Advertisement

Link Product/Engine

| Product | Market Product | Engine |

| C234 TIER 4B (FINAL) [NHM435463 - ] | North America | F5BFL413A*B007 |

| C238 TIER 4B (FINAL) [NHM435463 - ] | North America | F5BFL413A*B007 |

| L234 TIER 4B (FINAL) [NHM435463 - ] | North America | F5BFL413A*B007 |

Torque

Minimum tightening torques for normal assembly

METRIC NON-FLANGED HARDWARE

| NOM. SIZE | CLASS 8.8 BOLT and CLASS 8 NUT | CLASS 10.9 BOLT and CLASS 10 NUT | LOCKNUT CL.8 W/CL8.8 BOLT | LOCKNUT CL.10 W/CL10.9 BOLT | ||

| UNPLATED | PLATED W/ZnCr | UNPLATED | PLATED W/ZnCr | |||

| M4 | 2.2 N·m (19 lb in) | 2.9 N·m (26 lb in) | 3.2 N·m (28 lb in) | 4.2 N·m (37 lb in) | 2 N·m (18 lb in) | 2.9 N·m (26 lb in) |

| M5 | 4.5 N·m (40 lb in) | 5.9 N·m (52 lb in) | 6.4 N·m (57 lb in) | 8.5 N·m (75 lb in) | 4 N·m (36 lb in) | 5.8 N·m (51 lb in) |

| M6 | 7.5 N·m (66 lb in) | 10 N·m (89 lb in) | 11 N·m (96 lb in) | 15 N·m (128 lb in) | 6.8 N·m (60 lb in) | 10 N·m (89 lb in) |

| M8 | 18 N·m (163 lb in) | 25 N·m (217 lb in) | 26 N·m (234 lb in) | 35 N·m (311 lb in) | 17 N·m (151 lb in) | 24 N·m (212 lb in) |

| M10 | 37 N·m (27 lb ft) | 49 N·m (36 lb ft) | 52 N·m (38 lb ft) | 70 N·m (51 lb ft) | 33 N·m (25 lb ft) | 48 N·m (35 lb ft) |

| M12 | 64 N·m (47 lb ft) | 85 N·m (63 lb ft) | 91 N·m (67 lb ft) | 121 N·m (90 lb ft) | 58 N·m (43 lb ft) | 83 N·m (61 lb ft) |

| M16 | 158 N·m (116 lb ft) | 210 N·m (155 lb ft) | 225 N·m (166 lb ft) | 301 N·m (222 lb ft) | 143 N·m (106 lb ft) | 205 N·m (151 lb ft) |

| M20 | 319 N·m (235 lb ft) | 425 N·m (313 lb ft) | 440 N·m (325 lb ft) | 587 N·m (433 lb ft) | 290 N·m (214 lb ft) | 400 N·m (295 lb ft) |

| M24 | 551 N·m (410 lb ft) | 735 N·m (500 lb ft) | 762 N·m (560 lb ft) | 1016 N·m (750 lb ft) | 501 N·m (370 lb ft) | 693 N·m (510 lb ft) |

NOTE: M4 through M8 hardware torque specifications are shown in pound-inches. M10 through M24 hardware torque specifications are shown in pound-feet.

METRIC FLANGED HARDWARE

| NOM. SIZE | CLASS 8.8 BOLT and CLASS 8 NUT | CLASS 10.9 BOLT and CLASS 10 NUT | LOCKNUT CL.8 W/CL8.8 BOLT | LOCKNUT CL.10 W/CL10.9 BOLT | ||

| UNPLATED | PLATED W/ZnCr | UNPLATED | PLATED W/ZnCr | |||

| M4 | 2.4 N·m (21 lb in) | 3.2 N·m (28 lb in) | 3.5 N·m (31 lb in) | 4.6 N·m (41 lb in) | 2.2 N·m (19 lb in) | 3.1 N·m (27 lb in) |

| M5 | 4.9 N·m (43 lb in) | 6.5 N·m (58 lb in) | 7.0 N·m (62 lb in) | 9.4 N·m (83 lb in) | 4.4 N·m (39 lb in) | 6.4 N·m (57 lb in) |

