Table of Contents

Advertisement

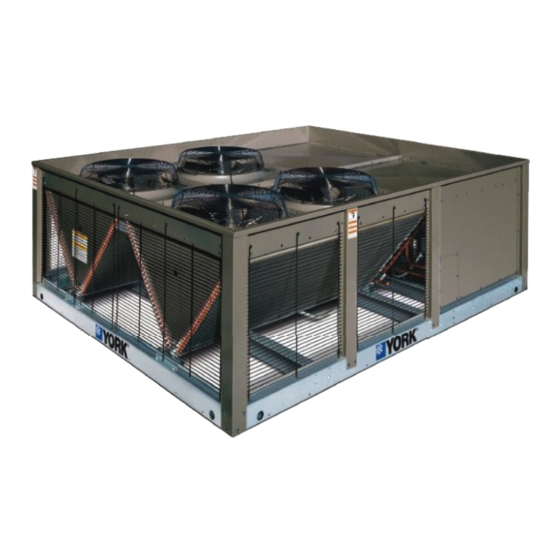

R-410A

MODELS:

YD360 Thru 600

30 - 50 Ton

60 Hertz

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Renewal Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Agency Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Phasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1 YD360 thru 600 Physical Data . . . . . . . . . . . . . . . . . . . . . 4

2 Unit Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Corner Weight & Center Of Gravity (Inches) . . . . . . . . . . 6

4 Minimum Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Electrical Data - Outdoor Unit . . . . . . . . . . . . . . . . . . . . . 9

1 Corner Weights & Center Of Gravity . . . . . . . . . . . . . . . . 6

2 Typical Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Matched with YD360/480/600 Condenser . . . . . . . . . . . 12

4 Typical ND360/480 & M1CZ600A Liquid Line Solenoid

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Typical Liquid Line Solenoid Wiring . . . . . . . . . . . . . . . . 13

6 YD Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7 30 Ton Power And Control Wiring Connections . . . . . . 15

9 30 Ton Piping Connections . . . . . . . . . . . . . . . . . . . . . . 16

TABLE OF CONTENTS

Refrigerant Mains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Piping And Electrical Connection Sizes . . . . . . . . . . . . . . 16

Piping And Electrical Connections . . . . . . . . . . . . . . . . . . 17

Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Crankcase Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Board Navigation Examples:. . . . . . . . . . . . . . . . . . . . . . . 21

Typical Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Start-Up Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

LIST OF TABLES

6 Unit Dimensions (Inches) . . . . . . . . . . . . . . . . . . . . . . . . 14

(Inches) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8 Electrical Power Knockout Sizes (Inches) . . . . . . . . . . . 16

9 Smart Equipment™ UCB Details . . . . . . . . . . . . . . . . . . 23

LIST OF FIGURES

10

40 & 50 Ton Piping Connections . . . . . . . . . . . . . . . . . 17

11 Fan Orientation Control Box End . . . . . . . . . . . . . . . . . . 19

12 Compressor Location . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

13 Unit Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

14 YD360 Charging Curves . . . . . . . . . . . . . . . . . . . . . . . . 29

15 YD480 Charging Curves . . . . . . . . . . . . . . . . . . . . . . . . 29

16 YD600 Charging Curves . . . . . . . . . . . . . . . . . . . . . . . . 30

17 Typical 208/230 Volt, YD360/480/600 Condensing Unit

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

18 Typical 460/575 Volt, YD360/480/600 Condensing Unit

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5012886-YIM-B-0517

Advertisement

Table of Contents

Summarization of Contents

Unit Nomenclature

Model Number Nomenclature

Details the coding system for model numbers.

General Unit Overview

Provides an overview of the condensing units' design and installation.

Safety and Pre-Installation

References, Approvals, and Inspections

Lists related documents, agency approvals, and inspection guidance.

Renewal Parts

Information on obtaining authorized replacement parts.

Installation Guidelines

Installation Limitations and Location

Requirements for installation, location selection, rooftop, and ground level placements.

Clearances and Rigging

Minimum Clearances

Specifies required clearances around the unit for airflow and servicing.

Rigging Procedures

Instructions and precautions for safely moving and lifting the unit.

Electrical and Wiring

Power and Control Wiring

Details for power supply, unit wiring, and routing control wires.

Compressor Information and Maintenance

Covers compressor types, POE oil, crankcase heaters, and phasing requirements.

Refrigerant Piping

Line Sizing and Precautions

Factors for sizing refrigerant lines and best practices for piping installation.

Start-Up Procedures

Crankcase Heater and Pre-Start Checks

Procedures for crankcase heater energization and pre-startup verification.

Initial Start-Up Steps

Steps for applying power and preparing for compressor startup.

Unit Operation

Unit Control and Safety Systems

Overview of Smart Equipment controls, safety features, and pump-out function.

Cooling Sequence and Fan Operation

Details cooling stages, blower operation, and condenser fan cycling.

Four-Stage Thermostat Operation

Connecting a 4-stage thermostat for unit control.

Smart Equipment Control Board Navigation

Navigation Components Overview

Lists components for accessing and navigating the control board.

Understanding the Local LCD

Step-by-step guide to navigating the unit's local LCD display.

Startup Sheet and Data

Startup Checklist and Warranty

Checklist for startup verification and statement on equipment warranty.

Equipment Startup Process

Instructions for completing the startup using the LCD or MAP Gateway.

Safety Warnings and Design Information

General Safety Warnings

Critical safety warnings for technician and equipment during startup.

Design Application Information

Placeholder for application specific data from the specifying engineer.

Reference and Inspection Checklists

General and Refrigerant Line Inspection

Checklists for unit, refrigerant lines, and air moving components.

Air Moving Inspection

Specific inspection points for fan motors and related components.

Operating Measurements

Air Flow Measurements

Procedures and fields for recording air flow measurements and adjustments.

Cooling Measurements and Safeties

Recording cooling operating parameters and refrigerant safety checks.

Electric Heating Measurements

Fields for recording electric heating operational data.

Staging Controls and Final Inspection

Staging Controls Verification

Verifying proper operation of heating/cooling staging and VFD.

Final Inspection and Data Backup

Final checks on set points, options, panels, and saving configuration data.

Need help?

Do you have a question about the YD600 Series and is the answer not in the manual?

Questions and answers