Table of Contents

Advertisement

Quick Links

Installation Instructions & Homeowner's Manual

WARNING! IF THE INFORMATION IN THIS MANUAL IS NOT FOLLOWED EXACTLY, A FIRE OR

EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE,PERSONAL INJURY OR LOSS OF LIFE.

FOR YOUR SAFETY

WHAT TO DO IF YOU SMELL GAS:

* Do not try to light any appliance.

* Do not touch any electric switch; do not use

any phone in your building.

* Extinguish all flames.

* Immediately call your gas supplier from

your neighbours phone. Follow the gas

suppliers instructions.

* If you cannot reach your gas supplier call the

fire department.

INSTALLER: DO NOT DISCARD THIS MANUAL - LEAVE FOR HOMEOWNER

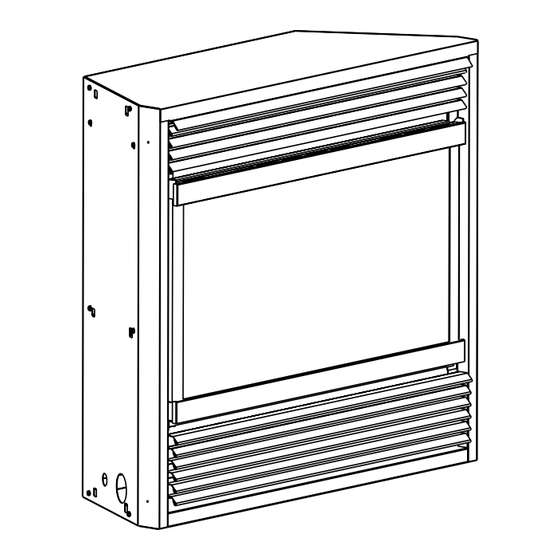

Builder

Rear Vent

Direct Vent

Models

DBR33

DBR36

DBR39

FOR YOUR SAFETY

DO NOT STORE

OR USE GASOLINE OR OTHER

FLAMMABLE VAPOURS AND LIQUIDS

IN THE VICINITY OF THIS OR ANY

OTHER APPLIANCE.

* Installation and service must be performed

by a qualified installer, service agency or

your gas supplier.

10002788

06/00 Rev. 0

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Majestic DBR33

- Page 1 Builder Rear Vent Direct Vent Models DBR33 DBR36 DBR39 Installation Instructions & Homeowner's Manual WARNING! IF THE INFORMATION IN THIS MANUAL IS NOT FOLLOWED EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE,PERSONAL INJURY OR LOSS OF LIFE. FOR YOUR SAFETY...

-

Page 2: Table Of Contents

TABLE OF CONTENTS PLEASE READ THE INSTALLATION & OPERATING INSTRUCTIONS BEFORE USING APPLIANCE. IMPORTANT: Read all instructions and warnings carefully before starting installation. Failure to follow these instructions may result in a possible fire hazard and will void the warranty. Installation Instructions ........................ -

Page 3: Installation Instructions

20 feet (610cm). See details in Venting Section. this fireplace must be installed on a metal or wood * When you install your Majestic fireplace in(D) Room panel extending the full width and depth of the fireplace. divider or (E) Flat on wall corner positions (Y), a minimum of 6 inches (153mm) clearance must be maintained from 12. -

Page 4: Fireplace Dimensions

FIREPLACE DIMENSIONS Fig. 2 FRAMING & FINISHING DBR33 DBR36 DBR39 39" 991mm 36" 914mm 33" 838mm 1/4" 870mm 7/8" 1/4" 870mm 733mm 21" 533mm 3/8" 21" 533mm 416mm 36" 914mm 33" 838mm 31" 787mm 24" 610mm 1/16" 24" 610mm 560mm 16"... -

Page 5: Mantels

CLEARANCE TO COMBUSTIBLES MANTELS Depending on the width of the mantel it may be installed Back ..0 mm/0 inches higher or lower from the top of the louvre opening. See Side ..0 mm/0 inches drawing and chart below for proper installation height of Floor .. -

Page 6: Final Finishing

W.C. for Natural Gas and 10 inches W.C. for LP gas.) GAS SPECIFICATIONS MAX. MIN. INPUT INPUT MODEL FUEL GAS CONTROL B.T.U.H B.T.U.H. DBR33 RN Natural Gas Millivolt Hi/Lo 15,000 10,500 DBR33 RP Propane Gas Millivolt Hi/Lo 15,000 11,250 DBR36 RN... -

Page 7: Gas Line Installation

REMOTE SWITCH INSTALLATION GAS LINE INSTALLATION FOR RN/RP When purging gas line the front glass must 1. Thread wire through the electrical knockout located on be removed. either side of fireplace.. Do not cut wire or insulation on metal edges. Ensure that wire is protected. Run the other end to a conveniently located wall receptacle The gas pipeline can be brought in through the right side, box. -