| M6 | 8.3 N·m (73 lb in) | 11 N·m (96 lb in) | 12 N·m (105 lb in) | 16 N·m (141 lb in) | 7.5 N·m (66 lb in) | 11 N·m (96 lb in) |

| M8 | 20 N·m (179 lb in) | 27 N·m (240 lb in) | 29 N·m (257 lb in) | 39 N·m (343 lb in) | 18 N·m (163 lb in) | 27 N·m (240 lb in) |

| M10 | 40 N·m (30 lb ft) | 54 N·m (40 lb ft) | 57 N·m (42 lb ft) | 77 N·m (56 lb ft) | 37 N·m (27 lb ft) | 53 N·m (39 lb ft) |

| M12 | 70 N·m (52 lb ft) | 93 N·m (69 lb ft) | 100 N·m (74 lb ft) | 134 N·m (98 lb ft) | 63 N·m (47 lb ft) | 91 N·m (67 lb ft) |

| M16 | 174 N·m (128 lb ft) | 231 N·m (171 lb ft) | 248 N·m (183 lb ft) | 331 N·m (244 lb ft) | 158 N·m (116 lb ft) | 226 N·m (167 lb ft) |

| M20 | 350 N·m (259 lb ft) | 467 N·m (345 lb ft) | 484 N·m (357 lb ft) | 645 N·m (476 lb ft) | 318 N·m (235 lb ft) | 440 N·m (325 lb ft) |

| M24 | 607 N·m (447 lb ft) | 809 N·m (597 lb ft) | 838 N·m (618 lb ft) | 1118 N·m (824 lb ft) | 552 N·m (407 lb ft) | |

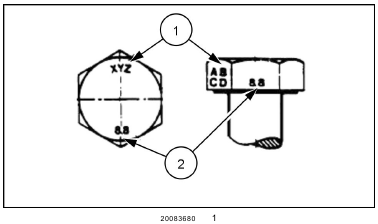

IDENTIFICATION

Metric Hex head and carriage bolts, classes 5.6 and up

- Manufacturer's Identification

- Property Class

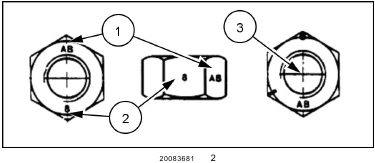

Metric Hex nuts and locknuts, classes 05 and up

- Manufacturer's Identification

- Property Class

- Clock Marking of Property Class and Manufacturer's Identification (Optional), i.e. marks 60° apart indicate Class 10 properties, and marks 120° apart indicate Class 8.

INCH NON-FLANGED HARDWARE

| NOMINAL SIZE | SAE GRADE 5 BOLT and NUT | SAE GRADE 8 BOLT and NUT | LOCKNUT GrB W/Gr5 BOLT | LOCKNUT GrC W/Gr8 BOLT | ||

| UN-PLATED or PLATED SILVER | PLATED W/ZnCr GOLD | UN-PLATED or PLATED SILVER | PLATED W/ZnCr GOLD | |||

| 1/4 | 8 N·m (71 lb in) | 11 N·m (97 lb in) | 12 N·m (106 lb in) | 16 N·m (142 lb in) | 8.5 N·m (75 lb in) | 12.2 N·m (109 lb in) |

| 5/16 | 17 N·m (150 lb in) | 23 N·m (204 lb in) | 24 N·m (212 lb in) | 32 N·m (283 lb in) | 17.5 N·m (155 lb in) | 25 N·m (220 lb in) |

| 3/8 | 30 N·m (22 lb ft) | 40 N·m (30 lb ft) | 43 N·m (31 lb ft) | 57 N·m (42 lb ft) | 31 N·m (23 lb ft) | 44 N·m (33 lb ft) |

| 7/16 | 48 N·m (36 lb ft) | 65 N·m (48 lb ft) | 68 N·m (50 lb ft) | 91 N·m (67 lb ft) | 50 N·m (37 lb ft) | 71 N·m (53 lb ft) |

