Oki OKIFAX 5650 Maintenance Manual

Hide thumbs

Also See for OKIFAX 5650:

- User manual (251 pages) ,

- Options manual (12 pages) ,

- User manual (138 pages)

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Oki OKIFAX 5650

- Page 1 OKIFAX 5650 Maintenance Manual First Edition Note: Throughout this manual there are many references to the G4/ ISDN option. This option is not available in the U.S. or CANADA. January, 2001 Oki Data Corporation...

- Page 3 PREFACE This manual is intended to be used for installing and maintaining OKIFAX 5650 facsimile trans- ceiver. Maintenance of the OKIFAX 5650 is assumed to be conducted at the following levels: • Assembly-level maintenance for mechanical portions • Unit-level maintenance for electrical at portions CAUTION: DANGER OF EXPLOSION IF BATTERY IS INCORRECTLY REPLACED.

-

Page 4: Table Of Contents

CONTENTS GENERAL INFORMATION ................7 General Performance ...................... 7 General User’s Function ....................10 General Maintenance Functions ..................13 General Appearance ....................... 14 Basic Performance Specifications ................... 16 Reports and Lists ......................26 Configuration ........................47 1.7.1 Print conditions ....................47 1.7.2 Report image ....................... - Page 5 6.13 Protocol Dump Data Printing ................... 215 6.14 System Reset ........................219 6.15 Service Code ........................220 TROUBLESHOOTING AND REPAIR FOR OKIFAX 5650 ......235 Overall Troubleshooting Flow Chart ................237 No LCD Operation ......................238 ALARM LED On ......................239 Printing Test Failure ......................

- Page 6 APPENDIX F SECOND PAPER FEEDER MAINTENANCE MANUAL ....450 OF5650 January 2001...

-

Page 7: General Information

• 128 mm to 356 mm Length setting : Unlimited (1500 mm) is also available. (7) Automatic document feeder (ADF) • 30 sheets (NA Letter/A4-size: 20-lb/75gm Oki Data recommended paper) • 15 sheets (NA Letter/A4-size: 13 to 28-lb/49 to 105gm) Note: NA is North America (8) Recording paper or sheet •... - Page 8 (12) Scanning resolution a) Horizontal : • 300 dots/inch b) Vertical : Transmission mode : 3.85 line/mm (STD), 7.7 line/mm (FINE), 15.4 line/mm (EX.FINE) or 300 dot/inch (EX.FINE) COPY mode : 7.7 line/ mm(FINE) or 300 dot/inch(EX.FINE) 300 dpi ¥ 300 dpi (Transmission is available.) Note : (13) Scanning method •...

- Page 9 PC Printer Function PC Scanner Function PC FaxModem Function Note: For details, see “OKIFAX 5650 Product Specification for MFP” Hardware is standard and software is option for Bi-Centro interface. (29) Fax2Net : Provider type (option) The following functions are available.

-

Page 10: General User's Function

General User’s Function (1) Transmit mode • Automatic transmit mode • Manual transmit mode (2) Receive mode • Automatic receive mode • Manual receive mode • TEL/FAX automatic switchover mode • TAD mode • Memory only receive mode • Forwarding mode •... - Page 11 (20) Confidential message reception • 16 mail boxes (21) PHOTO mode (Half-tone transmission) • 64 scale gradations (22) G3 sequential broadcast (Memory) • Broadcast mode 200 stations at maximum • Delayed broadcast mode (23) No paper/no toner reception (Memory) (24) Memory-only reception (Memory reception even if paper does not run out) (25) Distinguishing Text from picture (26) Page re-transmission (Only in case of memory TX mode)

- Page 12 (43) Quick scanning 3 sec. minimum Æ A4 size 3.85 (44) Time and date setting (45) PC interface (option) • Standard: ODA version • Option: INT'L version (46) Language selection • 2 languages (LCD and Reports) (47) Fax fowarding (48) 4 digit indication of YEAR (49) Memory password programming (50) Fax network programming (51) Fax2Net service...

-

Page 13: General Maintenance Functions

General Maintenance Functions 1) Local tests (1) Self-diagnosis • CPU ROM/RAM check • FLASH (/MASK) memory check (Program, Language, Default) • Modem version • RAM check • RAM check (MEMORY board: option) • PC-IF board (parallel) check • ISDN board (option) : CPU ROM/RAM check •... -

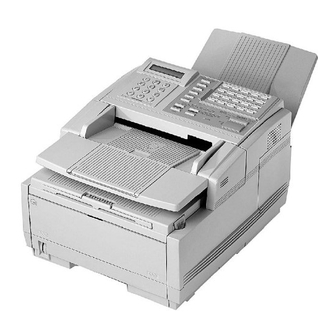

Page 14: General Appearance

General Appearance Figure 1.1 shows the general appearance. Figure 1.2 shows the control panel. Control Panel Document Stacker One-Touch Keypad Document Guides Document Tray Sub-Paper Tray Manual Paper Feeder Cover AC Switch Recording Paper Cassette Telephone Handset (Option) Figure 1.1 General Appearance OF5650 January 2001... - Page 15 Figure 1.2 Control Panel OF5650 January 2001...

-

Page 16: Basic Performance Specifications

Basic Performance Specifications Table 1.1 shows basic performance specifications. Note: TF: Technical function setting Function program setting One-touch key pressed SELECT FUNCTION key pressed Table 1.1 (1/10) Basic Performance Specifications Item Specifications Applicable line 1) Public switched telephone network (PSTN) 2) Private branch exchange (PBX) (OT9+2) 3) Integrated services digital network (ISDN) : option Line interface... - Page 17 Table 1.1 (2/10) Basic Performance Specifications Item Specifications Effective reading width Communication Effective reading Document width Copy size Mode/Paper width width ISO A4 (210 mm) 208 mm for TX G3/A4 202.8 mm for local copy [INT’L/FTZ] NA letter (216 mm) 215.1 mm for TX G3/A4 Letter...

- Page 18 3) Weight, thickness and condition: Same as above Note: One single sheet only should be loaded on the manual loading feeder for any one occasion. For best results use Oki Data recommended papers 1) Xerox 4200 (20 - lb/75gm weight paper) 2) L-type paper for photo-printers...

- Page 19 This table does not include vertical and horizontal addressing error +/- 3 mm) of recording paper. Copy stacking The fax can discharge printed copies and stack them face- down. Maximum sheets on the copy stacker: 100* *Note : Oki Data recommended paper, New standard 20-lb. (Xerox 4200) OF5650 January 2001...

