Advertisement

Quick Links

FL4C50-65-SMS-001

WARNING

Do not use the forklift before reading and understanding the operating instructions as

well as the waring decals on the truck.

Keep for future reference.

Operation & Maintenance Manual

FL4C50-65

series

INTERNAL COMBUSTION Forklift

NOBLELIFT INTELLIGENT EQUIPMENT CO., LTD.

Advertisement

Summary of Contents for Noblelift FL4C50-65 Series

- Page 1 WARNING Do not use the forklift before reading and understanding the operating instructions as well as the waring decals on the truck. Keep for future reference. Operation & Maintenance Manual FL4C50-65 series INTERNAL COMBUSTION Forklift NOBLELIFT INTELLIGENT EQUIPMENT CO., LTD.

- Page 2 1.8.2 Usage of NOBLELIFT specified parts and oil....................11 1.9 Basic information of the truck ..........................11 1.9.1 Truck basic information table (complete by NOBLELIFT dealer or agent) ..........12 1.9.2 Displaving position of the truck model and number ................12 1.9.3 Displaying position of the truck working hours ..................

- Page 3 2.3.5 Note on the safety devices ........................24 2.3.6 Practice before operation ......................... 24 2.3.7 It is prohibited to jump on and off the truck .................... 25 2.3.8 Keep the driving area clean and tidy ......................25 2.3.9 Notes when flushing truck ........................25 2.3.10 Beware of scalding ..........................

- Page 4 2.8.1 Notes when hanging up truck ........................50 2.8.2 Notes when loading or unloading the truck ..................... 50 2.9 Truck structure and stability ..........................51 2.9.1 Longitudinal stability ..........................51 2.9.2 Load center of gravity ..........................51 2.9.4 Actual loading capacity ..........................52 2.9.5 Instruction on the capacity chart ......................

- Page 5 4.2.8 Check through operating the working devices operation lever .............. 113 4.2.9 Safety function check ..........................115 4.3 Check after operation and report ........................116 4.4 Simple maintenance ............................117 4.4.1 Lubricating grease and fuel ........................117 4.4.1.1 Notes ............................117 4.4.1.2 Lubricating chart ..........................

- Page 6 Foreword 1.1 Application Scope and Instruction on the Manual • The manual contains the following contents: proper operation, easy maintenance and daily check: •Before operation, please read the manual thoroughly to guarantee safe and effective material handling through proper operation and maintenance; •Actual condition may be different from the description in the manual because of product improvement;...

- Page 7 1.2 Safety signal, expression and mark 1.2.1 It indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. You must observe this instruction. 1.2.2 It indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

- Page 8 1.3 Applied model . The manual is suitable for the following FL4C50-65 Forklift specification: FGL25T-LNJK3 with GCT GK25( CARB SIP LSI-1/EPA Tier2) FGL30T-LNJK3 with GCT GK25( CARB SIP LSI-1/EPA Tier2) FGL32T-LNJK3 with GCT GK25( CARB SIP LSI-1/EPA Tier2) FL25T-LNJX2 with HMC 2.4 L T3 LPG FL30T-LNJX2 with HMC 2.4 L T3 LPG FL32T-LNJX2 with HMC 2.4 L T3 LPG...

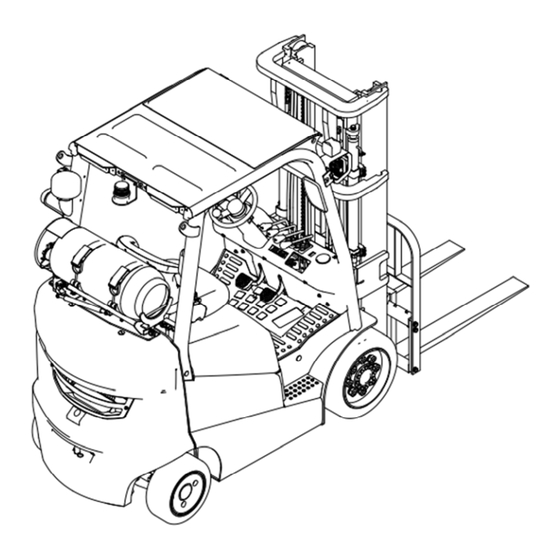

- Page 9 1.4 Truck general view 1.4.1 Truck application It is mainly used for load carrying. 1.4.2 Direction affirming Direction in this manual is affirmed from the operator's seat. 1.5 Measuring unit The measuring units used in the manual are international system units(SI).

- Page 10 Avoid sudden start, acceleration, brake or sharp turning. 1.7.2 Maintenance of the new truck The new truck needs oil changing, oil filter cleaning and bolts and nuts retightening during the first month usage (200 hours). NOBLELIFT vehicles are to be maintained by NOBLELIFT dealers.

- Page 11 1.9 Basic information of the truck Please offer NOBLELIFT dealer or agent the basic information of the truck such as model, truck number, engine series number, accessories, optional devices and so on when maintaining truck or ordering parts.

- Page 12 1.9.1 Truck basic information table (complete by NOBLELIFT dealer or agent) Model Truck number Engine series number Accessories, optional devices Dealer/agent Address Telephone number, fax number Service person Sales person 1.9.2 Displaving position of the truck model and number The truck model and number is displayed on the Dashboard.