| 1/2 | 74 N·m (54 lb ft) | 98 N·m (73 lb ft) | 104 N·m (77 lb ft) | 139 N·m (103 lb ft) | 76 N·m (56 lb ft) | 108 N·m (80 lb ft) |

| 9/16 | 107 N·m (79 lb ft) | 142 N·m (105 lb ft) | 150 N·m (111 lb ft) | 201 N·m (148 lb ft) | 111 N·m (82 lb ft) | 156 N·m (115 lb ft) |

| 5/8 | 147 N·m (108 lb ft) | 196 N·m (145 lb ft) | 208 N·m (153 lb ft) | 277 N·m (204 lb ft) | 153 N·m (113 lb ft) | 215 N·m (159 lb ft) |

| 3/4 | 261 N·m (193 lb ft) | 348 N·m (257 lb ft) | 369 N·m (272 lb ft) | 491 N·m (362 lb ft) | 271 N·m (200 lb ft) | 383 N·m (282 lb ft) |

| 7/8 | 420 N·m (310 lb ft) | 561 N·m (413 lb ft) | 594 N·m (438 lb ft) | 791 N·m (584 lb ft) | 437 N·m (323 lb ft) | 617 N·m (455 lb ft) |

| 1 | 630 N·m (465 lb ft) | 841 N·m (620 lb ft) | 890 N·m (656 lb ft) | 1187 N·m (875 lb ft) | 654 N·m (483 lb ft) | 924 N·m (681 lb ft) |

NOTE: For Imperial Units, 1/4 in and 5/16 in hardware torque specifications are shown in pound-inches. 3/8 in through 1 in hardware torque specifications are shown in pound-feet.

INCH FLANGED HARDWARE

| NOMINAL SIZE | SAE GRADE 5 BOLT and NUT | SAE GRADE 8 BOLT and NUT | LOCKNUT GrF W/Gr5 BOLT | LOCKNUT GrG W/Gr8 BOLT | ||

| UNPLATED or PLATED SILVER | PLATED W/ZnCr GOLD | UNPLATED or PLATED SILVER | PLATED W/ZnCr GOLD | |||

| 1/4 | 9 N·m (80 lb in) | 12 N·m (106 lb in) | 13 N·m (115 lb in) | 17 N·m (150 lb in) | 8 N·m (71 lb in) | 12 N·m (106 lb in) |

| 5/16 | 19 N·m (168 lb in) | 25 N·m (221 lb in) | 26 N·m (230 lb in) | 35 N·m (310 lb in) | 17 N·m (150 lb in) | 24 N·m (212 lb in) |

| 3/8 | 33 N·m (25 lb ft) | 44 N·m (33 lb ft) | 47 N·m (35 lb ft) | 63 N·m (46 lb ft) | 30 N·m (22 lb ft) | 43 N·m (32 lb ft) |

| 7/16 | 53 N·m (39 lb ft) | 71 N·m (52 lb ft) | 75 N·m (55 lb ft) | 100 N·m (74 lb ft) | 48 N·m (35 lb ft) | 68 N·m (50 lb ft) |

| 1/2 | 81 N·m (60 lb ft) | 108 N·m (80 lb ft) | 115 N·m (85 lb ft) | 153 N·m (113 lb ft) | 74 N·m (55 lb ft) | 104 N·m (77 lb ft) |

| 9/16 | 117 N·m (86 lb ft) | 156 N·m (115 lb ft) | 165 N·m (122 lb ft) | 221 N·m (163 lb ft) | 106 N·m (78 lb ft) | 157 N·m (116 lb ft) |

| 5/8 | 162 N·m (119 lb ft) | 216 N·m (159 lb ft) | 228 N·m (168 lb ft) | 304 N·m (225 lb ft) | 147 N·m (108 lb ft) | 207 N·m (153 lb ft) |

| 3/4 | 287 N·m (212 lb ft) | 383 N·m (282 lb ft) | 405 N·m (299 lb ft) | 541 N·m (399 lb ft) | 261 N·m (193 lb ft) | 369 N·m (272 lb ft) |

| 7/8 | 462 N·m (341 lb ft) | 617 N·m (455 lb ft) | 653 N·m (482 lb ft) | 871 N·m (642 lb ft) | 421 N·m (311 lb ft) | 594 N·m (438 lb ft) |

| 1 | 693 N·m (512 lb ft) | 925 N·m (682 lb ft) | 979 N·m (722 lb ft) | 1305 N·m (963 lb ft) | 631 N·m (465 lb ft) | 890 N·m (656 lb ft) |

