Summary of Contents for Lincoln Electric 12649

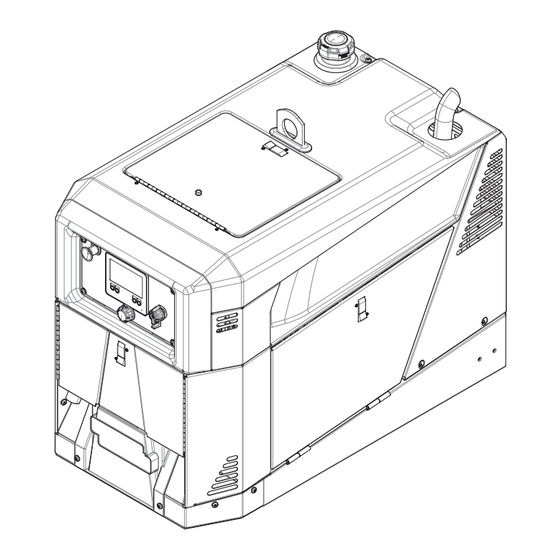

- Page 1 ® Ranger 330 MPX For use with machines having Code Numbers: Ranger ® 330 MPX: 12649, 13011 SERVICE MANUAL SVM300 | Issue D ate Apr - 19 © Lincoln Global, Inc. All Rights Reserved.

- Page 2 THANK YOU FOR SELECTING A QUALITY PRODUCT BY KEEP YOUR HEAD OUT OF THE FUMES. DON’T get too close to the arc. LINCOLN ELEC TRIC. Use corrective lenses if necessary to stay a reasonable distance away from the arc. READ and obey the Safety Data PLEASE EXAMINE CARTON AND EQUIPMENT FOR Sheet (SDS) and the warning label DAMAGE IMMEDIATELY...

- Page 3 W117.2. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 22801 2.d. All welders should use the following procedures in order to St. Clair Avenue, Cleveland, Ohio 44117-1199.

-

Page 4: Electric Shock Can Kill

SAFETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper filter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”... - Page 5 SAFETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove fire hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

-

Page 6: Case Cover Removal And Replacement Procedure

WARNING: Type of Hazard: Service and repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detai!e . d throughout this manual. - Page 7 13. Using a 7/16" open�end wrench, remove the nut and washer securing the encoder shaft to the control panel. 14. The control panel assembly can now be removed. 15. Using a 9/16" open�end wrench and a 1/2" open�end wrench, loosen the two nuts securing the choke control to the roof welded assembly.

- Page 8 Case cover component locations ,!11--__ ROOFWELDED ASSEMBLY CONTROL PANEL d: U h !/1- - - ASSEMBLY 1-!+��� ---ENGINE CONTROL SWITCH 4-4--- __ SIDE DOOR PANEL !illlll'"'-,'C----5AJL PANEL...

-

Page 9: Test Procedure

WARNING: Type of Hazard: Service and repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. - Page 10 Rotor brush holder terminals and slip ring locations...

- Page 12 The resistance of the windings will change with temperature. Higher temperatures will produce higher resistance and lower temperatures will produce lower resistance. Figure 1. Rotor brush holder terminals and slip ring locations ROTOR BRUSH HOLDER TERMINALS...

-

Page 13: Test Description

WARNING: Type of Hazard: Service and repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. - Page 14 Table 1. Output rectifier diode drop tests TEST POINT (NEG) EXPECTED READING TEST POINT (POS) o.3 voe - o. 7 voe AC TERMINAL 1 DC POSITIVE TERMINAL DC POSITIVE TERMINAL o.3 voe - o.7 voe AC TERMINAL 2 DC POSITIVE TERMINAL o.3 voe - o.7 voe AC TERMINAL 3 AC TERMINAL 1...

- Page 15 Output rectifier AC input terminals location -- - OUTPUT - - - RECTIFIER Figure 2. Output rectifier DC output terminals location Output rectifier DC output terminals location...

- Page 18 WARNING: Type of Hazard: Service and repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual.

