Endress+Hauser Proline Promass A 100 PROFIBUS DP Operating Instructions Manual

Coriolis flowmeter

Hide thumbs

Also See for Proline Promass A 100 PROFIBUS DP:

- Operating instructions manual (56 pages) ,

- Operating instructions manual (118 pages) ,

- Operating instructions manual (160 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Endress+Hauser Proline Promass A 100 PROFIBUS DP

- Page 1 Products Solutions Services BA01246D/06/EN/03.24-00 71674461 2024-11-01 Valid as of version 01.01.zz (Device firmware) Operating Instructions Proline Promass A 100 PROFIBUS DP Coriolis flowmeter...

- Page 2 • The manufacturer reserves the right to modify technical data without prior notice. Your Endress+Hauser sales organization will supply you with current information and updates to this manual. Endress+Hauser...

- Page 3 Proline Promass A 100 PROFIBUS DP Table of contents Table of contents 6.2.3 Mounting the measuring device ..25 About this document ....6 6.2.4...

- Page 4 10.5.2 Calculated process variables ..69 13.3 Endress+Hauser services ....125 10.5.3 Carrying out a sensor adjustment ..71 10.5.4 Configuring the totalizer .

- Page 5 Proline Promass A 100 PROFIBUS DP Table of contents 16.7 Mounting ......140 16.8 Environment ......140 16.9 Process .

- Page 6 About this document Proline Promass A 100 PROFIBUS DP About this document Document function These Operating Instructions contain all the information required in the various life cycle phases of the device: from product identification, incoming acceptance and storage, to installation, connection, operation and commissioning, through to troubleshooting, maintenance and disposal.

- Page 7 For an overview of the scope of the associated Technical Documentation, refer to the following: • Device Viewer (www.endress.com/deviceviewer): Enter the serial number from the nameplate • Endress+Hauser Operations app: Enter serial number from nameplate or scan matrix code on nameplate. Endress+Hauser...

- Page 8 About this document Proline Promass A 100 PROFIBUS DP The following documentation may be available depending on the device version ordered: Document type Purpose and content of the document Technical Information (TI) Planning aid for your device The document contains all the technical data on the device and provides an overview of the accessories and other products that can be ordered for the device.

- Page 9 Proline Promass A 100 PROFIBUS DP Safety instructions Safety instructions Requirements for the personnel The personnel for installation, commissioning, diagnostics and maintenance must fulfill the following requirements: ‣ Trained, qualified specialists must have a relevant qualification for this specific function and task.

- Page 10 Verification for borderline cases: ‣ For special fluids and fluids for cleaning, Endress+Hauser is glad to provide assistance in verifying the corrosion resistance of fluid-wetted materials, but does not accept any warranty or liability as minute changes in the temperature, concentration or level of contamination in the process can alter the corrosion resistance properties.

- Page 11 Proline Promass A 100 PROFIBUS DP Safety instructions IT security Our warranty is valid only if the product is installed and used as described in the Operating Instructions. The product is equipped with security mechanisms to protect it against any inadvertent changes to the settings.

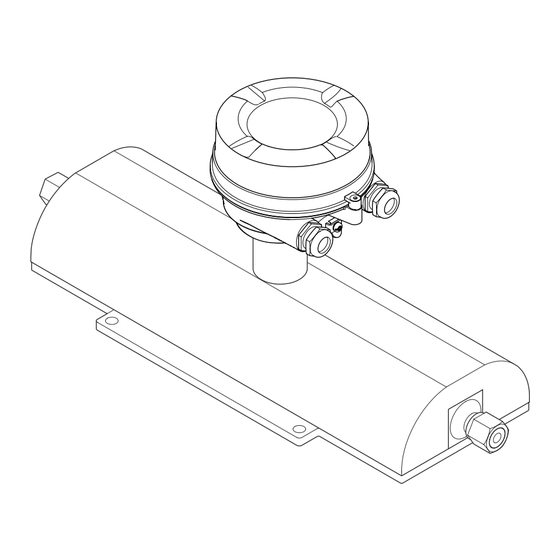

- Page 12 Product description Proline Promass A 100 PROFIBUS DP Product description The device consists of a transmitter and a sensor. The device is available as a compact version: The transmitter and sensor form a mechanical unit. Product design 3.1.1 Device version with PROFIBUS DP communication protocol A0023153 ...

- Page 13 • Enter the serial numbers from the nameplates in the Device Viewer (www.endress.com/deviceviewer): all the information about the device is displayed. • Enter the serial numbers from the nameplates into the Endress+Hauser Operations app or scan the DataMatrix code on the nameplate with the Endress+Hauser Operations app: all the information about the device is displayed.

- Page 14 Incoming acceptance and product identification Proline Promass A 100 PROFIBUS DP 4.2.1 Transmitter nameplate Order code: Ser. no.: Ext. ord. cd.: A0030222 2 Example of a transmitter nameplate Manufacturer address/certificate holder Name of the transmitter Order code Serial number Extended order code Electrical connection data, e.g.

- Page 15 Proline Promass A 100 PROFIBUS DP Incoming acceptance and product identification 4.2.2 Sensor nameplate Order code: Ser. no.: Ext. ord. cd.: Date: A0029199 3 Example of a sensor nameplate Name of the sensor Manufacturer address/certificate holder Order code Serial number (Ser. no.) Extended order code (Ext.

- Page 16 Incoming acceptance and product identification Proline Promass A 100 PROFIBUS DP 4.2.3 Symbols on the device Symbol Meaning WARNING! This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in serious or fatal injury. Please consult the documentation for the measuring instrument to discover the type of potential danger and measures to avoid it.

