Table of Contents

Advertisement

Residential Air Conditioners and Heat Pumps

Using R-22 and Puron® Refrigerant

Application Guideline and Service Manual

UNIT IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION GUIDELINE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Residential New Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Add-On Replacement (Retrofit) - R22 to Puron . . . . . . . . . . . . . . 4

Seacoast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ACCESSORY DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

LOW-AMBIENT COOLING GUIDELINE . . . . . . . . . . . . . . . . . . . 7

LONG LINE GUIDELINE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

CABINET ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Basic Cabinet Designs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Labeling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ELECTRICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Aluminum Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cycle Protector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Crankcase Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Time-Delay Relay (TDR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pressure Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Defrost Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Defrost Control Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

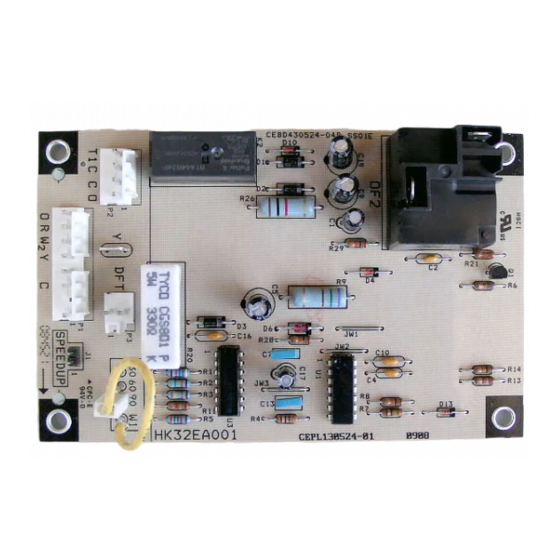

HK32EA001/007 DEFROST CONTROL. . . . . . . . . . . . . . . . . . 15

HK32EA009 DEFROST CONTROL . . . . . . . . . . . . . . . . . . . . . 17

HK32EA003 / 008 DEFROST CONTROL. . . . . . . . . . . . . . . . . 17

Troubleshooting (HK32EA003/008) . . . . . . . . . . . . . . . . . . . . . 18

HK32EA008 DEFROST CONTROL . . . . . . . . . . . . . . . . . . . . . 18

Quiet Shift-2 (non-communicating). . . . . . . . . . . . . . . . . . . . . . . 18

HK32EA010 DEFROST CONTROL . . . . . . . . . . . . . . . . . . . . . 18

HK32EA011 DEFROST CONTROL . . . . . . . . . . . . . . . . . . . . . 18

Outdoor Fan Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

ECM Fan Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

PSC Fan Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Compressor Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Low-Voltage Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

COPELAND SCROLL COMPRESSOR. . . . . . . . . . . . . . . . . . . 20

LG SCROLL COMPRESSOR. . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Characteristics of the LG Scroll Compressor: . . . . . . . . . . . . . . . 21

COMPRESSOR TROUBLESHOOTING . . . . . . . . . . . . . . . . . . 22

Compressor Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Mechanical Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Noisy Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Electrical Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

REFRIGERATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Servicing Systems on Roofs With Synthetic Materials . . . . . . . . 25

Brazing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Aluminum Brazing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Service Valves and Pumpdown . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Liquid Line Filter Drier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Suction Line Filter Drier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Accumulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Thermostatic Expansion Valve (TXV) . . . . . . . . . . . . . . . . . . . . 31

Make Piping Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

REFRIGERATION SYSTEM REPAIR. . . . . . . . . . . . . . . . . . . . . . 33

Leak Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Coil Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Aluminum Coil Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Compressor Removal and Replacement . . . . . . . . . . . . . . . . . . . 35

System Clean-Up After Burnout . . . . . . . . . . . . . . . . . . . . . . . . . 35

Evacuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Check Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

TROUBLESHOOTING with SUPERHEAT . . . . . . . . . . . . . . . . . . 37

quence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Sequence of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