- Page 13 Completed truck actual capacity is related to attachment, load center and lifting height. Please refer to the figure above. The truck number is also shown on the external plate of the truck.

- Page 14 1.9.3 Displaying position of the truck working hours It is in the middle of the meter.

- Page 15 SAFETY NOTES Please read the manual and safety notes carefully.When operating the truck, please follow the safety notes or serious injuries may be caused.

- Page 16 2.1 Description of the safety plate 2.1.1 Position of the safety plates Safety plate Position Mind your hands The rear side of the tilting cylinder mast pillar and top pillar (the middle cross beam of the external mast) Do not enter the space after the mast The rear side of the tilting cylinder mast pillar and top pillar (the middle cross beam of the external mast)

- Page 17 2.1.2 Safety plates (1)Caution: mind your hands Do not put your hands where may be caught. (2) No jump starting Start the engine only when the operator sit well on theseat; Never try to make the engine starting circuit short circuit on purpose to start the engine, or serious injury or fire may be caused.

- Page 18 (5) Notes when slinging Never sling the truck at the overhead guard top cover. Sling the truck at the shown positions. (6) Safe usage of the gas spring Please press the gas spring safe lock button before shut off the engine hood.

- Page 19 (10) Notes before operation occur. WARNING: Read the OPERATION AND MAINTENANCE MANUAL carefully before operation, maintenance, disassembling and assembling. Read the usage note plate to avoid improper operation. Check the truck before starting according to the checking points before starting.

- Page 20 Before starting the engine, check the following parts: if the battery terminal is loose, fix it. And ifthere is dirt such as smudginess, leaf or paper, remove it.It problems still exist, contact with NOBLELIFT dealer for repair. Check around engine ...

- Page 21 Clean all wire contactors and fix them; Check if the harness is loose, worn or damaged daily. Tighten the loose contactor and wire clamp.The damaged harness must be repaired or changed by NOBLELIFT dealer. 2.2.5 Protect against fire caused by oil pipe fault ...

- Page 22 2.2.6 Cleaning after operation Remove the dirt, leaves or paper with fan after operation. Around engine Clean around exhausting manifold. The bottom of the chassis Lay emphasis on the truck with bottom plate wheredirt is easy to gather.

- Page 23 2.2.7 If fire occurs If fire occurs, turn the starting switch to OFF position to shut off engine. Do not jump off the truck in a hurry. Support yourself with handle and pedal in order to leave safely. 2.3 Basic notes 2.3.1 Follow the rules Only trained and authorized person can operate the truck.

- Page 24 Do not disassemble the safety devices and make sure they are in good condition. If there is damage or loose of overhead guard or back rest, do not operate the truck until NOBLELIFT dealer or agent fix it well. 2.3.6 Practice before operation ...

- Page 25 2.3.7 It is prohibited to jump on and off the truck It is prohibited to jump on and off the Do not grasp control lever and truck. steering wheel when getting on or off Do not jump onto the truck to try to the truck.

- Page 26 2.3.10 Beware of scalding Cooling liquid with high temperature The cooling liquid is in high temperature if the truck is just stop. There is a danger of scalding caused by the ejecting of steam or boiling water if the radiator cap is removed at once.

- Page 27 Do not jump off the truck in a hurry. Support yourself with handle and pedal in order to leave safely. 2.3.13 Do not modify the truck Contact with NOBLELIFT sales and service agent before carrying out any modification (fix, disassembly and...

- Page 28 2.3.15 Ensure the working area safety Ensure the flatness of the road and working area and clean the oil and grease on the working area avoiding injury caused by bump and slip. When working in place that has a danger of falling such as dock,platform and so on, place blocks avoiding truck travelling surpassing boarder.

- Page 29 It is prohibited to check with flame. If there is leakage, turn off all valves, keep the truck away from the open flame and contact with NOBLELIFT dealer. Notes in cold weather Make the engine warm completely in cold weather, or the truck may move slowly or change direction suddenly which may cause accident.

- Page 30 2.5 Travelling 2.5.1 Preparation before travelling Wear safety belt Wear safety belt before operation; Check if the safety belt is well; Injury may occur if safety belt is improper fixed. Proper seat posture If you operate the truck with improper seat posture or away from the seat, accident may occur.

- Page 31 2.5.2 Notes when travelling Avoid sudden start, stop and direction change; Stop truck (hydraulic-powered truck) before direction change. Keep safety in mind during travelling Even the horn is sounded, pay Avoid sudden start, brake and sharp attention to the moving of people turning;...

- Page 32 Do not keep your foot on the inching pedal Keep foot away from the inching pedal during normal travelling or the untimely worn out of the clutch and overheat of transmission unit; Brake unit will be ineffective if the pedal is pressed to haft engaged with the clutch.

- Page 33 Keep in mind that the truck with LPG container has poor backview which has a danger of collision ofpeople around or goods. So make sure to check the back view; Contact with NOBLELIFT agent or dealer for detail when alarming devices such as backward flasher, backward sensor, backview mirror and so on are needed.