- Page 17 Proline Promass A 100 PROFIBUS DP Storage and transport Storage and transport Storage conditions Observe the following notes for storage: ‣ Store in the original packaging to ensure protection from shock. ‣ Do not remove protective covers or protective caps installed on process connections.

- Page 18 Storage and transport Proline Promass A 100 PROFIBUS DP 5.2.2 Measuring devices with lifting lugs CAUTION Special transportation instructions for devices with lifting lugs ‣ Only use the lifting lugs fitted on the device or flanges to transport the device.

- Page 19 Proline Promass A 100 PROFIBUS DP Installation Installation Installation requirements 6.1.1 Installation position Installation point A0028772 To prevent measuring errors arising from accumulation of gas bubbles in the measuring pipe, avoid the following mounting locations in the piping: • Highest point of a pipeline.

- Page 20 Installation Proline Promass A 100 PROFIBUS DP Ø orifice plate, pipe restriction [mm] [in] [mm] [in] ¹⁄₂₄ 0.03 ¹⁄₁₂ 0.06 ¹⁄₈ 0.12 Orientation The direction of the arrow on the sensor nameplate helps you to install the sensor according to the flow direction (direction of medium flow through the piping).

- Page 21 Proline Promass A 100 PROFIBUS DP Installation 6.1.2 Environmental and process requirements Ambient temperature range Measuring device • –40 to +60 °C (–40 to +140 °F) • Order code for "Test, certificate", option JM: –50 to +60 °C (–58 to +140 °F) ‣...

- Page 22 Installation Proline Promass A 100 PROFIBUS DP Heating NOTICE Electronics can overheat due to elevated ambient temperature! ‣ Observe maximum permitted ambient temperature for the transmitter. ‣ Depending on the medium temperature, take the device orientation requirements into account. NOTICE Danger of overheating when heating ‣...

- Page 23 Proline Promass A 100 PROFIBUS DP Installation WARNING Danger from medium escaping! Medium escaping under pressure can cause injury or material damage. ‣ Take precautions to prevent danger to persons and damage if the rupture disk is actuated. ‣ Observe the information on the rupture disk sticker.

- Page 24 Installation Proline Promass A 100 PROFIBUS DP Verification and adjustment cannot be carried out if the following process conditions are present: • Gas pockets Ensure that the system has been sufficiently flushed with the medium. Repeat flushing can help to eliminate gas pockets •...

- Page 25 Proline Promass A 100 PROFIBUS DP Installation SW 13 SW 10 A0019746 6 Post retainer mounting kit 8 x hexagonal nut M8 × 0.8 4 x threaded bolt M8 × 150 1 x post retaining plate 1 x post securing plate 4 x spring washer for M8 4 x hexagon bolt M6 ×...

- Page 26 Installation Proline Promass A 100 PROFIBUS DP 2. Install the measuring device or turn the transmitter housing so that the cable entries do not point upwards. A0029263 6.2.4 Turning the display module The local display is only available with the following device version: Order code for "Display;...

- Page 27 Proline Promass A 100 PROFIBUS DP Installation Post-installation check Is the device undamaged (visual inspection)? Does the measuring instrument correspond to the measuring point specifications? For example: • Process temperature → 141 • Pressure (refer to the "Pressure-temperature ratings" section of the "Technical Information"...

- Page 28 Electrical connection Proline Promass A 100 PROFIBUS DP Electrical connection WARNING Live parts! Incorrect work performed on the electrical connections can result in an electric shock. ‣ Set up a disconnecting device (switch or power-circuit breaker) to easily disconnect the device from the supply voltage.

- Page 29 Proline Promass A 100 PROFIBUS DP Electrical connection 7.2.3 Terminal assignment Transmitter PROFIBUS DP connection version For use in the non-hazardous area and Zone 2/Div. 2 Order code for "Output", option L Depending on the housing version, the transmitters can be ordered with terminals or device plugs.

- Page 30 Electrical connection Proline Promass A 100 PROFIBUS DP 7.2.4 Pin assignment, device plug Supply voltage For use in the non-hazardous area and Zone 2/Div. 2. Assignment DC 24 V Not assigned Not assigned DC 24 V Grounding/shielding A0016809 Coding Plug/socket...

- Page 31 Proline Promass A 100 PROFIBUS DP Electrical connection 7.3.1 Connecting the transmitter The connection of the transmitter depends on the following order codes: • Housing version: compact or ultra-compact • Connection version: device plug or terminals A0016924 8 Housing versions and connection versions...

- Page 32 Electrical connection Proline Promass A 100 PROFIBUS DP For device version with device plug: follow step 6 only. 1. Depending on the housing version, loosen the securing clamp or fixing screw of the housing cover. 2. Depending on the housing version, unscrew or open the housing cover and disconnect the local display from the main electronics module where necessary →...

- Page 33 Proline Promass A 100 PROFIBUS DP Electrical connection Special connection instructions 7.5.1 Connection examples PROFIBUS DP A0028765 10 Connection example for PROFIBUS DP, non-hazardous area and Zone 2/Div. 2 Control system (e.g. PLC) Cable shield provided at one end. The cable shield must be grounded at both ends to comply with EMC requirements;...

- Page 34 Electrical connection Proline Promass A 100 PROFIBUS DP Setting the address OFF ON - Software addressing - Write protection - Not used A0021265 11 Addressing using DIP switches on the I/O electronics module 1. Depending on the housing version, loosen the securing clamp or fixing screw of the housing cover.

- Page 35 Proline Promass A 100 PROFIBUS DP Electrical connection 390 Ω DIP 1 OFF ON Bus polarisation DIP 2 220 Ω Bus termination Bus polarisation Not used DIP 3 390 Ω A0021274 12 Termination using DIP switches on the I/O electronics module (for baud rates < 1.5 MBaud)

- Page 36 Electrical connection Proline Promass A 100 PROFIBUS DP Are the installed cables strain-relieved and securely routed? Are all cable glands installed, securely tightened and leak-tight? Cable run with "water trap" → 35? Depending on the device version: ...

