Table of Contents

Advertisement

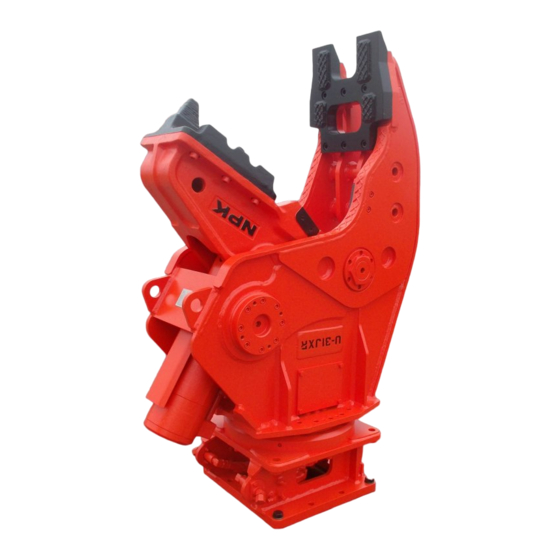

U and G-SERIES SECONDARY

CONCRETE CRUSHERS

MODELS U21J, U21JR, U31J, U31JR

OPERATION AND MAINTENANCE MANUAL

© Copyright 2018 NPK Construction Equipment, Inc.

G Series Crushers Operation Manual 10-18

U45J, U45JR, G7, G18J, G26J, G30JR

"Use Genuine NPK Parts"

"Use Genuine NPK Parts"

7550 Independence Drive

Walton Hills, OH 44146-5541

Phone (440) 232-7900

Toll-free (800) 225-4379

Fax (440) 232-6294

www.npkce.com

U000-9600B U and

Advertisement

Table of Contents

Summarization of Contents

Safety Information

Safety Notice Definitions

Explains DANGER, WARNING, CAUTION, and ATTENTION notice types.

Operational Safety Precautions

Lists essential safety rules for operating the NPK Crusher.

Maintenance Safety Precautions

Details safety measures to be followed during maintenance and repair.

Standard Maintenance Practices

Reviews common standard practices for hydraulic equipment maintenance.

Introduction and Compatibility

Product and Manual Overview

Welcome message and purpose of the operation and maintenance manual.

Excavator Compatibility Guidelines

Recommends matching crusher size to excavator weight for stability.

Model Specifications

U21J Secondary Crusher Specs

Details weight, jaw opening, oil flow, and cycle time for the U21J model.

U21JA Secondary Crusher Specs

Provides specifications for the U21JA model.

U21JR Secondary Crusher Specs

Provides specifications for the U21JR model.

U31J Secondary Crusher Specs

Provides specifications for the U31J model.

U31JA Secondary Crusher Specs

Provides specifications for the U31JA model.

U31JR Secondary Crusher Specs

Provides specifications for the U31JR model.

U45J Secondary Crusher Specs

Provides specifications for the U45J model.

U45JR Secondary Crusher Specs

Provides specifications for the U45JR model.

G7 Secondary Crusher Specs

Provides specifications for the G7 model.

G18J Secondary Crusher Specs

Provides specifications for the G18J model.

G26J Secondary Crusher Specs

Provides specifications for the G26J model.

G30JR Secondary Crusher Specs

Provides specifications for the G30JR model.

Serial Number Locations

U/UJR/U45J/JR Serial Number Location

Illustrates serial number placement for specific U-series models.

G7/G18J/G26J Serial Number Location

Illustrates serial number placement for specific G-series models.

G30JR Serial Number Location

Illustrates serial number placement for the G30JR model.

Crusher Booster and Cylinder System

Booster System Introduction

Explains the hydraulic booster's role in increasing cylinder pressure.

Boosted Cylinder Structure

Details the components that make up the boosted cylinder assembly.

Operating Principles

Describes the system's operation under no load and during booster actuation.

Hydraulic Installation Procedures

Hydraulic Installation Kits

Information on available hydraulic installation kits for NPK crushers.

Flow Direction and Shut-Off Valves

Explains hydraulic flow direction and the operation of shut-off valves.