- Page 20 Table 1.1 (5/10) Basic Performance Specifications Item Specifications Scanning resolution Horizontal: • 300 dot/inch Vertical: Transmission mode: • 3.85 line/mm (STD), 7.7 line/mm (FINE), 15.4 line/mm (EX.FINE) or 300 dot/inch,(EX. FINE) Note: 300 dpi ¥ 300 dpi ; Transmission is available COPY mode: 7.7 line/ mm (FINE) or 300 dot/inch (EX.

- Page 21 Specifications Minimum scan line time for receiv- 0 ms, when receiving in ECM mode or from an Oki Data facsimile. 5 ms at 15.4 line/mm or 7.7 line/mm and 10 ms at 3.85 line/mm when receiving from a non-Oki Data facsimile or non-ECM mode.

- Page 22 Item Specifications Protocol 1) ITU-T Rec. T.30 2) Oki Data special protocol High-speed protocol The T.30 protocol signal from the transmitting station is sent at message transmission speed instead of 300 bps. Note: In high-speed protocol, V.34 is not applied.

- Page 23 1) PC local printer function 2) PC scanner function 3) PC FaxModem function Note: This function will be supplied as the OKIFAX 5650 option in case Oki Data can get the approval in respective countries without modifying the optional unit.

- Page 24 Table 1.1 (9/10) Basic Performance Specifications Item Specifications ISDN G4 (Option) The following four modes are supplied. 1) G4 function 2) ISDN G4 communication 3) ISDN G3 communication 4) ISDN report and list Note: For details, see Appendix H “ISDN G4 option system specifications”...

- Page 25 Table 1.1 (10/10) Basic Performance Specifications Item Specifications Weight Approx. 13 kg (Main body) Excluding optional units, recording paper and packing mate- rials. 1) AC power cord ¥ 1 Attachment 2) I/D unit ¥ 1 (Already installed) (to the main body) 3) Toner cartridge ¥...

-

Page 26: Reports And Lists

Reports and Lists Table 1.2 shows Reports and Lists Specifications. Note: F +OT: Press FUNCTION and One-touch key Function program setting Technical function setting Table 1.2 (1/2) Reports and Lists Specifications Item Specifications Call-back message The transmitter sends a call-back message to the receiver only when the receiver does not respond to voice request of the transmitter. - Page 27 Table 1.2 (2/2) Reports and Lists Specifications Item Specifications Confidential reception report The fax can print out this report automatically on completion of a confidential reception. Telephone directory This directory is printed manually. (REPORT PRINTING +3) Configuration report This report is printed manually. (REPORT PRINTING +4) Active memory files This report will be manually or automatically printed out for...

- Page 28 (2) Sender ID (3) CSI/Personal ID (4) Letters "PLEASE CALL BACK" (5) Sender ID (6) Sender’s call back telephone number Sender ID Format: (Example) OKI ABC 1234 → 3454 2000 07/01/1999 15:06 NO.021 (1) Date and time (2) Sender ID (3) Receiver’s CSI/Personal ID...

-

Page 29: Power Outage Report

S,R-TIME DISTANT STATION ID MODE PAGES RESULT 06/30 10:10 0485-88-3385 LOST 9080 06/30 10:30 ODS TAKASAKI LOST 0000 06/30 12:05 01'20" OKI FAX CONF=01 LOST 0000 06/30 13:00 00'20" 03-5476-4300 LOST 0000 06/30 10:50 01'20" 0495-22-5400 LOST 0000 06/30 15:00 B.C. -

Page 30: Activity Report

TOTAL TIME CALLING=08:22' CALLED=17:30' DATE TIME S,R-TIME DISTANT STATION ID MODE PAGES RESULT (10) (11) (12) 05/17 10:00 01'20" OKI FAX CALLING 0000 05/17 10:10 01'00" 0485 88 3385 CALLING STOP 9080 05/17 10:30 00'20" ODS TAKASAKI POLLING 0000 05/17 12:05 01'20"... - Page 31 Title of the report Date and time when the report was printed Sender ID Total CALLING and CALLED time Date of transmission or reception Time when the communication started Time span of the fax communication. Identification of the remote station Personal ID/Location ID/TSI/CSI/Dial number or space Communication mode: CALLING...

-

Page 32: Message Confirmation

Message Confirmation Report Format (1/2): (Example) MESSAGE CONFIRMATION 07/01/1999 08:05 ID=OKI (10) DATE S.R-TIME DISTANT STATION ID MODE PAGES RESULT 07/01 00’20" OKI FAX CALLING 0000 OF5650 January 2001... - Page 33 MESSAGE CONFIRMATION 07/01/1999 17:05 ID=OKI (10) DATE S.R-TIME DISTANT STATION ID MODE PAGES RESULT 07/01 00’20" OKI FAX B.C. COMP 60A0 07/01/96 17:00 OKIFAX No.022 150 km (11) (1) Title of the report (2) Date and time when the report was printed...

- Page 34 BROADCAST ENTRY REPORT P1 02/14/2000 12:00 ID=ODS LOCATION ID LOCATION ID ONE TOUCH 1=12345678901234567890123456789012 2=12345678901234567890123456789012 3=OKI DATA CORP. 4=s-ishika@okidata.co.jp 5=timomo@alles.or.jp 6=0273265978 7=0273261234 8=0273267890 9=0273261447 10=0273265980 11=OT11 12=OT12 13=OT13 14=OT14 15=OT15 16=OT16 17=OT17 18=OT18 19=OT19 20=OT20 21=OT21 22=OT22 23=OT23 24=OT24 25=OT25...

- Page 35 BROADCAST ENTRY REPORT P2 02/14/2000 12:00 ID=ODS LOCATION ID LOCATION ID AUTO DIAL 095=12345678901234567890123456789012 096=12345678901234567890123456789012 097=ODS 098=OKI DATA SYSTEM 099=AD99 100=AD100 101=AD101 102=AD102 103=AD103 104=AD104 105=AD105 106=AD106 107=AD107 108=AD108 109=AD109 110=AD110 111=AD111 112=AD112 113=AD113 114=AD114 115=AD115 116=AD116 117=AD117 118=AD118 119=AD119...

