IFM Electronic efector150 KN5121 Operating Instructions Manual

Capacitive level sensor

Hide thumbs

Also See for efector150 KN5121:

- Operating instructions manual (23 pages) ,

- Operating instructions (3 pages) ,

- Operating instructions (3 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for IFM Electronic efector150 KN5121

- Page 1 Operating instructions Capacitive level sensor KN5121...

-

Page 2: Table Of Contents

Contents 1 Preliminary note ���������������������������������������������������������������������������������������������������3 2 Safety instructions �����������������������������������������������������������������������������������������������3 3 Functions and features ����������������������������������������������������������������������������������������3 4 Mounting ��������������������������������������������������������������������������������������������������������������4 5 Electrical connection ��������������������������������������������������������������������������������������������5 5�1 Setting the output function as normally closed or normally open ������������������5 5�2 Function check output / programming input ��������������������������������������������������6 5�2�1 Signals on the function check output ����������������������������������������������������6 5�2�2 Programming input �������������������������������������������������������������������������������6 6 Operation �������������������������������������������������������������������������������������������������������������6... -

Page 3: Preliminary Note

1 Preliminary note ► Instructions > Reaction, result Important note Non-compliance can result in malfunction or interference� Information Supplementary note� 2 Safety instructions • Please read the operating instructions prior to set-up of the device� Ensure that the product is suitable for your application without any restrictions� • The unit conforms to the relevant regulations and EC directives�... -

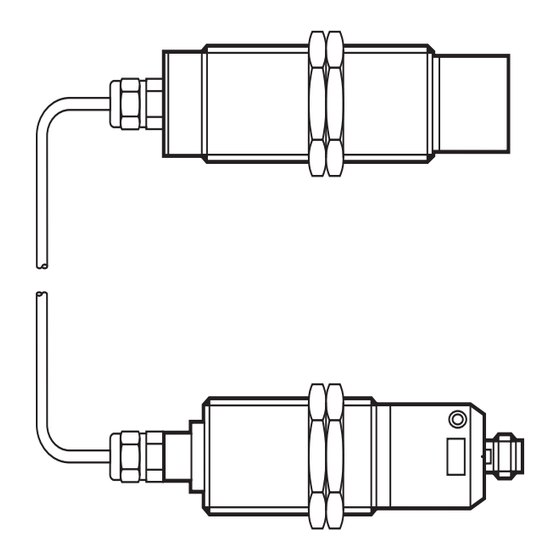

Page 4: Mounting

1: sensor 2: sensing face 3: threaded sleeve 4: programming button 5: LEDs red, yellow, green 6: evaluation electronics 4 Mounting ► Disconnect the system from power before mounting� ► Mount the unit as shown: 1: The connection cable must not be damaged� Minimum bending radius = 80 mm... -

Page 5: Electrical Connection

5 Electrical connection The unit must be connected by a qualified electrician� The national and international regulations for the installation of electrical equipment must be adhered to� ► Disconnect power� ► Connect the unit� p-switching (type FPKG) n-switching (type FNKG) 5.1 Setting the output function as normally closed or normally open The switching output of the unit can be operated as normally closed or normally... -

Page 6: 5�2 Function Check Output / Programming Input

5.2 Function check output / programming input You can select between function check output and programming input via the bidirectional wire (FC-OUT/CAL, pin 2)� • When used as function check output, output signals of the unit can be evaluated� • When used as programming input, operations can be performed� 5.2.1 Signals on the function check output Status Signal... -

Page 7: 6�1 Programming

6.1 Programming Overview of the modes and their basic functions • Operating mode Normal operating mode, all sensor functions are active� • Adjustment mode Setting of the switching threshold by empty and full adjustment� • Locking mode Locking and unlocking of the unit possible to avoid tampering� 6.1.1 Empty adjustment. -

Page 8: 6�1�2 Full Adjustment

The sensor is operational just with empty adjustment� However, it is recommended to carry out a "full adjustment" with the active zone being completely covered after empty adjustment� On the basis of the values for the empty state / full state the internal microprocessor determines the optimum position of the switching thresholds between the two states�... -

Page 9: 6�1�4 Unlocking

Factory setting: not locked� ► Press the programming button for min� 10 s� > The green LED first flashes slowly (about 1 Hz), after 5 s more quickly (about 2 Hz), after 10 s it goes out� > The unit is locked� ►... -

Page 10: Operation

• Empty adjustment outside the operating range (e�g� empty adjustment in case of direct contact with an electrically grounded medium, e�g� if the active zone is immersed in water)� ► Repeat the adjustment for error correction� Further errors • Electronic fault or sensing zone of the unit damaged� •... -

Page 11: Maintenance, Repair And Disposal

The red LED and the function check output are briefly active during the change between "medium not present" and "medium present"� This can occur in particular if the level changes very slowly and is no error message meaning a fault in the unit� 8 Maintenance, repair and disposal The operation of the unit is maintenance-free�...

Need help?

Do you have a question about the efector150 KN5121 and is the answer not in the manual?

Questions and answers