board the tractor and start the engine.

Procedure for boarding and starting the tractor.

NOTE: Set the 3-point lift control to “Position Control” so that the lift arms maintain a constant height when attaching the mower.

Note on using position control for 3-point hitch.

Turn off the tractor engine and dismount.

Procedure for shutting down the tractor after connection.

One lift arm at a time, align arm end hole between the set of A-frame lift lugs. Insert hitch pin through the lug and arm holes and insert retaining pin into hitch pin.

Aligning and inserting hitch pins for lift arms.

Walk around to opposite side and repeat procedure for remaining lift arm and hitch pin.

Repeating hitch pin procedure for the other lift arm.

Extend or retract 3-point top link to align its end hole with the holes of the mower’s top link. Insert the top link hitch pin and insert retaining pin into hitch pin.

Aligning and inserting hitch pin for the top link.

Adjust any lower link check chains, guide blocks, or sway blocks to prevent the mower from swaying side to side and possible contact with tractor rear tires.

Adjusting lower link components to prevent mower sway.

5.2 Safety Tow Chain

Importance and procedure for using a safety tow chain.

If the mower is towed on a public roadway, a safety chain with tensile strength equal to or greater than the gross weight of the mower must be connected between the tractor and mower.

Requirement for safety chain when towing on public roads.

After connecting both ends of the safety chain, drive the tractor to the right and left to check for proper chain length.

Checking proper chain length and adjustment.

IMPORTANT: Scan this QR Code with your smart phone to link to the PAMI Safe Implement Hitching Manual...

QR code for linking to the PAMI Safe Implement Hitching Manual.

6. SETTING THE MOWER

Instructions for setting the mower for optimal performance.

Properly setting the cutting height is essential for efficient and safe operation.

Importance of proper cutting height setting.

NOTE: Avoid very low cutting heights, striking the ground with the blades gives the most damaging shock loads...

Warning about low cutting heights and ground contact.

Never work under the Implement, the framework, or any lifted component unless the Implement is securely supported or blocked up...

Warning about working under raised implements without support.

6.1 Setting Mower Height- Lift Type - (Standard or Quick Hitch)

Procedure for setting mower height with lift type hitch.

Park the tractor and mower on level ground.

Step 1: Parking the tractor and mower on level ground.

Using the 3-point hitch control lever, position the front of the mower with the side skids 1” less off the ground than desired cut height.

Step 2: Adjusting mower height using the 3-point hitch control.

Shut down the tractor and remove the key.

Step 3: Shutting down the tractor and removing the key.

Adjust the mower deck front to rear by extending or retracting the 3-point top link. Always set front of deck 3/4” lower than rear for best performance.

Step 4: Adjusting mower deck pitch for optimal performance.

Level the mower side to side by manipulating one lower lift arm length. On most tractors, at least one of the lift arms is designed to allow for manipulation of its length. Shortening or extending will allow for deck leveling from side to side.

Step 5: Leveling the mower side to side.

Securely block up the mower at this height.

Step 6: Securely blocking up the mower.

Remove the adjusting fasteners securing the tailwheel frame in position and allow the tailwheel to rest on ground level. Align tailwheel frame between nearest sets of holes in adjustment strap and reinstall adjustment fasteners. Tighten all bolts and nuts.

Step 7: Adjusting the tailwheel frame.

Extend the tractor’s top 3-point link so that when lifting the mower, the front of the deck will raise 2 to 2-1/2” before the tailwheel leaves the ground. This will allow the mower to follow the contour of uneven terrain.

Step 8: Adjusting top link for mower contour following.

6.2 Setting Deck Pitch

Instructions for setting the mower deck pitch.

Lower Horse Power - Better Fuel Efficiency

Setting deck pitch for lower horsepower and better fuel efficiency.

Increase Mulching

Setting deck pitch for increased mulching.

7. DRIVELINE ATTACHMENT

Procedures for attaching the mower driveline.

To connect the mower driveline to the tractor PTO output shaft, pull the driveline yoke collar back...

Steps for connecting the mower driveline to the tractor PTO.

7.1 Driveline Length Check

Procedure for checking and adjusting driveline length.

WARNING! When attaching the Implement input driveline to the Tractor PTO, it is important that the connecting yoke spring activated locking collar slides freely...

Warning about driveline attachment to PTO.

Before operating the Implement, check to make sure the Implement input driveline will not bottom out or become disengaged.

Check to prevent driveline bottoming out or disengagement.

“Bottoming Out” Check Procedure

Procedure to check for driveline bottoming out.

Shorten the driveline profiles as follows:

Instructions for shortening driveline profiles.

Engagement Check Procedure

Procedure to check driveline engagement.

NOTE: When raising the mower, at least 1” clearance must be maintained between the driveline and the mower deck.

Note on maintaining clearance between driveline and mower deck.

8. PRE-OPERATION INSPECTION AND SERVICE

Procedures for pre-operation inspection and service.

WARNING! Always disconnect the main PTO Driveline from the Tractor before performing service on the Implement.

Warning to disconnect PTO driveline before service.

Perform scheduled lubrication as detailed in the maintenance section.

Performing scheduled lubrication as per maintenance section.

Ensure all safety signs are in place and legible.

Ensuring safety signs are in place and legible.

Ensure the driveline is securely attached to tractor. Make sure the driveline yoke locking collar is securely seated...

Ensuring secure attachment of the driveline yoke.

Inspect that the 3-point hitch pins are the proper size, correctly installed, and secured to the tractor lift arms with retaining pins inserted.

Checking 3-point hitch pins for proper size and installation.

Ensure deflectors are in position and not damaged. Replace worn, broken and missing pieces.

Checking and replacing deflectors.

Lift Type - Ensure the tailwheel frame position supports bolts are properly installed and tightened.

Ensuring tailwheel frame support bolts are installed and tightened.

Inspect all bolts and screws and tighten to the recommended torque.

