Summarization of Contents

About this document

Used symbols and signal words

Explains warning symbols, signal words, and other symbols used in the manual.

Checklists

Describes purpose of checklists for machine testing and commissioning.

Safety

Intended use and foreseeable misuse

Defines intended applications and potential misuse scenarios for the product.

Necessary competencies

Outlines qualifications and expertise required for personnel handling the device.

Responsibility for safety

Defines safety responsibilities between manufacturer and operator.

Disclaimer

States conditions for exclusion of manufacturer's liability.

Device description

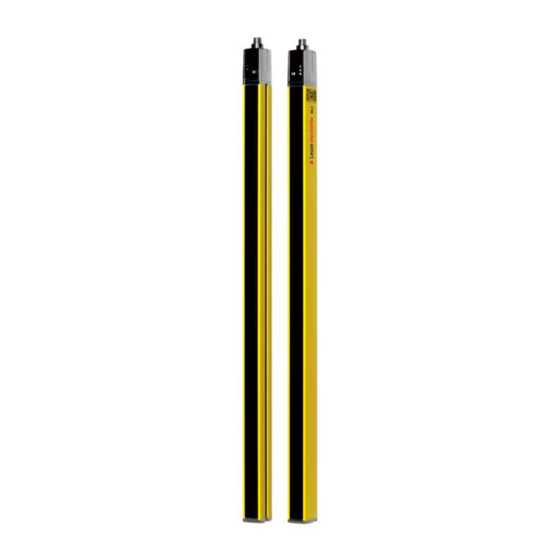

Device overview of the MLC family

Introduces the MLC product family and their features.

Connection technology

Describes the M12 connector interface for transmitter and receiver.

Operating indicators on the MLC 500 transmitter

Details function of LEDs on the MLC 500 transmitter.

Operating indicators on the MLC 530 SPG receiver

Explains LEDs and 7-segment display on MLC 530 SPG receiver.

Alignment display

Describes how the 7-segment display aids sensor alignment.

Smart Process Gating

Overview and principle

Introduces SPG as a timing-controlled control process for access guarding.

SPG requirements

Lists general and specific requirements for SPG operation.

SPG checklist for programmers

Provides a checklist for integrating SPG into a system.

SPG operating modes

Details the different operating modes available for SPG functions.

Operating mode 1 - Qualified stop

Explains the functions and parameters of Operating Mode 1.

Operating mode 4 - standard with short tolerance times

Details the functions and parameters of Operating Mode 4.

Operating mode 5 - Standard

Explains the functions and parameters of Operating Mode 5.

Operating mode 6 - Partial gating

Describes the functions and parameters of Operating Mode 6.

Controlled gating end

Explains how to minimize gaps by controlling the gating end.

Gating timeout extension

Details how to extend the bridging cycle time limit.

Gating sequence reset

Describes how to reset the gating sequence.

Gating restart

Explains how to restart the gating sequence after an interruption.

Override

Describes how to perform an override function.

Functions

Start/restart interlock RES

Explains the mandatory start/restart interlock for access guarding.

Transmission channel changeover

Details how to prevent interference between adjacent sensors.

Operating range selection

Explains how to select the operating range to prevent interference.

Signal output

Describes the signal output behavior during gating.

Blanking

Explains the use of blanking functions for objects in the protective field.

Fixed blanking

Describes the stationary blanking of protective field areas.

Fixed blanking with beam tolerance

Explains fixed blanking with tolerance for access guarding.

Applications

Access guarding with SPG

Highlights typical application areas for SPG in automotive and intralogistics.

Transport out of a danger zone

Details SPG application for vehicles exiting danger zones.

Inward transport of pallets

Explains SPG application for pallet transport into a machine.

Mounting

Arrangement of transmitter and receiver

Discusses optical protective device placement and delay times.

Calculation of safety distance S

Provides the general formula for calculating safety distance.

Calculation of safety distance if protective fields act orthogonally to the approach direction

Explains safety distance calculation for orthogonal approach.

Calculation of safety distance S for parallel approach to the protective field

Details safety distance calculation for parallel approach.

Minimum distance to reflective surfaces

Advises on minimum distances to avoid detection failures.

Resolution and safety distance during fixed blanking

Covers safety distance calculation with fixed blanking.

Preventing mutual interference between adjacent devices

Guides on avoiding interference between nearby sensors.

Mounting the safety sensor

Outlines the steps for physically mounting the sensor.

Suitable mounting locations

Provides a checklist for selecting appropriate mounting sites.

Fastening via BT-NC60 sliding blocks

Describes mounting using BT-NC60 sliding blocks.

Fastening via BT-2HF swivel mount

Details mounting with the BT-2HF swivel mount.

Fastening via BT-2SB10 swiveling mounting brackets

Explains mounting with BT-2SB10 swiveling brackets.

One-sided mounting on the machine table

Describes mounting the sensor on a machine table.

Electrical connection

Pin assignment transmitter and receiver

Details the pin assignments for transmitters and receivers.

Operating mode 1

Shows pin assignments for Operating Mode 1.

Operating mode 4

Details pin assignments for Operating Mode 4.

Operating mode 5

Explains pin assignments for Operating Mode 5.

Operating mode 6

Outlines pin assignments for Operating Mode 6.

Starting up the device

Switching on

Covers requirements and steps for powering up the safety sensor.

Aligning the sensor

Describes the process and importance of sensor alignment.

Unlocking start/restart interlock

Details how to unlock the start/restart interlock.

Teaching of fixed blanking areas

Describes the procedure for teaching fixed blanking areas.

Testing

Before commissioning and following modifications

Lists essential checks before initial use or after changes.

Checklist for integrator – to be performed prior to commissioning and following modifications

Provides a detailed checklist for system integrators.

To be performed periodically by competent persons

Outlines periodic testing requirements for qualified personnel.

Periodically by the operator

Defines periodic checks to be performed by operators.

Checklist – periodically by the operator

Lists checks for operators to perform periodically.

Maintenance

Cleaning the safety sensor

Provides instructions for cleaning soiled transmitter and receiver surfaces.

Troubleshooting

What to do in case of failure?

Guides users on identifying and resolving faults using displays and messages.

Operating indicators of the LEDs

Explains LED indicators on the transmitter and their causes/measures.

Error messages 7-segment display

Lists and explains error messages from the 7-segment display.

Disposing

Disposal of electronic components

Advises on proper disposal of electronic components.

Service and support

Service and support contact information

Provides contact information and service details.

Technical data

General specifications

Presents general specifications including protective field and safety data.

Dimensions and weights

Provides detailed dimensions and weight information for the device.

Order guide and accessories

Nomenclature

Explains the part designation system for ordering.

Part number code

Details the components of the safety sensor's part number code.

Part descriptions, examples

Provides examples and properties of different part numbers.

Part numbers of MLC 500 transmitter

Lists part numbers for MLC 500 transmitters by resolution and height.

Part numbers of MLC 530 SPG receiver

Lists part numbers for MLC 530 SPG receivers by resolution and height.

Accessories

Lists available accessories such as cables, connectors, and mounting hardware.

EU/EC Declaration of Conformity

EU/EC Declaration of Conformity

Official declaration of compliance with EU directives.

Need help?

Do you have a question about the MLC 510 and is the answer not in the manual?

Questions and answers