- Page 19 EXPECTED READING TEST POINT (POS) TEST POINT (NEG) voe - o.7 VDC TOP AC TERMINAL POSITIVE TERMINAL voe - o.7 VDC BOTTOM AC TERMINAL POSITIVE TERMINAL 0.3 VDC- 0.7 VDC NEGATIVE TERMINAL TOP AC TERMINAL voe - BOTTOM AC TERMINAL NEGATIVE TERMINAL Figure 1.

- Page 20 D4 rectifier location Figure 3. D3 and D4 rectifier schematic and lead locations D3 and D4 rectifier schematic and lead locations • 201A 03 RECTIFIER DIODE 04 RECTIFIER SCHEMATIC...

- Page 21 WARNING: Type of Hazard: Service and repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual.

- Page 22 B3 and B6 chopper/ control board terminal locations �() • • • • • • • □ �o � Figure 2. Negative output stud location Negative output stud location NEGATIVE OUTPUT TERMINAL...

- Page 24 8. Start the engine and run at high idle (3600 RPM). 9. Using a volVohmmeter, check the AC voltage reading. It should read between 236 and 252 VAC. 10. If the voltage readings are not within the specified limits, check for tripped or defective circuit breakers, loose connections or broken wires between the test points and the stator windings.

- Page 25 120 VAC, 240 VAC and 120 / 240 VAC receptacle locations _fll _ _ 120/ 240VAC RECEPTACLE 120VAC RECEPTACLES...

- Page 29 Table 1. Remote receptacle continuity tests EXPECTED READING TEST POINT TEST POINT LOW RESISTANCE PIN A PLUG J1 PIN 1 LOW RESISTANCE PIN B PLUG J1 PIN 2 LOW RESISTANCE PIN C PLUG J1 PIN 3 LOW RESISTANCE PIN D PLUG J1 PIN 4 LOW RESISTANCE PINE...

- Page 30 500,000 (500K) OHMS OR HIGHER PIN D PIN F 500,000 (500K) OHMS OR HIGHER PIN F PINE Figure 1. Remote receptacle location Remote receptacle location Figure 2. Chopper/ control board plug J1 locations Chopper/ control board plug J1 locations ..(�) □...

- Page 31 Remote receptacle pin locations Figure 4. Plug J1 pinout Plug J1 pinout � - UOOLJOOOO 1o o o o o o o 160 0...

- Page 33 Table 1. Spool gun receptacle continuity tests TEST EXPECTED READING TEST POINT POINT LOW RESISTANCE PLUG J1 PIN 6 PINA LOW RESISTANCE PLUG J1 PIN 7 PIN B PLUG J1 PIN 8 LOW RESISTANCE PIN C LOW RESISTANCE PLUG J1 PIN 9 PIN D PLUG J1 PIN 11 LOW RESISTANCE...

- Page 37 WARNING: Type of Hazard: Service and repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual.

- Page 38 57.5 STICK 14VOC 14VOC PIPE GOUGE Figure 1. Output terminal locations Output terminal locations NEGATIVE OUTPUT POSITIVE OUTPUT TERMINAL TERMINAL...

- Page 48 HIGH IDLE START Figure 1. Engine control switch location Engine control switch location Figure 2. Engine control switch terminal locations...

- Page 49 Engine control switch terminal locations...

- Page 51 15. When the stator short circuit and ground test has been completed, reconnect leads 7 and 9 to the D3 rectifier. All other stator leads should remain disconnected and isolated at this time. 16. Be sure that there are no leads of any kind across any of the stator windings, except the ?A- 9A winding. Examine stator wiring for damage, pinched leads, chafed insulation, etc.

- Page 55 Chopper/ control board location CHOPPER/ CONTROL BOARD Figure 2. Chopper/ control board plug and LED locations Chopper/ control board plug and LED locations LED 7 .--- LED3 LED2 ... LED4 "...

- Page 59 Chopper/ control board plug locations .. . J2----ll�l ..□ Figure 3. Chopper/ control board plug J2 pinout Chopper/ control board plug J2 pinout PLUGJ2...