Checking and tightening all bolts and screws.

All Safety Shields, Guards and Safety devices including (but not limited to) - the Deflectors, Chain Guards, Steel Guards, Gearbox Shields, PTO integral shields, and Retractable Door Shields should be used and maintained in good working condition.

Importance of using and maintaining all safety shields and guards.

Ensure the tractor PTO master shield and the mower slip clutch shield are in place, lowered, and in good condition.

Checking PTO master and slip clutch shields.

Ensure the driveline integral shield is in good condition and rotates freely.

Checking driveline integral shield condition.

Ensure the driveline slip clutch (if equipped) is properly adjusted.

Ensuring proper adjustment of the driveline slip clutch.

Inspect the gearbox oil level. A low oil level is a warning sign that the gearbox may be cracked or its seal is damaged and needs replacement.

Checking gearbox oil level and potential issues.

Ensure the gearbox vent is in place and free from clogs.

Checking gearbox vent for proper function.

Inspect blades and blade bolts for looseness and excessive wear.

Inspecting blades and blade bolts for wear and looseness.

Make sure the mower is securely blocked up before crawling beneath.

Importance of blocking the mower before working beneath it.

Replace damaged, worn and missing blades as complete sets to maintain rotary balance during operation.

Replacing blades in sets to maintain balance.

Ensure blade pan nut is tightened with the cotter pin inserted and spread.

Ensuring blade pan nut is properly tightened and secured.

8.3 Cutting Component Inspection

Inspection of cutting components like blades and blade pans.

Inspect blade pan and blade assembly for the following:

Specific items to inspect in the blade pan and assembly.

Inspect the Blades daily for abnormal wear. REPLACE BOTH BLADES on that carrier IMMEDIATELY if either blade has:

Daily inspection of blades and immediate replacement if worn or damaged.

Failure to replace abnormally worn blades may lead to catastrophic failure of the blades and ejection of the broken part with tremendous force which may cause serious bodily injury or death.

Consequences of not replacing worn blades.

8.4 Blade Bolt Inspection

Inspection procedures for blade bolts.

Inspect Blade Bolt Head daily for wear as followed:

Daily inspection of blade bolt heads for wear.

Inspect the Blade Bolt Heads daily for abnormal wear. REPLACE BOTH BLADE BOLTS on the Blades IMMEDIATELY if either blade bolts has:

Immediate replacement of blade bolts if signs of wear or damage are present.

Failure to replace abnormally worn blade bolts may lead to catastrophic failure of the blades and ejection of the broken part which may cause serious bodily injury or death.

Consequences of not replacing worn blade bolts.

Always replace Blade Bolts with new bolts whenever replacing the Blades.

Recommendation to always replace blade bolts with new ones.

Tractor PRE-OPERATION Inspection

Checklist for pre-operation inspection of the tractor.

Operator's Signature:

Field for operator's signature after inspection.

DO NOT OPERATE an UNSAFE TRACTOR or MOWER

Mandatory warning against operating unsafe equipment.

Rotary Mower PRE-OPERATION Inspection

Checklist for pre-operation inspection of the rotary mower.

Operator's Signature:

Field for operator's signature after inspection.

DO NOT OPERATE an UNSAFE TRACTOR or MOWER

Mandatory warning against operating unsafe equipment.

9. DRIVING THE TRACTOR AND IMPLEMENT

Guidelines for safely driving the tractor with the mower attached.

Never run the Tractor engine in a closed building or without adequate ventilation.

Warning about operating tractor engine in enclosed spaces.

Transport only at speeds where you can maintain control of the equipment.

Importance of maintaining control while transporting equipment.

Before transporting the Tractor and Implement, determine the proper transport speeds for you and the equipment.

Determining proper transport speeds before moving the equipment.

Test the tractor at a slow speed and increase the speed slowly.

Testing tractor speed and braking characteristics.

Determine the maximum transport speed not to exceed 20 mph (30 kph) for transporting this equipment.

Maximum recommended transport speed.

Test the equipment at a slow speed in turns. Increase the speed through the turn only after you determine that the equipment can be operated at a higher speed. Use extreme care and reduce your speed when turning sharply to prevent the tractor and implement from turning over.

Safe turning procedures to prevent tractor overturns.

Only transport the Tractor and Implement at the speeds which allow you to properly control the equipment.

Transporting only at speeds that allow proper control.

Be aware of the operating conditions. Do not operate the Tractor with weak or faulty brakes or worn tires.

Awareness of operating conditions and equipment status.

When operating down a hill or on wet or rain slick roads, the braking distance increases: use extreme care and reduce your speed.

Caution on hills and wet roads regarding braking distance.

When operating in traffic always use the Tractor’s flashing warning lights and reduce your speed.

Safety measures when operating in traffic.

9.1 Starting the Tractor

Procedures for safely starting the tractor.

The procedure to start the tractor is model specific.

Note that tractor starting procedures vary by model.

Refer to the tractor operator’s manual for starting procedures for your particular tractor.

Recommendation to consult the tractor operator's manual for starting procedures.

Ensure the 3-point control lever is in the lowered position and the PTO is disengaged before starting the tractor.

Pre-start checks for 3-point hitch and PTO.

9.2 Brake and Differential Lock Setting

Procedures for setting tractor brakes and differential lock.

Make sure the tractor brakes are in good operating condition.

Importance of ensuring brakes are in good condition.

Tractor brakes can be set to operate independently allowing single rear wheel braking action or locked together to provide simultaneous rear wheel braking.

Explanation of tractor brake operation modes.

FOR MOST DRIVING AND OPERATING CONDITIONS, THE BRAKE PEDALS SHOULD BE LOCKED TOGETHER TO PROVIDE THE MOST EFFECTIVE BRAKING ACTION.

Recommendation to lock brake pedals together for effective braking.

Always disengage the tractor differential lock when turning.

Warning to disengage differential lock when turning.