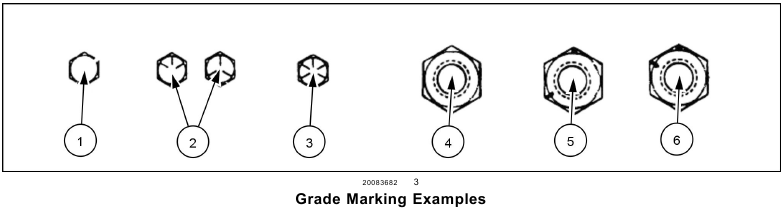

IDENTIFICATION

Inch Bolts and free-spinning nuts

Grade Marking Examples

SAE Grade Identification

- Grade 2 - No Marks

- Grade 5 - Three Marks

- Grade 8 - Five Marks

- Grade 2 Nut - No Marks

- Grade 5 Nut - Marks 120° Apart

- Grade 8 Nut - Marks 60° Apart

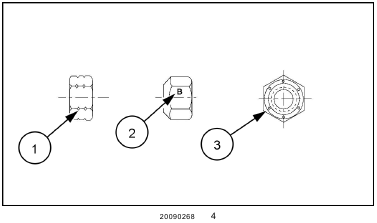

Inch Lock Nuts, All Metal (Three optional methods)

Grade Identification

| Grade | Corner Marking Method (1) | Flats Marking Method (2) | Clock Marking Method (3) |

| Grade A | No Notches | No Mark | No Marks |

| Grade B | One Circumferential Notch | Letter B | Three Marks |

| Grade C | Two Circumferential Notches | Letter C | Six Marks |

Standard torque data for hydraulics

INSTALLATION OF ADJUSTABLE FITTINGS IN STRAIGHT THREAD O RING BOSSES

- Lubricate the O-ring by coating it with a light oil or petroleum. Install the O-ring in the groove adjacent to the metal backup washer which is assembled at the extreme end of the groove (4).

- Install the fitting into the SAE straight thread boss until the metal backup washer contacts the face of the boss (5).

NOTE: Do not over tighten and distort the metal backup washer. - Position the fitting by turning out (counterclockwise) up to a maximum of one turn. Holding the pad of the fitting with a wrench, tighten the locknut and washer against the face of the boss (6).

STANDARD TORQUE DATA FOR HYDRAULIC TUBES AND FITTINGS

| TUBE NUTS FOR 37°FLARED FITTINGS | O-RING BOSS PLUGS ADJUSTABLE FITTING LOCKNUTS, SWIVEL JIC- 37° SEATS | |||

| SIZE | TUBING OD | THREAD SIZE | TORQUE | TORQUE |

| 4 | 6.4 mm (1/4 in) | 7/16-20 | 12 – 16 N·m (9 – 12 lb ft) | 8 – 14 N·m (6 – 10 lb ft) |

| 5 | 7.9 mm (5/16 in) | 1/2-20 | 16 – 20 N·m (12 – 15 lb ft) | 14 – 20 N·m (10 – 15 lb ft) |

| 6 | 9.5 mm (3/8 in) | 9/16-18 | 29 – 33 N·m (21 – 24 lb ft) | 20 – 27 N·m (15 – 20 lb ft) |

| 8 | 12.7 mm (1/2 in) | 3/4-16 | 47 – 54 N·m (35 – 40 lb ft) | 34 – 41 N·m (25 – 30 lb ft) |