- Page 34 Beware of the rear part rotation; The steering wheel of the truck is its rear wheel which is different from the other kind of truck; Keep a safe distance with the wall because the counter weight will rotate outside when steering.

- Page 35 Avoid travel on road shoulder. Do not travel close to the road shoulder which may sink. Keep a safe distance from the road shoulder or platform in preventing of truck falling. Notes when travelling on a slope ...

- Page 36 Notes when travel into railway lorry or container Check the brake and block applying to the lorry, trailer and container and make sure they are well stopped; Do not move the vehicles before the load carrying operation is finished; ...

- Page 37 2.5.4 Notes on towing Proper using of traction pin other truck. Damaged truck may have Traction pin is designed for the accident during travelling. towing when it is sunk into channel or mud; Do not use it for towing or lifting; ...

- Page 38 Do not put hand, feet or other parts of your body into mast; There is a danger of being caught by moving parts and serious injury. Do not stand between the mast and driver's cab because serious injury or death may be caused by extruding.

- Page 39 Take care when carrying long and wide goods; Take care when carrying long and wide goods. Lift the goods slowly so as not to collide anything around; Keep the goods as low as possible and keep balance when changing direction. ...

- Page 40 Do not carry goods with insecurity measure. Make sure the goods' center of gravity is in the same line with the truck's center of gravity. Do not carry unbalanced goods; Fix the goods avoiding falling or collapse. Do not carry unstable goods;...

- Page 41 Do not push goods by the tip of fork. Do not push goods by the tip of fork or the good may break away from the fork tip and be damaged. The reaction may cause the truck and goods to move accidentally and is dangerous.

- Page 42 Only easy check and maintenance are included in the OPERATION AND MAINTENANCE MANUAL. For the check and maintenance that should be carried out by trained and qualified people, please contact with NOBLELIFT dealer/agent. Do not start the truck before starting check;...

- Page 43 2.7.3 Keep the working area clean and tidy Keep the working area clean and tidy. Remove the barriers, grease and oil. The truck should work on flat ground with enough space. Ensure good ventilation if the truck works inside a building. 2.7.4 Notes before check and maintenance ...

- Page 44 2.7.7 Notes when working under the working devices Support fork and mast avoiding falling when working under the fork or serious accident will be caused. 2.7.8 Beware not to be caught by mast or falling Do not put your hand, foot or other part into mast or there is a danger of being caught.

- Page 45 2.7.9 Beware of the boiling cooling liquid Do not remove the radiator's cap as soon as the truck is stopped because the cooling liquid has high temperature and pressure, or you may be scalded. When removing the radiator's cap, rotate it slowly until the cooling liquid is cool to release inside pressure.

- Page 46 2.7.11 Beware of the rotating belt and fan Keep your hand away from the rotating belt and fan. Shut off the engine before open the engine hood which is only can be done by authorized person. 2.7.12 Notes when repairing electric system ...

- Page 47 2.7.14 Notes when dealing with battery The battery will produce hydrogen and oxygen during charging which may explode and electrolyte contains dilute sulphuric acid. Personal injury, explosion or fire may be caused if the battery is improper dealt. Please follow the rules below: ...

- Page 48 Rim will not well fit the tyre if its improper assembled or there is any fault with the tyre or rim. Rim should well contact with the tyre in any place. If necessary, contact with NOBLELIFT dealer.

- Page 49 Replace the key parts regularly. If there is any abnormal, change the key part even it is undue. Note Check and change of the key parts and lubrication grease adding should be carried out by NOBLELIFT dealer or agent.

- Page 50 2.8 Transportation and hanging up 2.8.1 Notes when hanging up truck Do not hang up the truck at the overhead guard. Before hanging up, check if the bolts of the mast and counter weight are tighten to the regulated torque. ...

- Page 51 2.9 Truck structure and stability 2.9.1 Longitudinal stability Load is balanced with the weight on the rear wheel with the front wheel as the supporting point so as to avoid truck tilting forward. If the truck is overloaded, the rear wheel will lift away from the surface.

- Page 52 will be out of balance. Ensure the load capacity stays in the allowed range. Series number plate on the truck shows the work in permit range. Contact with NOBLELIFT dealer or agent to change the damaged or unclear plate.

- Page 53 2.9.6 Instruction on safety devices choice Safety devices are optional. Contact with NOBLELIFT dealer or agent for detail. Devices and equipments listed below may not work in certain conditions. Install the devices according to the instructions for safety reason.

- Page 54 2.10 Towing Fault truck towing Be care if there is any of the fault below when towing a truck: Fault of brake fault of steering fault of tyre fault of traction pin Move the truck on a abrupt slope The truck is hard to control if the steering motor does not work.

- Page 55 OPERATION Please read the manual and safety notes carefully. When operating the truck, please follow the safety notes or serious injuries may be caused.

- Page 56 3.1 General view 3.1.1 Truck general view mast 11. counter weight Lifting chain 13. Rear wheel Lifting cylinder 14. Engine hood Rear view mirror 15. tilt cylinder Front lamp 16. Front wheel Steering light and stopping light 17. Fork Overhead guard 18.