Be aware of the operating conditions. Do not operate the Tractor with weak or faulty brakes.

Awareness of operating conditions and tractor brake status.

When operating down a hill or on wet or rain slick roads, the braking distance increases; use extreme care and reduce your speed.

Caution on hills and wet roads regarding braking distance.

9.3 Raising the Mower

Procedure for safely raising the mower.

Using the tractor 3-point hitch control lever, raise the mower off the ground about 6”, or just high enough to clear any ground obstacles.

Raising the mower using the 3-point hitch control.

When raising the mower, make sure all connection points are securely attached and at least 1” clearance is maintained between the driveline and the deck.

Checking driveline and deck clearance during mower raising.

If necessary, place an upper lift stop on the 3-point hitch control lever to limit the height the mower can be raised to avoid driveline damage.

Using an upper lift stop to prevent driveline damage.

9.4 Driving the Tractor and Mower

Procedures for driving the tractor with the mower attached.

Start off driving at a slow speed and gradually increase your speed while maintaining complete control of the tractor and mower.

Starting driving slowly and maintaining control.

Moving slowly at first will also prevent the tractor from rearing up and loss of steering control.

Benefits of starting slowly to prevent tractor rearing and loss of control.

The tractor should never be operated at speeds that cannot be safely handled or which will prevent the operator from stopping quickly during an emergency.

Operating speed limitations for safe handling and emergency stops.

If the power steering or engine ceases operating, stop the tractor immediately as the tractor will be difficult to control.

Action to take if power steering or engine fails.

Perform turns with the tractor and mower at slow speeds to determine how the tractor with an attached mower handles a turn.

Testing turning behavior with the mower attached.

Determine the safe speed to maintain proper control of the tractor when making turns.

Determining safe turning speeds for proper control.

When turning with a towed implement, the overall working length of the unit is increased.

Effect of towed implements on overall working length.

Allow additional clearance for the mower when turning.

Importance of additional clearance when turning.

To avoid overturns, drive the tractor with care and at safe speeds, especially when operating over rough ground, crossing ditches or slopes, and turning corners.

Driving carefully and at safe speeds to avoid overturns.

Tractor wheel tread spacing should be increased when working on inclines or rough ground to reduce the possibility of tipping.

Adjusting tractor wheel spacing for stability on inclines and rough ground.

Use extreme caution when operating on steep slopes.

Extreme caution required when operating on steep slopes.

Keep the tractor in a low gear when going downhill.

Using low gear when going downhill on slopes.

DO NOT coast or free-wheel downhill.

Warning against coasting or free-wheeling downhill.

9.5 Crossing Ditches and Steep Inclines

Procedures for safely crossing ditches and steep inclines.

When crossing ditches with steep banks or going up sharp inclines, it is possible that the main driveline inner profile will penetrate into the outer housing to its maximum depth until the assembly becomes solid (driveline is at its extreme shortest length).

Risk of driveline damage when crossing ditches or steep inclines.

This type of abusive operation can cause serious damage to the tractor and mower drive by pushing the PTO into the tractor and through the support bearings or downward onto the PTO shaft, breaking it off.

Consequences of abusive driveline operation.

When confronted with an incline or ditch, do not approach from an angle which is perpendicular or straight on as damaged to over collapse of the driveline may occur.

Proper approach angle for crossing ditches or inclines.

When crossing such terrain, the implement should be fully lowered for a lower center of gravity and added stability.

Lowering implement for stability on slopes and inclines.

Inclines and ditches should be approached along a line which is at an angle as shown. This type of path will reduce the possibility of over-collapse of the driveline and resulting damage.

Angled approach to inclines and ditches to reduce driveline damage.

When operating the tractor and mower across slopes and inclines, through ditches, and other uneven terrain conditions, it is important to maintain sufficient deck to ground clearance.

Maintaining deck clearance on slopes, inclines, and uneven terrain.

Blade contact with the ground may cause soil, rocks and other debris to be thrown out from under the mower resulting in possible injury and/or property damage.

Consequences of blade contact with the ground.

Ground contact also produces a severe shock load on the mower drive and to the mower blades resulting in possible damage and premature wear.

Impact of ground contact on mower drive and blades.

10. OPERATING THE TRACTOR AND IMPLEMENT

Guidelines for operating the tractor and implement.

THE OPERATOR MUST COMPLETELY UNDERSTAND HOW TO OPERATE THE TRACTOR AND IMPLEMENT AND ALL CONTROLS BEFORE ATTEMPTING TO OPERATE.

Operator's responsibility to understand all controls before operation.

These manuals must be read and explained to any operator who cannot read.

Ensuring operators who cannot read understand the manuals.

Never allow someone to operate the implement and tractor without complete operating instructions.

Prohibition of operating without complete instructions.

Before starting any operation, the operator must become familiar with the area to be worked in and any obstacles and hazards contained within to ensure safety to the operator, bystanders, and equipment.

Operator's duty to familiarize with the work area for safety.

Special attention should be paid to foreign debris, rough terrain, steep slopes, and passersby and animals in the area.

Areas requiring special attention for safe operation.

Extreme care should be taken when operating near loose objects such as gravel, rocks, wire, and other debris.

Caution when operating near loose objects.

Inspect the area before mowing. Foreign objects should be removed from the site to prevent machine damage and/or bodily injury or even death.

Inspect and remove foreign objects to prevent damage and injury.

Any objects that cannot be removed must be clearly marked and carefully avoided by the operator.

Marking and avoiding objects that cannot be removed.

Stop mowing immediately if blades strike a foreign object.

Immediate action if blades strike a foreign object.

Repair all damage and make certain rotor or blade carrier is balanced before resuming mowing.

Repairing damage and balancing rotor/blade carrier before resuming mowing.

10.1 Foreign Debris Hazards

Hazards associated with foreign debris in the mowing area.

Before mowing, inspect the area to make sure there are no foreign objects that the mower blades could hit or become entangled with.