-

Page 36: Broadcast Confirmation Report

= 01 START IME = 02/04 11:00 TOTAL TIME = 00:30’34" LOCATION PAGES RESULT LOCATION ID PAGES RESULT ONE TOUCH 1=123456789012345678901234 2=1234567890123456789012 3=OKI DATA CORP. 4=s-ishika@okidata.co.jp AUTO DIAL 001=12345678901234567890123 002=1234567890123456 003=ODS 004=OKI DATA SYSTEM 005=AD05 006=AD06 KEYPAD 123456789012345678901234 12345678901234567890 Max. 70-line Note: When the number of printed line exceeds Max.70-line, 2nd page is printed out. -

Page 37: Confidential Rx Report

CONFIDENTIAL RX REPORT 07/01/2000 17:05 ID=OKI DATE TIME S,R-TIME DISTANT STATION ID MODE PAGES RESULT 07/01 17:00 00'00" CONF=01 0000 Figure 1.6 Confidential RX Report OF5650 January 2001... -

Page 38: Telephone Directory

Telephone Directory 1.8.1 Print conditions OKIFAX 5650 Number of OTs Number of ADs Number of groups Maximum number of digits of OT/AD Tel No. Maximum number of digits of OT OR Tel No. Maximum number of digits of Email/Web 64 (Alphabetic small letters can be printed.) - Page 39 TELEPHONE DIRECTORY P1 02/14/2000 12:00 ID=ODS LOCATION ID TEL NO. G3-ECHO/G3-RATE/MODE ONE TOUCH ABCDEFGHIJKLMNO 1234567890123456789012345678901234567890 / 33.6K / G4 1234567890123456789012345678901234567890 123456789012345678901234567890 OFF / 9.6K / G3 12345678901234567890 / 33.6K / G4 12345678901234567890 / 33.6K / G4 12345678901234567890 / 33.6K / G4 s-ishika@okidata.cp.jp http://www.fax2net.com/ 12345678901234567890...

- Page 40 TELEPHONE DIRECTORY P2 02/14/2000 12:00 ID=ODS LOCATION ID TEL NO. G3-ECHO/G3-RATE/MODE ONE TOUCH ABCDEFGHIJKLMNO 1234567890123456789012345678901234567890 / 33.6K / G4 1234567890123456789012345678901234567890 OFF / 9.6K / G3 / 33.6K / G4 / 33.6K / G4 / 33.6K / G4 / 33.6K / G4 http://www.yahoo.co.jp/ / 33.6K / G4 http://www07.taka.okidata.co.jp/vb/install.HTM...

- Page 41 TELEPHONE DIRECTORY P3 02/14/2000 12:00 ID=ODS LOCATION ID TEL NO. G3-ECHO/G3-RATE/MODE AUTO DIAL AD46 1234567890123456789012345678901234567890 / 33.6K / G4 AD47 123456789012345678901234567890 / 33.6K / G4 AD48 12345678901234567890 / 33.6K / G4 / 33.6K / G4 / 33.6K / G4 / 33.6K / G4 / 33.6K / G4 / 33.6K / G4 / 33.6K / G4...

- Page 42 TELEPHONE DIRECTORY P4 02/14/2000 12:00 ID=ODS LOCATION ID TEL NO. G3-ECHO/G3-RATE/MODE AUTO DIAL AD111 1234567890123456789012345678901234567890 / 33.6K / G4 AD112 123456789012345678901234567890 / 33.6K / G4 AD113 12345678901234567890 / 33.6K / G4 / 33.6K / G4 / 33.6K / G4 / 33.6K / G4 / 33.6K / G4 / 33.6K / G4 / 33.6K / G4...

- Page 43 TELEPHONE DIRECTORY P5 02/14/2000 12:00 ID=ODS GROUP NUMBER = #1 #2 #3 #4 #5 <#1 ONE TOUCH> 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 <#1 AUTO DIAL>...

-

Page 44: Telephone Directory P6

TELEPHONE DIRECTORY P6 02/14/2000 12:00 ID=ODS GROUP NUMBER = #6 #7 #8 #9 #10 <#6 ONE TOUCH> 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 <#6 AUTO DIAL>... - Page 45 TELEPHONE DIRECTORY P7 02/14/2000 12:00 ID=ODS GROUP NUMBER = #11 #12 #13 #14 #15 <#11 ONE TOUCH> 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 <#11 AUTO DIAL>...

- Page 46 TELEPHONE DIRECTORY P8 02/14/2000 12:00 ID=ODS GROUP NUMBER = #16 #17 #18 #19 #20 <#16 ONE TOUCH> 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 <#16 AUTO DIAL>...

-

Page 47: Configuration

11) CALL BACK N0.: Up to 20 digits are printed. 12) FORWARDING N0.: Up to 40 digits are printed for OKIFAX 5650. 13) SERVER TEL N0.: When FAX2NET FUNCTION is set to ON, up to 40 digits are printed for OKIFAX 5650. - Page 48 20) ISDN CALLED N0.: Up to 20 digits are printed when an ISDN board is mounted. 21) Dial parameters other than REDIAL TRIES, REDIAL INTERVAL, PBX LINE, AUTO START, and DIAL PREFIX are left blank when an ISDN board is mounted and Service Bit = OFF. 22) 33: V.34 TX RETRY “ON,”...

-

Page 49: Report Image

1.7.2 Report image CONFIGURATION P1 02/14/2000 12:00 ID=ODS FUNCTION LIST 01:MCF (SINGLE-LOC.) 02:MCF (MULTI-LOC.) 03:ERR.REPORT (MCF) 04:IMAGE IN MCF 05:SENDER ID. 06:MONITOR VOLUME 07:BUZZER VOLUME 08:CLOSED NETWORK 09:TX MODE DEFAULT MIDDLE STD/NORMAL 10:T/F TIMER PRG. 11:RING RESPONSE 12:DISTINCTIVE RING 35SEC 1 RING 13:PAPER SIZE 14:USER LANGUAGE... - Page 50 CONFIGURATION P2 02/14/2000 12:00 ID=ODS DIAL PARAMETER REDIAL TRIES 3 TRY REDIAL INTERVAL 3 MIN DIAL TONE DETECT BUSY TONE DETECT MF(TONE)/DP(PULSE) PULSE DIAL RATE 10 PPS PULSE MAKE RATIO PULSE DIAL TYPE MF(TONE) DURATION 100MS PBX LINE PBX TYPE NORMAL AUTO START DIAL PREFIX...