- Page 57 3.1.2 Instrument and control devices Cab forward/backward operation lever Inching pedal (hydraulic-powered truck) 2. Steering wheel 10. Brake pedal 3. Horn 11. Starting motor switch 4. Steering hand wheel 12. Acceleration pedal Tiltable steering hand wheel 5. Combined light switch lock lever 6.

- Page 58 ON position. Check if the bulbs are damaged if any of the indicator is off. It is abnormal when the alarming indicator is on during operation. Repair it and contact with NOBLELIFT dealer or agent.

- Page 59 Fuel gauge Oil quantity is shown on the fuel gauge. Check it on a flat ground. Check the oil quantity when the engine starting switch is on ON position. Position E: it means that the oil level is low. Position F: it means the oil tank is full.

- Page 60 No charging alarm indicator When the engine is working, the alarm indicator means the abnormal of the AC type generator's charging system. When the starting switch is turned to ON position, the indicator will turn on and it will turn off after the engine is started.

- Page 61 Engine coolant temperature meter Engine coolant temperature is indicated by a pointer. White range: normal Red range: over heat Important Stop operating the truck at once and park it in a safe place if the pointer point to the red range and then carry out corresponding measures.

- Page 62 3.2.3 Operating devices Starting motor switch The switch is used to start or shut off the engine. (1) [0] position: on OFF position, you can insert or draw out the starting key. (2) [I] position: on ON position, the electric circuit has electricity.

- Page 63 Combined light (lighting/steering signal switch) The knob is fixed with lighting and steering signal switch. Lighting switch When the switch is turned according to the arrow mark, lights will turn on or off as shown below. Front Meter light, side marker, front width light, rear width light and light tail light ...

- Page 64 Parking brake handle The handle is used to operate parking brake. Pull the handle back completely (to lock position) and the parking brake is applied. When releasing parking brake, pull the handle back and press down the button on top of the handle at the same time.

- Page 65 Inching pedal When travelling with low speed (such as loads handing operation), the pedal is used to adjust the travelling speed. Step on the pedal slightly to make the clutch half engaged and the truck will inching forward. Step the pedal more and the brake pedal together, the brake force is applied.

- Page 66 Steering hand wheel Steering hand wheel is used to change the leftright direction. Tiltable steering hand wheel lock lever The lever is used to adjust the steering hand wheel tilting angle (upward/downward). Raise the lever, the steering hand wheel lock nut will lose and the steering hand wheel tilting angle can be adjusted.

- Page 67 Fork Lower the fork bracket and until the fork contact with the ground and the lifting chain is under the tight condition. Lose the fork stopper and move the fork to the middle position. Put the lower hook to the cut and disassemble the fork.

- Page 68 3.3 Operation 3.3.1 Starting check Do not operate the truck until all checks are done. If there is any abnormal, report to the manager and do not operate the fault truck until it is repaired. Carry out the starting check for safety. Refer to 4.2 Starting check for detail.

- Page 69 Seat position adjusting Adjust the seat position before getting on the truck or changing a driver. (Adjust only the truck is well stopped. Make sure you can step the brake pedal 4. Pull the seat forward or backward after fully when you lay against the seat.

- Page 70 Wear safety belt during operation. 1. Insert the spring bolt on the left side belt to the lock on the right side. Safety belt is locked when you hear a click. 2. Hold the safety belt with left hand and press the red button on the lock with right hand when loose.

- Page 71 Steering hand wheel position adjusting Park the truck well before adjusting the steering hand wheel position. After adjusting, move the steering hand wheel forward and backward to check if it is locked. 1.Stop the truck.; 2. Lift the steering wheel lock lever to A position;...

- Page 72 1. Place forward/backward operation lever on neutral position. Note: Engine can not be started unless the forward/backward operation lever is placed on neutral position. 2. Releasing the parking brake When releasing parking brake, pull the handle back and press down the button on top of the handle at the same time.

- Page 73 The starting key switch will go back to the ON (I) position automatically when undo the engine starting key switch as soon as the engine is started. When the engine is working, make sure the key stays at the position. ...

- Page 74 5. For hydraulic powered truck, please step on the inching pedal. 6. Starting switch operation Turn the starting key switch to the START position (II) when your foot move away from the acceleration pedal and then the engine will be started. The starting key switch will go back to the ON(I) position automatically when undo the engine starting key switch as...

- Page 75 What is more, the brake function will be affected. Contact with NOBLELIFT dealer or agent for check if the truck travels with parking brake applied for a long distance.

- Page 76 OPS If the seat does not bear your whole weight, for example stand or lean against forward, backward or side when operating, the safety device will prevent the truck from working. If you operate the truck with such posture, the OPS will be activated in5s and transmission box power will be cut.

- Page 77 2. Pull the parking brake to the lock position. 3. Keep the engine running for 5 minutes at an idle speed for cooling. 4. Turn off the releasing valve (rotate in clockwise direction) and wait until the engine is stopped naturally. Note: the engine will stop until the LPG remained in the pipe is used up.

- Page 78 6. Draw out the key switch and leave. Note: if the parking brake is unlocked when leave the truck, the alarm will sound up. (Optional) Important: If the engine is stopped when it is hot, its service life will be badly affected.

- Page 79 4. Turn the key switch to OFF position. 5. Draw out the key switch and leave. Note: if the parking brake is unlocked when leave the truck, the alarm will sound up. (Optional) Important: If the engine is stopped when it is hot, its service life will be badly affected.