Inspect mowing area for foreign objects.

Remove all foreign objects and debris. If objects are too big to remove, mark them clearly and be sure to prevent the mower blades from contacting them.

Removing or marking foreign objects before mowing.

If you hit a solid object or foreign debris, stop the mower and tractor at once. Immediately idle the engine speed and disengage the PTO.

Action to take if a solid object or debris is hit.

Wait for all mower rotating motion to stop, then raise the mower and move the tractor and implement off the object.

Steps to take after stopping the mower and tractor.

Inspect the condition of the mower and make any needed repairs immediately. Make sure the blades are not damaged and the carrier is balanced before resuming operation.

Inspect mower condition and make repairs before resuming operation.

Always wear your seat belt securely fastened and only operate the tractor and mower with the ROPS in the raised position.

Importance of seat belt and ROPS during operation.

If the tractor or mower hits a tree stump, rock, or bump, a sudden movement could throw you off of the seat and under the tractor and/or mower. The seat belt is your best protection from falling off the tractor and the ROPS provides protection from being crushed during a tractor roll-over.

Protection provided by seat belt and ROPS in case of impact or overturn.

10.2 Bystanders/Passersby Precautions

Precautions related to bystanders and passersby.

If a bystander comes within 300 feet of the tractor while the mower is being operated, stop the tractor at once, idle the engine and disengage the PTO. Do not engage the PTO again until all bystanders are well past the 300 foot distance.

Procedure for stopping operation when bystanders are too close.

Rotary Mowers are capable under adverse conditions of throwing objects for great distances (300 ft (100 m) or more) and causing serious injury or death.

Warning about rotary mower's ability to throw objects and cause injury.

STOP MOWING IF PASSERSBY ARE WITHIN 300 FEET (100 m) UNLESS:

Conditions under which mowing can continue with bystanders nearby.

NOTE: Where there are grass and weeds high enough to hide debris that could be struck by the blades, the area should be: inspected and large debris removed, mowed at an intermediate height, inspected, closely with any remaining debris being removed, and mowed again at desired final height.

Procedure for mowing tall grass and weeds with hidden debris.

10.3 Engaging the Power Take Off (PTO)

Procedures for engaging the PTO.

Before engaging the PTO, make certain that the area is clear of bystanders and passersby. The implement must be completely lowered and the deck positioned at a safe operating height. NEVER engage the PTO with the implement in the raised position.

Pre-engagement checks for PTO operation.

Set the tractor engine speed at approximately 1,000 RPM before engaging the PTO. Shift the PTO control to the on position, and slowly increase the engine speed until the PTO is operating at the rated speed.

Steps for engaging the PTO at the correct speed.

If you hear unusual noises or see or feel abnormal vibrations, disengage the PTO immediately. Inspect the implement to determine the cause of the noise or vibration and repair the abnormality.

Action to take if unusual noises or vibrations occur.

Do not let the Blades turn when the Mower Deck is raised for any reason, including clearance or for turning.

Warning against rotating blades when mower deck is raised.

Raising the Mower deck exposes the Cutting Blades which creates a potentially serious hazard and could cause serious injury or even death from objects thrown from the Blades.

Hazards associated with exposed cutting blades.

Do not put hands or feet under mower decks. Blade Contact can result in serious injury or even death. Stay away until all motion has stopped and the decks are securely blocked up.

Warning about keeping hands and feet away from mower decks.

10.4 PTO RPM and Ground Speed

Guidelines for PTO RPM and ground speed.

Ground speed for mowing will depend upon the height, type, and density of vegetation to be cut.

Factors affecting optimal ground speed for mowing.

Recommended speed for efficient mower performance is between 2 and 5 mph(3-8 kph).

Recommended ground speed range for efficient mowing.

Operate the mower at its full rated PTO speed to maintain blade speed for a clean cut.

Importance of operating at full rated PTO speed for clean cuts.

Refer to the tractor operator’s manual or the tractor instrument panel for the engine speed and gear to provide the required PTO and desired ground speed. Make sure that the mower is operating at its full rated speed before entering the vegetation to be cut.

Ensuring correct PTO and ground speed settings.

If it becomes necessary to temporarily regulate engine speed, increase or decrease the throttle gradually.

Procedure for adjusting engine speed gradually.

Ground speed is achieved by transmission gear selection and not by the engine operating speed. The operator may be required to experiment with several gear range combinations to determine the best gear and range which provides the most ideal performance from the mower and most efficient tractor operation. As the severity of cutting conditions increase, the ground speed should be decreased by selecting a lower gear to maintain the proper operating PTO speed.

Selecting gears for optimal performance and conditions.

Do not exceed the rated PTO speed for the Implement. Excessive PTO speeds can cause Implement driveline or blade failures resulting in serious injury or death.

Warning against exceeding rated PTO speed.

Mow at the speed that you can safely operate and control the tractor and mower. The correct mowing speed depends on terrain condition and grass type, density, and height of cut.

Determining safe mowing speed based on conditions.

Normal ground speed range is from 2 to 5 mph(3-8 kph).

Normal ground speed range for mowing.

Use slow mowing speeds when operating on or near steep slopes, ditches, drop-offs, overhead obstructions, power lines, or when debris and foreign objects are to be avoided.

When to use slow mowing speeds.

10.5 Operating the Mower

Instructions for operating the mower.

Only operate the mower from the tractor operator’s seat with the seatbelt securely fastened. The tractor must be equipped with a ROPS in the raised position or a ROPS cab.

Operator position and tractor requirements for safe mower operation.

The mower is designed to cut vegetation up to 1” in diameter. Sharp blades will produce a cleaner cut and require less power. Travel at a speed that allows the mower sufficient time to cut through the vegetation and maintain the PTO operating speed to prevent overloading the mower and tractor. Choose a driving pattern that provides the maximum pass length and minimizes turning.

Mower operation guidelines for cutting and tractor load management.

