Summary of Contents for Lombardini 12 LD 477/2

- Page 1 WORK SHOP MANUAL 12LD477-2, series engines, p.no. 1-5302-625 12 LD 477/2 Edition COMPILER TECO/ATI REG. CODE MODEL N° DATE OF ISSUE DATE ENDORSED REVISION 1-5302-625 50907 08-03 01.08.2003...

- Page 2 FOREWORD We have done all in our power to give up to date and accurate technical information in this manual. Lombardini engines are, however, constantly developing thus the data in this publication may be liable to modification without prior notice.

- Page 3 WARRANTY CERTIFICATE WARRANTY CERTIFICATE The products manufactured by Lombardini Srl are warranted to be free from conformity defects for a period of 24 months from the date of delivery to the first end user. For engines fitted to stationary equipment, working at constant load and at constant and/or slightly variable speed within the setting limits, the warranty covers a period up to a limit of 2000 working hours, if the above mentioned period (24 months) is not expired.

-

Page 4: Table Of Contents

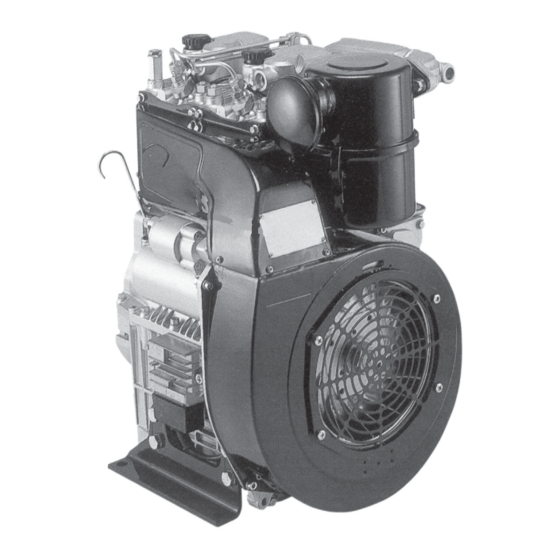

INDEX This manual contains pertinent information regarding the repair of LOMBARDINI air-cooled, indirect injection Diesel engines type 12LD477-2: updated August 01, 2003. TROUBLE SHOOTING __________________________________________________________ Page SAFETY AND WARNING DECALS - SAFETY INSTRUCTIONS ____________________________ ” MODEL NUMBER AND IDENTIFICATION _____________________________________________ ”... - Page 5 INDEX INJECTION EQUIPMENT ________________________________________________________ Page Checking injection pump ..............................26 Fuel circuit ..................................26 Injection pump ................................26 Injection pump assembly ............................... 27 Injection pump setting ..............................26 Injector checking and setting ............................28 Injectors ................................... 28 Testing air tightness ............................... 28 ELECTRICAL EQUIPMENT ______________________________________________________ Page Alternator checking (stator) .............................

- Page 6 INDEX ENGINE TESTING _____________________________________________________________ Page Checking for oil leaks ..............................42 Checking oil pressure ..............................42 Speed adjustment ................................42 Testing engine on brake ..............................43 STORAGE ___________________________________________________________________ Page How to prepare the engine for operation ........................44 Permanent protection (over 6 months) ........................... 44 Storage ....................................

-

Page 7: Trouble Shooting

TROUBLE SHOOTING POSSIBLE CAUSES AND TROUBLE SHOOTING The following table contains the possible causes of some failures which may occur during operation. Always perform these simple checks before removing or replacing any part. TROUBLE POSSIBLE CAUSE Clogged pipes Clogged fuel filter Air inside fuel circuit Clogged tank breather hole Faulty fuel pump... -

Page 8: Safety And Warning Decals - Safety Instructions

SAFETY INSTRUCTIONS • Lombardini Engines are built to supply their performances in a safe and long-lasting way. To obtain these results, it is essential for users to comply with the servicing instructions given in the relative manual along with the safety recommendations listed below. - Page 9 • Only check belt tension when the engine is off. • Only use the eyebolts installed by Lombardini to move the engine. These lifting points are not suitable for the entire machine; in this case, the eyebolts installed by the manufacturer should be used.

