Summarization of Contents

Safety

General Safety Notes

General information and instructions for machine operation and maintenance.

Warning and Danger Signals

Explains signal words, symbols, and their consequences for safe product use.

Personnel Qualification and Authorization

Covers personnel qualifications, authorized persons, and owner/operator responsibilities.

Safe Operation and Usage

Details safety notes for maintenance, PPE, protective devices, designated use, and foreseeable misuse.

Pump Description

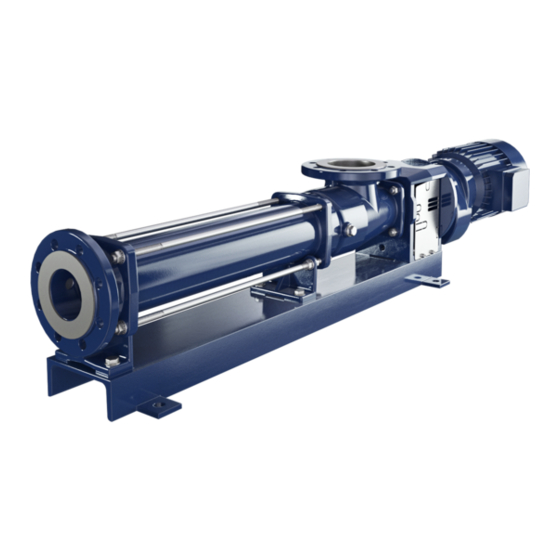

General Description and Features

Introduces seepex pumps as rotating displacement pumps with characteristic features.

Operating Principle

Explains how sealing bands create efficient pumping via geometric design.

Construction Details

Illustrates pump components with a diagram and part list.

Technical Data

Data Sheet and Specifications

Mentions data sheets, characteristic curves, and declarations are commission-specific.

Transport, Storage, and Disposal

Transport Safety and Procedures

Details safety, dimensions, symbols, lashing points, and unpacking for transport.

Temporary Storage and Corrosion Protection

Advises on applying corrosion protection for temporary storage in suitable conditions.

Disposal Guidelines

Provides guidance on environmental protection and proper disposal of the machine.

Assembly and Installation

Mounting and Space Requirements

Covers mounting tools, lifting gear, space considerations, and stator replacement dimensions.

Pump Assembly and Power Supply

Guides on assembling the pump, its power supply, and safety precautions.

Pipeline Installation

Covers suction, pressure, and residue-free pipeline assembly requirements.

Commissioning and De-commissioning

Pre-Commissioning Checks

Lists measures before commissioning, including pipelines, protective devices, and electrical connections.

Initial Commissioning Procedures

Details starting the pump, avoiding dry running, and managing pressure connections.

De-commissioning Process

Outlines switching off, emptying, removing the pump, and preservation for storage.

Maintenance

Preventive Maintenance and Lubrication

Covers preventive measures, pump downtime, and detailed lubrication points and types.

Inspection Schedule

Provides an inspection schedule with intervals and actions for joints, stator, shaft seal, and drive unit.

Dismantling and Reassembly

SCT Pump Dismantling & Reassembly

Covers dismantling and reassembly of SCT pump, stator, rotor, and unit components.

Rotating Unit Parts Handling

Procedures for dismantling, preparing, and mounting individual parts of the rotating unit.

Holding Band Assembly Procedures

Detailed steps for preparing, checking, assembling, and tensioning the holding band.

Shaft Seal Safety and Operation

Covers safety precautions and operating conditions for shaft seals.

Spare Parts

Spare Parts Identification

Mentions spare parts list and sectional drawing for component identification.

Ordering Spare Parts

Provides forms and information for ordering spare parts, including personal and commission details.

Spare Parts Catalog

Lists components for plug-in shafts, coupling rods, pumping elements, and miscellaneous items.

Complete Parts Packages

Details the contents of small and large wearing parts packages for maintenance.

Special Tools

Ordering Special Tools

Provides forms and information for ordering specialized tools required for pump assembly.

Special Tools Catalog

Lists special tools with their denominations, application, and order numbers.

Associated Documents

Accessories and Technical Information

Notes that accessories and technical information are commission-specific and external to these instructions.

Appendix

Manufacturer and Supplier Documents

States that manufacturer and supplier documents are commission-specific and not part of these instructions.

Need help?

Do you have a question about the BN 130-6LS and is the answer not in the manual?

Questions and answers