- Page 80 3.3.5 Inching Do not make the truck inching through stepping on the acceleration pedal and adjusting brake pedal pressing distance. Make the truck inching through inching pedal. ------------------------------------------------------------------------------------- 3.3.6Stering When steering, take care that the external side of the counter weight may collide with the person or object around.

- Page 81 3.3.7 Operate on snow field and icy field Slipping can not be prevented completely even the truck is assembled with anti-slipping tyre or chain. Some model may not be suitable to assemble anti-slipping tyre or chain. When travelling on snow or icy field, assemble anti-slipping tyre or chain. ...

- Page 82 Truck parking procedures 1. Park the truck on flat ground. 2. Apply parking brake. 3. Place the forward/backward operation lever on neutral position. 4. Tilt the mast forward and lower the fork to the ground. 5. Turn the starting key switch to OFF (0) position.

- Page 83 3. Turn off the releasing valve (rotate in clockwise direction) and wait until the engine is stopped naturally. Note: the engine will stop until the LPG remained in the pipe is used up. 4. After the engine is stopped, turn the key switch to OFF position.

- Page 84 7. Starting switch operation Turn the starting key switch to the START position (II) when your foot move away from the acceleration pedal and then the engine will be started. The starting key switch will go back to the ON (I) position automatically when undo the engine starting key switch as soon as the engine is started.

- Page 85 3. After the engine is stopped, turn the key switch to OFF position. 4. Turn on the releasing valve (rotate in anti clockwise direction) 5. For hydraulic powered truck, step on the inching pedal. 6. Starting switch operation Turn the starting key switch to the START position (II) when your foot move away from the acceleration pedal and then the engine will be started.

- Page 86 3.3.10 Load handing operation Space between fork adjustment Adjust the space between the fork before loading to suits pallet size and loads. Take care not to make hand or finger be caught when adjusting. 1. Stop the truck right before the loads. move towards two sides and goods may fall down 2.

- Page 87 Tilting operation lever Tilting forward: push the operation lever upward Tilting backward: press the operation lever downward NOTE The fork forward and backward tilting speed can be adjusted by the operation lever tilting degree and pressing distance of the acceleration pedal. Load picking 1.

- Page 88 3.3.11 LPG charging Change the LPG cylinder in well ventilated place and be away from open fire. The LPG cylinder for the truck must confirm to GB 17259 LPG cylinder for automotive vehicle and regulations for cylinder safety supervision. LPG for the truck must confirm to GB 191592012 and other relative standards.

- Page 89 4. Replace the cylinder with a full one. 5. Push the lock plate (4) until it is locked. Push the LPG cylinder slightly (5) and check if it is safely locked. 6. Tighten the LPG cylinder connecting bolt (2) and connect the high pressure pipe (3) to engine.

- Page 90 5. Lay down the LPG cylinder (5)and loose two lock plate (7). Then remove the cylinder (5) from bracket. 6. Replace the cylinder from the bracket and keep the cylinder valve side up. When installing cylinder, the side with valve must be kept up.

- Page 91 8. Uplift the cylinder (5) and bracket. 9. Pull out the safety switch (6) and make it align to the hole on the bracket. Insert the switch (6) to the hole. Push the LPG cylinder bracket slightly and check if it is safely locked. 10.

- Page 92 3.3.12 Check after operation Carry out all checks described above and clean the truck. Before storing, carry out the checks below: 1. Check if there is leakage of fuel, battery and electrolyte. 2. Check if there are any cracks or damage. 3.

- Page 93 3.4 Transporting Refer the technical parameter for truck size and weight.Refer to the following figure for truck center of gravity. For more information, please contact with NOBLELIFT dealer. ------------------------------------------------------------------------------------- 3.4.1 Truck fixing Authorized transporting company is recommended to transport the truck through highway, railway and waterway.

- Page 94 Forklift truck fixing method in a container: 1. For container space limit, trucks position is compact. The min. distance between the two trucks is20-30mm to ensure disconnecting with each one. 2. Protect the left and right sides of the frame and counter weight with felt pads before going to the container avoiding truck appearance damage.

- Page 95 ------------------------------------------------------------------------------------- 3.4.2 Mast transporting and reassembling Some mast has to be disassembled during transporting for height limit. 1. Seal the hydraulic pipeline disassembling ends after disassembly. Fix the pipelines with belts. Wrap the connectors and transport with the whole truck. 2.

- Page 96 The lifting plate shown in the figure shows the proper lifting points. The points are on the mast and counter weight. For more information, contact with NOBLELIFT dealer or agent. IMPORTANT Make sure all slings have the safe capacity to lift up the truck.

- Page 97 CHECKINGAND MAINTENANCE Please read the manual and safety notes carefully. When checking and maintaining the truck, please follow the safety notes or serious injuries may be caused.

- Page 98 Staring check, oil change, filter cleaning and other simple maintenance work are described below. For others that are not described, contact with NOBLELIFT dealer or agent. Refer to the second chapter SAFETY NOTE for safe checking and maintenance. Improper maintenance and repair may cause serious accident and shorten truck service life.