- Page 51 CONFIGURATION P3 02/14/2000 12:00 ID=ODS FUNCTION LIST 01:SERVICE BIT 02:MONITOR CONT. 03:COUNTRY CODE 04:TIME/DATE PRINT 05:TSI PRINT 06:TAD MODE TYPE2 07:REAL TIME DIAL 08:TEL/FAX SWITCH 09:MDY/DMY TYPE2 10:LONG DOC. SCAN 11:TONE FOR ECHO 12:MH ONLY 13:H/MODEM RATE 14:T1(TX) TIMER VALUE 15:T1(RX) TIMER VALUE 33.6K 16:T2 TIMER VALUE...

-

Page 52: Active Memory Files

TIME DISTANT STATION ID MODE PAGES POLL TX 07/02 12:05 POLL RX TRANSMISSION DATE TIME DIDTANT STATION ID MODE PAGES 07/01 20:00 OKI DATA SYSTEMS 07/01 12:03 0273242117 07/01 19:00 ODC TAKASAKI Figure 1.9 Active Memory Files OF5650 January 2001... -

Page 53: Protocol Dump P1

• JM information is moved in the arrangement of CM information. • 00 is printed always since the received SID on the 2nd page is invalid. PROTOCOL DUMP P1 12/24/1998 19:00 ID=OKI TAKASAKI DATE TIME S,R-TIME DISTANT STATION ID MODE... -

Page 54: Protocol Dump P2

PROTOCOL DUMP P2 12/24/1998 19:00 ID=OKI TAKASAKI RECEIVED FRAME FF C8 01 00 73 17 22 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00... -

Page 55: Self Diagnosis Repor

ID character strings of PnP device. Small letters can be printed. The maximum number of each of letters and characters shall be 45. Printing is available for OKIFAX 5650 only when option memory is mounted. (“2M.” or “4M”) Printed only when ISDN option is provided. - Page 56 LANGUAGE VERSION aaaa HASH hhhh DEFAULT VERSION aaaa HASH hhhh RAM1 RAM2 DEFAULT TYPE 03/03/2000 12:00 DEVICE ID MFG:OKI DATA CORP; MDL:FX-046FAX; DES:OKI FX-046FAX; OPT-RAM ISDN BOARD CPU-ROM VERSION aaaa HASH hhhh CPU-RAM PROGRAM VERSION aaaa HASH hhhh DPRAM Figure 1.11 Self Diagnosis...

- Page 57 G4 Protocol Dump The printing image is as follows: PROTOCOL DUMP P1 08/25/2000 19:00 ID=OKI TAKASAKI DATA TIME S,R-TIME DISTANT STATION ID MODE PAGES RESULT 04/19 14:49 00’07" OKI SHIBAURA(6412) TX-G4 0000 Dch. SETUP CONN-ACK +Bch+ DISC REL-C STATUS SETUP-ACK CONN +Bch+ Bch.

- Page 58 PROTOCOL DUMP P2 CR/CN 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 CA/CC 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00...

- Page 59 Transmission (Except Polling TX) Table 1.3 Multiple Function Combinations for Transmissions : Combination Possible : Combination Impossible Feeder TX Instant Dialing Memory TX Single Loc. TX Broadcast TX Delayed TX Confidential TX Relay Broadcast Initiate Manual TX Chain Dialing Automatic Alternate Selecting Call Closed User Group Page Retransmit Redial if Communication Error in Memory TX...

- Page 60 Reception (Except Polling RX) Table 1.4 Multiple Function Combinations for Reception : Combination Possible : Combination Impossible Paper Reception In-between Memory Reception Memory Reception Memory Only Reception Confidential RX Closed Network TSI Print TIME/DATE Print Voice Request (Initiate) Voice Request (Reception) Manual Reception Remote Reception Handled as memory reception if the real time print is not available at the cancellation of...

- Page 61 Paper Reception Feeder TX In-between Memory Reception Memory TX Initial Memory Reception Closed Network Memory Only Reception Page Re-transmit Closed Network Redial for Memory TX (Error) TSI Print Sender ID TIME/DATE Print Voice Request (Initiate) Voice Request (Initiate) Voice Request (Reception) Voice Request (Reception) Call Back Message Manual Reception...

- Page 62 Functions Voice Voice Redial if Automatic Closed Sender ID Page Call Back Communication Alternate Request Request Stop Error in Network Retransmit Preparation Message Selecting Call (Initiate) (Reception) Communication Mode Memory TX Manual Calling Automatic Call Confidential Initiate Origination Relay Broadcast Initiate Delayed Polled Auto Reception...

- Page 63 Table 1.8 Preparation TX as Dual Access PC1 ON 2'nd 1'st Standby ON HOOK During FAX Calling During RING RESPONSE Call Reception During detection of TEL/FAX During TAD detection 1st Phase B Calling ~ Transmission Feeder TX Transmission after scanning During Scanning Memory TX Dialling and Calling...

- Page 64 User Setting Items Setting Selection Note E-INT E-GER E-FRE 0-AUS 0-NZL 0-SIN 0-HNG L-AG MCF (single-loc.) ON/OFF MCF (multi-loc.) ON/OFF ERR.REPORT (MCF.) ON/OFF IMAGE IN MCF. ON/OFF SENDER ID ON/OFF MONITOR VOLUME OFF/LOW/HIGH BUZZER VOLUME LOW/MID/HIGH CLOSED NETWORK OFF/ T/R / RX TX MODE DEFAULT STD/FINE/EX-FINE/PHOTO NORMAL/DARK/LIGHT...

- Page 65 (21) User Setting Items Setting Selection Note Factory MCF (single-loc.) ON/OFF MCF (multi-loc.) ON/OFF ERR.REPORT (MCF.) ON/OFF IMAGE IN MCF. ON/OFF SENDER ID ON/OFF MONITOR VOLUME OFF/LOW/HIGH HIGH HIGH HIGH HIGH HIGH HIGH BUZZER VOLUME LOW/MID/HIGH CLOSED NETWORK OFF/ T/R / RX TX MODE DEFAULT STD/FINE/EX-FINE/PHOTO NORMAL/DARK/LIGHT...

- Page 66 50 kinds of service codes Only ISDN opt. Installed E-XXX=OEL-XXX, O-XXX=OKI-XXX, L-XXX=LANIER-XXX Note: As for the setting of the part of mesh, Default-data does'nt exist in the Default-file. This setting has the data which are characteristic of the device.