DEFROST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

QUIET SHIFT-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

LIQUID LINE SOLENOID ACCESSORY . . . . . . . . . . . . . . . . 49

MAJOR COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Systems Communication Failure . . . . . . . . . . . . . . . . . . . . . . . . . 49

Pressure Switch Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Control Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

24V Brown Out Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Compressor Voltage Sensing. . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

or Loss of 230V Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Contactor Shorted Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

No 230V at Compressor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Temperature Thermistors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Thermistor Sensor Comparison . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Failed Thermistor Default Operation. . . . . . . . . . . . . . . . . . . . . . 50

TWO-STAGE 286B/289B 180B/187B . . . . . . . . . . . . . . . . . . . . . . 52

Application Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Model Plug. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

nicating (Non-Evolution) Thermostats . . . . . . . . . . . . . . . . . . . . 53

Airflow Selection for FV4 Fan Coils for 180B, 187B, 286B, 289B Us-

ing Non-Communicating (Non-Evolution) Thermostats. . . . . . . 53

GENERAL INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Low Ambient Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Quiet Shift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

(part # HK38EA016, HK38EA022, HK38EA023) . . . . . . . . . . . 54

Liquid-Line Solenoid Accessory . . . . . . . . . . . . . . . . . . . . . . . . . 54

Check Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Heating Check Chart Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . 54

55

Cooling and Heating Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Advertisement

Table of Contents

Troubleshooting

Summarization of Contents

UNIT IDENTIFICATION

Air Conditioner and Heat Pump Model Number Nomenclature

Explains how to identify model numbers by code.

Serial Number Nomenclature

Details the components of the unit's serial number.

SAFETY CONSIDERATIONS

UNIT OPERATION AND SAFETY HAZARD

Outlines potential dangers during unit operation and service.

INSTALLATION GUIDELINE

Residential New Construction

Specifies requirements for new residential installations.

Add-On Replacement (Retrofit) - R22 to Puron

Details specifications for replacing R22 systems with Puron.

Seacoast

Describes features for units in coastal environments.

ACCESSORIES

Required Field-Installed Accessories for Air Conditioners

Lists accessories needed for AC units based on application.

Required Field-Installed Accessories for Heat Pumps

Lists accessories needed for heat pumps based on application.

ACCESSORY DESCRIPTIONS

Crankcase Heater

Describes the function and usage of a crankcase heater.

Evaporator Freeze Thermostat

Explains the evaporator freeze thermostat's role in preventing coil freezing.

Isolation Relay

Describes the isolation relay used in heat pumps with low ambient kits.

Low-Ambient Pressure Switch

Details the low-ambient pressure switch for condenser fan speed control.

Outdoor Air Temperature Sensor

Explains the function of the outdoor air temperature sensor.

Thermostatic Expansion Valve (TXV)

Describes the TXV's function in metering refrigerant flow.

Time-Delay Relay

Explains the function of the time-delay relay for indoor blower operation.

Wind Baffle

Describes the use of wind baffles to prevent abnormal control operation.

Winter Start Control

Explains the winter start control for AC units in low ambient cooling.

CABINET ASSEMBLY

Basic Cabinet Designs

Illustrates and describes the three basic cabinet designs for units.

ACCESS COMPRESSOR OR OTHER INTERNAL CABINET COMPONENTS

Remove Top Cover - Mid-Tier / Deluxe

Provides steps for removing the top cover on Mid-Tier/Deluxe units.

Remove Fan Motor Assembly - Mid-Tier / Deluxe

Details the procedure for removing the fan motor assembly on these units.

Control Box Cover-Base Products

Describes the control box cover for base product models.

Remove Top Cover-Base Products

Steps for removing the top cover on base product models.

Remove Fan Motor Assembly-Base Products

Procedure for removing the fan motor assembly on base product models.

ELECTRICAL

Aluminum Wire

Guidelines for using aluminum wire in branch circuits and connections.

Contactor

Explains the function and troubleshooting of contactors.

Capacitor

Describes the role and testing of capacitors in single-phase motors.

Cycle Protector

Details the cycle protector's function in preventing compressor short cycling.