Under certain conditions, tractor tires may roll some grasses down preventing them from being cut at the same height as the surrounding area. When this occurs, reduce the tractor ground speed while maintaining the operating speed of the mower. A slower ground speed will permit grasses to at least partially rebound and be cut. Taking a partial cut and/or reversing the direction of travel may also help produce a cleaner cut.

Adjusting tractor speed for better grass cutting.

Avoid mowing in the reverse direction when possible. In situations where the mower must be backed to access areas to be cut, make sure there are no persons or other foreign debris behind the mower before mowing in reverse. When mowing in reverse, operate the tractor and mower at a reduced ground speed to ensure tractor and mower control is maintained.

Safety precautions for mowing in reverse.

Do not mow with two machines in the same area except with Cab tractors with the windows closed.

Warning against mowing with multiple machines in the same area.

Mow only in conditions where you have clear visibility in daylight or with adequate artificial lighting. Never mow in darkness or foggy conditions where you cannot clearly see at least 300 feet (90 m) in front and to the sides of the tractor and mower.

Visibility requirements for safe mowing operations.

Make sure that you can clearly see and identify passersby, steep slopes, ditches, drop-offs, overhead obstructions, power lines, debris and foreign objects. If you are unable to clearly see these type of items discontinue mowing.

Importance of clear visibility of surroundings and potential hazards.

Avoid mowing in reverse direction when possible. Check to make sure there are no persons behind the mower and use extreme care when maneuvering in reverse. Mow only at a slow ground speed where you can safely operate and control the tractor and mower. Never mow an area that you have not inspected and removed debris or foreign material.

Safety precautions for reverse mowing.

Follow these guidelines to reduce the risk of equipment and grass fires while operating, servicing, and repairing the Mower and Tractor:

Guidelines to reduce the risk of equipment and grass fires.

Equip the Tractor with a fire extinguisher in an accesible location.

Recommendation to equip the tractor with a fire extinguisher.

Do Not operate the Mower on a Tractor with an underframe exhaust.

Warning against operating mower with underframe exhaust.

Do Not smoke or have an open flame near the Mower and Tractor.

Warning against smoking or open flames near equipment.

Do Not drive into burning debris or freshly burnt areas.

Warning against driving into burning debris.

Ensure slip clutches are properly adjusted to prevent excessive slippage and plate heating.

Importance of proper slip clutch adjustment.

Never allow clippings or debris to collect near drivelines, slip clutches, and gearboxes. Periodically shut down the Tractor and Mower and clean clippings and collected debris from the mower deck.

Preventing buildup of clippings and debris near drivelines and gearboxes.

When you get to the end of a pass, slightly raise the mower (2-4”) before turning. Never raise the mower entirely while the blades are turning. If the mower must be raised higher than 12” from ground level, disengage the tractor PTO and wait for all mower rotation to come to a complete stop before proceeding to raise the mower.

Procedure for turning at the end of a pass.

When turning, the angle between the tractor and mower should not be so great that a clattering of the U-joints occurs. Sharp turns can cause premature failure of the joints and place pressure on the tractor PTO shaft and could cause extensive mechanical damage to the mower and tractor.

Avoiding sharp turns to prevent U-joint and PTO damage.

Do not let the Blades turn when the Mower Deck is raised for any reason, including clearance or for turning.

Warning against rotating blades when mower deck is raised.

Raising the Mower deck exposes the Cutting Blades which creates a potentially serious hazard and could cause serious injury or even death from objects thrown from the Blades.

Hazards of exposed cutting blades when mower deck is raised.

Large, dense, or wet vegetation may need to be mowed in two or more passes to achieve a uniform cut. In such conditions, raise the cutting height to 12” or more on the first pass.

Procedure for mowing large, dense, or wet vegetation.

Then lower the mower to the desired height and mow the vegetation a second time. If possible, select a mowing pattern that is at a 90 degree angle to the first pass to reduce streaking for a more uniform cut.

Second mowing pass for uniform cut and reduced streaking.

Stay alert and watch for trees, low hanging limbs, power lines, and other overhead obstacles and solid ground objects while you are operating. Use care to avoid hitting these items.

Staying alert for overhead and ground obstacles.

Do not mow, or drive the tractor into material that is burning, or areas that recently burnt and may contain hot spots.

Warning against mowing burning or recently burnt areas.

Burning material, sparks, and coals could be thrown from the mower to areas of vegetation that might ignite. Tire damage can occur when driving over hot material. Oil and grease on the tractor and mower could ignite resulting in equipment destruction. Carry a fire extinguisher on the tractor at all times to extinguish possible fires encountered.

Fire hazards associated with burning material and hot spots.

10.6 Right of Way (Highway) Mowing

Safety practices for mowing along right-of-way or highways.

USE DOUBLE CHAIN GUARDS for highway, right-of-way, parks, greenbelt mowing, or all other mowing where human dwellings, vehicles, or livestock could be within 300 feet of the mower.

Requirement for double chain guards in specific mowing areas.

No shielding is 100% effective in preventing thrown objects. To Reduce Possibility of Injury:

Reducing possibility of injury from thrown objects.

MAINTAIN MOWER SHIELDING in good operational condition,

Importance of maintaining mower shielding.

DAILY INSPECT the condition of the Thrown Object Guards, mower Side Skirts, and skid shoes: Replace or repair worn or damaged guards.

Daily inspection and maintenance of guards, skirts, and shoes.

DAILY INSPECT the condition of the Blades and Blade Bolts. Replace any cracked, worn, bent or damage blades. Always replace blade bolts and nuts when replacing blades. Make sure the blade bolts are properly tightened.

Daily inspection of blades and bolts, and replacement procedures.

RAISE CUTTING HEIGHT to 6 INCHES minimum.

Recommended minimum cutting height for safety.

INSPECT AREA thoroughly before mowing to REMOVE potential THROWN OBJECT HAZARDS.

Thorough area inspection to remove thrown object hazards.