| 10 | 15.9 mm (5/8 in) | 7/8-14 | 72 – 79 N·m (53 – 58 lb ft) | 47 – 54 N·m (35 – 40 lb ft) |

| 12 | 19.1 mm (3/4 in) | 1-1/16-12 | 104 – 111 N·m (77 – 82 lb ft) | 81 – 95 N·m (60 – 70 lb ft) |

| 14 | 22.2 mm (7/8 in) | 1-3/16-12 | 122 – 136 N·m (90 – 100 lb ft) | 95 – 109 N·m (70 – 80 lb ft) |

| 16 | 25.4 mm (1 in) | 1-5/16-12 | 149 – 163 N·m (110 – 120 lb ft) | 108 – 122 N·m (80 – 90 lb ft) |

| 20 | 31.8 mm (1-1/4 in) | 1-5/8-12 | 190 – 204 N·m (140 – 150 lb ft) | 129 – 158 N·m (95 – 115 lb ft) |

| 24 | 38.1 mm (1-1/2 in) | 1-7/8-12 | 217 – 237 N·m (160 – 175 lb ft) | 163 – 190 N·m (120 – 140 lb ft) |

| 32 | 50.8 mm (2 in) | 2-1/2-12 | 305 – 325 N·m (225 – 240 lb ft) | 339 – 407 N·m (250 – 300 lb ft) |

These torques are not recommended for tubes of 12.7 mm (1/2 in) OD and larger with wall thickness of 0.889 mm (0.035 in) or less. The torque is specified for 0.889 mm (0.035 in) wall tubes on each application individually.

Before installing and torquing 37° flared fittings, clean the face of the flare and threads with a clean solvent or Loctite cleaner and apply hydraulic sealant to the 37° flare and the threads.

Install fitting and torque to specified torque, loosen fitting and retorque to specifications.

PIPE THREAD FITTING TORQUE

Before installing and tightening pipe fittings, clean the threads with a clean solvent or Loctite cleaner and apply sealant for all fittings including stainless steel or for most metal fittings. For high filtration/zero contamination systems use.

| PIPE THREAD FITTING | |

| Thread Size | Torque (Maximum) |

| 1/8-27 | N·m (10 lb ft) |

| 1/4-18 | N·m (12 lb ft) |

| 3/8-18 | N·m (16 lb ft) |

| 1/2-14 | N·m (30 lb ft) |

| 3/4-14 | N·m (40 lb ft) |

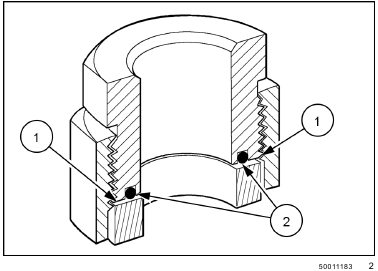

INSTALLATION OF ORFS (O-RING FLAT FACED) FITTINGS

When installing ORFS fittings thoroughly clean both flat surfaces of the fittings (1) and lubricate the O-ring (2) with light oil. Make sure both surfaces are aligned properly. Torque the fitting to specified torque listed throughout the repair manual.

NOTICE: If the fitting surfaces are not properly cleaned, the O-ring will not seal properly. If the fitting surfaces are not properly aligned, the fittings may be damaged and will not seal properly.

NOTICE: Always use genuine factory replacement oils and filters to ensure proper lubrication and filtration of en- 50011183 2 gine and hydraulic system oils.

The use of proper oils, grease, and keeping the hydraulic system clean will extend machine and component life.

Safety rules

Personal safety

Carefully study these precautions, and those included in the external attachment operators manual, and insist that they be followed by those working with and for you.

- Thoroughly read and understand this manual and the attachment Operator's Manual before operating this or any other equipment.

- Be sure all people and pets are clear of the machine before starting. Sound the horn, if equipped, three times before starting engine.

- Only the operator should be on the machine when in operation. Never allow anyone to climb on to the machine while it is in motion. If the machine is equipped with an Instructors Seat, this must only be used for training purposes. Passengers must not be allowed to use the Instructors Seat.

