Advertisement

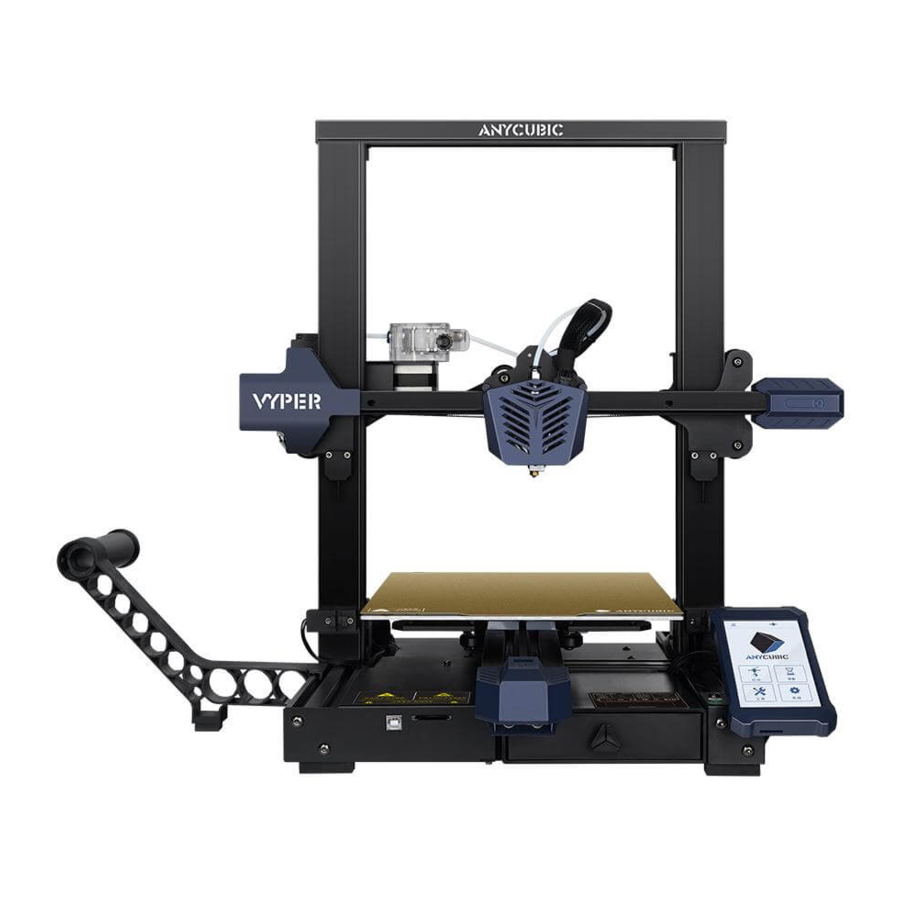

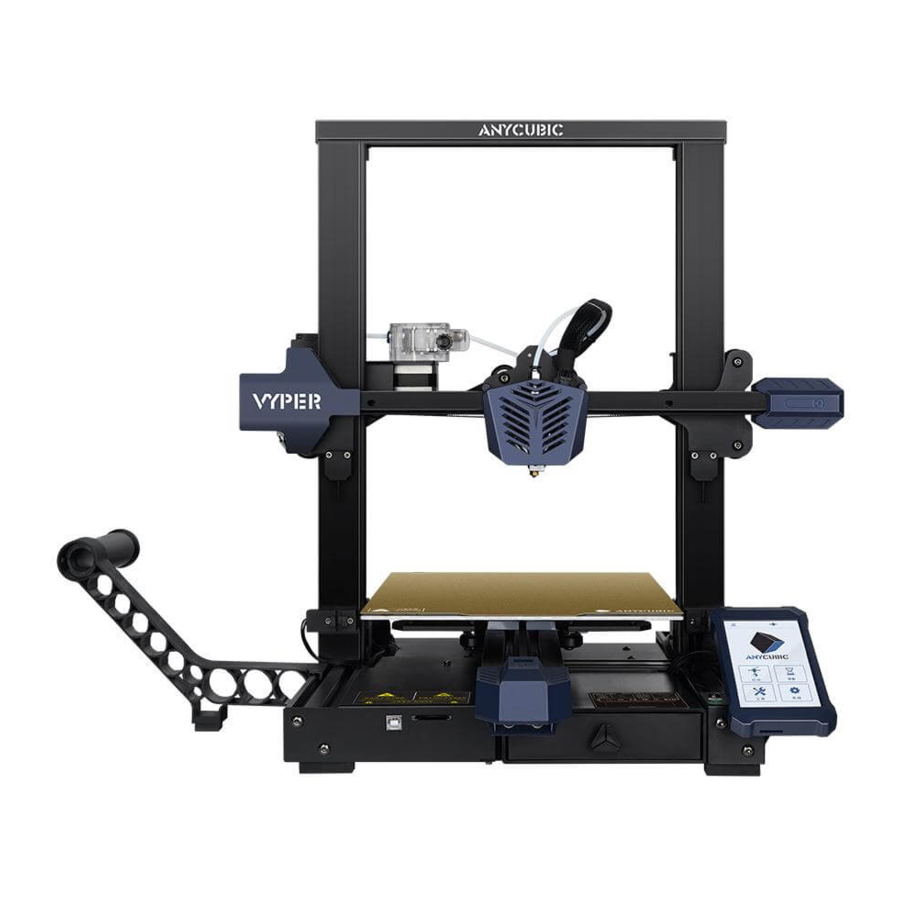

Technical Specification

| Printing | |

| Technology | FDM (Fused Deposition Modeling) |

| Build Size | 245 mm(L) x 245 mm(W) x 260 mm(H) |

| Print Accuracy | +/- 0.1 mm |

| Positioning Accuracy | X/Y/Z 0.0125 / 0.0125 / 0.002 mm |

| Extruder Quantity | Single |

| Nozzle Diameter | 0.4 mm |

| Print Speed | 20-100 mm/s (suggested 80 mm/s) |

| Supported Materials | ABS, PLA, TPU, PETG, Wood, etc |

| Temperature | |

| Ambient Operating Temperature | 8C - 40C |

| Operational Extruder Temperature | Max 260C |

| Operational Print Bed Temperature | Max 110C |

| Software | |

| Slicing Software | Cura |

| Software Input Formats | .STL, .OBJ, .AMF |

| Software Output Formats | GCode |

| Connectivity | Memory card; Data cable (expert users only) |

| Electrical | |

| Power Input | 110V / 220 V AC, 50 / 60 Hz |

| Output rating | 24V/14.6A (350W) |

| Physical Dimensions | |

| Printer Dimensions | 508 mm(L) x 457 mm(W) x 516 mm(H) |

| Net Weight | ~10 kg |

Packing List

Product Overview

Menu Directory

Prepare

Tools

Light: Turn on/off the light of the print head

Motor: Disable all motors (only valid when machine is not printing).

System

Language: Change language (English / Chinese).

Voice: Turn on/off the screen sound.

About: Display the information about the product.

Installation

- Be cautious during assembly as some parts may have sharp edges.

- It is suggested to use a flat desktop and place the parts in an orderly manner for quick assembly.

- The color of some parts may be different from what in the manual, but the assembly is the same.

- Firmware has been pre-uploaded to the motherboard. After completing the assembly, please level the platform and load the filament then you could start the first test print.

* Take tools from the toolbox on the front right side of the machine base for assembly.

- Install frame.

![ANYCUBIC - VYPER - Installation - Step 1 Installation - Step 1]()

- Install touchscreen.

![ANYCUBIC - VYPER - Installation - Step 2 Installation - Step 2]()

- Install the filament holder.

![ANYCUBIC - VYPER - Installation - Step 3 Installation - Step 3]()

! Pay attention to the routing position of the Teflon tube and the print head cable.

- Insert the Teflon tube into the extruder.

![ANYCUBIC - VYPER - Installation - Step 4 Installation - Step 4]()

- Wiring: connect all these cables to their corresponding ports by the label respectively.