- Page 99 Starting checking parts table Item Checking parts Check the abnormal found the day before Leakage of oil and electrolyte Crack, damage and fixing condition (overhead guard, fork, backrest and so on) Tightness of the locking nut of the tilting cylinder piston rod Forklift truck Check if the light and glass cover are clean or damaged.

- Page 100 Item Checking parts Mast operation condition Load handling Tightness of lifting chain; check if it is damaged or rust. Safety function check Parking brake ------------------------------------------------------------------------------------- 4.2.1 Check the abnormal found the day before Check the abnormal found the day before. Make sure there is no fault.

- Page 101 Crack, damage and fixing condition check Check if there is any damage, cracks, loose and clearance through visual check. Check following parts preferentially: Overhead guard Fork Backrest Fork bracket Mast Fuel tank Hydraulic oil tank ...

- Page 102 Check if the rim nut is loose. Check if there is loose nut by wrench. IMPORTANT Tighten the rim nut to the regulated torque. For proper tighten torque, refer to 4.16 REPAIR PARAMETER. Tyre and rim checking Check if the tyres are worn, damaged. Check if there is any adhered nail and other foreign matters.

- Page 103 3. Draw out the oil dipstick and check if the adhered oil is in normal range. 4. Add oil if oil level is low; if oil run out, clean it. IMPORTANT Only pure NOBLELIFT hydraulic oil or recommended oil can be used.

- Page 104 IMPORTANT If the engine oil is polluted or goes color, change the engine oil. Only pure NOBLELIFT engine recommended oil can be used. Electrolyte level check Flammable hydrogen produced by the battery is explosive. Dilute sulphuric acid is also contained in the electrolyte.

- Page 105 98N. The belt deflation should be 10-13mm. NOTE: Change the belt if it is stretched and there is no adjusting possibility or it is damaged. Please contact with NOBLELIFT dealer or agent for belt change.

- Page 106 Brake liquid level check Brake liquid may leak and brake may be badly affected if brake liquid is improperly used. Useregulated brake liquid (non-mineral oil brake liquid for truck). 1. Open the cap on the left side of the cabinet and check the brake liquid level. 2.

- Page 107 Brake pedal check Check if the brake pedal operation force and pedal distance are correct. Refer to 4.16 REPAIR PARAMETER for clearance standard value (S1) and pedal height (H) during brake. Inching pedal check Check the inching pedal operation force, clearance and interlocking distance.

- Page 108 Horn check Check if the horn can sound normally. Rear mirror check Check if the driver can see the rear view easily from the rear mirror. Check if it is dirty or damaged. ------------------------------------------------------------------------------------- 4.2.5 Check when the starting key switch is on ON position ...

- Page 109 Engine coolant temperature meter When the engine is cold, the pointer points to the left side and when the engine is preheated, the pointer points to the white range. oil-water separator alarm indicator ((it used fault indicator.)(Truck with diesel engine) ...

- Page 110 Check the fuel meter and make sure if it is enough for one day's work. If the pointer points to F, the tank is full. if the fuel level is low, shut off the engine and add fuel from the adding point.

- Page 111 4.2.6 Check when the engine is started Take care of the ventilation condition when starting engine indoor or in poor ventilated place because the exhausting air is poison. Alarm indicator on the meter Check if the alarm indicator on the meter turns off as soon as the engine is started. ...

- Page 112 If high pressure pipe leaks, turn off the exhausting valve at once and contact with dealer. Keep the truck away from the open fire before technician arrives. NOBLELIFT Do as follows to make the LPG flow to the vaporizer inlet port and then check if the high pressure pipe leaks.

- Page 113 4.2.7 Check when travelling slowly Steering wheel check Check the steering wheel when driving slowly: Check if there is clearance; Check if the steering wheel is stable in left and right side when driving straightly; Check if the steering wheel is heavy or if there is abnormal shake when rotating the steering wheel.

- Page 114 Lifting chain check If the lifting chain is broken, the goods may fall down or truck may tip over. If there is any fault with the chain, contact with NOBLELIFT dealer/agent to replace the lifting chain. Rust on the chain is the main cause of chain damage, so keep the chain from rusting in early stage.

- Page 115 4.2.9 Safety function check Park the truck on a flat ground before carrying out the check. Make sure there are no people and barriers around and there is enough driving space. OPS (travelling function) check The truck is not allowed to move by the OPS system when the driver goes away from the seat. Check the safety function.

- Page 116 Checking steps 1. Park the truck on a flat and solid ground and apply parking brake. 2. Place the forward/backward operation lever on neutral position and shut off the engine. 3. Make sure the starting motor and engine do not work even starting switch is turned to starting position when the forward/backward operation lever is placed on forward or backward position.

- Page 117 LUBRICATING CHART. Change the oil in regulated time even it does not go bad. Be sure to use NOBLELIFT specified engine oil. Oil listed in the OIL TYPE TABLE is filled in the truck before delivery. Do not use oil mixing with different degrees and numbers.

- Page 118 Fuel Only NOBLELIFT specified fuel is allowed to be used or the cleanness of the exhausting air can not meet thestandard requirement. For your health and environment, use NOBLELIFT specified fuel. Add the fuel to the full level after one day's work. Reducing the air in the tank is helpful to ...

