Summary of Contents for Mosa GE 20 YR-5-RENTAL

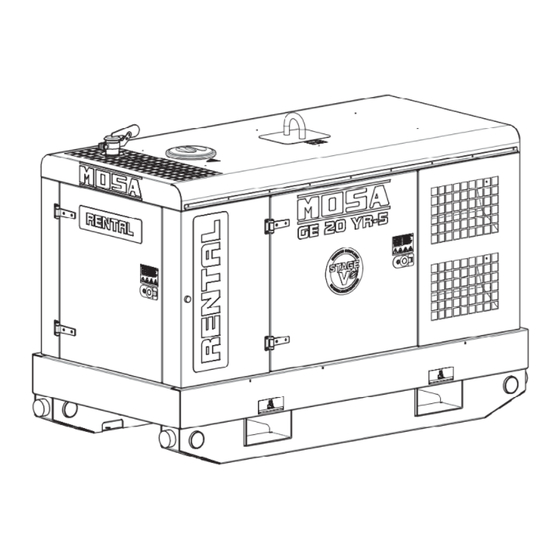

- Page 1 CP0Q30G19003_EN 09-2024 Use and Maintenance Manual D5266260 Generating set GE 20 YR-5 - RENTAL Original instructions...

-

Page 3: Table Of Contents

Contents Contents Introduction ............................1 Foreword ............................1 Supplied documentation ........................2 Customer service ..........................2 Spare parts ............................2 Declaration of conformity ........................2 Unauthorized changes ........................2 Allowed and non-allowed use ......................2 1.8 Identification data ..........................3 Sound power level ..........................4 Safety ..............................5 Safety information ..........................5 Positioning of safety decal and information ..................6 2.2.1 Decal explanation ........................7 General precautions .........................10... - Page 4 Contents Electrical protection ..........................28 4.2.1 Main machine switch ......................28 4.2.2 Residual current circuit breaker ...................28 4.2.3 Circuit breaker ........................28 4.2.4 Residual current circuit breaker with overcurrent protection (RCBO) ........28 4.2.5 Ground differential relay ......................28 4.2.6 Insulation monitor ........................29 4.3 Optional fittings ..........................31 4.3.1 3-way kit for fuel supply .......................31 4.3.2...

-

Page 5: Introduction

If the manual is lost, damaged or becomes illegible, request a copy to MOSA, indicating the model of the generating set, the serial number and the year of construction. -

Page 6: Supplied Documentation

(e.g. engine). Customer service The Technical Assistance and Spare Parts Service are available to the Customers. MOSA recommends that you contact the nearest authorised service centre for specialised intervention for all control and overhaul operations. In order to obtain quick and effective responses, indicate the Model and Serial Number shown on the identifi- cation plate (see “1.8 Identification data”). -

Page 7: Identification Data

Introduction Identification data The data identifying the generating set are given on the data plate applied in the area indicated in the figure. They are necessary for spare parts requests and communications with the Customer Service Department. D5266270 A - Manufacturer 's data B - Machine data • Made In: Country and year of manufacture • TYPE: Model • SERIAL N°: Serial number • Generating Set ISO 8528: Technical standard reference C - Machine technical data •... -

Page 8: Sound Power Level

Introduction Sound power level The sound power level of the generating set is given on the decal applied in the area indicated in the figure. D5266280 The value indicates the guaranteed sound power level in compliance with Directive 2000/14/EC. • Sound power level (LWA) - Unit of measurement dB(A): represents the amount of acoustic energy emit- ted in the unit of time regardless of the distance of the measuring point. -

Page 9: Safety

Safety Safety Safety information Always respect the warnings contained in this manual and present on the decal applied to the machine. This allows the machine to be used safely, avoiding damage to property and injury or death to people. The following words and symbols were used to identify important safety messages. Symbol identifies important safety messages on the machine, in the manual and elsewhere. When you see this symbol, follow the instructions in the safety messages. -

Page 10: Positioning Of Safety Decal And Information

Safety Positioning of safety decal and information D5266290... -

Page 11: Decal Explanation

Safety 2.2.1 Decal explanation Pos. 1 Consult the manual Read the contents of the manual carefully before using the machine or carrying out maintenance operations on it. M734500253 Pos. 2 - Electrical voltage hazard Stop the generating set before carrying out checks or maintenance. - Page 12 Safety Pos. 5 - Fire and exhaust gas inhalation hazard Fuel is highly flammable. Turn the engine off and allow it to cool before fuelling. Engine carbon monoxide emissions are highly toxic and poisonous. CARBON MONOXIDE (CO) DANGER STOP ENGINE WHEN FUELING Use the machine in outdoor and ventilated places. D5263040 Pos. 6 - Draining the coolant and the engine oil M849000250 Pos.