Test Port Locations

Identifies locations for pressure testing ports on the hydraulic system.

Preventing Hydraulic Contamination

Guidelines to prevent contamination in the hydraulic system.

Hydraulic Quick Disconnects

Recommendations and warnings regarding the use of quick disconnects.

Mounting and Installation

Mounting Kit Components

Lists parts included in NPK mounting kits for crusher installation.

Rotating Top Bracket Features

Describes the U and G Series rotating top bracket's functionality.

Mounting and Removal Procedures

Step-by-step instructions for mounting and removing the crusher.

Crusher Storage Guidelines

Procedures for storing the crusher when it is not in use.

Hose Installation Tips

Whip Hose Installation Best Practices

Best practices for installing and torquing hydraulic hoses, including bend radius.

Operating Instructions and Techniques

General Operating Instructions

Essential instructions and warnings before operating the crusher.

Intended Application and Techniques

Specifies the intended use and proper operating techniques for the crushers.

Prohibited Operations

Lists operations that should not be performed with the crusher to prevent damage.

General Maintenance

Daily Inspection and Maintenance

Daily checks and maintenance tasks to ensure proper crusher function.

Lubrication Points and Schedule

Identifies all lubrication points and their recommended service intervals.

Cutter Blade Maintenance

Instructions for grinding, flipping, and replacing cutter blades for optimal performance.

Shim Kits Information

Details on available shim kits for model adjustments and maintenance.

Jaw Inspection and Maintenance

Weekly Jaw Inspection

Weekly checks for jaw wear and minimum gap maintenance.

Teeth Maintenance and Replacement

Procedures for maintaining, building up, and replacing jaw teeth.

Jaw and Tooth Rebuild Procedure

Detailed steps for rebuilding worn jaws and teeth using welding.

Frame Maintenance and Repair

Main Frame Rework Guide

Procedures for main frame rework based on wear levels.

Frame Crack Repair Procedure

Instructions for inspecting and repairing frame cracks using welding techniques.

Booster Cylinder Maintenance

Booster Cylinder Disassembly

Step-by-step guide for disassembling the booster cylinder.

Cylinder Components Inspection and Assembly

Procedures for inspecting, cleaning, and reassembling cylinder components.

Top Bracket Conversion

"U" Series Conversion Packages

Lists conversion packages for changing top bracket types on "U" series crushers.

Slewing Ring Maintenance

Measuring Axial Movement

Procedure for measuring axial movement in the slewing ring to check wear.

Rotation Bearing Outer Dirt Seal Replacement

Steps for replacing the outer dirt seal on the rotation bearing.

Swivel Manifold Maintenance

Swivel Manifold Assembly and Function

Describes the swivel manifold's structure and role in crusher operation.

Seal Leakage Testing and Replacement

Procedures for testing and replacing seals within the swivel manifold.

Torque Specifications

Fastener Torque Charts

Torque values for fasteners in main frame, cylinder, and rotation assemblies.

Hose Torque Specifications

Torque values for JIC and ORFS hose connections.

Troubleshooting Guide

Troubleshooting: Power and Speed Issues

Classifies problems and guides on initial diagnosis of power or speed loss.

Troubleshooting: Relief Valve Checks

Guides on checking and setting relief valves for low power conditions.

Troubleshooting: Intensifier Issues

Diagnosing problems related to the pressure intensifier's operation.

Troubleshooting: Slow Cycle Speed

Steps for diagnosing slow cylinder speed by checking hydraulic flow.

Troubleshooting: Jaw Drift and Rotation

Diagnosing jaw drift causes and resolving rotation issues.

Component Information and Warranty

Crusher Component Keywords

Glossary of common crusher part names and their labels.

Warranty Statements

Outlines NPK's warranty terms and conditions for the crushers.

Notes and Service Record

User Notes Section

Space for recording important crusher and excavator details.

Service Record Log

Log for recording maintenance and inspection dates.

Need help?

Do you have a question about the U31JR and is the answer not in the manual?

Questions and answers