Summarization of Contents

Important Safety Information

Machine Stability and Power Supply

Ensure stable placement and correct power supply for safe operation.

Grounding, Overload, and Cleaning Safety

Proper grounding, avoiding overloads, and safe cleaning procedures.

Operational Precautions

Rules on object insertion, water, cords, pets, supplies, and accessibility.

Service and Interlock Safety

Do not remove covers or defeat interlocks; refer servicing to professionals.

Battery Replacement Safety

Caution on battery type replacement to prevent explosion risk.

Safety Notes

Hazardous Moving Parts Warning

Warning about hazardous moving parts and keeping body parts away.

Battery Handling Caution

Warning about battery replacement type and disposal.

1 Installation

1-1. Unpacking List

Lists all items included with the machine, including optional items.

1-2. Choosing a Location

Guidelines for selecting an appropriate and safe place for the machine.

1-3. Handling the Machine

Instructions on the correct method for lifting and moving the machine safely.

1-4. Setting Up Your Machine

1-4-1. Power Cord

How to connect the power cord to the machine and power outlet.

1-4-2. Printer

Instructions for connecting a printer to the machine's serial interface port.

2 Description of the Parts

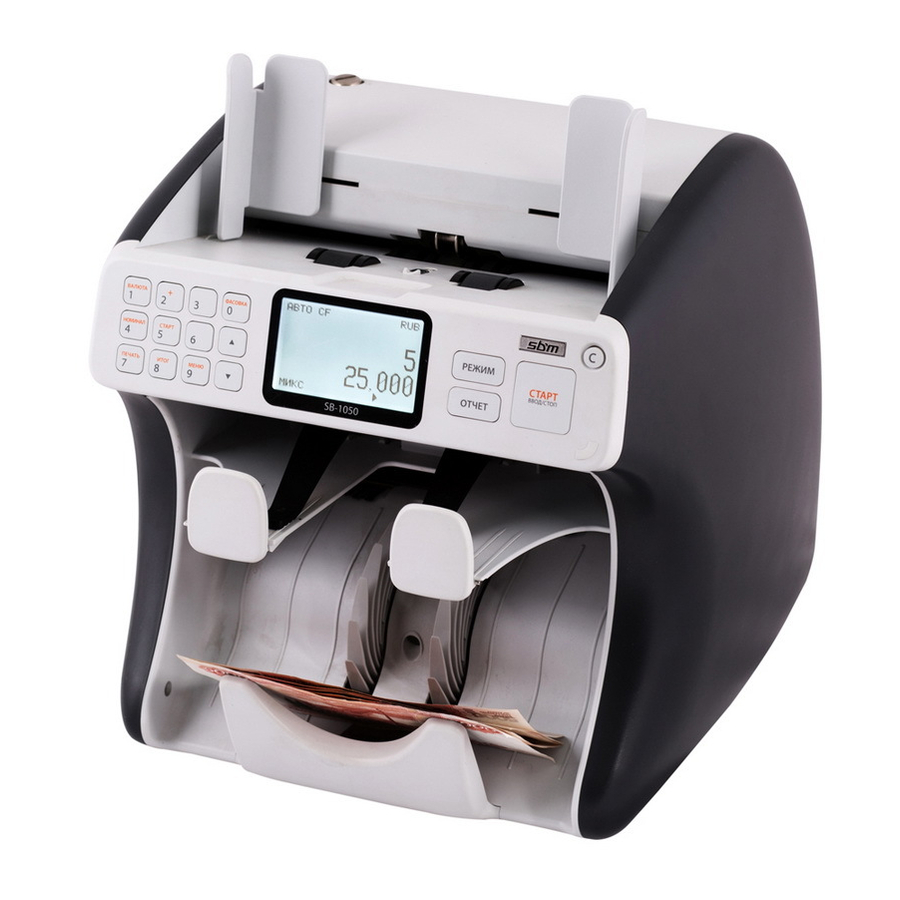

2-1. Out Side

Identifies and labels the external components of the machine.

2-2. Interface Port

Details the different types of interface ports and their functions.

3 Overview of Control Panel

3-1. Operation Panel

Shows a diagram of the control panel with labeled buttons.

3-2. Key Define

Explains the function of each key on the operation panel.

4 Reject Reason and Error Message

4-1. Reject Reason

Explains different reject reasons displayed by the machine.

5 Board & Component

5-1. Connection Diagram

Illustrates the internal wiring and component connections.

5-2. Board Descriptions

5-2-1. P-MAIN

Details the components and layout of the P-MAIN board.

5-2-2. P-POWER_IO

Details the components and layout of the P-POWER_IO board.

5-2-3. P-AMP

Details the components and layout of the P-AMP board.