- Page 13 Safety Pos. 11 - Fuel drainage FUEL DRAIN MCN1R50F10250 Pos. 12 - Coolant high temperature hazard Do not remove the cap when the engine is at the working temperature (high). Steam or the high temperature of the coolant leaking from the radiator can cause injury and/or burns to people.

-

Page 14: General Precautions

Safety General precautions Any errors during use, checks or maintenance could cause the risk of injury, even serious • Before performing the operations, read this manual and the decals applied to the machine and follow the warn- ings. If you don't understand any part of the manual, ask your Safety Officer for explanations. -

Page 15: Fire Prevention

Safety Fire prevention 2.4.1 Fire due to fuel, oil, coolant • Avoid approaching any flame to flammable substances such as fuel, oil, coolant. • Do not smoke or use open flames near flammable sub- stances. • Stop the generating set before refuelling. • Make sure not to spill flammable substances on over- heated surfaces or on parts of the electrical system. • After refuelling, remove any spills and tighten all filling caps tightly. -

Page 16: Handling Precautions

Safety Handling precautions 2.5.1 Lifting by chains or ropes • Make sure that the handling area is clear of obstacles and people. • Lift the generating set using only the lifting points provid- ed and indicated by the decals. • The operator carrying out the lifting work must be quali- fied to work with the crane. -

Page 17: Transport With Towing Carriages

Safety • Widen the forks as much as possible to distribute the weight evenly while keeping the generating set horizon- tal. D5260120 2.5.3 Transport with towing carriages • Do not tow the machine manually or with tow vehicles without the intended towing carriage. • Check the correct assembly of the machine to the drive device. •... -

Page 18: Installation Precautions

Safety Installation precautions 2.6.1 Installation site precautions • Do not install machines or equipment near heat sources, in areas at risk with explosion hazard or fire hazard. Install the machine at a safe distance from fuel tanks, from flammable material (rags, paper, etc.), from chemicals. Follow the instructions of the competent authorities. • To limit potentially dangerous situations, isolate the area around the generating set, thus preventing any unauthorized personnel from getting close to it. •... -

Page 19: Precautions During Operation

Safety Precautions during operation • Keep the doors closed during normal operation. • Access to the internal parts of the generating set must only be carried out for maintenance purposes. • Keep the area near the muffler free from objects such as rags, paper, cartons. The high temperature of the muffler could cause the objects to burn and cause a fire. • Immediately stop the machine in case of malfunctions. Do not restart the machine without first identifying and solving the problem. -

Page 20: Maintenance Precautions

Safety Maintenance precautions • Maintenance must be performed by qualified personnel. • During maintenance, if unauthorized persons start the machine, there is a danger of serious personal injury or death. Do not allow unauthorized persons to approach the machine. • Stop the machine and turn the battery disconnect switch to off. • To avoid injury, do not perform maintenance with the engine running, if it is not necessary. -

Page 21: Precautions For Disposal Of Waste Material

Safety • Do not smoke, avoid open flames and sparks near the battery; exhaled vapours may cause the battery to ex- plode. D5260170 2.10 Precautions for disposal of waste material • Be sure to store the waste liquid in containers or tanks. • Do not discharge the oil directly into the soil or sewage system, rivers, seas or lakes. •... -

Page 22: Technical Data

Technical data Technical data Machine dimensions 1885 mm 1835 mm 1235 mm 325 mm 1936 mm 900 mm 100 mm 750 mm D5266300... -

Page 23: Technical Data (Mod. Ge 20 Yr-5)