Crankcase Heater

Explains the crankcase heater's purpose in keeping compressor oil warm.

Time-Delay Relay (TDR)

Describes the TDR's function in keeping the indoor blower running post-cycle.

Pressure Switches

Explains the function of Puron system pressure switches.

High-Pressure Switch (AC & HP)

Details the high-pressure switch's role in protecting the condenser coil.

Loss of Charge Switch (HP Only)

Explains the loss of charge switch for heat pumps.

Defrost Thermostat

Check Defrost Thermostat

Provides instructions for checking the defrost thermostat's operation.

Defrost Control Boards

HK32EA001/007 DEFROST CONTROL

Describes the HK32EA001/007 defrost control board for Legacy Series.

Cooling Sequence of Operation (HK32EA001/007)

Explains the cooling sequence for the HK32EA001/007 control.

Heating Sequence of Operation (KH32EA001)

Explains the heating sequence for the HK32EA001 control.

Defrost Sequence (HK32EA001/007)

Details the defrost sequence for the HK32EA001/007 control.

Defrost Speedup

Describes how to initiate a forced defrost cycle using speedup pins.

If unit will not defrost

Troubleshooting steps when the unit fails to initiate defrost.

To fully troubleshoot defrost thermostat and control function (HK32EA001/007)

Comprehensive troubleshooting for defrost thermostat and control.

HK32EA009 DEFROST CONTROL

Details the HK32EA009 defrost control for units with ECM outdoor motors.

HK32EA003/008 DEFROST CONTROL

Describes the HK32EA003/008 defrost control for Preferred Series heat pumps.

System function and Sequence of operation (HK32EA003/008)

Explains the system functions and sequences for the HK32EA003/008 control.

Cooling

Details the cooling sequence of operation for the control.

Heating

Details the heating sequence of operation for the control.

Defrost Sequence

Explains the defrost sequence timing and termination for the control.

Deluxe Defrost Speedup

Describes the deluxe defrost speedup feature for forced defrost initiation.

Troubleshooting (HK32EA003/008)

Troubleshooting steps for the HK32EA003/008 defrost control.

HK32EA008 DEFROST CONTROL

Details the HK32EA008 defrost control for non-communicating Preferred Series.

Quiet Shift-2 (non-communicating)

Explains the Quiet Shift-2 feature for reducing defrost-related noise.

HK32EA010 DEFROST CONTROL

Details the HK32EA010 defrost control for units with ECM outdoor motors.

HK32EA011 DEFROST CONTROL

Details the HK32EA011 defrost control for Legacy Series with aluminum coils.

Outdoor Fan Motors

ECM Fan Motor

Describes ECM fan motor characteristics and troubleshooting.

PSC Fan Motor

Explains the PSC fan motor and its electrical checks.

COPELAND SCROLL COMPRESSOR

Scroll Gas Flow

Illustrates and describes the scroll compressor's gas flow.

LG SCROLL COMPRESSOR

Characteristics of the LG Scroll Compressor

Details the LG scroll compressor's unique characteristics and features.

Internal Motor Overload Protection (OLP)

Explains the OLP system for protecting the motor from overloads.

Vacuum protection device

Describes the vacuum protection feature to prevent internal damage.

Internal Pressure Relief (IPR)

Explains the IPR valve's function to relieve high internal pressure.

Quiet Shut Down Device

Details the quiet shut down device for minimizing noise.

Discharge Temperature Protection

Explains discharge temperature protection to prevent overheating.

COMPRESSOR TROUBLESHOOTING

Compressor Failures

Categorizes compressor failures into mechanical and electrical types.

Locked Rotor

Describes the locked rotor failure mode and its diagnosis.

Runs, Does Not Pump

Explains the 'runs but does not pump' failure mode and its causes.

COMPRESSOR TROUBLESHOOTING

Electrical Failures

Focuses on diagnosing electrical issues causing compressor failure.

Open Circuit

Details how to test for open circuits in compressor windings.

Short Circuit

Explains how to test for short circuits within compressor windings.