5-2-4. P-IR_RCV

Details the components and layout of the P-IR_RCV board.

5-2-5. P-MRS_L

Details the components and layout of the P-MRS_L board.

5-2-6. P-MRS_R

Details the components and layout of the P-MRS_R board.

5-2-7. P-MRA

Details the components and layout of the P-MRA board.

5-2-8. P-JP_TRN

Details the components and layout of the P-JP_TRN board.

5-2-9. P-SP_TRN

Details the components and layout of the P-SP_TRN board.

5-2-10. P-JPSP_RCV

Details the components and layout of the P-JPSP_RCV board.

5-2-11. P-IF

Details the components and layout of the P-IF board.

5-2-12. P-OPE

Details the components and layout of the P-OPE board.

7 SERVICE MENU 1

7-1. How to enter SERVICE MENU 1

Step-by-step guide to access the Service Menu 1.

7-2. Service Menu1

Lists the main options available within Service Menu 1.

Service Menu 1 Options

1. ERROR STOP CTRL.

Controls whether the machine stops on errors or continues operation.

2. SENSOR LEVEL

Adjusts reference levels for Hopper and Double detection sensors.

3. SYSTEM REPORT

Displays counting reports and software/currency version information.

4. SET A/S CALL No.

Allows setting the machine's After-Sales service telephone number.

5. SET MACHINE S/N

For displaying and setting the machine's serial number.

6. SHADING

Explains the purpose of shading and its sub-options.

7. SENSOR SELECT

Allows enabling or disabling specific sensors for testing or operation.

8 SERVICE MENU 2

8-1. How to enter SERVICE MENU 2

Instructions to access the Service Menu 2.

8-2. Service Menu2

Lists the available test categories in Service Menu 2.

Service Menu 2 Tests

1. SENSOR TEST

Performs tests on various sensors including LED, Hopper, and logic status.

IR LOGIC TEST

Tests for IR sensor channels.

IRA TEST

Tests for IR note patterns.

2. KEY TEST

Verifies the functionality of each key on the control panel.

3. MOTOR TEST

Tests the driving and feeding functions of the machine's motors.

4. SELECTOR TEST

Tests the note selector's function for stacking or rejecting.

5. WING SPEED SETTING

Allows adjustment of the wing stacker speed.

9 Shading

What is Shading?

Defines Shading as creating a reference waveform for signal analysis.

Shading Preparation

Steps required before performing shading, including parameter loading and sensor cleaning.

10 Adjustment

10-1. Gap of ADF

Procedure for adjusting the Automatic Document Feeder (ADF) gap.

10-2. ADF & Pickup Roller Timing

How to adjust the timing of the ADF and pickup rollers.

10-3. Guide Selector

Adjustment procedure for the guide selector to prevent note damage.

10-4. Brightness of LCD (Back Light)

Steps to adjust the brightness of the machine's LCD screen.

10-5. Hopper sensitivity

Procedure for adjusting the sensitivity of the hopper sensor.

10-6. Reject Pocket Sensor Level

Adjusting the sensitivity of the reject pocket sensors.

13 Assembly Drawings

13-1. Cover Exp View

Exploded view of the machine's covers.

13-2. Ass'y Exp View

Exploded view of the assembled components.

13-3. Frame Exp View

Exploded view of the machine's frame.

13-4. Roller Exp View

Exploded view of the roller assembly.

13-5. Cover Door Top

Exploded view of the top door assembly.

13-6. Cover Door Top Upper

Exploded view of the upper part of the top door.

13-7. Housing Pocket

Exploded view of the housing pocket assembly.

13-8. Ass'y OP PANEL

Exploded view of the operational panel assembly.

13-9. Plate Side R

Exploded view of the right side plate assembly.

13-10. Plate Side L

Exploded view of the left side plate assembly.

13-11. Base Exp View

Exploded view of the machine's base.

13-12. Bkt Stacker Sensor

Exploded view of the stacker sensor bracket.

13-13. Cover Top

Exploded view of the top cover assembly.

13-14. Shaft Case Detector

Exploded view of the shaft case detector assembly.

13-15. Case Detector With MR

Exploded view of the case detector with Magnetic Reader.

13-16. Plate Reinforce

Exploded view of the plate reinforce assembly.

13-17. Plate Guide Upper

Exploded view of the upper plate guide assembly.

13-18. Plate Guide Lower

Exploded view of the lower plate guide assembly.

13-19. Exp Guide Lower-P

Exploded view of the lower guide assembly.

13-20. Bkt SMPS Bottom

Exploded view of the bottom SMPS bracket.

13-21. Bkt SMPS Top

Exploded view of the top SMPS bracket.

Need help?

Do you have a question about the SB-1050 and is the answer not in the manual?

Questions and answers