![ANYCUBIC - VYPER - Installation - Step 5 Installation - Step 5]()

- Use zip ties to fasten the print head cable and the Teflon tube.

![ANYCUBIC - VYPER - Installation - Step 6 Installation - Step 6]()

Check before using

- Make sure that the 4 zip ties shown below have been cut off before operating the machine.

![ANYCUBIC - VYPER - Check before using - Step 1 Check before using - Step 1]()

- D-shape wheels of the base may be loosened due to transportation, please check it after unpacking.

Place the base on a flat desktop. Shake the platform to confirm whether the printing platform is shaking up and down. If so, please tighten the hexagonal pillars of the D-shape wheels on the right under the platform.

- Move the platform to the front for tightening the pillar A.

- Move the platform to the rear for tightening the pillar B.

![ANYCUBIC - VYPER - Check before using - Step 2 Check before using - Step 2]()

Leveling

Leveling the printing platform is a key step in 3D printing, which determines to a large extent whether the model can be reliably adhered to the printing platform. If the distance between the nozzle and the printing platform is too wide, the model will not adhere to the printing platform properly. If the nozzle is too close to the printing platform, it will hinder material extrusion and scratch the platform. Once leveled, it is not necessary to level every time before each printing.

Vyper supports auto-leveling, which is easy to level the platform.

* Before leveling, please ensure that the platform and nozzle are clean and free of foreign matters to avoid affecting the leveling effect.

- Select the correct voltage mode according to your local voltage ratings (NI IOV or N220V) before plugging in. The red switch is inside the power supply casing and 220V is a default setting. A hex key can be used to move the switch. Finally, double check the wirings, plug in the power cord, and power on the printer.

![ANYCUBIC - VYPER - Leveling - Step 1 Leveling - Step 1]()

In some cases, 220V labeled as "230", 110 V labeled as "115"

- Return to main menu, then click Prepare → Leveling → Auto-leveling.

A pop-up window appears that prompts you to use a tool to touch nozzle for calibration.

Note that you need to do the calibration within 1 minute.

![ANYCUBIC - VYPER - Leveling - Step 2 Leveling - Step 2]()

- When the calibration succeeds, the machine will home and preheat the print head and heated bed (If you manually heat them up to the target temperature before leveling, the preheating will be skipped automatically) When the machine reaches the target temperature, it will probe 16 spots on the platform automatically.

* During leveling, please do not touch the nozzle to prevent scalding.

Loading Filament

- When the nozzle reaches to the target temperature, click "Filament In" again. The filament would be automatically fed in by the extruder and it would be melted through the nozzle. Now, click "Stop". You may use tweezers to clean the filament residue on the nozzle tip.

![ANYCUBIC - VYPER - Loading Filament - Step 2 Loading Filament - Step 2]()

If the melted filament is not smooth, please increase the extrusion force by rotating clockwise.

If the melted filament is too thin, please reduce the extrusion force by rotating counterclockwise.

Printing Models

After the leveling and filament feeding are completed, the printing can be started. A printable file "owl.gcode" has been preloaded in the memory card and the users can print it directly.

* In order to let the printer better recognize the GCode file in the memory card, you need to back up all the files in the memory card to the computer, and keep the memory card only for the GCode files. Please save all the GCode files in root directory of the memory card.

- Insert the memory card into the memory card slot, and choose the "owl.gcod e" file to print. (owl, author: etotheipi, www.thingiverse.com)

![]()

* Before printing, the nozzle only start to heat up after the heated bed reaches the target temperature. After the nozzle and heated bed are heated to the target temperature, the printer will start printing.

- There might be three kinds of results for the first or second layer of the test print:

- Nozzle is too close to the platform, resulting in insufficient extrusion of filament.

![]()

- Proper distance between nozzle and platform can achieve the best printing effect.

![]()

- Nozzle is too high and the gap is large, which lead to poor adhesion of filament to the platform.

![]()

- Nozzle is too close to the platform, resulting in insufficient extrusion of filament.

The printing effect  and

and  can be improved by adjust Z-offset during printing.

can be improved by adjust Z-offset during printing.