- Page 37 Proline Promass A 100 PROFIBUS DP Operation options Operation options Overview of operation options A0017760 Computer with web browser or with "FieldCare" operating tool Automation system, e.g. "RSLogix" (Rockwell Automation) and work station for measuring instrument operation with Add-on Profile Level 3 for "RSLogix 5000" software (Rockwell Automation)

- Page 38 Operation options Proline Promass A 100 PROFIBUS DP Structure and function of the operating menu 8.2.1 Structure of the operating menu For an overview of the operating menu for experts: see the "Description of Device Parameters" document supplied with the device → 152...

- Page 39 Proline Promass A 100 PROFIBUS DP Operation options 8.2.2 Operating philosophy The individual parts of the operating menu are assigned to certain user roles (e.g. operator, maintenance etc.). Each user role contains typical tasks within the device life cycle. Menu/parameter...

- Page 40 Operation options Proline Promass A 100 PROFIBUS DP Displaying the measured values via the local display (optionally available) 8.3.1 Operational display The local display is optionally available: Order code for "Display; operation", option B ""4-line, illuminated; via communication". X X X X X X X 1120.50...

- Page 41 Proline Promass A 100 PROFIBUS DP Operation options • Density • Reference density Temperature Totalizer The measurement channel number indicates which of the three totalizers is displayed. Measurement channel numbers Symbol Meaning Measurement channel 1 to 4 The measurement channel number is displayed only if more than one channel is present for the same measured variable type (e.g.

- Page 42 Operation options Proline Promass A 100 PROFIBUS DP Access to operating menu via web browser 8.4.1 Function range With the integrated web server, the device can be operated and configured via a web browser service interface (CDI-RJ45) WLAN interface. In addition to the measured values, status information on the device is displayed and can be used to monitor device health.

- Page 43 Proline Promass A 100 PROFIBUS DP Operation options Network connections Only the active network connections to the measuring device should be used. Switch off all other network connections. In the event of connection problems: → 85 Measuring device: Via CDI-RJ45 service interface...

- Page 44 Operation options Proline Promass A 100 PROFIBUS DP 2. Enter the IP address of the web server in the address line of the web browser: 192.168.1.212 The login page appears. 2 3 4 Device name: Device tag: Signal Status:...

- Page 45 Proline Promass A 100 PROFIBUS DP Operation options 8.4.5 User interface A0032879 Picture of device Device name Device tag Status signal Current measured values Navigation area Local display language Header The following information appears in the header: • Device name •...

- Page 46 Operation options Proline Promass A 100 PROFIBUS DP Functions Meaning Configuration and checking of all the parameters required for establishing the connection to the measuring device: Network • Network settings (e.g. IP address, MAC address) • Device information (e.g. serial number, firmware version)

- Page 47 Proline Promass A 100 PROFIBUS DP Operation options 1. Select the Logout entry in the function row. The home page with the Login box appears. 2. Close the Web browser. 3. If no longer needed: Reset the modified properties of the Internet protocol (TCP/IP) → 43.

- Page 48 FieldCare Function range FDT-based (Field Device Technology) plant asset management tool from Endress+Hauser. It can configure all smart field units in a system and helps you manage them. By using the status information, it is also a simple but effective way of checking their status and condition.

- Page 49 DeviceCare Function range Tool for connecting and configuring Endress+Hauser field devices. The fastest way to configure Endress+Hauser field devices is with the dedicated "DeviceCare" tool. Together with the device type managers (DTMs) it presents a convenient, comprehensive solution. Innovation brochure IN01047S Source for device description files →...

- Page 50 System integration Proline Promass A 100 PROFIBUS DP System integration Overview of device description files 9.1.1 Current version data for the device Firmware version 01.01.zz • On the title page of the manual • On the transmitter nameplate • Parameter: Firmware version parameter Diagnostics →...

- Page 51 Proline Promass A 100 PROFIBUS DP System integration 9.2.1 Manufacturer-specific GSD This GSD guarantees the unrestricted functionality of the measuring device. Device-specific process parameters and functions are therefore available. Manufacturer-specific GSD ID number File name PROFIBUS DP 0x1561 EH3x1561.gsd The fact that the manufacturer-specific GSD should be used is specified in the Ident number selector parameter by selecting the Manufacturer option.

- Page 52 System integration Proline Promass A 100 PROFIBUS DP Integration into a PROFIBUS network 9.3.1 Block model • Physical block • Function blocks • Analog Input Block • Analog Output Block • Discrete Input Block • Discrete Output Block • Totalizer Block Technical values for the individual blocks →...

- Page 53 Proline Promass A 100 PROFIBUS DP System integration Channel Measured variable 1056 Exciter current 0 1057 Exciter current 1 1440 HBSI Analog Output 1 to 3 (AO) Channel Measured variable External pressure External temperature External reference density The compensation variables must be transmitted to the device in the SI basic unit.

- Page 54 System integration Proline Promass A 100 PROFIBUS DP Cyclic data transmission Cyclic data transmission when using the device master file (GSD). 9.4.1 Block model The block model shows which input and output data the measuring device makes available for cyclic data exchange. Cyclic data exchange takes place with a PROFIBUS master (Class 1), e.g.

- Page 55 Proline Promass A 100 PROFIBUS DP System integration AI module (Analog Input) Transmit an input variable from the measuring device to the PROFIBUS master (Class 1). The selected input variable including its status is cyclically transmitted to the PROFIBUS master (Class 1) via the AI module. The input variable is depicted in the first four bytes in the form of a floating point number as per the IEEE 754 standard.

