Table of Contents

Advertisement

Advertisement

Table of Contents

Summarization of Contents

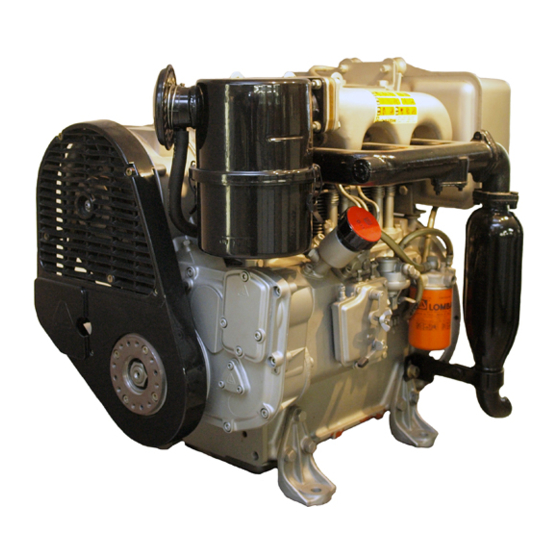

Engine Characteristics Overview

Characteristic Power, Torque, and Specific Consumption Curves

Presents power, torque, and fuel consumption curves for different engine models.

Maintenance, Oil Type, and Refilling Guide

Recommended Oil Type and Grades

Lists recommended oil types, grades, and viscosity for engine maintenance.

Engine Capacities

Details fuel tank and oil sump capacities for various engine models.

Maintenance Operations and Intervals

Outlines periodic maintenance operations and their recommended intervals.

Torque Specifications

Standard Bolt Torque Specifications

Provides torque values for standard bolts based on size and material grade.

Disassembly and Reassembly Procedures

Oil-Bath Air Cleaner Servicing

Instructions for checking and cleaning the oil-bath air cleaner.

Dry Air Cleaner for Specific Models

Details components and usage of the dry air cleaner for specific models.

Exhaust Manifold Inspection and Refitting

Procedures for inspecting and refitting the exhaust manifold.

Intake Manifold Checks

Instructions for checking and refitting the intake manifold.

Fan Control Belt Maintenance

Guidance on removing, checking, and adjusting the fan belt.

Belt Tension Adjustment Method

Method for adjusting belt tension using spacers or an adjustment bolt.

Blower Assembly Details

Describes the blower assembly and its components for different alternator types.

Oil Cooler Cleaning

Cleaning instructions for the oil cooler.

Fuel Tank Checks

Steps for disconnecting, emptying, and checking the fuel tank.

Flywheel Removal and Refitting

Procedure for removing and refitting the flywheel, including heat application.

Valve and Rocker Arm Clearance Setting

How to set valve and rocker arm clearance when the engine is cold.

Rocker Arm Assembly Dimensions

Provides dimensions for the rocker arm assembly.

Injector Checks and Refitting

Instructions for checking and refitting injectors, including tightening nuts.

Valve Component Details

Details components of the valve assembly and removal method.

Valve Spring Measurement

Instructions for measuring valve spring length under different loads.

Valve Material Specifications

Specifies materials used for intake and exhaust valves.

Valve Guides and Housings Dimensions

Provides dimensions for valve guides and their housings.

Valve Guide Insertion Procedure

Procedure for inserting valve guides into the cylinder head.

Clearance Between Valve Guides and Valves

Specifies dimensions and clearance limits for valve guides and valves.

Valve Seats and Housings Dimensions

Provides dimensions for valve seats and their bores.

Valve Seat Grinding and Lapping

Guidance on lapping valve seats and checking valve recess depth.

Injector Projection Adjustment

How to set injector nozzle projection using copper shims.

Pushrod Tube Spring Installation

Instructions for installing the pushrod tube spring with tool B.

Cylinder Head Tightening Sequence

Procedure for progressively tightening cylinder heads to 90 Nm.

Cylinder Bore Measurement and Wear Check

How to measure cylinder bore diameter and check for wear.

Cylinder Roughness Requirements

Specifies requirements for cylinder wall inclination and roughness.

Piston and Cylinder Dimensions

Details piston and cylinder dimensions and availability.

Checking for Original Piston Part

How to verify if a piston is an original spare part.

Piston Weight for Balance

Importance of weighing pistons to avoid unbalance during replacement.

Piston Rings End Gap Measurement

How to measure the end gaps of piston rings.

Piston Rings Fitting Sequence

Correct order for installing piston rings onto the piston.

Piston Refitting Procedure

Procedure for connecting the piston to the connecting rod.

Piston Clearance and Head Gasket

How head gasket thickness affects piston clearance.

Head Gasket Thickness Selection

How to select head gasket thickness based on piston clearance.

Connecting Rod Checks

Steps for removing connecting rods and performing checks.

Connecting Rod Alignment Check

Checking and correcting axial alignment of the connecting rod.

Connecting Rod Weight Balancing

Importance of weighing connecting rods for balance.

Connecting Rod Big End Bearing Installation

Proper fitting and tightening of connecting rod big end bearings.