- Page 67 50 kinds of service codes Only ISDN opt. Installed E-XXX=OEL-XXX, O-XXX=OKI-XXX, L-XXX=LANIER-XXX Note: As for the setting of the part of mesh, Default-data does’nt exist in the Default-file. This setting has the data which are characteristic of the device.

- Page 68 Table 1.11 Default Setting of Dial Parameters OF5650 January 2001...

- Page 69 Model. Description ID for Plug & Play Close Setting Items Setting Selection Note E-INT E-FRE 0-AUS 0-NZL 0-SIN 0-HNG L-AG Plug & Play ID Default 00/01/02/03/04 (21) Factory 00 - ODA, 01 - OEL, 02 - Lanier, 03 - Telenolma, 04 - OKI...

- Page 70 User Setting Item XPARA[ ] MCF (single-loc.) MCF (multi-loc.) ERR. REPORT (MCF.) IMAGE IN MCF. SENDER ID MONITOR VOLUME BUZZER VOLUME CLOSED NETWORK TX MODE DEFAULT T/F TIMER PRG. RING RESPONSE DISTINCTIVE RING 1'ST PAPER SIZE USER LANGUAGE INCOMING RING REMOTE RECEIVE MEM./FEED SWITCH POWER SAVE MODE...

- Page 71 User Setting Item XPARA[ ] SPECIAL SETTINGS CLOCK ADJUSTMENT TSI/CSI SENDER ID FORWARDING TEL No. not assign not assign for TBR21 (DT detect mask LANIER Special Settings XPARAE *1: LANIER Special Settings ("0": User setting are possible. "1": User setting are impossible.) CLOCK ADJUSTMENT TSI/CSI TIME/DATE PRINT...

-

Page 72: Installation Procedure

INSTALLATION PROCEDURE Setup Information 2.1.1 General The following flowchart outlines the installation procedure. (See 2.1.2) Site selection (See 2.1.3) Unpacking (See 2.1.4) Check of contents (See 2.1.5) Installation of attachments (See 2.1.6) AC cord connection (See 2.1.7) Telephone and line connections (See 2.1.8) Packing for shipment (See 2.2.1.1) - Page 73 (See 2.2.1.7) Dual access operations System data programming (See 2.2.1.8) TSI/sender ID included. One-touch key programming Two-digit auto dial programming Group setting (See 2.2.1.9) Dial parameter settings Programming mail box password Memory operations (See 2.2.1.10) Off-line tests (See 2.2.1.11) On-line tests (See 2.3) Installation of optional units Memory PC Board...

-

Page 74: Site Selection

2.1.2 Site Selection INSTALLATION Precautions for Installation (1) Fluctuation in line voltage • 120VAC (102V to 127V) • 230VAC (198V to 264V) (2) Room temperature 50 to 90°F (10 to 32°C) (3) Humidity 20 to 80% RH (4) Operating environment Pressure: Equivalent to altitude of 2500 m (8020 feet) and below. - Page 75 (196mm) (46mm) 11.81" 19.69" (300mm) (500mm) In case of scanning length (Max. 14 inches: 356mm) *Note 1: This space is necessary for handling the handset. (option) (page 2-3) This space is necessary for removing the recording paper cassette. This space is necessary for installing the document stacker and to allow space for the fan exhaust.

-

Page 76: Unpacking

2.1.3 Unpacking 2.1.3.1 Unpacking Procedure (1) Remove tape on the top of the carton box and open its cover. External carton box Packing tape Packing tape Carton label Figure 2.1 (1/3) Unpacking Procedure (2) Take out the accessory box from the carton box. (See Figure 2.1) (3) Take out the machine with plastic wrapper from the box. - Page 77 Accessories box Right cushion assembly Left cushion assembly (Top) (Top) Front Fixed tape Machine Left cushion assembly (Bottom) Polyethylene film Right cushion assembly (Bottom) External carton box Figure 2.1 (2/3) Unpacking Procedure OF5650 January 2001...

- Page 78 Top carton box Cushion AC power cord Cellophane tape Modular cord Polyethylene bag Polyethlene bag Toner cartridge (In damp proof bag) Document stacker Carton frame Accessories box Separation frame Packing tape Accessories box Figure 2.1 (3/3) Unpacking Procedure OF5650 January 2001...

-

Page 79: Identification Contents

After having taken out the machine and accompanied accessories from the carton box, check the contents according to the following list: Table 2.1 Contents List Item No. Name Q'ty Remarks OKIFAX 5650 facsimile AC power cord I/D unit Already installed. Toner cartridge Document stacker Line cord One touch sheet Already installed. -

Page 80: Installation Of Attachments

2.1.5 Installation of Attachments 2.1.5.1 Installation of Attachments (1) Items • Image Drum (ID) Unit (already installed) • Toner cartridge • Recording paper • Document stacker (2) Procedure Toner cartridge • Peel off the fixed tape attached to the copy stacker. •... - Page 81 • Take out the toner cartridge from the damp proof bag, shake it five or six times as shown in the illustration to eliminate the toner deflection, and peel off the seal gently. Seal Toner cartridge Figure 2.2 (3/5) Toner Cartridge Installation •...

- Page 82 • Push the blue tab forward until it stops. Toner cartridge Blue tab Figure 2.2 (5/5) Toner Cartridge Installation • Clean the toner scattered in the vicinity of the toner cartridge using a cloth moistened with cold water. Do not use hot water since it makes the toner stick there. •...

- Page 83 (3) Recording paper Note: About 250 sheets of the new paper can be set in the recording paper cassette. • Remove the paper cassette from the facsimile by pulling the cassette tab. Paper cassette Figure 2.3 (1/2) Recording Paper Cassette Installation •...

- Page 84 (4) Document stacker • Hang the document stacker onto hanging position. Hanging position Document stacker Figure 2.4 Document Stacker Installation OF5650 January 2001...