NEVER ALLOW BLADES to CONTACT SOLID OBJECTS like wire, rocks, posts, guardrails, or ground while mowing.

Warning against blade contact with solid objects.

ROTARY MOWERS CAN THROW OBJECTS 300 FEET OR MORE UNDER ADVERSE CONDITIONS.

Warning about object throwing distance under adverse conditions.

TO AVOID SERIOUS INJURY OR DEATH TO OPERATOR OR BYSTANDERS FROM THROWN OBJECTS:

Instructions to avoid injury from thrown objects.

INSPECT AREA FOR POTENTIAL THROWN OBJECTS BEFORE MOWING:

Area inspection for potential thrown objects.

REMOVE debris, rocks, wire, cable, metal objects and other foreign material from area.

Removing debris from the mowing area.

Wire, cable, rope, chains and metal objects can be thrown or swung outside deck with great velocity:

Hazards of thrown wire, cable, rope, chains, and metal objects.

MARK objects that cannot be removed.

Marking objects that cannot be removed.

AVOID these objects when mowing.

Avoiding marked objects during mowing.

STOP MOWING IF PASSERSBY IS WITHIN 300 FEET UNLESS:

Conditions for stopping mowing if bystanders are present.

All THROWN OBJECT SHIELDING including Front and Rear Deflectors, Chain Guards, Steel Guards, Bands, Side Skirts and Skid Shoes are in place and in good condition when mowing.

Requirement for all thrown object shielding to be in place and good condition.

Mower sections or wings are adjusted to be close and parallel to ground without exposing blades.

Mower sections/wings adjustment for safety.

MOWING AREA has been inspected and foreign materials and debris have been removed.

Ensuring mowing area is free of debris.

PASSERSBY are inside enclosed vehicle.

Condition for bystanders to be considered safe.

10.7 Shutting Down the Implement

Procedures for shutting down the mower.

To shut down attached mower head, first bring the tractor to a complete stop. Decrease engine RPM to idle then disengage cutterhead.

Steps for shutting down the mower head.

The mower head will come to a complete stop within a suitable amount of time. Do not engage or disengage the cutterheads at a high RPM unless there is an emergency situation.

Information on mower head stopping time and RPM engagement.

Park the tractor on a level surface, place the transmission in park or neutral and apply the parking brake, lower the attached implement to the ground, shut down the engine, remove the key, and wait for all motion to come to a complete stop before exiting the tractor.

Procedure for safely parking and shutting down the tractor and implement.

11. DISCONNECTING THE MOWER FROM THE TRACTOR

Procedures for disconnecting the mower from the tractor.

Before disconnecting the mower, the PTO must be disengaged and blade rotation at a complete stop.

Pre-disconnection steps: PTO disengagement and blade stop.

Move the mower to a level storage location and lower it to the ground. If the mower is not resting securely on the ground, block the mower up securely before attempting to disconnect it from the tractor.

Moving mower to storage and securing it before disconnection.

Use extreme care to keep feet and hands from under the mower and clear of any pinch points caused by the tractor hitch arms and mower pins.

Caution to keep hands and feet clear of pinch points during disconnection.

Always shut the Tractor completely down, place the transmission in park, and set the parking brake before you or anyone else attempts to connect or disconnect the Implement and Tractor hitches.

Safety steps before connecting or disconnecting implements.

To disconnect the mower, first extend the tractor 3-point hitch top link to remove tension on the top link hitch pin.

Extending top link to remove tension from hitch pin.

When the pin is loose and easy to rotate, remove the pin from the mower. Next remove both lower hitch pins.

Removing hitch pins after tension release.

After disconnecting the 3 lift points, remove the mower driveline from the tractor PTO shaft. Lay the driveline down carefully on support flat to avoid damaging the driveline or its shield. Do not let the driveline fall into mud or dirt, which can contaminate the bearing and shorten the life of the driveline.

Disconnecting and handling the mower driveline.

12. MOWER STORAGE

Procedures for properly storing the mower at the end of the season.

Properly preparing and storing the mower at the end of the season is critical to maintaining its appearance and to help ensure years of dependable service.

Importance of proper preparation and storage for mower longevity.

The following are suggested storage procedures:

Suggested procedures for mower storage.

Thoroughly clean all debris off the mower to prevent damage from rotting grass and standing water.

Cleaning the mower before storage.

Lubricate all mower grease points and fill gearbox oil levels as detailed in the maintenance section.

Lubricating grease points and filling gearbox oil.

Tighten all bolts and pins to the recommended torque.

Tightening all bolts and pins to recommended torque.

Check the mower for worn or damaged parts. Make replacements immediately.

Checking for and replacing worn or damaged parts.

Place driveline in storage position resting on bracket.

Storing the driveline in the designated position.

Store the mower in a clean, dry place with the mower housing resting securely on blocks or at ground level.

Storing the mower in a clean, dry place.

Use spray touch-up enamel where necessary to prevent rust and maintain the appearance of the cutter.

Using touch-up enamel to prevent rust.

It is critical that driveline clutches slip when an obstacle or heavy load is encountered to avoid mower and/or tractor damage.

Importance of driveline clutch slippage to prevent damage.

If the mower sits outside for an extended period of time or is exposed to rain and/or humid air, the clutch lining plates must be inspected to ensure they are not frozen together from rust or corrosion.

Inspecting clutch lining plates after exposure to elements.

If the mower has been exposed to such conditions, at the start of each mowing season, and any time it is suspected that the slip clutch plates may be frozen together, readjust the slip clutch as detailed in Seasonal Clutch Maintenance of the maintenance section in this manual.

Readjusting slip clutch if plates are frozen.

Never allow children or other persons to ride on the Tractor or Implement.

Warning against allowing passengers on tractor or implement.

13. TRANSPORTING THE TRACTOR AND IMPLEMENT

Guidelines for safely transporting the tractor and mower.