- Page 119 4.4.1.2 Lubricating chart Oil and grease adding chart (oil and grease adding position and maintenance interval).

- Page 120 Engine oil(CD)(refer to Applying temperature note) (℃) ~+30 ~+30 ~+40 ~+50 HLW-40(Dedicated for NOBLELIFT) Normal temperature: Low temperature: Hydraulic oil Mobil DTE 10 Excel 25 Mobil DTE Excel 46 Shell Tellus S2 V 46 Shell Donax TC 10W HLT-9(Dedicated for NOBLELIFT)

- Page 121 4.4.2 Filter element cleaning When the engine is working, serious injury may be caused by fun or belt. Shut off the engine before disassemble or clean filter element. When cleaning filter element, dust on it may get into eye or be breathed inside. Wear protection glass, dust-proof cover and other protection devices.

- Page 122 1. Preheat the engine fully for 5 minutes in idling state. 2. When engine is running, turn off the exhausting valve fully on LPG cylinder and make the engine stop naturally. Note: The engine will stop when the remaining LPG in the pipe is used up. 3.

- Page 123 2. Place blocks under the tyres needed to be replaced. 3. Lift the truck at the required position. (1) Replace the front tyre: (A) under the outer mast (2) Replace the rear tyre: (B) under the counter weight 4. Lift the truck to the position where the tyre connects with the ground a little and place a support under the frame.

- Page 124 6. Install a new tyre to the hub. For the front wheel, rotate the nut one by one, then tighten the nut diagonally; for the rear wheel, fix the bearing inner ring to the steering knuckle (2), then fix the bearing outer ring and oil seal to the hub successively.

- Page 125 Change the fuse with the same standard and capability. If the replaced fuse is burn again, it may be caused by the abnormal electric system. please contact with NOBLELIFT dealer or agent. 1. Switch the starting key switch to OFF position.

- Page 126 Number Capability Color Corresponding electric parts Note Bule and Green Headlight Blue and Red Horn Blue and Black Lifting valve Red and Black Spare I Yellow Panel Brown and Black Reversing light Red and White Spare II Refer to the following table for relay capability and corresponding electric parts. Number Capability Corresponding electric parts...

- Page 127 Controller The controller has OPS function. OPS (driving function) If the condition that the seat switch is open or driver goes away from the seat or sits on the seat with improper posture is detected by controller for 5s, the controller will disconnect the power of transmission commutator and thus driving power will be disconnected.

- Page 128 Change the bulb with the same standard. If the bulb still does not light on, it may be caused by the abnormal system. Please contact with NOBLELIFT dealer or agent. 1.Switch the starting key and light switch to the OFF position.

- Page 129 4.5 Steps of dealing with the fault battery If a battery has fault, start the truck with jumper cable to use other truck's battery. Notes when disconnecting and connecting jumper cable Never connect the positive(+) and negative (-) terminal when connecting he jumper cable. ...

- Page 130 Engine starting Check if the forward/backward operation levers of two trucks are placed on neutral position and if parking brakes are applied. 1. Make sure clamps are connected to battery terminal firmly. 2. Start the normal truck's engine and make it run at highest speed. 3.

- Page 131 Coolant is poison and take care not to get in touch with your skin. If so, wash with lots of clean water and see a doctor. Contact professional company or NOBLELIFT dealer or agent to deal with the drained coolant. Never pour it onto ground or drainage ditch because it is poison.

- Page 132 5. If the coolant or engine oil level is low, add to proper level.If the fault reasons, contact with manager and stop use the truck. And then contact with NOBLELIFT dealer or agent. Clean the interior of the cooling system ...

- Page 133 Applications prohibited in this manual; Others. IMPORTANT NOBLELIFT will not bear the responsibility if the truck is used under the special environment or with force. Technology may not involve in certain condition. The truck can not be used where has a danger of explosive.

- Page 134 Do not touch mast, fork, chain or other working devices or truck may move accidently and serious accident may be caused. Contact with NOBLELIFT dealer or agent for repairing. 1. Stop working at once if the fork can not be lowered during operation.

- Page 135 4.10 Truck cleaning There is a danger of truck being out of work or mis-moving if water entering into electric system (controller, sensor, contactor and so on). Do not clean the electric system with water or air with high pressure. Cleaning steps 1.

- Page 136 Check the engine oil before and after engine starting. If the engine oil is mixed with moisture, change the engine oil. IMPORTANT Please contact with NOBLELIFT dealer or agent before operation when using the truck without anti-rust maintenance once a month.

- Page 137 4.12 slinging the truck Put the sling into the specified holes on top of the overhead guard and counter weight. Never sling the truck at the over head guard and cab base (if cab is assembled), or there is a danger of falling down. ...

- Page 138 4.13 Loading and unloading the truck There is a danger of tipping over and falling when loading or unloading the forklift truck. So follow the rules below: Park the trailer on a flat road. Apply parking brake and wedge the wheels. ...

- Page 139 4.14 Check and maintenance time table Please contact NOBLELIFT dealer or agent for check and maintenance items not described in the manual. Serious accident may be caused or truck service life may be affected if the truck is not checked or maintained ...