-

Page 10: Model Number And Identification

MODEL NUMBER AND IDENTIFICATION MODEL NUMBER ENGINE IDENTIFICATION Nr. Cylinders R.P.M. Displacement (cc) Customer's code Diesel Approval code LOMBARDINI Engine Serial Number Engine group number COMPILER TECO/ATI REG. CODE MODEL N° DATE OF ISSUE DATE ENDORSED REVISION 1-5302-625 50907 08-03... -

Page 11: Technical Data

TECHNICAL DATA CHARACTERISTICS ENGINE TYPE 12 LD 477-2 Number of cylinders Bore Stroke Swept volume cm³ Compression ratio 19:1 @ 3000 RPM 15(20,5) N 80/1269/CEE-ISO 1585 @ 3600 RPM 17(23) @ 3000 RPM 14(19) Power kW (HP) NB ISO 3046 - 1 IFN @ 3600 RPM 15,7(21,4) @ 3000 RPM... -

Page 12: Vcharacteristics

Max. power tolerance is 5%. Power decreases by approximately 1% every 100 m di altitude and by 2% every 5°C above 25°C. Note: Consult LOMBARDINI for power, torque curves and specific consumptions at rates differing from those given above. COMPILER TECO/ATI REG. -

Page 13: Overall Dimensions

OVERALL DIMENSIONS Note: Dimensions in mm COMPILER TECO/ATI REG. CODE MODEL N° DATE OF ISSUE DATE ENDORSED REVISION 1-5302-625 50907 08-03 01.08.2003... -

Page 14: Special Tools

SPECIAL TOOLS TOOL CODE DESCRIPTION 00365R0010 Extractor 00365R0940 Injection advance control tool 00365R0020 Flywheel extractor 00365R0040 Oil seal insertion tool 00365R0260 Oil seal protection cone 00365R0210 Injection pump spanner 00365R0450 Valve guide gauge Ø 7 mm (0.27 inch.) 00365R0850 Valve guide grinder Ø 7 mm (0.27 inch.) 00365R0540 Tool for valve seat 00365R0500... - Page 15 MAINTENANCE - RECOMMENDED OIL TYPE - REFILLING VIII Failure to carry out the operations described in the table may lead to technical damage to the machine and/or system MANUTENANCE INTERVAL (HOURS) OPERATION COMPONENT 500 2500 5000 OIL-BATH AIR CLEANER HEAD AND CYLINDER FINS CLEANING FUEL TANK INJECTOR...

-

Page 16: Maintenance - Recommended Oil Type - Refilling

VIII MAINTENANCE - RECOMMENDED OIL TYPE - REFILLING The engine could be damaged if allowed to operate with insufficient oil. It is also dangerous to add too much oil as its combustion could sharply increase the rotation speed. Use a suitable oil in order to protect the engine. The lubrication oil influences the performances and life of the engine in an incredible way. -

Page 17: Disassembly Of The Engine

DISASSEMBLY AND REASSEMBLY Besides disassembly and reassembly operations this chapter also includes checking and setting specifications, dimensions, repair and operating instructions. Always use original LOMBARDINI spare parts for repair operations. Flywheel extraction Use extractor cod. 00365R0020, as shown in figure 1. -

Page 18: Cylinder Heads

CHECKS AND OVERHAUL Cylinder heads Details of fig. 5: 1. Cylinder head - 2. Pipe - 3. O-Ring - 4. Rockerarms - 5. Rockers - 6. Cotters - 7. Plates - 8. Springs - 9. Guides - 10. Seats - 11. Valves - 12. - Page 19 CHECKS AND OVERHAUL Cutting of the valve seats involves the widening of the valve seat face P with a consequent reduction of seal of the valve itself, fig. 9 If face P is more than 2 mm wide, invert cutter and lower level Q of the seat, fig.

-

Page 20: Xchecks And Overhaul

CHECKS AND OVERHAUL Valves and springs In order to check the springs for possible failure measure the lengths under load as shown in figure 13. The permissible tolerance for loads and lengths is ± 10%. If the 14,6 kg figures measured do not fall within these values, the springs must be renewed. -

Page 21: Piston Rings - Pistons - Piston Pins

CHECKS AND OVERHAUL Piston rings - Pistons - Piston pins Check the wear of piston rings by fitting them into the cylinder through the lower end and measuring the end gap (fig.17). The values should be: Fitting mm Max. wear mm Piston ring Compression 0,30... -

Page 22: Connecting Rods

CHECKS AND OVERHAUL Connecting rods On the small end there is a groove (A, fig. 20) for the lubrication of the gudgeon pin. The small end and the gudgeon pin are coupled without a bush in between. Assembly clearance between connecting rod small end and piston pin in millimetres: Ø... -