Technical data Technical data (mod. GE 20 YR-5) Rated power Three-phase stand-by power ( 20 kVA (16 kW) / 400V / 28.9A Three-phase PRP power ( 18 kVA (14.4 kW) / 400V / 26A Single-phase PRP power ( 7 kVA / kW / 230V / 30.4A Frequency 50 Hz Cosφ General specifications Fuel tank capacity 100 ℓ Autonomy (75% PRP) 29.5 h Protection IP 44 Maximum dimension on base (LxWxH) -

Page 24: Description

Description Description The Generating Set is a machine that transforms mechanical energy, generated by an engine, into electrical energy through an alternator. Main components 4.1.1 External components D5266310... - Page 25 Description Control panel Emergency button Control panel access door Lifting hook Radiator cap access door Rain cover for exhaust pipe Quick couplings for external fuel tank (optional) Oil drain plug Coolant drain plug 10 - Anti-tip side pockets for handling with forklift trucks 11 - Engine compartment access door 12 - Electrical distribution panel with three-phase and single-phase output sockets 13 - Fuel tank cap...

-

Page 26: Internal Components

Description 4.1.2 Internal components D5266320... - Page 27 Description Fuel tank Alternator 3 - Engine air filter 4 - Fuel filter Engine Radiator cap Coolant expansion tank 8 - Oil filler plug Exhaust silencer 10 - Oil filter 11 - Vibration dampers 12 - Fuel level sensor 13 - Oil level dipstick 14 - Fuel tank cleaning access 15 - Fuel pre-filter 16 - Fuel supply pump 17 - Battery disconnect switch...

-

Page 28: Control Panel Components

Description 4.1.3 Control panel components D5266330 16A 230V 2P+E CEE plug - Optional (Engine heater and battery charger power supply) Control panel power switch (ON-OFF) Command and control unit Generator voltage controller – Optional (+/- 10% Vn) 5 - Ground differential relay (EU panel) Isolation monitor (DGUV panel) Main machine switch Buzzer Emergency button... - Page 29 Description EU Standard D5266340 Residual current circuit breaker with overcurrent protection (RCBO) (4P 16A - 30mA Type A) for three- phase 16A 400V socket Residual current circuit breaker with overcurrent protection (RCBO) (2P 16A - 30mA Type A) for sin- gle-phase 16A 230V socket PE ground terminal (EU panel) Equipotential ground terminal (DGUV panel)

- Page 30 Description DGUV version D5266350 Residual current circuit breaker with overcurrent protection (RCBO) (4P 16A - 30mA Type B) for three- phase 16A 400V socket Residual current circuit breaker (4P 40A - 30mA Type B) for three-phase 32A 400V socket Residual current circuit breaker with overcurrent protection (RCBO) (2P 16A - 30mA Type B) for SCHU- KO 16A 230V sockets Equipotential ground terminal (DGUV panel) 32A 400V 3P+N+T CEE IP67 socket...

-

Page 31: Electrical Panel

Description 4.1.4 Electrical panel D5266360 1 - Auxiliary terminal block for the following connections: - Global alarm - Remote start and stop - Connection to PAC-I switchboard Battery charge 3 - Water heater and battery charge protection residual circuit breakers Auxiliaries (fuses and relays) 5 – Ground differential relay (EU panel) Isolation monitor (DGUV panel) Main machine switch Ground cable collector Power terminal block... -

Page 32: Electrical Protection

Description Electrical protection 4.2.1 Main machine switch The generating set is protected against short circuits and overloads by a circuit breaker (1) located upstream of the system. Overload protection tripping is not instantaneous; it follows an overcurrent/time characteristic. The greater the overcur- rent, the shorter the tripping time. The rated tripping current refers to an operating temperature of 30°C. -

Page 33: Insulation Monitor

Description Ground fault current adjustment potentiometer Intervention time adjustment potentiometer Multifunction led for internal electronics fault report/in- ternal temperature out of range / potentiometer t(SES) not centred correctly Power supply presence signal led 5 - Differential relay tripped signal led Tool set-up microswitches Test button Manual reset button DER3/ 0D model factory settings •... - Page 34 Description SRI3/ D2 operation • ON indicator (4) indicates that the equipment is powered. • Pressing the test button (6) for at least 5 seconds, turns on the Alarm (5) and Pre-alarm (3) LEDs. • When the button (6) is released, the Pre-alarm led (3) turns off and the Alarm led (5) remains ON. Press the test button (6) again to turn off the Alarm led (5). • If the isolation resistance drops below the set pre-alarm value, the Pre-alarm led (3) lights up and the contact of the Pre-alarm relay switches.