Ground Circuit

Describes how to test for a direct short to ground in compressor windings.

REFRIGERATION SYSTEM

Refrigerant

Provides critical information about Puron refrigerant and system safety.

SERVICING SYSTEMS ON ROOFS WITH SYNTHETIC MATERIALS

Synthetic Roof Precautionary Procedure

Outlines steps to protect roofing materials from compressor oil.

BRAZING

Aluminum Brazing

Provides instructions and considerations for brazing aluminum coils.

SERVICE VALVES AND PUMPDOWN

Heating Piston (AccuRater®) - Heat Pumps Only

Details the Accurater piston's function in heat pump heating mode.

LIQUID LINE FILTER DRIER

Install Liquid-line Filter Drier Indoor - AC

Instructions for installing the liquid line filter drier on AC units.

Install Liquid-line Filter Drier Indoor - HP

Instructions for installing the liquid line filter drier on heat pumps.

THERMOSTATIC EXPANSION VALVE (TXV)

TXV Operation

Explains how the TXV operates to maintain preset superheat.

Install TXV

Provides guidelines for installing the TXV correctly.

Installing TXV in Place of Piston in a Rated Indoor Coil (pre-2006)

Steps for replacing a piston with a TXV in older indoor coils.

THERMOSTATIC EXPANSION VALVE (TXV)

Replacing TXV on Indoor Coil (post-2006)

Instructions for replacing a TXV in newer indoor coils.

Make Piping Connections

Details important considerations for making refrigerant piping connections.

REFRIGERATION SYSTEM REPAIR

Leak Detection

Methods and tools for detecting refrigerant leaks in the system.

EVACUATION

Deep Vacuum Method

Explains the deep vacuum method for system evacuation.

EVACUATION

Triple Evacuation Method

Describes the triple evacuation method for system drying.

TROUBLESHOOTING WITH SUPERHEAT

Basic Diagnostics

Initial checks for diagnosing superheat issues in TXV systems.

Low Superheat with Normal or Low Suction Pressure

Troubleshooting steps for low superheat with normal/low suction pressure.

Low Superheat with High Suction Pressure

Troubleshooting steps for low superheat with high suction pressure.

High Superheat with Normal or Low Pressure

Troubleshooting steps for high superheat with normal/low pressure.

TROUBLESHOOTING WITH SUPERHEAT

Hunting Superheat

Addresses hunting superheat issues, typically an application problem.

Pseudo Evaporator Superheat Instructions

Provides instructions for calculating evaporator superheat using available data.

TROUBLESHOOTING WITH SUPERHEAT

Example 1

A detailed example of checking charge and superheat.

TROUBLESHOOTING WITH SUPERHEAT

Example 2

A detailed example of performing Pseudo Evaporator Superheat check.

Single-Stage Communicating Heat Pump System Functions and Sequence of Operation

Sequence of Operation

Overview of the control's sequence of operation for cooling and heating.

Cooling & Heating Operation

Details the sequence of operations for cooling and heating modes.

Communication and Status Function Lights For Evolution Control only, Green communications (COMM) Light

Explains the green COMM light for indicating communication status.

Amber Status Light

Describes the amber status light for operation modes and fault codes.

Outdoor Fan Motor Operation

Explains when the outdoor fan motor operates and its delays.

Time Delays

Lists and describes the various time delays in the unit's operation.

Crankcase Heater Operation

Explains the operation of the crankcase heater during off cycles.

Single-Stage Communicating Heat Pump System Functions and Sequence of Operation

Utility Interface

Describes the utility interface for interrupting compressor operation.

Low Ambient Cooling

Details requirements and operation for low ambient cooling.

Standard Thermostat low ambient cooling mode

Explains requirements for low ambient cooling with standard thermostats.

DEFROST

Covers defrost control intervals, auto defrost, and defrost hold.

Forced Defrost

Explains how to initiate a forced defrost cycle manually or via UI.

QUIET SHIFT-2

Describes the Quiet Shift-2 feature for reducing defrost noise.