-

Page 85: Ac Cord Connection

2.1.6 AC Cord Connection The power supply is provided as follows. Nominal input voltage 120VAC (Voltage range 102 to 127VAC) Nominal input voltage 230VAC (Voltage range 198 to 250VAC) Check whether the AC voltage of your input is within the above-mentioned voltage range and if so, check that the power switch is turned OFF. -

Page 86: Telephone And Line Connections

Figure 2.5 Telephone and Line Connections 2.1.8 Packing for Shipment CAUTION: When packing the OKIFAX 5650 for shipment, REMOVE THE IMAGE DRUM AND TONER FROM THE UNIT AND SHIP SEPARATELY! Failure to do this will result in damage to the machine.” OF5650 January 2001... -

Page 87: Programming And Initial Settings

Programming and Initial Settings 2.2.1 Initial Settings 2.2.1.1 General Procedure of Key Operation Figure 2.6 shows the general procedure of key operation. (STANDBY MODE) (Press the SELECT FUNCTION key.) COPY COPY X2 SELECT FUNCTION (OT) Selection by One-touch key To technical program [Prg. - Page 88 Powered on while holding the 01: MCF. (SIGNLE-LOC.) SELECT FUNCTION key down. 02: MCF. (MULTI-LOC.) 03: ERR. REPORT (MCF.) *4 04: IMAGE IN MCF. Selection by YES/NO keys or digit (1 to 8) 05: SENDER ID 06: MONITOR VOLUME OT9: USER PROGRAMMING 07: BUZZER VOLUME 08: CLOSED NETWORK 09: TX MODE DEFAULT...

- Page 89 Powered on while holding the COPY key down. Selection by YES/NO keys or digit (1 to 5) TECHINICAL PROGRAMMING Selection by YES/NO keys or digit (1 to 8) 1: SELF DIAGNOSIS 1: LOCAL TEST 2: SENSOR CALIBRATION 9: LOOP BACK 1 3: LED TEST 10: LOOP BACK 2 4: TONE SEND TEST...

- Page 90 Note: When the machine is in POWER SAVE MODE, the machine returns to standby mode by pressing the START key. *1: In case of Germany, Austria and Switzerland version, ACTIVITY REPORT message does not appear on the LCD display. *2: User can read no. of counter in LCD but can not clear. *3: User can not select in some countries.

- Page 91 2.2.1.2 Technical Functions This section explains setting items generally conducted by service personnel, not by users. Table 2.2 shows the initial setting items and their purposes. (The default setting is different by the individual countries.) Each item can be accessed by entering the corresponding service number on Technical Function.

- Page 92 Table 2.2 (1/8) Service Personnel Initial Settings T.F. Item Specifications Default Service bit Switching serviceman/user operation. ON : Service personnel’s features are avail- able. OFF : Service personnel’s features are not available. To enable or disable the following functions: • Drum (Total, Print, Scan), and toner counter clear •...

- Page 93 Table 2.2 (2/8) Service Personnel Initial Settings T.F. Item Specifications Default TAD mode Switches an automatic voice message response (For external telephone to the calling station. answering device.) TAD mode is of three types (TYPE1/TYPE2/ TYPE3). OFF/TYPE1/TYPE2/TYPE3 selectable. TYPE1 means: 1.

- Page 94 Table 2.2 (3/8) Service Personnel Initial Settings T.F. Item Specifications Default Long document SCAN Switches the function of transmitting long-size document (more than 360 mm). ON : 1500 mm or 60 min. OFF : 360 mm or 60 min. Note: 60 min is transmitting time.

- Page 95 Table 2.2 (4/8) Service Personnel Initial Settings T.F. Item Specifications Default T2, timeout value T2, timeout value (layer) Registers the time duration (in seconds) for which the receiving fax detects the EOL (End Of Line) signal during phase C. The fax will discon- nect the line when EOL cannot be detected within T2.

- Page 96 Table 2.2 (5/8) Service Personnel Initial Settings T.F. Item Specifications Default Modem attenuator Adjusts the attenuation (dB) for the message send signal power level. Adjusting value is 0 to 15 dB in one dB steps. Since the maximum send signal power level (dB) of the fax is at 0 dB, you can select 0 dB to -15 dB in one dB steps for the send signal power level.

- Page 97 Table 2.2 (6/8) Service Personnel Initial Settings T.F. Item Specifications Default Strobe for LED head Setting of LED print head strobe signals (00000- 11111). Selection of strobe width in LED head. "00000" is lightest and "11111" is darkest. Note 1: When the rank marking of the new replaced LED print head (new part) is same as that of the old used LED print head (old part), you do not always have...

- Page 98 T.F. Item Specifications Default • When transmitting, even if OKI NSF signal is detected from the remote machine, the fax transmits DCS signal (The fax does not trans- mit NSC signal.) • When Remote Diag. = ON, the fax transmits NSF signal.

- Page 99 Table 2.2 (8/8) Service Personnel Initial Settings T.F. Item Specifications Default CED Send Sets to send CED or not at the time of incoming call. ON : Sending CED OFF : Not sending CED Fax2Net Function Set up whether to make Fax2Net service. ON : Enable OFF : Disable...

- Page 100 50 kinds of service codes Only ISDN opt. Installed E-XXX=OEL-XXX, O-XXX=OKI-XXX, L-XXX=LANIER-XXX Note: As for the setting of the part of mesh, Default-data does’nt exist in the Default-file. This setting has the data which are characteristic of the device.

- Page 101 It doesn't have default data with each default type. Only one kind has data as a device. G3 FALLBACK CAUSE Only ISDN opt. Installed E-XXX=OEL-XXX, O-XXX=OKI-XXX, L-XXX=LANIER-XXX Note: As for the setting of the part of mesh, Default-data does’nt exist in the Default-file. This setting has the data which are characteristic of the device.

- Page 102 (1) TEL/FAX automatic switching This function is used for the purpose of TEL/FAX automatic switching as follows. 1) If the machine detects a call with a CNG signal indicating an auto send facsimile call, it starts an automatic document receiving operation. 2) If machine detects a call without a CNG signal, machine generates the buzzer sounds as a telephone call.

- Page 103 Switch Over Time (20/35 sec) LIFT HANDSET Load document NSF, CSI, DIS Press START AUTO REC. START Button OKI TOKYO RECEIVING G3/33.6K Manual Transmission CML"OFF" 1 sec 1 sec 3.2.sec To detect CNG signal *Note 1: Ring Back Tone — 1 sec. ON, 3.2 sec. OFF 2: When you want to talk by phone, pick up handset.

- Page 104 (2) TAD mode TAD: Telephone Answering Device TAD can be connected to external telephone terminal to record your messages. TAD records your speech and switches an automatic voice message response to the calling station. Note 1: A choice of TAD mode is available by Technical Function No. 07. 2: The predetermined time is selectable between 20 or 35 sec.