-

Page 35: Optional Fittings

Description Optional fittings 4.3.1 3-way kit for fuel supply The 3-way kit allows you to supply the engine of the generating set from the fuel tank of the machine or from an external tank of greater capacity to increase the operating range. D5260410 It consists mainly of two parts: •... -

Page 36: Remote Start/Stop Control

Description 4.3.2 Remote Start/Stop control Pairing the TCM 35 with the generating set allows it to be started and stopped by remote. 1 - Connect the cable (1) of the TCM 35 remote control to the auxiliary terminal block (2) located inside the electrical panel. -

Page 37: Pac-I Mains/Generator Switchboard

Description 4.3.3 PAC-I mains/generator switchboard Non-automatic versions CAUTION • Make the connections under safe conditions. • The installation of the PAC-I switchboard and all connections between the board and the commercial electricity grid (MAINS), the system to be powered (LOAD) and the generating set (GENERATOR) must be carried out by a qualified electrician and in accordance with the regula- tions in force in the place of installation. - Page 38 Description 3 - Follow the steps below for first start-up. ◦ Check that the main machine switch is closed (inser- tion lever upwards). ◦ Set the command and control unit (1) to AUT (auto- matic) mode. ◦ Press the MAN key on the command and control unit of the PAC-I switchboard, check for the absence of danger and press the KG key to start the generating set.

-

Page 39: Installation

Installation Installation WARNING • Before proceeding with the installation, carefully read section “2. Safety” - “2.6 Installation precautions” and “2.7 Precautions during operation”. • The installation and the electrical connection described in this chapter are indicative. For these operations, it is necessary to contact Specialized Technicians who must issue the necessary certifications. -

Page 40: Indoor Installation

Installation Indoor installation Important • The room where the generating set will be installed must comply with the legislation in force at the place of installation. Installation of the generating set indoor must be carried out in accordance with the instructions described. D5260270 (1) Generating set Recommended minimum size... -

Page 41: Supporting Floor

Installation 5.3.1 Supporting floor For a correct support of the electronic unit and to avoid the transmission of vibrations, it is necessary to build a reinforced concrete platform (7) on the floor, isolated from the rest of the structure. The generating set frame must be fixed to the platform (7) with dowels or anchor bolts. The platform must have a length (D) and a width (E) greater than 400 mm (200 mm per side) with respect to the support base of the generating set (200 mm per side). -

Page 42: Grounding With Isolation Monitor

Installation 5.4.2 Grounding with isolation monitor In machines equipped with an insulation monitor, connection of the grounding terminal (1) to a grounding system is not required. Located on the front of the machine, the isolation monitor continuously monitors the ground insulation of the active parts. -

Page 43: Operation

Operation Operation WARNING • Before starting the machine, carefully read section “2. Safety”. • It is forbidden to connect the set to the public grid and/or other source of electricity. • Continuous operation at low load In general, all machinery (in particular those equipped with motors with after-treatment devic- es) must operate with a load (i.e. - Page 44 Operation • The nominal frequency of 50Hz or 60Hz is reached at the maximum output power (kW) of the generating Power factor - cos ϕ The power factor is a data that depends on the electrical characteristics of the load. It indicates the ratio between the Active Power (kW) and the Apparent Power (kVA). The apparent power is the total power required for the load, given by the sum of the active power delivered by the engine (after the alternator has transformed the mechanical power into electrical power) and the Re- active Power (kVAR) delivered by the alternator.

-

Page 45: Checks Before Start-Up

Operation Checks before start-up 1 - Check that the battery disconnect switch is turned ON. D5266380 2 - Check the oil, fuel and coolant levels. 3 - Check that the engine compartment, radiator and battery access doors are locked. 4 - Check that there are no oil, fuel and coolant leaks. 5 - Check that there is no flammable or dirty material around the exhaust pipe. - Page 46 Operation 3 - Turn the control panel power switch (2) ON. D5263900 4 - Press the start button (3) to launch the generating set start sequence. Note The start button only works in MAN mode. 5 - Before drawing a load, let the engine run for the time shown in the following table.