- Keep all shields in place. Never work around the machine or any of the attachments while wearing loose clothing that might catch on moving parts.

- Observe the following precautions whenever lubricating the machine or making adjustments.

- Disengage all clutching levers or switches.

- Lower the attachment, if equipped, to the ground or raise the attachment completely and engage the cylinder safety locks. Completing these actions will prevent the attachment from lowering unexpectedly.

- Engage the parking brake.

- Shut off the engine and remove the key.

- Wait for all machine movement to stop before leaving the operators platform.

- Always keep the machine in gear while travelling downhill.

- The machine should always be equipped with sufficient front or rear axle weight for safe operation.

- Under some field conditions, more weight may be required at the front or rear axle for adequate stability. This is especially important when operating in hilly conditions or/when using heavy attachments.

- Always lower the attachment, shut off the engine, set the parking brake, engage the transmission gears, remove the key and wait for all machine movement to stop before leaving the operators platform.

- If the attachment or machine should become obstructed or plugged; set the parking brake, shut off the engine and remove the key, engage the transmission gears, wait for all machine or attachment motion to come to a stop, before leaving the operators platform to removing the obstruction or plug.

- Never disconnect or make any adjustments to the hydraulic system unless the machine and/or the attachment is lowered to the ground or the safety lock(s) is in the engaged position.

- Use of the flashing lights is highly recommended when operating on a public road.

- When transporting on a road or highway, use accessory lights and devices for adequate warning to the operators of other vehicles. In this regard, check local government regulations. Various safety lights and devices are available from your NEW HOLLAND CONSTRUCTION dealer.

- Practice safety 365 days a year.

- Keep all your equipment in safe operating condition.

- Keep all guards and safety devices in place.

- Always set the parking brake, shut off the engine and remove the key, engage the transmission gears, wait for all machine or attachment motion to come to a stop, before leaving the operators platform to service the machine and attachment.

- Remember: A careful operator is the best insurance against an accident.

- Extreme care should be taken in keeping hands and clothing away from moving parts.

Ecology and the environment

Soil, air, and water quality is important for all industries and life in general. When legislation does not yet rule the treatment of some of the substances that advanced technology requires, sound judgment should govern the use and disposal of products of a chemical and petrochemical nature.

Familiarize yourself with the relative legislation applicable to your country, and make sure that you understand this legislation. Where no legislation exists, obtain information from suppliers of oils, filters, batteries, fuels, anti-freeze, cleaning agents, etc., with regard to the effect of these substances on man and nature and how to safely store, use, and dispose of these substances.

Helpful hints

- Avoid the use of cans or other inappropriate pressurized fuel delivery systems to fill tanks. Such delivery systems may cause considerable spillage.

- In general, avoid skin contact with all fuels, oils, acids, solvents, etc. Most of these products contain substances that may be harmful to your health.

- Modern oils contain additives. Do not burn contaminated fuels and or waste oils in ordinary heating systems.

- Avoid spillage when you drain fluids such as used engine coolant mixtures, engine oil, hydraulic fluid, brake fluid, etc. Do not mix drained brake fluids or fuels with lubricants. Store all drained fluids safely until you can dispose of the fluids in a proper way that complies with all local legislation and available resources.

- Do not allow coolant mixtures to get into the soil. Collect and dispose of coolant mixtures properly.

- The air-conditioning system contains gases that should not be released into the atmosphere. Consult an air-conditioning specialist or use a special extractor to recharge the system properly.

- Repair any leaks or defects in the engine cooling system or hydraulic system immediately.

- Do not increase the pressure in a pressurized circuit as this may lead to a component failure.

- Protect hoses during welding. Penetrating weld splatter may burn a hole or weaken hoses, allowing the loss of oils, coolant, etc.

Have any questions please write to me: admin@servicemanualperfect.com

Documents / ResourcesDownload manual

Here you can download full pdf version of manual, it may contain additional safety instructions, warranty information, FCC rules, etc.

Advertisement

Need help?

Do you have a question about the 200 Series and is the answer not in the manual?

Questions and answers