Table of Contents

Advertisement

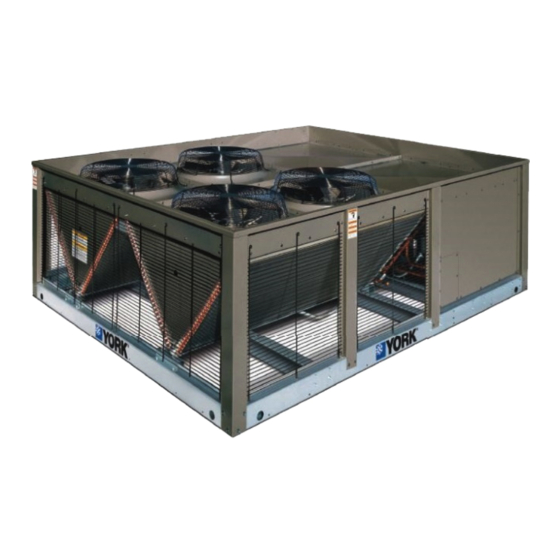

R-410A

MODELS:

YD360 Thru 600

30 - 50 Ton

60 Hertz

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Renewal Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Agency Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Phasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1 YD360 thru 600 Physical Data . . . . . . . . . . . . . . . . . . . . . 4

2 Unit Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Corner Weight & Center Of Gravity (Inches) . . . . . . . . . . 6

4 Minimum Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Electrical Data - Outdoor Unit . . . . . . . . . . . . . . . . . . . . . 9

1 Corner Weights & Center Of Gravity . . . . . . . . . . . . . . . . 6

2 Typical Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Matched with YD360/480/600 Condenser . . . . . . . . . . . 12

4 Typical ND360/480 & M1CZ600A Liquid Line Solenoid

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Typical Liquid Line Solenoid Wiring . . . . . . . . . . . . . . . . 13

6 YD Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7 30 Ton Power And Control Wiring Connections . . . . . . 15

9 30 Ton Piping Connections . . . . . . . . . . . . . . . . . . . . . . 16

TABLE OF CONTENTS

Refrigerant Mains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Piping And Electrical Connection Sizes . . . . . . . . . . . . . . 16

Piping And Electrical Connections . . . . . . . . . . . . . . . . . . 17

Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Crankcase Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Board Navigation Examples:. . . . . . . . . . . . . . . . . . . . . . . 21

Typical Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Start-Up Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

LIST OF TABLES

6 Unit Dimensions (Inches) . . . . . . . . . . . . . . . . . . . . . . . . 14

(Inches) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8 Electrical Power Knockout Sizes (Inches) . . . . . . . . . . . 16

9 Smart Equipment™ UCB Details . . . . . . . . . . . . . . . . . . 23

LIST OF FIGURES

10

40 & 50 Ton Piping Connections . . . . . . . . . . . . . . . . . 17

11 Fan Orientation Control Box End . . . . . . . . . . . . . . . . . . 19

12 Compressor Location . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

13 Unit Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

14 YD360 Charging Curves . . . . . . . . . . . . . . . . . . . . . . . . 29

15 YD480 Charging Curves . . . . . . . . . . . . . . . . . . . . . . . . 29

16 YD600 Charging Curves . . . . . . . . . . . . . . . . . . . . . . . . 30

17 Typical 208/230 Volt, YD360/480/600 Condensing Unit

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

18 Typical 460/575 Volt, YD360/480/600 Condensing Unit

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5012886-YIM-B-0517

Advertisement

Table of Contents

Summarization of Contents

Nomenclature

Configured Split Condenser Model Number Nomenclature

Explains the breakdown of the model number for split system condensers.

General Unit Description

System Application Caution

Warning about system application and potential failures.

Safety and Reference Information

Safety Considerations

Guidance on safety warnings, cautions, and notes.

Reference Documents

List of related documents for installation and operation.

Renewal Parts

Information on obtaining authorized replacement parts.

Agency Approvals

Details of CSA certification for unit usage.

Unit Inspection

Procedure for inspecting the unit upon receipt.

Physical and Application Data

Physical Data Table

Detailed physical specifications for YD360, YD480, and YD600 models.

Unit Application Data Table

Application parameters including voltage and temperature limits.

Installation and Location Guidelines

Installation Limitations

Requirements for installation adhering to national and local safety codes.

Location Selection

Guidelines for selecting suitable locations for the unit.

Rooftop Locations

Specific considerations for installing the unit on a rooftop.

Ground Level Locations

Requirements for a stable base at ground level installations.

Weight and Rigging Information

Corner Weight and Center of Gravity Data

Table detailing weight distribution and center of gravity points.

Center of Gravity Diagram

Diagram illustrating corner weights and center of gravity.