Inherent hazards of operating the tractor and implement and the possibility of accidents are not left behind when you finish working in an area. Therefore, the operator must employ good judgement and safe operation practices when transporting the tractor and implement between locations.

Importance of good judgment and safe practices when transporting equipment.

By using good judgement and following safe transport procedures, the possibility of accidents while moving between locations can be substantially minimized.

Minimizing accidents through good judgment and safe transport.

Before transporting the tractor and mower, idle the tractor engine, disengage the PTO and wait for all mower moving parts to come to a complete stop.

Steps before transporting: idle engine, disengage PTO, stop all mower parts.

Once all mower parts are completely stopped, raise the mower to transport height. NOTE: When raising the mower, maintain 1” clearance between the driveline and mower deck. If additional mower deck height is needed for safe transport, disconnect the driveline from the tractor and secure its end to the mower deck. The mower can then be raised to the maximum lift height.

Raising mower to transport height and ensuring clearance.

If the tractor’s hydraulic pump is not independent of the tractor PTO, or if the tractor PTO has to be run to have hydraulic power, disconnect the mower driveline from the tractor PTO output shaft. Secure the driveline to the mower deck to prevent driveline damage or loss during transport.

Disconnecting driveline if tractor PTO is not independent.

13.1 Transporting on Public Roadways

Safety guidelines for transporting on public roadways.

Extreme caution should be used when transporting the tractor and implement on public roadways. The tractor must be equipped with all required safety warning features including a SMV emblem and flashing warning lights to alert drivers of the tractor’s presence.

Caution for transporting on public roadways; required safety features.

Remember that roadways are primarily designed for automotive drivers and most drivers will not be looking out for you, therefore, you must look out for them. Check your side view mirrors frequently and remember that vehicles will approach quickly because of the tractor’s slower speed. Be extremely cautious when the piece of equipment that you are towing is wider than the tractor tire width and/or extends beyond your lane of the road.

Awareness of other road users and equipment dimensions.

Make sure that a proper size safety tow chain is secured between the tractor and implement before entering a public road.

Importance of securing a safety tow chain before road transport.

Make certain that the “Slow Moving Vehicle” (SMV) sign is installed in such a way as to be clearly visible and legible.

Ensuring SMV sign visibility and legibility.

When transporting the Equipment use the Tractor flashing warning lights and follow all local traffic regulations.

Using tractor warning lights and following traffic regulations.

When operating on public roads, have consideration for other road users. Pull to the side of the road occasionally to allow all following traffic to pass. Do not exceed the legal speed limit set in your country for agricultural tractors. Always stay alert when transporting the tractor and implement on public roads. Use caution and reduce speed if other vehicles or pedestrians are in the area.

Consideration for other road users and traffic laws.

13.2 Hauling the Tractor and Implement

Procedures for safely hauling the tractor and implement.

Before transporting a loaded tractor and implement, measure the height and width dimensions and gross weight of the complete loaded unit. Ensure that the load will be in compliance with the legal limits set for the areas that will be traveled through

Measuring loaded unit dimensions and weight for legal compliance.

Use adequately sized and rated trailers and equipment to transport the tractor and implement. Consult an authorized dealer to determine the proper equipment required. Using adequately sized chains, heavy duty straps, cables and/or binders, securely tie down both the front and rear of the tractor utilizing the proper tie down locations as specified by the tractor manufacturer.

Using appropriate trailers and tie-down equipment for transport.

While hauling the tractor and implement, make occasional stops to check that the tractor and implement have not moved or shifted and that the securing chains have maintained tension. If during transport a hard braking, sharp turning, or swerving action was performed, stop at the next safe location to inspect the security of the load.

Checking securing devices and load stability during transport.

14. TROUBLESHOOTING GUIDE

Guide to diagnosing and resolving common mower problems.

Uneven Cut

Troubleshooting guide for uneven cutting performance.

Uncut Material

Troubleshooting guide for uncut material.

Poor Shredding

Troubleshooting guide for poor shredding.

Windrowing or Uneven

Troubleshooting guide for windrowing issues.

Blade Bolts Working Loose

Troubleshooting for loose blade bolts.

Gearbox Noisy

Troubleshooting for noisy gearbox.

Gearbox Leaking

Troubleshooting for gearbox leaks.

Streaking Conditions

Troubleshooting for streaking conditions.

Gearbox Overheating

Troubleshooting for gearbox overheating.

Shear Pin Shears Excessively

Troubleshooting for excessive shear pin shearing.

Maintenance Section

HAZARDS WITH MAINTENANCE OF IMPLEMENT

Hazards associated with performing maintenance on the mower.

AVOID SERIOUS INJURY OR DEATH FROM COMPONENT FAILURE BY KEEPING IMPLEMENT IN GOOD OPERATING CONDITION IN PERFORMING PROPER SERVICE, REPAIRS AND MAINTENANCE.

Importance of keeping implement in good condition for safe maintenance.

BEFORE PERFORMING SERVICE, REPAIRS AND MAINTENANCE ON THE IMPLEMENT:

Steps to take before performing maintenance.

SECURE EQUIPMENT FOR SERVICE

Procedures for securing equipment for service.

BLOCK OUT POTENTIAL ENERGY HAZARDS; Rotating Parts, Raised Components, Hydraulic Pressure.

Blocking potential energy hazards before service.

WEAR SAFETY GLASSES, PROTECTIVE GLOVES and follow SAFETY PROCEDURES when performing service, repairs and maintenance on the implement:

Personal protective equipment and safety procedures for maintenance.

PERFORM SERVICE, REPAIRS, LUBRICATION AND MAINTENANCE OUTLINED IN IMPLEMENT MAINTENANCE SECTION:

Instructions for performing service, repairs, and maintenance.

BLADE INSPECTION:

Inspection procedures for mower blades.

SAFETY SHIELDS, GUARDS AND SAFETY DEVICES INSPECTION:

Inspection of safety shields, guards, and devices.