Single-Stage Communicating Heat Pump System Functions and Sequence of Operation

LIQUID LINE SOLENOID ACCESSORY

Explains the liquid line solenoid's role in controlling refrigerant migration.

MAJOR COMPONENTS

Lists the major components controlled by the outdoor unit control board.

Control Board

Details the functions controlled by the heat pump control board.

Field Connections

Explains field wiring connections for Evolution and standard thermostats.

TROUBLESHOOTING

Provides guidance for diagnosing system faults and errors.

Systems Communication Failure

Describes troubleshooting steps for lost communication with the UI.

Model Plug

Explains the importance and function of the model plug.

Pressure Switch Protection

Details how pressure switches protect the unit operation.

Control Fault

Describes troubleshooting for a failed outdoor unit control board.

24V Brown Out Protection

Explains the 24V brown out protection feature and its voltage limits.

Compressor Voltage Sensing

Describes how the control monitors compressor voltage status.

Compressor Thermal Cutout or Loss of 230V Power

Addresses issues related to compressor thermal cutout or loss of power.

TROUBLESHOOTING

Contactor Shorted Detection

Diagnoses a contactor stuck closed or a wiring error.

No 230V at Compressor

Troubleshoots lack of 230V at the compressor due to open contactor or wiring.

Temperature Thermistors

Thermistor Sensor Comparison

Explains how the control compares outdoor and coil thermistor readings.

Failed Thermistor Default Operation

Describes default operations when thermistors fail.

Status Codes

Explains how to interpret status codes flashed by the amber status light.

TWO-STAGE 286B/289B 180B/187B

Application Guidelines

Provides application guidelines for two-stage units with Puron refrigerant.

Model Plug

Explains the function and importance of the model plug for unit identification.

TWO-STAGE 286B/289B 180B/187B

Airflow Selections for 187B / 286B / 180B/289B Using Non-Communicating (Non-Evolution) Thermostats

Guidance on selecting airflows for units with non-communicating thermostats.

Airflow Selection for 58CVA/58MVB Furnaces

Details airflow selection for 58CVA/58MVB furnaces.

Airflow Selection for FV4 Fan Coils for 180B, 187B, 286B, 289B Using Non-Communicating (Non-Evolution) Thermostats

Instructions for selecting airflows for FV4 fan coils with non-communicating thermostats.

GENERAL INFORMATION

Provides general information on unit operation and features.

Low Ambient Cooling

Discusses low ambient cooling requirements and operation modes.

Evolution Controlled low ambient cooling

Explains low ambient cooling capabilities with Evolution control.

Defrost

Details defrost control options and operation for two-stage units.

GENERAL INFORMATION

Defrost

Continues discussion on defrost control options and operation.

Defrost Hold

Explains the defrost hold feature for non-communicating systems.

Forced Defrost

Describes how to initiate a forced defrost cycle manually or via UI.

Quiet Shift

Explains the Quiet Shift feature for reducing defrost-related noise.

Quiet Shift-2 (communicating models)

Details the Quiet Shift-2 feature for communicating systems.

Liquid-Line Solenoid Accessory

Explains the liquid line solenoid's role in controlling refrigerant migration.

Check Charge

Provides guidance on checking and adjusting refrigerant charge.

Heating Check Chart Procedure

Outlines the procedure for checking system operation during heating.

System Functions and Sequence Of Operation (286B/89B/180B/187B)

Cooling and Heating Operation

Details the cooling and heating operation sequence for two-stage units.

Communication and Status Function Lights For Evolution Control only, Green communications (COMM) Light

Explains the green COMM light for indicating communication status.

Amber Status Light

Describes the amber status light for operation modes and fault codes.

Utility Interface With Evolution Control

Describes the utility interface for interrupting compressor operation.

Compressor Operation

Explains the operation of the two-stage scroll compressor.

Fan Motor

ECM Fan Motor Troubleshooting

Troubleshooting steps for ECM fan motor failures.

Time Delays

Lists and describes the various time delays in the unit's operation.

Thermistors

Outdoor Ambient Thermistor

Explains the function of the outdoor ambient air thermistor.