- Page 105 • TAD mode flow chart In case of TYPE 2: If the fax does not detect CNG signal during working of TAD, the machine will go to standby mode. In case of TYPE 3: The fax does not detect CNG signal during 15 seconds from TAD operation starting. The fax starts CNG signal detection after 15 seconds from TAD operation.

-

Page 106: The Display Shows

2.2.1.3 Technical Functions Example Note: The fonts displayed on the LCD operation panel may differ from the fonts written this manual. (1) Service Bit Setting Purpose To enable or disable the following functions: • Drum and toner counter display (clear) •... - Page 107 (2) Technical functions Operations: The display shows: 14:14 (Standby) Press SELECT FUNCTION key. FUNCTION SELECT FUNCTION (OT) MEMORY AVAIL.=100% COPY Press COPY key twice. COPY TECH. PROGRAMMING YES(←/1-5) NO(→) ← ← Press key. 1:LOCAL TEST YES(←) NO(→/1-6) → Press key. →...

- Page 108 Table 2.4 (1/6) Technial Functions T.F. Name of Function The Display Shows Service bit → 01:SERVICE BIT Setting (Toggle) [ X ] YES(←) NO(→) → ← X: OFF Line monitor control → 02:MONITOR CONT. Setting (Toggle) [ X ] YES(←) NO(→) →...

- Page 109 Table 2.4 (2/6) Technial Functions T.F. Name of Function The Display Shows High-speed modem rate → 13:H/MODEM RATE Setting [ X ] YES(←) NO(→) → → X: 4.8k 9.6k → → 14.4k 28.8k → 33.6k T1 (TX), timeout value 14:T1(TX)TIMER VALUE (XTTO value) [ X ] YES(←) NO(→) To 15: T1(RX)

-

Page 110: Off Hook Bypass

Table 2.4 (3/6) Technial Functions T.F. The Display Shows Name of Function Error criterion 18:ERR. CRITERION [ X ] YES(←) NO(→) To 19: OFF HOOK BYPASS → X: 00 - 99% 18:ERR. CRITERION [00] ENTER 00-99 2-digit timer entered. → 18:ERR. - Page 111 Table 2.4 (4/6) Technial Functions T.F. Name of Function The Display Shows Ring duration detection time 24:RING DURA. *10 MS [ X ] YES(←) NO(→) To 25: CML TIMING → X: 10 - 99 24:RING DURA. *10 MS ] ENTER 10-99 —...

- Page 112 Table 2.4 (5/6) Technial Functions T.F. Name of Function The Display Shows ID/TSI priority → 30:ID/TSI PRIORITY Setting (Toggle) [ X ] YES(←) NO(→) → ← X: ID Toner count clear → 31:TONER COUNT CLEAR Setting (Toggle) [ X ] YES(←) NO(→) →...

- Page 113 Table 2.4 (6/6) Technial Functions T.F. Name of Function The Display Shows Note 5 G3 setup BC → 42:G3 SETUP BC Setting (Toggle) [ X ] YES(←) NO(→) → ← X: OFF Note 5 G3 Fallback cause 43:G3 FALLBACK CAUSE Note 6 [ BA01] YES(←) NO(→) →...

- Page 114 Table 2.5 G3 Fallback Object Service Code List (If G4 TX is faulty) Classification Code Description Remarks Dch layer 3 BA01 Unallocated (unassigned) number BA02 No route to specified transit network BA03 No route to destination BA06 Channel unacceptable BA07 Call awarded and being delivered in an established channel BA10 Procedure sequence error, Line disconnected during in-band procedure...

- Page 115 2.2.1.4 User’s Functions This section explains the items usually set up by general users. Table 2.6 shows the initial setting items and their purposes. Each F.P.can be accessed by entering the corresponding function number on Function Program- ming. The detailed procedure of the initial setting items will be explained on the following pages. Note: S-ON: Effective if the service bit has been set on.

- Page 116 TEL No. or Web Url is deleted. 2: Maximum number of entered digits: 64 3: When E-mail is already registered for the OKIFAX 5650, even if the account No. is deleted, the registered contents are stored. (E-mail is recovered by entering the account No.

- Page 117 3: When Web Url is registered in a one- touch in a group, the one-touch is deleted from the group destination. 4: Since the OKIFAX 5650 is already registered in Web Url, the registered con- tents are stored even if the account number is deleted.

- Page 118 Table 2.6 (3/6) User's Functions Item Specifications 4) Chain dial The number of dialling digits can be expanded to longer digit numbers by chaining any number of the above 1), 2) and 3). 5) Mixed dial Type of dialling can be changed from pulse dial to tone dial halfway in dialling process.

- Page 119 Table 2.6 (4/6) User's Functions Item Specifications 4) Search processing by the SEARCH key is performed. • OT for Tel or E-mail registration is searched in the Fax2Net enabled state. (OT for Web Url registration is not a search target.) •...

- Page 120 Table 2.6 (5/6) User's Functions Item Specifications Delayed transmission from the The fax can automatically transmit documents at 20 specified memory times from the memory. Polling transmission Document(s) placed on the feeder can be collected by a (To be polled) remote station.

-

Page 121: Specifications

Table 2.6 (6/6) User's Functions Item Specifications Dual Access Combination Table PC1 ON 2'nd 1'st Standby ON HOOK During FAX Calling During RING RESPONSE Call Reception During detection of TEL/FAX During TAD detection 1st Phase B Calling ~ Transmission Feeder TX Transmission after scanning During Scanning Memory TX... - Page 122 User's Initial Settings Note: The fonts displayed on the LCD operation panel may differ from fonts written this manual. 2)-1 One Touch Key Operations Restrict Access = ON ID NG 1 4 : 1 4 F A X POWER ON E N T E R I D →...

- Page 123 OKIFAX 5750/5950: 01 to 16 OKIOFFICE84/OKIFAX 4500: 01 to 08 OKIFAX 4550/OKIFAX4550 ISDN: 01 to 08 OKIFAX 5650 01 to 16 Relay broadcast initiate transmis- This function automatically originates a message call via sion relay key station (which must be equipped with OKIFAX 2600, OF-38, OF-27, OKIFAX 5950 or equivalent) up to 120 locations for OKIFAX 2600 and 99 locations for OF-38 or OF-27.