- Page 140 Check and maintenance interval Item Checks Tool Daily Monthly Quarterly Semiannually Annually (8 hrs) (200hrs) (600hrs) (1200hrs) (2400hrs) Check if fuel filter is blocked ○ Clean the fuel filter (gasoline engine) ○ Check the nozzle; adjusting pressure, ○ condition (diesel engine) Check vaporizer connecting...

- Page 141 Table 4-2 Transmission system maintenance time table Check and maintenance interval Daily Item Checks Tool Monthly Quarterly Semiannually Annually (200hrs) (600hrs) (1200hrs) (2400hrs) hrs) Leakage condition ○ Check the oil level or ○ ● change the oil Gear shifting lever operation condition and ○...

- Page 142 Table 4-3 Wheel maintenance time table Check and maintenance interval Item Checks Tool Daily Monthly Quarterly Semiannually Annually (8 hrs) (200hrs) (600hrs) (1200hrs) (2400hrs) Crack or damage ○ Wear condition Denth ○ meter Tyre Abnormal wear condition ○ Check if there are any foreign matters ○...

- Page 143 Table 4-4 Steering system maintenance time table Check and maintenance interval Item Checks Tool Daily Monthly Quarterly Semiannually Annually (8 hrs) (200hrs) (600hrs) (1200hrs) (2400hrs) Clearance check ○ Check if there is any loose in axial ○ direction. Steering wheel Check if there is any loose in radial ○...

- Page 144 Table 4-5 Braking system maintenance time table Check and maintenance interval Item Checks Tool Daily Monthly Quarterly Semiannually Annually (8 hrs) (200hrs) (600hrs) (1200hrs) (2400hrs) Spare travel ○ ○ Pedal travel pedal Brake ○ Operation condition ○ Check if brake works well and has enough travel. Parking brake operation ○...

- Page 145 Table 4-6 Lifting system maintenance time table Check and maintenance interval Daily Item Checks Tool Monthly Quarterly Semiannually Annually (200hrs) (600hrs) (1200hrs) (2400hrs) hrs) ○ Check forks for damage, deformation and wear condition. ○ Fork Check for stopper pin for damage or wear. ○...

- Page 146 Check and maintenance interval Item Checks Tool Daily Monthly Quarterly Semiannually Annually (8 hrs) (200hrs) (600hrs) (1200hrs) (2400hrs) ●(1500hrs for Oil level check and thefursttime,every ○ oil change 2400hrsin thefuture) Hydraulic oil tank Clean oil suction ○ filter element Remove the foreign ○...

- Page 147 Table 4-8 Electric system maintenance time table Check and maintenance interval Item Checks Tool Daily Monthly Quarterly Semiannually Annually (8 hrs) (200hrs) (600hrs) (1200hrs) (2400hrs) Check distributor cap for check. ○ Check spark plug for burn. ○ Adjust spark plug clearance ○...

- Page 148 Table 4-9Safety devices and accessories maintenance time table Check and maintenance interval Item Checks Tool Daily Monthly Quarterly Semiannually Annually (8 hrs) (200hrs) (600hrs) (1200hrs) (2400hrs) Check if the mounting is firm Test ○ Overhead guard hammer and backrest Check if there is deformation, crack ○...

- Page 149 4.15 Change the safety key parts regularly Safety parts listed in the table below should be changed regularly for safety reason. If the parts exceed their service life, they may be aging and go bad. Their condition is hard to be known through regular maintenance. So no matter how are the parts, change them if their service life is reached.If there is any abnormal before its service life is reached, repair or replace the part at once.

- Page 150 4.16 Repair parameter Parts Checks Unit 2-2.5t 3-3.5t Front tyre 480-560 480-560 Driving system Hub nut Tighten torque Rear tyre 130-194 130-194 Steering hand Clearance (when pump is working) 10-15° 10-15° wheel Clearance Inching travel Inching pedal The initial height of the front Steering system&braking floor board system...

- Page 151 Optional Optional item Optional details Air heater Heater and air conditioner air conditioner Weighing device Weighing device LPG Only Model LPG and Gasoline Driver’s cab Overhead guard Overhead guard + ceiling Overhead guard + ceiling + Windshields + wiper Black forkliftsolidtyre (no pattern) Tire White forkliftsolidtyre (no pattern) Three way multi-way valve...

- Page 152 Optional item Optional details Prefilter Prefilter Speed limiting device Speed limiting device Steel cylinder Steel cylinder Gantry dip angle 6°/6° NO Gantry Two level(2500mm) Two level(3300mm) Two level(3500mm) Two level(3700mm) Two level(4000mm) Two level(4300mm) Two level(4500mm) Gantry height Two level(4700mm) Two level(5000mm)...

- Page 153 Optional item Optional details External side shifter Side shifter Built in side shifter side shifter and Adjustable distance External side shifter pipeline (Three way) External side shifter pipeline (Four way) Built in side shifter pipeline (Three way) Side shifter pipeline Built in side shifter pipeline (Four way) side shifter and Adjustable distance (Four way)

- Page 154 Electric principle diagram...

Need help?

Do you have a question about the FL4C50-65 Series and is the answer not in the manual?

Questions and answers