Page 8: General Information On Assembling Vent Pipes

GENERAL INFORMATION ON ASSEMBLING THE VENT PIPES TWIST LOCK PIPES CRIMPED END PIPES When using twist lock pipe it is not necessary to use Before joining elbows and pipes apply a bead of high sealant at the twist lock joints. temperature sealant to crimped end of elbow or pipe. -

Page 9: General Venting Information

24" from the the side wall, or vertical through the roof. front of the termination hood. Only Majestic venting components specifically Do not locate termination hood where excessive snow or approved and labelled for this fireplace may be ice build up may occur. -

Page 10: Termination Clearances

Termination Clearances Termination clearances for buildings with combustible and noncombustible exteriors. Inside Corner Recessed Location Outside Corner Combustible 6"(152mm) Combustible 6"(152mm) Noncombustible 2"(50mm) Noncombustible 2"(50mm) Balcony - Balcony - with no side wall with perpendicular side wall C = Maximum depth of 48" (1219mm) for recessed location. -

Page 11: Rear Wall Installations

STEP 3 REAR WALL INSTALLATIONS Measure from fireplace collar or elbow face to face of outside wall (add 2" for vent pipe overlap. Mark pipes and STEP 1 cut to length. It is very important that the two pipes are flush with the outside wall once the fireplace is in its final location. -

Page 12: Vertical Sidewall Applications

The maximum number of 90 degree elbows per side wall VERTICAL SIDEWALL APPLICATIONS installation is three (3) plus one transition elbow, 7DVRT90 off back of unit. Since it is very important that the venting system maintain its balance between the combustion air intake The maximum number of 45 degree elbows permitted per and the flue gas exhaust, certain limitations as to vent side wall installation is two (2). -

Page 13: How To Use The Vertical Sidewall Vent Graph

The maximum number of elbow degrees in a system is VERTICAL SIDEWALL VENTING GRAPH . (This does not include transition elbow from rear (Dimensions in Feet) vent to vertical vent.) Fig. 22. Sample: (Fig. 20) Total eg: A eg: B Fig. -

Page 14: Vertical Sidewall Installation

STEP 2 VERTICAL SIDEWALL INSTALLATION Fig. 26. Measure wall thickness and cut adjustable zero clearance sleeve parts to proper length (MAXIMUM 12"/ STEP 1 305mm). Adjust sleeve to minimum (9-3/8" x 9-3/8") and attach to firestop with #8 sheet metal screws (supplied). Locate vent opening on the wall. - Page 15 STEP 3 (Fig. 27) Apply a bead of high temperature sealant to the inner and outer flue collars of the fireplace and using appropriate venting component(s) attach to fireplace with three (3) screws. Follow with the installation of the inner and outer elbow.

-

Page 16: Below Grade Installations

BELOW GRADE INSTALLATIONS When it is not possible to meet the required vent terminal FOUNDATION RECESS clearances of 12 inches (305mm) above grade level a SNORKEL model #7DVSKS vent kit is required. It allows installation WATERTIGHT depth of down to 7 inches (178mm) below grade level. The SEAL AROUND WALL... -

Page 17: Vertical Through The Roof Installations

VERTICAL THRU THE ROOF INSTALLATION 1. Locate your fireplace. MAX. 8 FEET 2. Plumb to centre of the (4") 90º transition elbow 2438mm (7DVRT90) from ceiling above and mark position. 3. Cut opening equal to 9-3/8" x 9-3/8" (240 mm x 240 mm). -

Page 18: Operating Instructions

OPERATING INSTRUCTIONS GENERAL GLASS INFORMATION GLASS FRAME FIREPLACE Only glass approved for use in products FRONT may be used for replacement. 1 . The use of subsitute glass will void all product warranties. 2. Care must be taken to avoid breakage of the glass. 3. -

Page 19: Installation Of Logs

INSTALLATION OF LOGS LOGS DBR33 DBR36 DBR39 Front Left Log 1 . Remove front glass. (See "Glass Removal" Section) 2. Remove logs from the packaging. Front Right Log Rear Log As with all plastics — these are not toys and should be kept away from children and Top Left Log infants. -

Page 20: Flame Characteristics

Fig. 47 month during the operating season. 4. Contact your local representative to arrange an DBR33 annual service program. CLEANING THE STANDING PILOT CONTROL SYSTEM The burner and control system consists of: •... -