-

Page 61: Replacement Procedure

REPLACEMENT PROCEDURE Procedure Steps: 1. Carefully position the output panel on the machine. 2. Using a Torx nutdriver (size T20), attach the two screws securing the output panel to the machine. 3. Using a 3/4" socket and a 9/16" socket, attach the bolt, lock washer and flat washer securing the leads to the negative output terminal. - Page 65 Engine control switch mounting nut location A ffi W ARNING<'.} f;,/4 STOP AUTO IDLE :.:k · HIGH ■ IDLE • START � �Ll:CT SC RO...

-

Page 66: Removal Procedure

WARNING: Type of Hazard: Service and repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. - Page 69 4. Using a 7/16" nutdriver, attach the three bolts and flat washers securing leads W1, W2, W3 and TW1 to the AC terminals of the output rectifier. See Wiring Diagram. 5. Perform the Output Panel Replacement Procedure 6. Perform the Case Cover Replacement Procedure 7.

- Page 70 Output rectifier positive and negative terminal locations Figure 3. Output rectifier mounting nut and insulator locations Output rectifier mounting nut and insulator locations...

- Page 73 WARNING: Type of Hazard: Service and repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual.

- Page 74 REPLACEMENT PROCEDURE Procedure Steps: 1. Carefully position the new chopper/ control board onto the electronics panel. 2. Using a 3/8" nutdriver, attach the four screws securing the chopper/ control board to the electronics panel. 3. Using a 7/16" wrench, attach the screw and washer securing lead W4 to the bus bar. See Wiring openMend Diagram.

- Page 79 WARNING: Type of Hazard: Service and repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual.

- Page 80 7. Perform the Retest After Repair Procedure . Figure 1. Electric fuel pump fuel lines, red and black leads and mounting screw locations Electris; fuel pump fue, I lines, red and black leads and mounting screw rocat1ons...

- Page 83 22. Replace cable ties as necessary. 23. Using a 7/16" nutdriver, attach the three bolts and flat washers securing leads W1, W2, W3 and to the AC terminals of the output rectifier. See Wiring Diagram. 24. Connect leads 7, 8 and 9 to their quick connect terminals. See Wiring Diagram. 25.

- Page 84 Uppe_ r muffler baffle, lower muffler baffle and muffler locations Figure 3. Stator and rotor component locations Stator and rotor component locations _, = • \ · 11 �' " " '\. STATOR MOONT\IIG fRI/SH oo,� • ===IP MOUmlNG 60\T ._·...

-

Page 85: Retest After Repair

RETEST AFTER REPAIR Retest a machine: If it is rejected under test for any reason that requires you to remove any part which could affect the machine's electrical characteristics. • If you repair or replace any electrical components. Table 1. LOAD RPM MODE NO LOAD RPM... -

Page 86: Auxiliary Power Output

Table 4. WELDER TIG OUTPUT OPEN CIRCUIT LOAD AMPS LOAD VOLTS MODE OUTPUT CONTROL VOLTAGE MAXIMUM Table 5. WELDER DC PIPE OUTPUT OPEN CIRCUIT VOLTAGE LOAD VOLTS LOAD AMPS MODE OUTPUT CONTROL DC PIPE MAXIMUM Table 6. AUXILIARY POWER OUTPUT LOAD AMPS LOAD VOLTS RECEPTACLE...

Need help?

Do you have a question about the 12649 and is the answer not in the manual?

Questions and answers

My welding machine is not getting fuel, I changed out the electric fuel pump but it only makes a loud tapping noise but will not start, It will only turn over the engine

A possible cause of a Lincoln Electric welding machine not getting fuel after replacing the electric fuel pump and making a loud tapping noise could be overfilling the fuel tank. The manual warns that overfilling can lead to engine damage. Additionally, ensure that the correct Lincoln Electric fuel cap with an internal safety vent is used, as improper venting can prevent fuel flow. Also, check that clean, fresh, lead-free gasoline is used and the filler neck is not completely filled, allowing room for expansion.

This answer is automatically generated