Outdoor Coil Thermistor (OCT)

Describes the outdoor coil thermistor's role in temperature sensing.

Thermistor Curve

Provides a chart of thermistor resistance values versus temperature.

Control Box

Contactor And Capacitor

Discusses contactors, capacitors, and incoming power connections.

Incoming Power

Details the connection and grounding of incoming power.

TROUBLESHOOTING

Troubleshooting circuit board

Guidance on troubleshooting the unit's control board.

Systems Communication Failure

Steps for diagnosing communication failures with the user interface.

Model Plug

Explains the function and importance of the model plug.

Pressure Switch Protection

Details how pressure switches protect the unit operation.

Control Fault

Describes troubleshooting for a failed outdoor unit control board.

Brown-Out Protection

Explains the 24V brown out protection feature and its voltage limits.

TROUBLESHOOTING

230v Brown-Out Protection Defeated

Explains how to defeat the brownout feature if severe noisy power conditions exist.

230V Line (Power Disconnect) Detection

Troubleshoots lack of 230V at the compressor contactor.

Compressor Voltage Sensing

Describes how the control monitors compressor voltage status.

Contactor Shorted Detection

Diagnoses a contactor stuck closed or a wiring error.

Compressor Thermal Cutout

Addresses issues related to compressor thermal cutout or loss of power.

Low or High Contactor Open/No 230V at Compressor Contractor

Troubleshoots open contactors or lack of 230V to the compressor.

Troubleshooting units for proper switching between low & high stages

Steps to troubleshoot proper switching between low and high stages.

Unloader Test Procedure

Details how to test the compressor unloader mechanism for proper operation.

Temperature Thermistors

Thermistor Sensor Comparison

Explains how the control compares outdoor and coil thermistor readings.

Failed Thermistor Default Operation

Describes default operations when thermistors fail.

Status Codes

Explains how to interpret status codes flashed by the amber status light.

Two Stage Non-Communicating

Operating Ambient

Details the operating ambient temperature ranges for cooling.

Airflow Selections (ECM Furnaces)

Guidance on selecting airflows for ECM furnaces.

Airflow Selection for 58CVA/58MVB Furnaces

Details airflow selection for 58CVA/58MVB furnaces.

Airflow Selection for FV4 Fan Coils for 180B, 187B, 286B, 289B Using Non-Communicating (Non-Evolution) Thermostats

Instructions for selecting airflows for FV4 fan coils with non-communicating thermostats.

Airflow Selection for Variable Speed Furnaces (non-communicating)

Details airflow selection for variable speed furnaces.

Airflow Selection for FV4C Fan Coils (non-communicating)

Instructions for selecting airflows for FV4C fan coils.

Airflow Selection for FZ4A Fan Coils (non-communicating)

Details airflow selection for FZ4A fan coils.

System Functions and Sequence Of Operation (286B/89B/180B/187B)

Cooling and Heating Operation

Details the cooling and heating operation sequence for two-stage units.

Communication and Status Function Lights For Evolution Control only, Green communications (COMM) Light

Explains the green COMM light for indicating communication status.

Amber Status Light

Describes the amber status light for operation modes and fault codes.

Utility Interface With Evolution Control

Describes the utility interface for interrupting compressor operation.

Compressor Operation

Explains the operation of the two-stage scroll compressor.

Fan Motor

ECM Fan Motor Troubleshooting

Troubleshooting steps for ECM fan motor failures.

Time Delays

Lists and describes the various time delays in the unit's operation.

CARE AND MAINTENANCE

Desert and Seacoast Locations

Special considerations for installation and maintenance in harsh environments.

Maintenance in desert and seacoast locations

Specific maintenance tasks for units in desert and seacoast environments.

Cleaning Coil

Provides instructions for cleaning the unit's coil effectively.

Cleaning Outdoor Fan Motor and Blade

Details the process for cleaning the outdoor fan motor and blade.

Need help?

Do you have a question about the Legacy and is the answer not in the manual?

Questions and answers