- Page 56 System integration Proline Promass A 100 PROFIBUS DP TOTAL module Transmit a totalizer value from the measuring device to the PROFIBUS master (Class 1). A selected totalizer value, along with the status, is cyclically transmitted to a PROFIBUS Master (Class 1) via the TOTAL module. The totalizer value is depicted in the first four bytes in the form of a floating point number as per the IEEE 754 standard.

- Page 57 Proline Promass A 100 PROFIBUS DP System integration Data structure Output data of SETTOT Byte 1 Control variable 1 Input data of TOTAL Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Measured value: floating point number (IEEE 754)

- Page 58 System integration Proline Promass A 100 PROFIBUS DP standard. The fifth byte contains standardized status information pertaining to the compensation value. Three Analog Output blocks are available (slot 12 to 14). Assigned compensation values A compensation value is permanently assigned to the individual Analog Output blocks.

- Page 59 Proline Promass A 100 PROFIBUS DP System integration Data structure Input data of Discrete Input Byte 1 Byte 2 Discrete Status DO module (Discrete Output) Transmit discrete output values from the PROFIBUS master (class 1) to the measuring device. Discrete output values are used by the PROFIBUS master (class 1) to enable and disable device functions.

- Page 60 Commissioning Proline Promass A 100 PROFIBUS DP Commissioning 10.1 Post-mounting and post-connection check Before commissioning the device: ‣ Make sure that the post-installation and post-connection checks have been performed successfully. • Checklist for "Post-installation" check→ 27 • Checklist for "Post-connection" check→ 35 10.2...

- Page 61 Proline Promass A 100 PROFIBUS DP Commissioning 10.4.1 Defining the tag name To enable fast identification of the measuring point within the system, you can enter a unique designation using the Device tag parameter and thus change the factory setting.

- Page 62 Commissioning Proline Promass A 100 PROFIBUS DP Parameter overview with brief description Parameter Description Selection Factory setting Mass flow unit Select mass flow unit. Unit choose list Country-specific: • kg/h (DN > 150 (6"): t/h Effect option) The selected unit applies to: •...

- Page 63 Proline Promass A 100 PROFIBUS DP Commissioning Parameter Description Selection Factory setting Temperature unit Select temperature unit. Unit choose list Country-specific: • °C Effect • °F The selected unit applies to: • Electronic temperature parameter (6053) • Maximum value parameter (6051) •...

- Page 64 Commissioning Proline Promass A 100 PROFIBUS DP 10.4.3 Selecting and setting the medium The Select medium wizard submenu contains parameters that must be configured in order to select and set the medium. Navigation "Setup" menu → Medium selection ‣ Medium selection Select medium →...

- Page 65 Proline Promass A 100 PROFIBUS DP Commissioning Parameter Prerequisite Description Selection / User entry Reference sound velocity In the Select gas type parameter, the Enter sound velocity of gas at 0 °C (32 1 to 99 999.9999 m/s Others option is selected.

- Page 66 Commissioning Proline Promass A 100 PROFIBUS DP 10.4.5 Configuration of the Analog Inputs The Analog inputs submenu guides the user systematically to the individual Analog input 1 to n submenu. From here you get to the parameters of the individual analog input.

- Page 67 Proline Promass A 100 PROFIBUS DP Commissioning 10.4.6 Configuring the low flow cut off The Low flow cut off submenu contains the parameters that must be set in order to configure the low flow cut off. Navigation "Setup" menu → Low flow cut off ‣...

- Page 68 Commissioning Proline Promass A 100 PROFIBUS DP 10.4.7 Configuring partially filled pipe detection The Partially filled pipe detection submenu contains parameters that have to be set for configuring empty pipe detection. Navigation "Setup" menu → Partially filled pipe detection ‣...

- Page 69 Proline Promass A 100 PROFIBUS DP Commissioning 10.5 Advanced settings The Advanced setup submenu with its submenus contains parameters for specific settings. The number of submenus can vary depending on the device version, e.g. viscosity is available only with the Promass I.

- Page 70 Commissioning Proline Promass A 100 PROFIBUS DP Navigation "Setup" menu → Advanced setup → Calculated values ‣ Calculated values ‣ Corrected volume flow calculation → 70 "Corrected volume flow calculation" submenu Navigation "Setup" menu → Advanced setup → Calculated values → Corrected volume flow calculation ‣...

- Page 71 Proline Promass A 100 PROFIBUS DP Commissioning Parameter Prerequisite Description Selection / User Factory setting interface / User entry Reference temperature The Calculated reference Enter reference temperature –273.15 to 99 999 °C Country-specific: density option is selected in for calculating the reference • +20 °C the Corrected volume flow density.

- Page 72 Commissioning Proline Promass A 100 PROFIBUS DP Performing density adjustment Note the following before performing the adjustment: • A density adjustment only makes sense if there is little variation in the operating conditions and the density adjustment is performed under the operating conditions.

- Page 73 Proline Promass A 100 PROFIBUS DP Commissioning 4. Select the Measure density 1 option and confirm. In the Execute density adjustment parameter the following options are now available: Measure density 2 Restore original 5. Select the Measure density 2 option and confirm.

- Page 74 Commissioning Proline Promass A 100 PROFIBUS DP Parameter Prerequisite Description Selection / User Factory setting entry / User interface Density setpoint 2 In the Density adjustment The entry depends on – mode parameter, the 2 point the unit selected in adjustment option is selected.

- Page 75 Proline Promass A 100 PROFIBUS DP Commissioning Navigation "Setup" menu → Advanced setup → Sensor adjustment → Zero point adjustment ‣ Zero point adjustment Zero point adjustment control → 75 Progress → 75 Parameter overview with brief description...

