Summarization of Contents

Introduction and Symbols

Manual Overview

Details on the manual's purpose and user guidance.

Understanding Machine Symbols

Explains the meaning of various symbols used throughout the manual.

Safety and Training Guidelines

Covers employer responsibilities and general training requirements for machine operation.

Safety and Hazard Warnings

General Safety Precautions

Essential safety rules for personal protection, machine care, and regulatory compliance.

Safety Symbol and Label Guidance

Explanation of safety symbols and instructions for maintaining labels.

Key Safety Warnings and Procedures

Details critical actions for maintenance, hazard zone awareness, and operation safety.

Safety Label Placement Diagram

Illustrates the location of all safety warning labels on the implement.

Measured Sound Pressure Levels

Presents noise level data for tractor-only and tractor-implement configurations.

Safe Lifting Procedures

Provides instructions and warnings for safely lifting the machine with equipment.

Machine Familiarization

Intended Application of the Machine

Defines the proper agricultural uses for the NGH and NGS harrows.

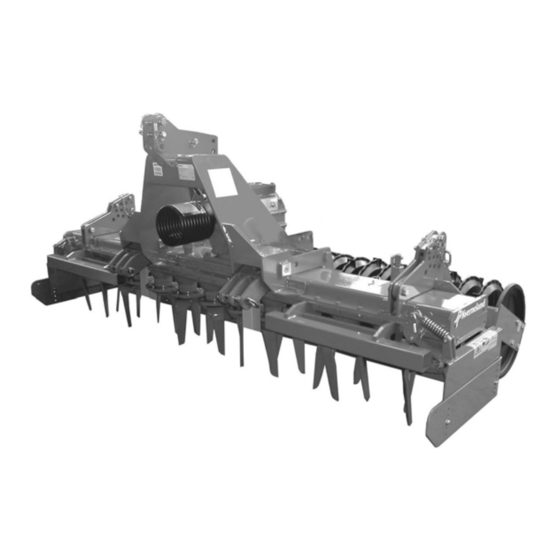

Identification of Machine Components

Lists and illustrates key parts of the NGH and NGS harrow models.

Detailed Technical Specifications

Provides technical data including model, weight, and dimensions for NGH and NGS series.

Machine Delivery and Preparation

Initial Inspection and Setup

Covers checks upon delivery and essential preparation steps before use.

Roller Setup for Field Work

Instructions for correctly positioning the roller for optimal field performance.

Lateral Stone Guard Adjustment

Guides adjustment of stone guards from transport to working position.

Hitching the Implement

Tractor Linkage Compatibility

Ensures correct 3-point linkage category matching between tractor and implement.

Harrow Attachment Procedure

Step-by-step guide for connecting the harrow to the tractor's hydraulic linkage.

Tractor-Implement Weight Limits

Critical warnings on exceeding maximum tractor and implement weight capacities.

Drive Shaft Installation and Checks

Details on checking and connecting the drive shaft for safe power transmission.

Connecting Drive Shaft to Harrow

Procedure for securely attaching the drive shaft to the implement's input.

Connecting Drive Shaft to Tractor

Procedure for safely connecting the drive shaft to the tractor's PTO.

Work Preparation and Checks

Fluid and Lubricant Level Verification

Instructions for checking transmission grease and gearbox oil levels.

Gearbox Oil Level Management

Details on checking and topping up gearbox oil for different types.

Tractor PTO Speed and Working Speed

Table of standard gearbox speeds and recommended PTO speeds for optimal results.

Speed Selection and Gearbox Operations

Guidance on selecting speeds for exchange and lever-change gearboxes.

Lever Change Gearbox Speed Adjustment

Step-by-step instructions for adjusting speeds on the lever-change gearbox.

Road Transport Procedures

Road Transport Safety and Width Limits

Emphasizes safety rules and maximum transport width for road travel.

Stone Guard Securing for Transport

Instructions for positioning stone guards to limit movement during transport.

Field Operation Setup

Adjusting Lateral Stone Guards

Procedure for setting lateral stone guards to the correct working position.

Setting the Working Depth

Guide to adjusting the machine's working depth using pin settings.

Levelling Bar Adjustment for Soil

Instructions for adjusting the levelling bar to manage soil and clods.

Positioning Track Eradicators

Details on positioning track eradicators centrally in tractor tracks for effective operation.

Care and Storage Instructions

Machine Storage and Maintenance

Guidelines for safe storage, including winterization and pre-season checks.

Maintenance and Lubrication

Oil and Grease Management

Procedures for changing gearbox oil and applying necessary grease.

Gearbox Oil and Interval Specifications

Details on oil types, quantities, and change intervals for gearboxes.

Transmission Grease Capacities

Table listing grease types and quantities for different machine models.

Lubricant Viscosity Comparison

Chart comparing lubricant viscosities across ISO VG, AGMA, and SAE standards.

Component Maintenance

Replacing Harrow Tines

Step-by-step guide for safely removing and replacing worn harrow tines.

Packer Roller Scraper Adjustment

Instructions for adjusting or replacing scrapers on the packer roller.

Disc Roller Scraper Adjustment

Guide to adjusting or replacing scrapers and blades on disc rollers.

Optional Accessories

Universal Seed Drill Attachment

Information on the universal seed drill attachment, including assembly and connection.

Hydraulic Seed Drill Attachment

Details on the hydraulic seed drill attachment, covering assembly and attachment to the harrow.

Accord Seed Drill Mounting Frame

Instructions for assembling and positioning the Accord triangular mounting frame.

Troubleshooting Guide

Drive Shaft and Gearbox Problems

Addresses common issues with drive shafts (noise, wear) and gearboxes (overheating).

Oil Leaks and Machine Obstructions

Covers oil leakage from tine holders and soil accumulation due to bent guards.

Warranty and Service Support

Understanding Warranty Terms

Outlines the conditions and limitations of the machine's warranty coverage.

Obtaining Service and Support

Provides essential information required for contacting customer service for assistance.

End-of-Life Machine Disposal

Environmentally Responsible Disposal

Guidelines for disposing of metal, rubber, plastic, oil, and electrical components.

EU Conformity Declaration

Product Compliance Statement

Declaration of conformity for the NGH and NGS models with EC Directive 2006/42/EC.

Need help?

Do you have a question about the NGS 301 and is the answer not in the manual?

Questions and answers