-

Page 47: Stopping The Generating Set

Operation Stopping the generating set 1 - Turn off the loads connected to the generating set. 2 - Set the main machine switch (1) to OFF (insertion lever downwards). D5263890 3 - Press the stop button (7) to launch the generating set stop sequence. The engine stops at the end of the cooling cycle. For immediate stop, press the stop button (7) again. -

Page 48: Maintenance

Maintenance Maintenance WARNING • Before proceeding with maintenance, carefully read section “2. Safety”. Refuelling Use fuel, coolant and lubricants according to the ambient temperature. 7.1.1 Fuel The fuel must comply with EN590 and ASTM D975. The cetane number of the fuel should be at least 45. In order to ensure an efficient and long service life of the engine, the fuel must be sulphur-free diesel fuel: •... -

Page 49: Engine Oil

Maintenance 7.1.2 Engine oil • To ensure adequate protection of the engine and keep it efficient for a long time, use only the recom- mended oil. Using different oils can reduce the life of the engine. • The viscosity must be appropriate to the ambient temperature. • The oil to be used must comply with the following specifications: CJ-4 Low S.A.P.S ACEA E6 Low S.A.P.S. Low S.A.P.S. (low sulphated ash, phosphorus, sulphur oil) keeps the catalyst in good working condition. SAE oil classification In the SAE classification, oils are identified according to the viscosity. -

Page 50: Coolant

Maintenance 7.1.3 Coolant The engine cooling system is fuelled with OAT: ENI ANTIFREEZE SPEZIAL coolant, mixed at 50% with dem- ineralised water. It is recommended to continue using the same coolant. If the type of coolant is changed for refuelling, the system must be thoroughly washed. By mixing with each other, the residues of additives of different types contained in the different liquids would create gelatinous substances that could obstruct the system. Use a mixture of 50% demineralised water and 50% low silicate ethylene glycol coolant. Use a coolant free from silicates, phosphates, borates, nitrites and amines. -

Page 51: Checking And Cleaning The Engine Air Filter

Maintenance 2 - Remove the cap (2) and pour the coolant into the radiator. 3 - Top up the liquid until it covers the pipes inside the radiator by about 5 mm. Note • Do not overfill the radiator; allow room for coolant expan- sion. 4 - Refit the cap (2) and tighten securely. 5 - After the top-up operations, run the engine for a short D5263960 period, check the coolant level again and refill if neces- sary. -

Page 52: Routine Maintenance

Maintenance Routine maintenance WARNING • Pay the utmost attention to the generating sets equipped with an automatic or remote interven- tion system. Make sure that the generating set does not start during routine maintenance or repair opera- tions by carrying out the following operations: Disconnect power to the generating set control board. -

Page 53: Precautions For Generating Sets With Automatic Or Remote Start-Up

Maintenance Precautions for generating sets with automatic or remote start-up • Pay the utmost attention to the generating sets with automatic or remote start-up system, including: ◦ Generators in emergency service to the mains. ◦ Generators with programmable automatic test function. ◦ Generators with remote control via PC, via telephone modem or GSM modem and other communica- tion systems. -

Page 54: Every Year

Maintenance Every year • Check electric connections and clean control panel. • Replace the engine oil. Storage • Carefully clean the fairings and all other machine parts. • Run the machine with load every 10 days for 15-30 minutes. Doing so ensures proper lubrication of the engine, keeps the battery charged and prevents any blockage of the injection system. -

Page 55: Overall Dimensions For Installation

Overall dimensions for installation Overall dimensions for installation (1/2) 1885 2525 2551 D5266470 IN - Air inlet grid OUT - Air outlet grid... - Page 56 Overall dimensions for installation (2/2) Gx-871 1235 No. 4 Ø 20 D5266480 Front bumper 4 - Anti-tip side pockets for handling with forklift trucks Rear bumper Fluid drain plug in the base Exhaust pipe Fuel drain plug in the tank...

- Page 58 MOSA div. della BCS S.p.A. Viale Europa, 59 20047 Cusago (Milano) Italy Tel.+39 - 0290352.1 Fax +39 - 0290390466 www.mosa.it...

Need help?

Do you have a question about the GE 20 YR-5-RENTAL and is the answer not in the manual?

Questions and answers