- Page 76 Commissioning Proline Promass A 100 PROFIBUS DP Parameter overview with brief description Parameter Prerequisite Description Selection Factory setting Assign process variable – Select process variable for • Mass flow – totalizer. • Volume flow • Corrected volume flow • Target mass flow •...

- Page 77 Proline Promass A 100 PROFIBUS DP Commissioning Parameter overview with brief description Parameter Description User entry / Selection Define access code Define release code for write access to parameters. 0 to 9 999 Device reset Reset the device configuration - either entirely or in part - to a •...

- Page 78 Commissioning Proline Promass A 100 PROFIBUS DP Parameter Prerequisite Description Selection / User entry Diagnostic event category – Select a diagnostic event category. • Sensor • Electronics • Configuration • Process Simulation diagnostic event – Select a diagnostic event for the • Off simulation process that is activated.

- Page 79 Proline Promass A 100 PROFIBUS DP Commissioning 10.7.2 Write protection via write protection switch The write protection switch makes it possible to block write access to the entire operating menu with the exception of the following parameters: • External pressure •...

- Page 80 Operation Proline Promass A 100 PROFIBUS DP Operation 11.1 Reading the device locking status Device active write protection: Locking status parameter Navigation "Operation" menu → Locking status Function scope of "Locking status" parameter Options Description Hardware locked The write protection switch (DIP switch) for hardware locking is activated on the I/O electronic module.

- Page 81 Proline Promass A 100 PROFIBUS DP Operation Navigation "Diagnostics" menu → Measured values → Measured variables ‣ Measured variables Mass flow → 81 Volume flow → 81 → 81 Corrected volume flow Density → 82 Reference density →...

- Page 82 Operation Proline Promass A 100 PROFIBUS DP Parameter Prerequisite Description User interface Density – Shows the density currently measured. Signed floating-point number Dependency The unit is taken from the Density unit parameter (→ 62). Reference density – Displays the reference density that is Signed floating-point currently calculated.

- Page 83 Proline Promass A 100 PROFIBUS DP Operation Navigation "Diagnostics" menu → Measured values → Totalizer ‣ Totalizer Totalizer value 1 to n → 83 Totalizer overflow 1 to n → 83 Parameter overview with brief description Parameter Prerequisite...

- Page 84 Operation Proline Promass A 100 PROFIBUS DP Navigation "Operation" menu → Totalizer handling ‣ Totalizer handling Control Totalizer 1 to n → 84 Preset value 1 to n → 84 → 84 Reset all totalizers Parameter overview with brief description...

- Page 85 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting Diagnostics and troubleshooting 12.1 General troubleshooting For local display Error Possible causes Remedial action Local display is dark, but signal output is within The cable of the display module is not plugged in...

- Page 86 Diagnostics and troubleshooting Proline Promass A 100 PROFIBUS DP Fault Possible causes Remedial action ‣ The Ethernet interface on the PC is incorrectly Check the properties of the Internet protocol configured. (TCP/IP). ‣ Check the network settings with the IT manager.

- Page 87 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting A0029689 Supply voltage Device status Not used Communication Service interface (CDI) active, Ethernet Link/Activity 1. Open the housing cover. 2. Remove the display module. 3. Fold open the terminal cover. Color...

- Page 88 Diagnostics and troubleshooting Proline Promass A 100 PROFIBUS DP A0032880 Status area with status signal Diagnostics information → 88 and remedial measures with service ID In addition, diagnostic events which have occurred can be shown in the Diagnostics menu: •...

- Page 89 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting 12.3.2 Calling up remedy information Remedy information is provided for every diagnostic event to ensure that problems can be rectified quickly. These measures are displayed in red along with the diagnostic event and the related diagnostic information.

- Page 90 Diagnostics and troubleshooting Proline Promass A 100 PROFIBUS DP Diagnostic information Diagnostic code Status signal Diagnostic number Short text ↓ ↓ ↓ Example Process limit A0013958 3-digit number 12.4.2 Calling up remedy information Remedy information is provided for every diagnostic event to ensure that problems can be rectified quickly: •...

- Page 91 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting Diagnostic behavior Description Logbook entry only The device continues to measure. The diagnostic message is only displayed in the Event logbook submenu (Event list submenu) and is not displayed in alternating sequence with the operational display.

- Page 92 Diagnostics and troubleshooting Proline Promass A 100 PROFIBUS DP Diagnostic information pertaining to the sensor: diagnostic number 000 to 199 Measured value status (fixed assignment) Diagnostic behavior Device diagnosis Quality Coding Category (configurable) (fixed assignment) Quality Substatus (hex) (NE107) Maintenance...

- Page 93 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting Diagnostic information pertaining to the process: diagnostic number 800 to 999 Measured value status (fixed assignment) Diagnostic behavior Device diagnosis Quality Coding Category (configurable) (fixed assignment) Quality Substatus (hex) (NE107) Process...

- Page 94 Diagnostics and troubleshooting Proline Promass A 100 PROFIBUS DP Diagnostic information Remedy instructions Influenced measured variables Short text 046 Sensor limit exceeded 1. Inspect sensor • Carrier mass flow 2. Check process condition • Concentration • Density Status signal • Dynamic viscosity...

- Page 95 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting Diagnostic information Remedy instructions Influenced measured variables Short text 083 Memory content 1. Restart device • Carrier mass flow 2. Contact service • Concentration • Density Status signal • Dynamic viscosity...

- Page 96 Diagnostics and troubleshooting Proline Promass A 100 PROFIBUS DP Diagnostic information Remedy instructions Influenced measured variables Short text 190 Special event 1 Contact service • Carrier mass flow • Concentration • Density Status signal • Dynamic viscosity Diagnostic behavior Alarm •...