Page 21: Lighting And Operating Instructions

LIGHTING AND OPERATING INSTRUCTIONS FOR YOUR SAFETY READ BEFORE LIGHTING WARNING: If you do not follow these instructions exactly, a fire or explosion may result causing property damage, personal injury or loss of life. This fireplace has a pilot which must be lit manually. Use only your hand to push in or turn the gas control When lighting the pilot follow these instructions exactly. -

Page 22: Trouble Shooting The Gas Control System

TROUBLE SHOOTING THE GAS CONTROL SYSTEM SIT 820 NOVA MILLIVOLT VALVE GLASS DOOR TO BE REMOVED BEFORE SERVICE WORK START CHECK GAS SUPPLY ON • SHUTOFF VALVE OPEN • CONFIRM GAS HOOK-UP • ELECTRODE GAP MIN. 1/8" LIGHT PILOT WITH •... -

Page 23: Troubleshooting Gas Control (822 Millivolt Honeywell Valve)

TROUBLE SHOOTING THE GAS CONTROL SYSTEM HONEYWELL MILLIVOLT VALVE START CHECK • SUPPLY LINE HOOKED UP GAS SUPPLY ON • SHUTOFF VALVE OPEN • LOCKOUT HAS ENGAGED. WAIT 60 SECONDS AND TRY AGAIN. • PIEZO NOT TIGHT ENOUGH FOR GOOD GROUND. •... -

Page 24: Replacement Parts List

REPLACEMENT PARTS LIST - REAR BUILDER SERIES DBR33 DBR36 DBR39 ESCRIPTION Log Set Complete 10000470 10000023 10000024 Log Front Left Log Front Right `BB7 Log Rear Log Top Left Log Top Right BB10 Lava Rock (Package) 10001454 10001454 10001454 Ember (Package) -

Page 25: Replacement Parts Pictorial

FOR FIREPLACES EQUIPPED WITH SIT 820 MILLIVOLT GAS VALVE 4a/b 8 a/b 6 a/b 16 a/b 7 a/b 34 a/b 8 a/b #1 - COMPLETE LOG SET #1 - COMPLETE LOG SET #1 - COMPLETE LOG SET DBR33 DBR39 DBR36... -

Page 26: Optional Accessories Kits

FK12 OPTIONAL FAN KIT - FK12 and FK24 This auxiliary fan system increases the efficiency of the circulation of the heating air. FK24 Fan Assembly The FK12 Fan Assembly is a fixed speed fan system and does not allow for variable speed control. It does This auxiliary fan system increases the efficiency of the not use the speed control unit or the heat sensor used in circulation of the heating air. -

Page 27: Electrical Box Eb1

ELECTRICAL BOX TEMPERATURE FASTENING GAS INLET HOLE SCREWS SENSOR OUTSIDE VIEW SPEED CONTROL Black White INSIDE VIEW Ground Fig. 54 Fig. 55 Method B (Using the EB-1 Box.) For instruction on wiring the EB-1 Electrical Junction Box OPTIONAL BAY WINDOW INSTALLATION see the chapter EB-1 Electrical Box. -

Page 28: Screen Kit Installation

OPTIONAL CERAMIC REFRACTORY INSTALLATION DBR33/DBR36/DBR39 1. Remove glass and logs. 2. Place refractory side supports so that the hole fits over the screw head on the firebox floor. 3. Place refractory base sides on the floor of the firebox. 4. Place back refractory - small brick edge down into support (See Fig. -

Page 29: Crimped End Venting Components

CRIMPED ENDS VENTING COMPONENTS 7DVRVT - Through the wall Rear Vent Termination Starter Kit -Model 7DVSK - Sidewall Venting Starter Kit - Model 7TDVSKV - Vertical Venting for 7DVSKV-A order 1/12 to 6/12 roof pitch for 7DVSKV-B order 7/12 to 12/12 roof pitch for 7DVSKV-F order flat roof Starter Kit - Model 7TDVSKS -Snorkel Kit for Below Grade Installation... -

Page 30: Twist Lock Venting Components

TWIST LOCK VENTING COMPONENTS Starter Kit -Model 7TDVSK - Sidewall Venting Starter Kit - Model 7TDVSKV - Vertical Venting for 7TDVSKV-A order 1/12 to 6/12 roof pitch for 7TDVSKV-B order 7/12 to 12/12 roof pitch for 7TDVSKV-F order flat roof Starter Kit - Model 7TDVSKS -Snorkel Kit for Below Grade Installation 45º... - Page 32 The Company neither assumes, nor authorizes any third party to assume, responsabilités en ce qui a trait à la vente de ce produit CFM Majestic, Inc.. on its behalf, any other liabilities with respect to the sale of this CFM Les garanties, telles que décrites dans ce document, ne s'appliquent pas aux...

Need help?

Do you have a question about the DBR33 and is the answer not in the manual?

Questions and answers