Page 23: Crankshaft

CHECKS AND OVERHAUL Crankshaft Whenever the engine is dismantled, particularly for the replacement of cylinders and pistons due to wear caused by the aspiration of dust, it is good practice to check the condition of the crankshaft. 1. Remove the plugs “A” from the oil passages (fig.23). 2. -

Page 24: Camshaft

CHECKS AND OVERHAUL Camshaft Check cams and support pins for wear or scores. Check amount of wear by measuring points A and B shown in fig. 27 and 28 and comparing to the figures of the tables hereunder: exhaust inlet Distribution cam dimensions (fig. -

Page 25: Governor Lever And Spring

CHECKS AND OVERHAUL Governor lever and spring Check that the shoes (S, fig. 30) are level and that the springs have not lost their elasticity. Renew any excessively worn parts after consulting the spare parts catalogue. Supplement and governor spring dimensions (fig. 30): Lenght Lenght under Load... -

Page 26: Injection Equipment

INJECTION EQUIPMENT Fuel circuit Feeding is carried out by a diaphram pump actuated by a camshaft eccentric coupled to a cap. See assembly on page 36 and consult spare parts catalogue for replacement. Details of fig. 33: 1.Tank - 2.Diesel filter - 3.Feeding pump - 4.Injection pump - 5.Injection pipes - 6.Injectors - 7.Diesel discharge pipe. -

Page 27: Injection Pump Assembly

INJECTION EQUIPMENT The quantity of diesel is in relation to 1000 deliveries with the rack bar at 8 mm from the stop position. Ø Pumping Valve Ø Capacity Pump Engine element mm valve 12LD477-2 24 ÷ 26 1500 Injection pump assembly After having dismantled... -

Page 28: Injector Checking And Setting

INJECTION EQUIPMENT Testing air tightness Feed pressurized air at 6 kg/cm² into the fuel sullpy union and completely immerse the pump in oil or diesel fuel for about 20 ÷ 30 seconds (fig.40); check that no air bubbles are released. N.B.: Tightness can be checked by compressing the springs to 52.8 ÷... -

Page 29: Electrical Equipment

ELECTRICAL EQUIPMENT Electric starting with motor and alternator for battery re-charging Characteristics Starter motor: anticlockwise rotation. 12V - 1.5 HP (1.1 kW) Flywheel alternator: For re-charging 12V/280W batteries giving 17A charge at 3000 RPM. Regulator: Electronic with controlled diodes and preset for battery re-charging pilot light connection. -

Page 30: Alternator Checking (Stator)

ELECTRICAL EQUIPMENT Alternator checking (stator) Disconnect alternator cables from the regulator and check continuity between the windings with an Ohmmeter. Also check that there is good insulation between cables and earth (fig. 45). In the event of an open circuit, replace the stator. - Page 31 ELECTRICAL EQUIPMENT Diagram of electric starting wiring system with flywheel alternator (fig. 47). 1.Battery - 2.Regulator - 3.Alternator - 4.Starter motor - 5.Pressure gauge - 6.Oil pressure warning light - 7.Starter key - 8.Battery charging light. Diagram of electric starting wiring system with external alternator (fig.

-

Page 32: Engine Assembly

ENGINE ASSEMBLY Notice: These instructions are valid for engines up-dated prior to the publication of this manual. Any modifications must be checked on the technical circulars. Before assembling the engine carefully clean all parts and dry them with compressed air. Lubricate moving parts to prevent seizing when starting up. -

Page 33: Crankshaft Preparation

ENGINE ASSEMBLY XIII Crankshaft preparation The insertion of the main distribution gear onto the crankshaft must be carried out while hot. Heat by means of dry heating or an oil bath at 70/80 °C (fig. 53). Upper crankcase preparation 1. Insert accelerator internal lever onto crankcase taking care not to damage the oil seal O-Ring. -

Page 34: Timing Cover Assembly

8. Insert oil seal rings on the drive side of the crankshaft (fig. 58). A warped oil retainer may allow the introduction of air into the engine thus causing crankcase ventilation problems. Use genuine oil retainers with the LOMBARDINI. 9. Mount lower crankcase complete with studs, centering pins and bearings. -

Page 35: Fitting Of Oil Seal Rings

A warped oil retainer may allow the introduction of air into the engine thus causing crankcase ventilation problems. Use genuine oil retainers with the LOMBARDINI. The oil seal rings are to be fitted with the arrow pointing in the same direction of the crankshaft rotation. -