- Page 97 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting Diagnostic information Remedy instructions Influenced measured variables Short text 192 Special event 9 Contact service • Carrier mass flow • Concentration • Density Status signal • Dynamic viscosity Diagnostic behavior Alarm •...

- Page 98 Diagnostics and troubleshooting Proline Promass A 100 PROFIBUS DP Diagnostic information Remedy instructions Influenced measured variables Short text 242 Software incompatible 1. Check software • Carrier mass flow 2. Flash or change main electronics • Concentration module • Density Status signal •...

- Page 99 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting Diagnostic information Remedy instructions Influenced measured variables Short text 262 Module connection 1. Check module connections • Carrier mass flow 2. Change main electronics • Concentration • Density Status signal • Dynamic viscosity...

- Page 100 Diagnostics and troubleshooting Proline Promass A 100 PROFIBUS DP Diagnostic information Remedy instructions Influenced measured variables Short text 271 Main electronic failure 1. Restart device • Carrier mass flow 2. Change main electronic module • Concentration • Density Status signal •...

- Page 101 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting Diagnostic information Remedy instructions Influenced measured variables Short text 273 Main electronic failure Change electronic • Carrier mass flow • Concentration • Density Status signal • Dynamic viscosity Diagnostic behavior Alarm •...

- Page 102 Diagnostics and troubleshooting Proline Promass A 100 PROFIBUS DP Diagnostic information Remedy instructions Influenced measured variables Short text 311 Electronic failure 1. Reset device • Carrier mass flow 2. Contact service • Concentration • Density Status signal • Dynamic viscosity...

- Page 103 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting Diagnostic information Remedy instructions Influenced measured variables Short text 382 Data storage 1. Insert DAT module • Carrier mass flow 2. Change DAT module • Concentration • Density Status signal • Dynamic viscosity...

- Page 104 Diagnostics and troubleshooting Proline Promass A 100 PROFIBUS DP Diagnostic information Remedy instructions Influenced measured variables Short text 390 Special event 2 Contact service • Carrier mass flow • Concentration • Density Status signal • Dynamic viscosity Diagnostic behavior Alarm •...

- Page 105 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting Diagnostic information Remedy instructions Influenced measured variables Short text 392 Special event 10 Contact service • Carrier mass flow • Concentration • Density Status signal • Dynamic viscosity Diagnostic behavior Alarm •...

- Page 106 Diagnostics and troubleshooting Proline Promass A 100 PROFIBUS DP Diagnostic information Remedy instructions Influenced measured variables Short text 411 Up-/download active Up-/download active, please wait • Carrier mass flow • Concentration • Density Status signal • Dynamic viscosity Diagnostic behavior Warning •...

- Page 107 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting Diagnostic information Remedy instructions Influenced measured variables Short text 437 Configuration incompatible 1. Restart device • Carrier mass flow 2. Contact service • Concentration • Density Status signal • Dynamic viscosity...

- Page 108 Diagnostics and troubleshooting Proline Promass A 100 PROFIBUS DP Diagnostic information Remedy instructions Influenced measured variables Short text 453 Flow override Deactivate flow override • Carrier mass flow • Concentration • Density Status signal • Dynamic viscosity Diagnostic behavior Warning •...

- Page 109 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting Diagnostic information Remedy instructions Influenced measured variables Short text 485 Simulation measured variable Deactivate simulation • Carrier mass flow • Concentration • Density Status signal • Dynamic viscosity Diagnostic behavior Warning •...

- Page 110 Diagnostics and troubleshooting Proline Promass A 100 PROFIBUS DP Diagnostic information Remedy instructions Influenced measured variables Short text 590 Special event 3 Contact service • Carrier mass flow • Concentration • Density Status signal • Dynamic viscosity Diagnostic behavior Alarm •...

- Page 111 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting Diagnostic information Remedy instructions Influenced measured variables Short text 592 Special event 11 Contact service • Carrier mass flow • Concentration • Density Status signal • Dynamic viscosity Diagnostic behavior Alarm •...

- Page 112 Diagnostics and troubleshooting Proline Promass A 100 PROFIBUS DP Diagnostic information Remedy instructions Influenced measured variables Short text 825 Operating temperature 1. Check ambient temperature • Carrier mass flow 2. Check process temperature • Concentration • Density Status signal • Dynamic viscosity...

- Page 113 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting Diagnostic information Remedy instructions Influenced measured variables Short text 832 Electronic temperature too high Reduce ambient temperature • Carrier mass flow • Concentration • Density Status signal • Empty pipe detection...

- Page 114 Diagnostics and troubleshooting Proline Promass A 100 PROFIBUS DP Diagnostic information Remedy instructions Influenced measured variables Short text 835 Process temperature too low Increase process temperature • Carrier mass flow • Concentration • Density Status signal • Dynamic viscosity Diagnostic behavior Warning •...

- Page 115 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting Diagnostic information Remedy instructions Influenced measured variables Short text 862 Partly filled pipe 1. Check for gas in process • Carrier mass flow 2. Adjust detection limits • Concentration • Density Status signal •...

- Page 116 Diagnostics and troubleshooting Proline Promass A 100 PROFIBUS DP Diagnostic information Remedy instructions Influenced measured variables Short text 912 Medium inhomogeneous 1. Check process cond. • Carrier mass flow 2. Increase system pressure • Concentration • Density Status signal • Dynamic viscosity...

- Page 117 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting Diagnostic information Remedy instructions Influenced measured variables Short text 944 Monitoring failed Check process conditions for Heartbeat • Carrier mass flow Monitoring • Concentration • Density Status signal • Mass flow...