Operating, servicing and maintaining this equipment can expose you to chemicals including gasoline, diesel fuel, lubricants, petroleum products, engine exhaust, carbon monoxide, and phthalates, which are known to the State of California to cause cancer and birth defects or other reproductive harm.

Health hazards from chemicals associated with equipment operation and maintenance.

Lubrication

Lubrication procedures for the mower.

Before operating your Rotary Cutter, make sure it is properly lubricated and thoroughly inspected.

Importance of proper lubrication and inspection before operation.

Always disengage the PTO before raising the Rotary Cutter for transporting or making adjustments.

Warning to disengage PTO before raising or making adjustments.

Do not let excess grease collect on or around parts, particularly when operating in sandy areas.

Caution about excess grease collection.

The illustrations below shows lubrication points (Figure Mnt-R-0333). The chart gives the frequency of lubrication in hours, based on normal operating conditions. Severe or unusual conditions may require more frequent lubrication.

Lubrication points and frequency chart.

Use Multi-Purpose Gear Oil when required in Gearbox. Use N.L.G.I #2 grease for all locations designated with grease gun.

Recommended lubricants for gearbox and grease points.

Failure to maintain proper lubrication will result in damage to U-joints, gearbox, and/or driveshaft.

Consequences of improper lubrication.

PARTS INFORMATION

Information about mower parts and specifications.

Rhino mowers use balanced and matched system components for blade carriers, blades, cuttershafts, knives, knife hangers, rollers, drivetrain components, and bearings.

Description of Rhino mower component selection.

Non-genuine "will fit" parts do not consistently meet these specifications. The use of “will fit” parts may reduce mower performance, void warranties, and present a safety hazard. Use genuine Rhino mower parts for economy and safety.

Warning against using non-genuine parts and recommendation for genuine parts.

SEE YOUR RHINO DEALER

Instruction to consult the Rhino dealer.

GEARBOX

Maintenance procedures for the gearbox.

The gearbox should be full (18 ounces) 0.54 liters and not require additional lubricant unless the box is cracked or a seal is leaking.

Gearbox lubricant level and conditions requiring additional lubricant.

It is recommended that the hex oil level check plug be removed to check oil level after every 8 hours of operation. If required, oil should be added until it runs out hole.

Procedure for checking and adding gearbox oil.

Recommended lubricant is EP85W-140 Gear Oil.

Type of recommended lubricant for the gearbox.

NOTE: Make sure mower is level when checking oil in the gearbox.

Note on ensuring mower is level when checking oil.

Gearbox capacity is 18 oz.

Gearbox oil capacity.

NOTE: Overfilling of Gearbox will cause pressure to build up and cause Grease Seals to leak.

Warning about consequences of overfilling the gearbox.

DRIVELINE LUBRICATION

Lubrication procedures for the driveline.

Grease Fittings are located on the Cross Assembly of each U-Joint and on the telescoping tubes.

Location of driveline grease fittings.

Grease the U-Joint after each 8 hours of use (Figure MntP-R-0021).

U-joint lubrication frequency.

Do not force grease through the Needle Cup Assemblies.

Warning against forcing grease through needle cup assemblies.

Grease the telescoping tubes after every 8 hours of use.

Telescoping tube lubrication frequency.

To grease profile tube, disconnect drive from PTO and pull halves apart. Pump grease into outer profile tube and reinstall together. Lube slide Collar weekly with WD40 or equivalent weight oil.

Procedure for greasing profile tubes and slide collar.

The Driveline Integral Shields should not become dented or otherwise damaged. The Integral Shield Assembly has a Nylon Bearing at each end and should turn freely. This nylon bearing should require lubrication every 40 hours.

Maintenance of driveline integral shields and nylon bearings.

To remove the Integral Shields for replacement or repair, turn the three Nylon Nuts 1/4 turn in the Shield Slots of the Cone and Tube and remove them. Slip the Shield Cone Assembly off inner section of the Driveline.

Procedure for removing integral shields.

Install the new or repaired Shield on the Driveline. Place the split Nylon Bearing over the Driveline Housing of Shaft against the Yoke and in the Bearing groove. Install shield over the Housing so the Nylon Bearing fits into the Shield Bearing Retainer. Align a slot in the Shield Cone with on of the slots in the Shield. Put one of the Nylon Nuts back in through the aligned slots and turn until it is perpendicular to the slots. Add the other two Nylon Nuts.

Procedure for installing new or repaired integral shields.

Make certain that the Driveline Integral Shields are free to telescope and rotate around the driveline without binding.

Ensuring driveline shields telescope and rotate freely.

SHEAR PIN YOKE

Information and maintenance of the shear pin yoke.

Yoke is supplied with a grease fitting to lube between gearbox shaft and yoke. This allows yoke to spin freely on gearbox shaft when pin shears.

Lubrication of the shear pin yoke.

Failure to lube may cause yoke to gall and spin weld to shaft. Adding even small amounts of grease will greatly prolong life of yoke. The shear bolt (1/2” x 3”) MUST BE a Grade 2 to ensure that it shears when high torque load is encountered.

Importance of lubrication and shear bolt grade for yoke life.

IMPORTANT: Scan this QR Code with your smart phone to link to the ADMA Driveline Safety Manual...

QR code for ADMA Driveline Safety Manual.

SLIP CLUTCH

Information and maintenance of the slip clutch.

If a slip clutch is incorporated in the PTO driveline, it is designed to slip, absorb the shock load, and protect the driveline.

Function of the slip clutch in the PTO driveline.

After the first hour of operation, the slip clutch should be checked for overheating. After this first check, the slip clutch should be checked weekly or anytime there is overheating.

Checking slip clutch for overheating.

To adjust the slip clutch, tighten the spring nuts 1/8 (maximum) turn at a time. Bolts should NEVER be adjusted to the point where the springs are compressed solid.

Procedure for adjusting the slip clutch.