Page 36: Connecting Rod-Crankshaft Coupling

XIII ENGINE ASSEMBLY Feeding pump assembly 1. Insert fuel feeding pump cap into its housing and make sure it moves freely. The length of the cap is : 34 ÷ 34,2 mm 2. Fit gasket (0.5 mm and 0.2 mm thick). 3. -

Page 37: Cylinder Mounting

ENGINE ASSEMBLY XIII Piston ring fitting Fit rings onto pistons in the following order (fig. 68): 1. Chromed compression seal ring. 2. Torsional compression seal ring (with internal notch turned upwards). 3. Expander oil scraper ring. Piston ring working position Before mounting cylinders, rotate rings 120°... -

Page 38: Checking Injector Protrusion

XIII ENGINE ASSEMBLY Cylinder height adjustement Between the top face of the cylinder and the piston at top dead center, there must be a clearance of: 0,25 ÷ 0,35 mm In order to carry out this operation correctly, make the check with the cylinder pressed well down on its crankcase (fig. -

Page 39: Fitting Cylinder Heads

ENGINE ASSEMBLY XIII Adjustment is effected by inserting copper washers between the injector and injector supporting faces on the heads (fig. 76). Washer thickness 1 mm. Fitting cylinder heads Insert oil seal O-rings on rocker arm housing and fit the cylinder head in place. -

Page 40: Checking T.d.c

XIII ENGINE ASSEMBLY Injection pump fitting Fit injection pump into timing case inserting adjusting shim between supporting flange and crankcase (fig. 80). To facilitate the insertion of the pump, rotate the flywheel so as to bring the actuating cam to rest position and set the rack bar in a half way position. -

Page 41: Checking Start Of Injection

ENGINE ASSEMBLY XIII Checking start of injection 1. Connect fuel tank to injection pump. 2. Bring accelerator lever to max. position and piston, flywheel side, at compression beginning (cylinder No 1) All operations are to be carried out with the rack bar in working position to annul the delay caused by the notch on the pumping element of the injection pump. -

Page 42: Engine Testing

ENGINE TESTING Speed adjustment 1. With engine hot set minimum speed at 1000 RPM (fig. 88) and maximum to idle (fig. 89) at: 3150 RPM for engines at 3000 rpm 3750 RPM for engines at 3600 rpm 2. Then stop the engine. 3. -

Page 43: Testing Engine On Brake

ENGINE TESTING Testing engine on brake After having placed the engine on the brake (fig. 92), proceed with the following operations: 1. Check oil level (fig. 93). 2. Start engine and run at minimum speed. 3. Check oil pressure on pressure gauge (fig. 90). 4. -

Page 44: Storage

STORAGE Storage Prepare engines as follows for storage over 30 days Temporary protection (1/6 months) • Let engine run at idling speed in no-load conditions for 15 minutes. • Fill crankcase with protection oil MIL-1-644-P9 and let engine run at 3/4 full speed for 5/10 minutes. •... -

Page 45: Quick Reference Charts

QUICK REFERENCE CHARTS Couplings Spiel (mm) Grezen (mm) Camshaft journal and housing in timing cover 0,017÷ 0,047 Camshaft journal and housing in crankcase 0,015÷ 0,048 End gap of compression rings 0,30 ÷ 0,50 End gap of oil scraper rings 0,25 ÷ 0,40 Connecting rod and wrist pin 0,023 ÷... -

Page 46: Standard Screw Tightening Torques

QUICK REFERENCE CHARTS Tightening torques (Nm) Crankcase (12,8) Connecting rod 3,8 ÷ 4,0 (37,3 ÷ 39,3) Bolt on power take off end (245,5) Timing cover (9,8) Oil sump (12,8) Injectors (22,6) Injection pump (22,6) Oil pump cover (5,9) Cylinder head (49) Flywheel (274,9) - Page 47 NOTE COMPILER TECO/ATI REG. CODE MODEL N° DATE OF ISSUE DATE ENDORSED REVISION 1-5302-625 50907 08-03 01.08.2003...

- Page 48 E-MAIL: atl@lombardini.it Internet: http://www.lombardini.it La Lombardini si riserva il diritto di modificare in qualunque momento i dati contenuti in questa pubblicazione. Lombardini se rèserve le droit de modifier, à n'importe quel moment, les données reportées dans cette publication. Data reported in this issue can be modified at any time by Lombardini .

Need help?

Do you have a question about the 12 LD 477/2 and is the answer not in the manual?

Questions and answers