- Page 118 Diagnostics and troubleshooting Proline Promass A 100 PROFIBUS DP Diagnostic information Remedy instructions Influenced measured variables Short text 991 Special event 8 Contact service • Carrier mass flow • Concentration • Density Status signal • Dynamic viscosity Diagnostic behavior Alarm •...

- Page 119 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting Navigation "Diagnostics" menu Diagnostics Actual diagnostics → 119 Previous diagnostics → 119 → 119 Operating time from restart Operating time → 119 Parameter overview with brief description...

- Page 120 Diagnostics and troubleshooting Proline Promass A 100 PROFIBUS DP Navigation path Diagnostics menu → Event logbook submenu → Events list The event history includes entries for: • Diagnostic events → 93 • Information events → 120 In addition to the operating time when the event occurred, each event is also assigned a symbol that indicates whether the event has occurred or is finished: •...

- Page 121 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting Info number Info name I1187 Settings downloaded with display I1188 Display data cleared I1189 Backup compared I1209 Density adjustment ok I1221 Zero point adjust failure I1222 Zero point adjustment ok I1256...

- Page 122 Diagnostics and troubleshooting Proline Promass A 100 PROFIBUS DP 12.11 Device information The Device information submenu contains all parameters that display different information for device identification. Navigation "Diagnostics" menu → Device information ‣ Device information Device tag → 122 Serial number →...

- Page 123 Proline Promass A 100 PROFIBUS DP Diagnostics and troubleshooting Parameter Description User interface Factory setting Order code Shows the device order code. Character string composed of – letters, numbers and certain The order code can be found on the punctuation marks (e.g.

- Page 124 "Manufacturer' s information" document. The manufacturer' s information is available: • In the Download Area of the Endress+Hauser web site: www.endress.com → Downloads • Specify the following details: •...

- Page 125 • Observe the maximum permitted medium temperature for the measuring device . 13.2 Measuring and test equipment Endress+Hauser offers a variety of measuring and testing equipment, such as Netilion or device tests. Your Endress+Hauser Sales Center can provide detailed information on the services.

- Page 126 • The measuring devices have a modular design. • Spare parts are grouped into logical kits with the associated Installation Instructions. • Repairs are carried out by Endress+Hauser Service or by appropriately trained customers. • Certified devices can only be converted to other certified devices by Endress+Hauser Service or at the factory.

- Page 127 Proline Promass A 100 PROFIBUS DP Repair 14.5 Disposal If required by the Directive 2012/19/EU on waste electrical and electronic equipment (WEEE), the product is marked with the depicted symbol in order to minimize the disposal of WEEE as unsorted municipal waste. Do not dispose of products bearing this marking as unsorted municipal waste.

- Page 128 Various accessories, which can be ordered with the device or subsequently from Endress +Hauser, are available for the device. Detailed information on the order code in question is available from your local Endress+Hauser sales center or on the product page of the Endress+Hauser website: www.endress.com.

- Page 129 Via the Internet: https://portal.endress.com/webapp/applicator Netilion lloT ecosystem: Unlock knowledge With the Netilion IIoT ecosystem,Endress+Hauser allows you to optimize your plant performance, digitize workflows, share knowledge, and enhance collaboration. Drawing upon decades of experience in process automation, Endress+Hauser offers the process industry an IIoT ecosystem designed to effortlessly extract insights from data.

- Page 130 Accessories Proline Promass A 100 PROFIBUS DP 15.4 System components Accessories Description Memograph M graphic The Memograph M graphic data manager provides information on all the relevant data manager measured variables. Measured values are recorded correctly, limit values are monitored and measuring points analyzed. The data are stored in the 256 MB internal memory and also on a SD card or USB stick.

- Page 131 Proline Promass A 100 PROFIBUS DP Technical data Technical data 16.1 Application The measuring device is intended only for the flow measurement of liquids and gases. Depending on the version ordered, the measuring device can also measure potentially explosive, flammable, poisonous and oxidizing media.

- Page 132 Technical data Proline Promass A 100 PROFIBUS DP 16.3 Input Measured variable Direct measured variables • Mass flow • Density • Temperature Calculated measured variables • Volume flow • Corrected volume flow • Reference density Measuring range Measuring range for liquids Measuring range full scale values ...

- Page 133 • Operating pressure to increase measurement accuracy (Endress+Hauser recommends the use of a pressure measuring instrument for absolute pressure, e.g. Cerabar M or Cerabar S) •...

- Page 134 Technical data Proline Promass A 100 PROFIBUS DP Local display Plain text display With information on cause and remedial measures Backlight Red backlighting indicates a device error. Status signal as per NAMUR recommendation NE 107 Interface/protocol • Via digital communication: PROFIBUS DP •...

- Page 135 Proline Promass A 100 PROFIBUS DP Technical data Output values Analog input 1 to 8 (from measuring instrument to • Mass flow automation system) • Volume flow • Corrected volume flow • Target mass flow • Carrier mass flow • Density •...

- Page 136 Technical data Proline Promass A 100 PROFIBUS DP Transmitter DC 20 to 30 V Power consumption Transmitter Maximum Order code for "Output" Power consumption Option L: PROFIBUS DP 3.5 W Current consumption Transmitter Maximum Maximum Order code for "Output" Current consumption...

- Page 137 Proline Promass A 100 PROFIBUS DP Technical data Maximum measurement o.r. = of reading; 1 g/cm³ = 1 kg/l; T = medium temperature error Base accuracy Design fundamentals → 139 Mass flow and volume flow (liquids) ±0.10 % o.r.