Clearances and Rigging Procedures

Minimum Clearances Table

Required clearances for air flow and servicing.

Air Discharge Obstruction Warning

Warning against obstructing the condenser air discharge.

Rigging Guidelines

Instructions for safely lifting and moving the unit.

Rigging Diagram

Illustration of proper rigging techniques with spreader bars.

Rigging Cautions

Cautions regarding spreader bar length and fork truck usage.

Electrical and Control Wiring

Power Wiring Requirements

Guidelines for connecting power supply to the unit.

Power Wiring Code Compliance

Warning for adhering to electrical codes for wiring.

Control Wiring Routing

Instructions for routing low voltage control wires.

Compressor Specifications

Information on scroll compressors and R-410A refrigerant compatibility.

Refrigerant and Oil Handling Cautions

Cautions regarding R-410A refrigerant and POE oil.

POE Oil on Roofing Caution

Warning about potential damage from POE oil to roofing materials.

Compressor Mounting Bolt Caution

Instruction not to loosen compressor mounting bolts.

Compressor Crankcase Heaters

Function of crankcase heaters for compressor protection.

Compressor Phasing and Rotation

Importance of correct compressor rotation for proper operation.

System Open to Atmosphere Caution

Warning against leaving the system open to the atmosphere.

Electrical Data Summary

Outdoor Unit Electrical Data

Table detailing electrical specifications for the outdoor unit.

Refrigerant Piping and System Setup

Split-System Application Considerations

Caution regarding application considerations for split systems.

Refrigerant Line Sizing

Factors to consider when sizing refrigerant piping.

Flash Gas Effects

Explanation of how flash gas impacts system performance.

Installation Precautions

General precautions for ensuring a clean and dry system.

Filter-Drier Installation Note

Note emphasizing the importance of filter-drier installation.

Nitrogen Flow During Brazing

Procedure for using nitrogen flow during brazing operations.

Refrigerant Line Installation Steps

Start Installation Procedure

Step-by-step guide to starting refrigerant line installation.

Access Port Cap Removal Warning

Warning regarding the removal of access port caps.

R-410A Refrigerant Handling Caution

Caution for handling R-410A refrigerant and compatible equipment.

Personal Protective Equipment Warning

Warning to wear safety glasses and gloves when handling refrigerants.

Piping Installation Reference

Reference to document for refrigerant piping recommendations.

Wiring Diagrams and Connections

Field Wiring Diagram for Evaporator Units

Diagram showing typical field wiring for evaporator units.

Isolation Relays for Non-ND Models Note

Note on using isolation relays for non-ND evaporator models.

Liquid Line Solenoids Note

Note on liquid line solenoids for specific DX coil matchups.

Liquid Line Solenoid Wiring Diagram

Diagram showing typical wiring for liquid line solenoids.

Liquid Line Solenoid Wiring Diagram

Typical Liquid Line Solenoid Wiring Diagram

Detailed wiring diagram for liquid line solenoids.

Unit Dimensions

YD Unit Dimensions Diagram

Diagram showing the physical dimensions of YD units.

Unit Dimensions Table

Table listing the dimensions (A-H) for YD models.

Power and Control Wiring Connections

30 Ton Wiring Connections Diagram

Diagram for power and control wiring on 30-ton units.

40 & 50 Ton Wiring Connections Diagram

Diagram for power and control wiring on 40/50-ton units.

Piping and Electrical Connection Details

Piping and Electrical Connection Sizes Table

Table of sizes for piping and electrical connections.

Electrical Power Knockout Sizes Table

Table specifying power knockout sizes.

30 Ton Piping Connections Diagram

Diagram showing piping connections for 30-ton units.

Start-Up Procedures and Checks

40 & 50 Ton Piping Connections Diagram

Diagram showing piping connections for 40/50-ton units.

Piping and Electrical Connections Overview

General information on connecting piping and electrical wiring.

Start-Up Overview

Introduction to the start-up process.

Crankcase Heater Operation

Instructions for ensuring proper crankcase heater operation.

Crankcase Heater Caution

Caution against starting the compressor without sufficient crankcase heat.

Pre-Start Checklist

A comprehensive checklist before unit start-up.

Initial Start-Up Power Supply

Steps for supplying power to the unit before compressor start.

Unit Operation and Safety Controls

Unit Control Overview

Description of Smart Equipment controls for unit functionality and safety.

Safety Controls Explained

Details on high-pressure, low-pressure, and ambient air sensors.

Pump Out Functionality

Explanation of the 'Pump-Out on Start-Up' feature.

Sequence of Operation

Description of how the unit operates through cooling stages.

Fan and Cooling Operation Details

Continuous Blower Operation

How the supply air blower operates continuously.

Intermittent Blower Operation

How the supply air blower operates intermittently.