Crankshaft Pulley Removal and Refitting

Procedure for removing and refitting the crankshaft pulley.

Timing Cover Removal and Refitting

Steps for removing and refitting the timing cover, checking oil seal.

Camshaft Gear Nut Tightening

How to loosen and tighten the camshaft gear nut.

Idler Gear and Support Servicing

Dimensions, clearance, and refitting of the idler gear.

Oil Pump Gear Removal and Refitting

Procedure for removing and refitting the oil pump gear.

Speed Governor Lubricating Tube

Description of the lubricating tube for the speed governor.

Timing Gear Removal for 5LD825-2

Instructions for removing and refitting the timing gear for 5LD825-2.

Timing Gear Removal for Other Models

Instructions for removing and refitting timing gears for other models.

Main Bearing Support, Flywheel Side

Details components of the main bearing support on the flywheel side.

Crankshaft Removal Procedure

Procedure for removing the crankshaft using a hammer.

Crankshaft Center Main Bearing Supports

How to fit and tighten crankshaft center main bearing supports.

Thrust Ring Installation and Check

Instructions for fitting thrust half-rings and checking wear.

Oil Sprayer Description

Description of the oil jet for lubricating pistons.

Crankshaft End Play Check

How to check crankshaft end play after refitting.

Crankshaft Lubrication Ducts Cleaning

Instructions for cleaning and checking crankshaft lubrication ducts.

Crankshaft Journal Radius Specifications

Specifies the radius values for crankshaft journals and crank pins.

Main Bearing and Connecting Rod Bearing Dimensions

Details dimensions for main journals, crankpins, and clearances.

Main Bearing Supports Dimensions

Provides dimensions for the main bearing supports.

Main Bearing Housings Dimensions

Provides dimensions for the main bearing housings.

Camshaft Removal Technique

How to tilt the engine for camshaft removal.

Camshaft Bearing and Journal Diameter

Dimensions for camshaft bearings, journals, and their clearances.

Camshaft Journals and Bores Dimensions

Specifies dimensions and clearances for camshaft journals/bores.

Intake/Exhaust Cam Height Measurement

How to measure intake/exhaust cam height using a micrometer.

Camshaft Plugs Servicing

Instructions for removing and refitting lubrication duct plugs.

Camshaft End Play Check

Procedure for checking camshaft end play.

Camshaft Timing Alignment

How to align timing marks for idler gear, crankshaft, and camshaft gear.

Valve Timing Without Marks

Method to set valve timing by piston position and tappet height.

Valve Timing Check Procedure

How to check valve timing using crankshaft rotation and measurements.

Hydraulic Pump PTO Installation

Information on installing Bosch hydraulic pumps on the gear side.

Hydraulic Pump 3rd PTO Group 2 Components

Lists components of the hydraulic pump 3rd p.t.o., group 2.

Speed Governor Identification

Identifies engine types fitted with ball-type or weight-type speed governors.

Ball-Type Speed Governor Components

Lists components of the standard ball-type speed governor.

Weight-Type Speed Governor Components

Lists components of the weight-type speed governor.

Speed Governor Operation Explanation

Explains how the speed governor maintains engine speed.

Starting Fuel Supply Spring

Description of the starting assistance device for fuel delivery.

Speed Governor Spring Hook-up Guide

How to hook the speed governor spring based on engine RPM.

Speed Governor Springs with Rocker Yoke

Details the system of springs and rocker yoke for idle speed control.

Tool for Speed Governor Adjustment

Lists available tools for adjusting speed governor to injection pump.

Speed Governor Timing with Injection Pump

Procedure for timing the speed governor with the injection pump.

Turbocharger Maintenance Notes

Maintenance notes and components of the turbocharger.

Lubrication System Details

Oil Pump Checks

Checks for gear teeth, clearances, and control shaft end float.

Oil Pressure Relief Valve Components

Lists components of the oil pressure relief valve.

Oil Filter Characteristics and Cleaning

Describes oil filter characteristics and cleaning.

Oil Pressure Check Procedure

How to connect a gauge and check oil pressure as a function of temperature.

Oil Pressure Curve at Idling Speed

Graph showing oil pressure vs. temperature at idling speed.

Oil Pressure Curve at Full Speed

Graph showing oil pressure vs. temperature at full speed.

Fuel System Components and Procedures

Fuel Feeding/Injection System (5LD825-3 Models)

Diagram and components of the fuel system for specific models.

Fuel Feeding/Injection System (5LD825-4 Models)

Diagram and components of the fuel system for other models.

Fuel Filter Specifications

Details fuel filter characteristics and maximum working pressure.

Fuel Feeding Pump Operation

Describes the diaphragm type fuel feeding pump operation.

Fuel Feeding Pump Drive Rod Protrusion Adjustment

How to adjust drive rod protrusion using gaskets.

Injection Pump Components Listing

Lists and illustrates the components of the injection pump.

Injection Pump Reassembly Steps

Steps for reassembling the injection pump.

Barrel and Plunger Dimensions (5LD825-2)

Dimensions for the barrel and plunger specific to 5LD825-2.