- Page 138 Technical data Proline Promass A 100 PROFIBUS DP US units 1:10 1:20 1:50 1:100 1:500 [inch] [lb/min] [lb/min] [lb/min] [lb/min] [lb/min] [lb/min] ¹⁄₂₄ 0.735 0.074 0.037 0.015 0.007 0.001 ¹⁄₁₂ 3.675 0.368 0.184 0.074 0.037 0.007 ¹⁄₈ 16.54 1.654 0.827 0.331...

- Page 139 Proline Promass A 100 PROFIBUS DP Technical data [kg/m ] [°C] [°F] -40 0 40 80 120 160 200 240 280 320 360 400 A0016616 Field density adjustment, for example at +20 °C (+68 °F) Special density calibration Temperature ±0.005 · T °C (± 0.005 · (T – 32) °F)

- Page 140 Technical data Proline Promass A 100 PROFIBUS DP Example of maximum measurement error E [%] 100 Q [%] A0024173 Maximum measurement error in % o.r. (example) Flow rate in % of maximum full scale value 16.7 Mounting Mounting requirements → 19 16.8...

- Page 141 Proline Promass A 100 PROFIBUS DP Technical data Shock half-sine, according to IEC 60068-2-27 6 ms 30 g Rough handling shocks according to IEC 60068-2-31 Internal cleaning • CIP cleaning • SIP cleaning Options Oil- and grease-free version for wetted parts, without declaration Order code for "Service", option HA...

- Page 142 Technical data Proline Promass A 100 PROFIBUS DP involving high gas pressures, and particularly in applications in which the process pressure is greater than 2/3 of the sensor housing burst pressure. If there is a need to drain the leaking medium into a discharge device, the sensor should be fitted with a rupture disk.

- Page 143 Proline Promass A 100 PROFIBUS DP Technical data • The minimum recommended full scale value is approx. 1/20 of the maximum full scale value • In most applications, 20 to 50 % of the maximum full scale value can be considered ideal •...

- Page 144 Technical data Proline Promass A 100 PROFIBUS DP 16.10 Mechanical construction Design, dimensions For the dimensions and installation lengths of the device, see the "Technical Information" document, "Mechanical construction" section Weight All values (weight exclusive of packaging material) refer to devices with EN/DIN PN 40 flanges.

- Page 145 Proline Promass A 100 PROFIBUS DP Technical data Cable entries/cable glands A0020640 17 Possible cable entries/cable glands Female thread M20 × 1.5 Cable gland M20 × 1.5 Adapter for cable entry with female thread G ½" or NPT ½"...

- Page 146 Technical data Proline Promass A 100 PROFIBUS DP Process connections VCO coupling • Stainless steel, 1.4404 (316/316L) • Alloy C22, 2.4602 (UNS N06022) Tri-clamp Stainless steel, 1.4539 (904L) Adapter, flanges as per EN 1092-1 (DIN 2501), ASME B16.5, JIS B2220 •...

- Page 147 Proline Promass A 100 PROFIBUS DP Technical data Surface roughness All data refer to parts in contact with the medium. The following surface roughness categories can be ordered: • Not polished • Ra ≤ 0.76 µm (30 µin) • Ra ≤0.38 µm (15 µin) 16.11 Operability...

- Page 148 Technical data Proline Promass A 100 PROFIBUS DP A0020903 18 Options for remote operation via PROFIBUS DP network Automation system Computer with PROFIBUS network card PROFIBUS DP network Measuring device Service interface Via service interface (CDI-RJ45) PROFIBUS DP A0021270 ...

- Page 149 The device meets the legal requirements of the applicable EU Directives. These are listed in the corresponding EU Declaration of Conformity along with the standards applied. Endress+Hauser confirms successful testing of the device by affixing to it the CE mark. UKCA marking The device meets the legal requirements of the applicable UK regulations (Statutory Instruments).

- Page 150 The application packages can be ordered with the device or subsequently from Endress+Hauser. Detailed information on the order code in question is available from your local Endress+Hauser sales center or on the product page of the Endress+Hauser website: www.endress.com.

- Page 151 Proline Promass A 100 PROFIBUS DP Technical data Heartbeat Verification Meets the requirement for traceable verification to DIN ISO 9001:2008 Chapter 7.6 a) "Control of monitoring and measuring equipment". • Functional testing in the installed state without interrupting the process.

- Page 152 For an overview of the scope of the associated Technical Documentation, refer to the following: • Device Viewer (www.endress.com/deviceviewer): Enter the serial number from the nameplate • Endress+Hauser Operations app: Enter serial number from nameplate or scan matrix code on nameplate. Standard documentation Brief Operating instructions...

- Page 153 Proline Promass A 100 PROFIBUS DP Technical data Installation instructions Contents Note Installation instructions for spare part sets and • Access the overview of all the available spare part accessories sets via Device Viewer → 126 • Accessories available for order with Installation Instructions →...

- Page 154 Index Proline Promass A 100 PROFIBUS DP Index 0 … 9 Density adjustment ......71 Design 3-A approval .

- Page 155 Proline Promass A 100 PROFIBUS DP Index Electromagnetic compatibility ....141 Installation ......27 EMPTY_MODULE module .

- Page 156 Index Proline Promass A 100 PROFIBUS DP Totalizer Setup (Menu) ......61 SETTOT_MODETOT_TOTAL ....57 Simulation (Submenu) .

- Page 157 Proline Promass A 100 PROFIBUS DP Index Settings Supply voltage ......135 Adapting the measuring device to the process Surface roughness .

- Page 158 Index Proline Promass A 100 PROFIBUS DP Wizard Define access code ......78 Density adjustment ..... . . 72 Low flow cut off .

- Page 160 *71674461* 71674461 www.addresses.endress.com...

Need help?

Do you have a question about the Proline Promass A 100 PROFIBUS DP and is the answer not in the manual?

Questions and answers