( * In most cases, there is no need to adjust Z-offset after auto-leveling.)

How to adjust the Z-offset:

Click Settings on printing status interface, then click "+" or "—" of the Z-offset to adjust the distance between nozzle and printing platform and observe the printing effect.

—: Decrease the distance between nozzle and printing platform.

+: Increase the distance between nozzle and printing platform.

- The range of Z-offset value is -0.5æO.5. (

Note: Less than -0.5 may cause damage to machine parts.)

- After adjusting the offset setting, click "0K" on the settings interface, and the offset will be effective for subsequent printing; if you only click the Return button without clicking "0K", the offset will only be effective for this printing.

Please adjust the Z-offset patiently until the effect likes  . If the printing effect is still not good after multiple adjustments, please stop printing and level the platform again.

. If the printing effect is still not good after multiple adjustments, please stop printing and level the platform again.

- The nozzle and heated bed are still at a high temperature when printing is finished. Make sure to wait for nozzle and heated bed to cool down before removing the model from the printing platform.

* Tip: To eject the memory card, please press it.

Introduction to slicing software

3D printer reads GCode file and prints. It is necessary to convert 3D files (such as stl file) into GCode files for machine to recognize. Software that convert 3D files into GCode files is called slicing software.

Introduction of slicing software:

- Cura Installation

- Machine Settings

- Import the Configuration File

- Manipulate 3D model in Cura

- Slice and Preview

- Print Offline and Online

- Cura Installation

Double click Ultimaker_Cura-4.2.1-win64, and follow the steps as shown below.

* Ultimaker Cura 4.2.1 is used for example here, please refer to the memory card for the actual version.

* File path: Memory card → "Files _ English_Vyper"→ "Cura" -9 "Windows" or "Mac".

![]()

![]()

* Printing online requires the installation of a driver, as shown below. If you don't print online, you don't need to install it.

- Machine Settings

Upon completion of installation, the first launch of the software will display the following welcome screen. Click Get started to start the machine settings.

![]()

![]()

According to the wizard, we have selected the Anycubic i3 Mega printer. Now, we will set the parameters of Vyper based on the printer.- Click Anycubic i3 Mega→ Manage printers on the top left corner, and rename the printer to Anycubic Vyper.

![]()

- In the same interface opened in Step (1 ), click Machine Settings and set the X (Widch) / Y (Depth) / Z (Height) parameters of printer as 250, 255 and 265 respectively, as shown below.

![]()

- Click Anycubic i3 Mega→ Manage printers on the top left corner, and rename the printer to Anycubic Vyper.

- Import the Configuration File

After continuous testing, we provided users the suggested printing parameters of different filaments for Vyper, and the user could directly import the parameter files to the software.- Click Settings → Configure setting visibility..., and then tick Check all box to make all settings visible.

![]()

![]()

- In the same interface opened in Step (1), click Profiles on the left side. Then click Import button to import the desired print profile.

* Choose different parameter profiles according to different filament types.

* Profile path: Memory card → "Files _ English _Vyper" → "Suggested parameters for Vyper"

![]()

- Select the profile that you just imported, and then click the Activate button

![]()

- Click Settings → Configure setting visibility..., and then tick Check all box to make all settings visible.

Supplementary Explanation

- You can customize some parameters after importing the profile, but we still recommend that you use the parameters in the profile that we provide.

![]()

- The paremeter Build Plate Adhesion→ Build Plate Adhesion Type needs to be set to "None" when you print the maximum size model.

![]()

- Manipulate 3D model in Cura

* Model files can be downloaded from www.anycubic.com (ANYCUBIC website) and www.thingiverse.com.- Click the open file button in the top left corner to import the model file or directly drag the file into the software.

![]()

- Left click the model to activate the adjustment tool on the left side of the interface. Choose one of the adjustment tool, and then click and drag the controls on the model to adjust it.

![]()

- Click the open file button in the top left corner to import the model file or directly drag the file into the software.

Other operations:

- Press the mouse wheel and move the mouse to move the platform.

- Scroll the mouse wheel to zoom in and out the platform.

