Advertisement

Proportional Digital Control Signal Input and

Applications

©

1993 Johnson Controls, Inc.

Part No. 34-636-70

Rev—

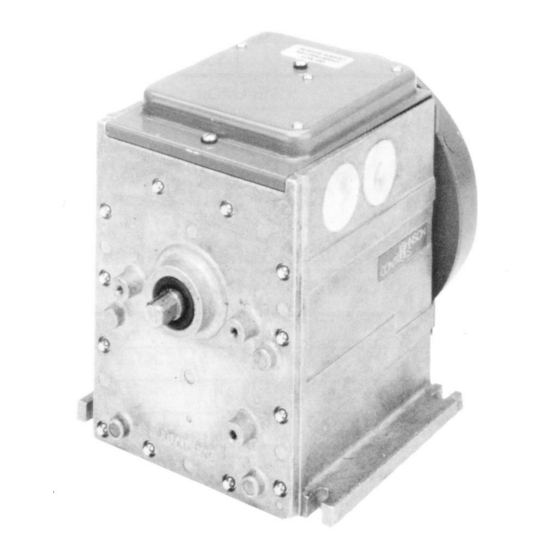

M100C Series of Motor Actuators with

R81C Interface Board

The M100C Series Motor Actuator is used in damper and valve

applications where proportional control from a digital controller is

required.

The M100C has the capability of communicating with Metasys ®

AHU/UNT or DSC1000 controllers depending on the position of the 8-pin

DIP switch. Other functions that are user programmable include master or

slave configuration, direct or reverse acting mode, the address to which the

actuator will respond and the linear or S-curve response characteristic.

Installation Sheets Manual 121

Motor Actuators Section M

Figure 1: M100

Technical Bulletin M100C

Issue Date 0493

1

Advertisement

Table of Contents

Summarization of Contents

Technical Specifications

Torque Ratings

Lists torque specifications for different M100 models.

Power Source and Accessories

Details available input voltage options and factory-mounted accessories.

Control Input and Travel

Describes digital control input and the actuator's travel and timing characteristics.

Physical and Operational Details

Direction of Rotation

Explains how to interpret the direction of rotation for the actuator's load end.

Dimensions

Provides physical dimensions of the M100 Series Motor Actuator.

Installation Procedures

Tools, Safety, and Mounting

Lists required tools, safety precautions, code requirements, and mounting guidelines.

R81 Circuit Board Installation

Removing and Installing Boards

Steps to safely remove existing and install new circuit boards, including terminal and vertical boards.

Wiring Diagrams

Single Unit and Parallel Master Wiring

Diagrams for single M100 units and parallel systems with master actuators.

Calibration and Configuration

DIP Switch Settings

Using the 8-position DIP switch to configure operating parameters like master/slave and response curves.

Operation Modes and Characteristics

Master/Slave and Flow Curves

Setting master/slave configurations and understanding linear/S-curve flow characteristics.

Actuator Control Settings

Action, Bus, and Address Configuration

Setting direct/reverse action, communication bus, and unique addresses via DIP switches.

Controller Specific Addressing

C500 Controller Address Selection

Details on selecting addresses for C500 controllers, referring to technical bulletins and switch settings.

Sequence Operations and AHU Addressing

Sequence Modes and AHU Addressing

Describes sequence operation modes and AHU controller address assignment via software.

Advanced Settings and Adjustments

AHU Address Switches and Travel Adjustment

AHU address switch settings and adjusting the actuator's rotation range.

Travel Adjustment Procedure

Full Range Rotation Example

Illustrates how controller commands translate to actuator rotation for full range operation.

Troubleshooting and Maintenance

Operational Check and Replacement

Procedures for verifying operation, maintenance, and contacting support for parts or repairs.

Need help?

Do you have a question about the M150 and is the answer not in the manual?

Questions and answers