Cooling Sequence of Operation

Step-by-step operation during cooling mode.

Condenser Fan Operation

How condenser fans regulate system head pressure.

Fan Orientation Diagram

Diagram showing fan orientation relative to the control box.

Four-Stage Thermostat Operation

Connecting and operating with a four-stage thermostat.

Component Location and Maintenance

Compressor Location Diagram

Diagram showing the location of compressors within the unit.

Control Board Navigation Components

Components needed to navigate the Smart Equipment control board.

Normal Maintenance Procedures

Routine maintenance for filters, coils, and motors.

Maintenance Cautions

Cautions regarding coil cleaning and air discharge.

Troubleshooting Warning

Warning for troubleshooting electrical components with power connected.

Troubleshooting Wire Designation Caution

Caution about potential variations in wire numbers or colors.

Smart Equipment Control Board Navigation

Firmware 3.2 Navigation Examples

Step-by-step guide to navigating the control board LCD.

Understanding the Local LCD Display

How to navigate the unit control board's LCD.

Control Board Commissioning Navigation

Accessing the Commissioning Menu

Steps to access and begin navigating the commissioning menu.

Viewing Commissioning Parameters

How to enter and view different parameter sections.

HVAC Zone and Indoor Fan Parameters

Overview of HVAC zone and indoor fan parameter sections.

Cooling Set Point Adjustment

Steps for adjusting cooling set points and parameters.

Saving Set Point Values

Procedure for saving adjusted set point values.

Unit Control Board Details

Unit Control Board Diagram

Diagram identifying components on the unit control board.

UCB Terminal Details

Description of terminals and functions on the Unit Control Board.

Further UCB Terminal Information

Continued UCB Terminal Details

Continuation of Unit Control Board terminal descriptions.

More UCB Terminal Information

Continued UCB Terminal Details

Further details on Unit Control Board terminals and connections.

Additional UCB Terminal Details

Continued UCB Terminal Details

More information on Unit Control Board terminals and safety switches.

UCB Terminal and Bus Details

Continued UCB Terminal Details

Details on SA BUS terminals and connections.

UCB Communication Sub-board Details

Continued UCB Terminal Details

Details on communication board terminals and LEDs.

Refrigerant Charging Curves

YD360 Charging Curves Diagram

Graph showing charging curves for 30 Ton units.

YD480 Charging Curves Diagram

Graph showing charging curves for 40 Ton units.

YD600 Charging Curves

YD600 Charging Curves Diagram

Graph showing charging curves for 50 Ton units.

Typical Wiring Diagrams

208/230 Volt Wiring Diagram

Diagram for 208/230V, 360/480/600 Condensing Unit wiring.

460/575 Volt Wiring Diagram

460/575 Volt Wiring Diagram

Diagram for 460/575V, 360/480/600 Condensing Unit wiring.

Start-Up and Warranty Information

Start-Up Sheet Overview

Instructions for start-up and service data collection.

Start-Up Checklist

A checklist of common points for equipment startup.

Warranty Statement

Statement detailing the equipment warranty coverage.

Equipment Startup Procedure

Guidance on completing startup using LCD or MAP Gateway.

Safety Warnings and Application Data

General Safety Warnings

Mandatory safety practices and warnings for technicians.

Lethal Voltages Warning

Warning about lethal voltages during startup checks.

Moving Parts Warning

Warning about exposed moving parts during startup checks.

Document Review Note

Note to review the entire document before startup procedures.

Design Application Information

Section for recording design application parameters from the engineer.

Reference and Inspection Checklists

General Inspection Checklist

Items to check during the general inspection of the unit.

Refrigerant Line Inspection Checklist

Items to verify for proper refrigerant line installation.

Air Moving Inspection Checklist

Items to check for proper air moving component installation.

Operating Measurements - Air Flow

Air Flow Measurement Procedures

Steps for measuring and adjusting air flow.

Electrical Data for Measurements

Table for recording electrical data during measurements.

Cooling and Electric Heating Measurements

Operating Measurements - Cooling

Table for recording cooling performance measurements.

Refrigerant Safeties Checks

Checks to verify the proper function of refrigerant safety devices.

Operating Measurements - Electric Heating

Table for recording electric heating performance measurements.

Final Inspection and Observations

Staging Controls Operation Verification

Verifying proper operation of heating/cooling staging controls.

Variable Frequency Drive Operation

Verifying proper operation of the variable frequency drive.

Final Inspection Checks

Final checks on set points, options, and panels.

Backup Control Board Settings

Saving control board parameters to a USB drive.

Observed Product Deficiencies

Space to record any observed product deficiencies or concerns.

Need help?

Do you have a question about the YD360 Series and is the answer not in the manual?

Questions and answers