- Right click and move the mouse to change the viewing angle.

- Slice and Preview

Now that the configuration and print settings are in place, it's time to slice the model. Click Slice button in the bottom right corner. When the process completes, it will immediately show a Preview button, click it to go to the preview stage.

![]()

![]()

Use the layer slider and simulation view to check important parts of your 3D slice.

![]()

- Print offline and online

There are two operational modes for Vyper: print offline and print online.

- Print offline: Insert memory card into the memory card slot, click on the Home Menu "Print" to enter the file list, and print a selected file (GCode files ONLY).

- Print online: Install CH340 driver to bridge PC and machine, and install Cura for slicing and control the machine to print via data cable.

![]()

It is suggested to use Print Offline mode to minimize the noisy signal via data cable.

- Print offline (Recommended)

After slicing, click Save to File in the bottom right corner. Save the GCode file to the memory card, and then insert the memory card to the printer and control via the touchscreen for offline printing.

* GCode file name should only contain English letters, underscore and space. File name contains special characters could not be recognized by the printer. In order to let the printer better recognize the GCode file in the memory card, you need to back up all the files in the memory card to the computer, and keep the memory card only for the GCode file. Please save all the GCode files in root directory of the memory card.

![]()

- Print online

Printing online requires the installation of a driver. And you can control the printer through Cura after connecting the data cable.

- Turn on the machine, connect the printer (data cable port) and your PC via data cable. The driver may not be installed automatically, so it is required to check that. Right-mouse click "This PC"→ "Properties" →"Device manager", if there is an exclamation mark as shown below, then it needs to be installed manually.

* Vyper uses CH340 chip for communication.

* CH340 driver file path: "Files_English_Vyper" → "Driver_CH341 There are two versions, Windows and Mac version. (CH341 driver file is suitable for CH340 chip).

![]()

- Here we take Windows PC system for example. Double click "CH1341SerSetup.exe" and follow the wizard to install it. If the driver has installed automatically in step (1), skip this step.

* After the installation is completed, refer to the method in step (1 ) to see if the driver has been identified (no exclamation mark). - After slicing, click Print via USB in the bottom right corner to go to the monitor stage. After waiting for about ten seconds, the operation panel will be displayed on the right side of the interface. And the printing platform will be heated up for printing.

* If the printer is not connected properly, the Monitor interface will be blank. Please plug the data cable to connect again.

* In the process of printing, do not plug the data line, or it will interrupt the printing.

* In case of abnormal sound during the printing process, you can directly turn off the power of the machine. Please check the Troubleshooting chapter for more detail or contact Customer Service.

![]()

Resume from Outage

In case of a power loss during printing, the machine will automatically save the printing status. After restarting, you will see the interface shown below, please click "Continue" to continue your printing or "Cancel" to cancel it.

Safety Instructions

To avoid any unnecessary damage to the printer or individual injury, please always follow the safety instructions when assembling and using the machine.

- Please contact our customer service first if you have any problem after receiving the products.

- Be cautious when using the scraper. Never direct the scraper towards your hand.

- In case of emergency, please immediately cut off the power of ANYCUBIC 3D printer and contact the technical support.

- ANYCUBIC 3D printer includes high speed running parts that can cause injury.

- It is recommended to use protection glasses when cleaning/sanding the printed models to avoid small particles in eyes.

- Keep the 3D printer and its accessories out of the reach of children.

- Vapors or fumes may be irritating at operating temperature.

- Always use the ANYCUBIC 3D printer in an open and well ventilated area.

- ANYCUBIC 3D printer must not be exposed to water or rain.

- ANYCUBIC 3D printer is designed to be used within ambient temperature ranging 80C-400C, and humidity ranging 20%-50%. Working outside those limits may result in low quality printing.

- Do not disassemble ANYCUBIC 3D printer, please contact technical support if you have any question.

![]()

Documents / Resources

References

Download manual

Here you can download full pdf version of manual, it may contain additional safety instructions, warranty information, FCC rules, etc.

Advertisement

Need help?

Do you have a question about the VYPER and is the answer not in the manual?

Questions and answers