Barrel and Plunger Dimensions (5LD825-3)

Dimensions for the barrel and plunger specific to 5LD825-3.

Barrel and Plunger Dimensions (Other Models)

Dimensions for barrel and plunger for other models.

Injection Pump Delivery Valve Dimensions

Dimensions and displaced volume of the delivery valve.

Checking Barrel and Plunger for Leakage

Procedure for checking for internal leakage in barrel and plunger.

Checking Injection Pump Delivery Valve Sealing

How to check the sealing of the injection pump delivery valve.

Injection Pump Delivery Testing (5LD825-2)

Test data for injection pump delivery testing.

Injection Pump Delivery Testing (5LD825-3)

Test data for injection pump delivery testing for 5LD825-3.

Injection Pump Delivery Testing (Other Models)

Test data for injection pump delivery testing for other models.

Injection Pump for 5LD825-4 and 5LD930-4

Details the injection pump for 5LD825-4 and 5LD930-4 models.

Injection Pump Reassembly Preparation (Bosch PES)

Steps for preparing the Bosch PES type injection pump for refitting.

Injection Pump Reassembly to Engine (Bosch PES)

Procedure for refitting the Bosch PES type injection pump to the engine.

Static Injection Timing Procedure

How to set static injection timing using a testing device.

Injection Timing Corrections (Bosch PES)

How to correct injection timing by rotating the flange or pump.

Static Injection Timing Correction (5LD825-2 Models)

How to correct static injection timing by adding/removing shims.

Static Injection Timing Reference Marks

Identifies reference marks on crankcase and flywheel for timing.

Injection Timing Marks on Pulley and Gear Cover

Identifies reference marks on pulley and gear cover for timing.

Injector Components Overview

Lists components of the injector.

Injector Nozzle Features

Features of the nozzle, including hole size, spray angle, and cleaning.

Injector Setting Procedure

How to check and adjust injector setting pressure.

Electric System Components and Checks

Electrical Starting Layout (No Charging Light)

Diagram and components of the starting system without a charging light.

Electrical Starting Layout (With Charging Light)

Diagram and components of the starting system with a charging light.

12.5 V, 14 A Alternator Details

Features and dimensions of the 12.5V, 14A alternator.

Alternator Charging Curve (12.5 V, 14 A)

Graph showing charging curve for 12.5V, 14A alternator.

12 V, 21 A Alternator Details

Features and dimensions of the 12V, 21A alternator.

Alternator Charging Curve (12 V, 21 A)

Graph showing charging curve for 12V, 21A alternator.

Checking Cable Continuity

How to check stator winding continuity and insulation.

Voltage Regulator Information

Information on voltage regulator types and tab sizes.

Checking Voltage Regulator Operation

Procedure to check voltage regulator operation using voltmeter and ammeter.

Bosch G1 Alternator (14 V, 33 A)

Description of the optional Bosch G1 alternator.

Bosch G1 Alternator Layout

Diagram and components of the Bosch G1 alternator.

Bosch G1 Alternator Charging Curve

Graph showing charging curve for the 14V, 33A alternator.

Bosch JF (R) 12 V, Class 2.5 Starter Motor

Details of the Bosch JF (R) 12V starter, class 2.5.

Bosch JF (R) 12 V Starter Performance Curves

Performance curves for the Bosch JF (R) 12V starter motor.

Bosch JF 12 V, Class 3 Starter Motor

Details of the Bosch JF 12V starter, class 3.

Bosch JF Class 3 Starter Performance Curves

Performance curves for the Bosch JF class 3 starter motor.

Key Switch Functionality

Identifies the functions of the key switch positions.

Engine Settings and Adjustments

Idling Speed Setting (No-Load)

How to set the engine idling speed in no-load conditions.

Full Speed Setting (No-Load)

How to set the engine's full speed in no-load conditions.

Injection Pump Delivery Setting

Procedure for setting injection pump delivery on a dynamometer.

Standard Idling and Full Speed Setting

How to set idling and full speed for specific engine models.

Engine Stop Setting Procedure

Procedure for setting the engine to stop using screws and lever.

Engine Storage Procedures

Temporary Engine Protection (1-6 Months)

Instructions for protecting the engine for storage up to 6 months.

Permanent Engine Protection (Over 6 Months)

Additional instructions for protecting the engine for storage over 6 months.

Preparing Stored Engine for Operation

Steps to take to get a stored engine ready for use.

Special Equipment and Tools

Flywheel Puller Tool

Tool for removing the flywheel.

Yoke for Timing Control Gear Extraction

Tool for extracting timing control gears.

Rocker Arm Pin Extractor Tool

Tool for removing rocker arm pins.

Valve Spring Assembly Tool

Tool for assembling valve springs.

Injection Pump Lever Timing Gauge

Gauge for timing the injection pump lever.

Injection Pump Static Timing Test Device

Device for performing static timing tests on the injection pump.

Need help?

Do you have a question about the 5LD825-3 and is the answer not in the manual?

Questions and answers