- Page 124 Table 2.7 (2/6) User's Initial Settings (One-touch key Program) F+OT Item Specifications Report printing The report print in 6 items are as follows: 1. Activity report 2. Broadcast message confirmation report (Multi location) 3. Activity memory files report 4. Phone directory report 5.

- Page 125 Table 2.7 (3/6) User's Initial Settings (One-touch key Program) F+OT Item Specifications Location program 1) One-touch key One-touch keys allow registering: (1) Telephone number (numeral, -, P and space) in 40 digits. (2) Alternate fax telephone number in 40 digits. (additional registration) (3) ID for the telephone directory function in 15 characters (alphabetic, numeric and symbolic).

- Page 126 1) Number of forwarding for incoming call destination that can be specified. OKIFAX 5650: 1 2) Number of characters used to specify a destination. 40 characters (numeral, -, P and Space). OF5650 January 2001...

- Page 127 Table 2.7 (5/6) User's Initial Settings (One-touch key Program) F+OT Item Specifications 7) Memory password programming Registering the password required (4-digit numerals) for outputting the data received by Memory Only Reception mode or change from Memory Only Reception mode. When the four-digit numeric password is registered.

- Page 128 Table 2.7 (6/6) User's Initial Settings (One-touch key Program) F+OT Item Specifications #. ISDN programming Sets to Country code, ISDN No. (subscriber number), ISDN ID (subscriber code) and ISDN sub address. 1) Setting values This setting consists of the following: •...

- Page 129 2)-2 Function Program Table 2.8 (1/5) User's Initial Settings (Function Program) P.F. Item Specifications Default Message confirmation report Enables or disables the automatic message (Single location) confirmation report printing after a single loca- tion call. ON : Printing the MCF report. OFF : Disables this function.

- Page 130 Table 2.8 (2/5) User's Initial Settings (Function Program) P.F. Item Specifications Default Closed network The fax compares lower four digits of TSI/CSI received from remote station with fax numbers registered locally for one-touch dial and two-digits autodial. If unmatched, the communication will be auto- matically disconnected.

- Page 131 Table 2.8 (3/5) User's Initial Settings (Function Program) P.F. Item Specifications Default User language A choice of 2 languages for LCD and print mes- sage are available. GER, FRE etc. are displayed insted of OTHER. ENGLI/OTHER selectable. Incoming ring Instead of ringer circuit, software can control built- in speaker to ring sound.

- Page 132 Table 2.8 (4/5) User's Initial Settings (Function Program) P.F. Item Specifications Default PC/FAX switch To enable or disable PC interface function. When PC reception is not available, for example, application is not activated on the PC or cable is missing between PC and fax etc., this setting allows to switch from PC to fax reception auto- matically.

- Page 133 Table 2.8 (5/5) User's Initial Settings (Function Program) P.F. Item Specifications Default Width Reduction This function can print characters written at the edges of a document. Switches the reduction of the horizontal scanning direction. ON : Reduction printing (216 mm to 203 mm) Reduction rate is shown as below.

- Page 134 User Setting Items Setting Selection Note E-INT E-GER E-FRE 0-AUS 0-NZL 0-SIN 0-HNG L-AG MCF (single-loc.) ON/OFF MCF (multi-loc.) ON/OFF ERR.REPORT (MCF.) ON/OFF IMAGE IN MCF. ON/OFF SENDER ID ON/OFF MONITOR VOLUME OFF/LOW/HIGH BUZZER VOLUME LOW/MID/HIGH CLOSED NETWORK OFF/ T/R / RX TX MODE DEFAULT STD/FINE/EX-FINE/PHOTO NORMAL/DARK/LIGHT...

- Page 135 (21) User Setting Items Setting Selection Note Factory MCF (single-loc.) ON/OFF MCF (multi-loc.) ON/OFF ERR.REPORT (MCF.) ON/OFF IMAGE IN MCF. ON/OFF SENDER ID ON/OFF HIGH HIGH HIGH MONITOR VOLUME OFF/LOW/HIGH HIGH HIGH HIGH BUZZER VOLUME LOW/MID/HIGH CLOSED NETWORK OFF/ T/R / RX TX MODE DEFAULT STD/FINE/EX-FINE/PHOTO NORMAL/DARK/LIGHT...

-

Page 136: The Display Shows

2.2.1.5 User's Functions Example Note : The fonts displayed on the LCD operation panel may differ from fonts written this manual. Function Program Operations: The display shows: To bring the LCD up to the desired message, 1:FUNC. PROGRAMMING press SELECT FUNCTION key once and ←... - Page 137 Table 2.10 (1/3) User's Functions Tap No. Name of Function The Display Shows → Message 01:MCF(SINGLE-LOC.) Setting (Toggle) confirmation report → ← X: OFF ← → ] YES( ) NO( (Single location) → Message 02:MCF (MULTI-LOC.) Setting (Toggle) confirmation report →...

- Page 138 Table 2.10 (2/3) User's Functions Tap No. Name of Function The Display Shows → User language 14:USER LANGUAGE Setting → ← X: ENG. (Other) ← → ] YES( ) NO( → Incoming ring 15:INCOMING RING Setting (Toggle) ← → ] YES( ) NO( X: OFF Remote receive...

- Page 139 Table 2.10 (3/3) User's Functions Tap No. Name of Function The Display Shows → Width reduction 27:WIDTH REDUCTION Setting (Toggle) ← → ] YES( ) NO( → ← X: OFF → Toner save 28:TONER SAVE Setting (Toggle) ← → ] YES( ) NO( →...

- Page 140 Note 1: RESOLUTION & ORIGINAL of Tx mode defult setting can be selected by using Æ key. STD / NORMAL STD / DARK STD / LIGHT FINE / NORMAL EX. FINE / NORMAL FINE / LIGHT FINE / DARK EX. FINE / DARK EX.FINE / LIGHT PHOTO / NORMAL PHOTO / DARK...

-

Page 141: Ring Response

Ring response time Before specifying the ring response time, set the service bit on following the operations shown in 2.2.1.3. (Service Bit Setting). Operations: The display shows: To bring the LCD up to the desired SELECT FUNCTION (OT) message, press SELECT FUNCTION MEMORY AVAIL.=100% key once and one-touch key No. - Page 142 Dial parameters (In case the service bit is "OFF".) To get the "DIAL PARAMETER" message on the display, perform the same operetion as Table 2.11. (Dial parammeters settings). 2:DIAL PARAMETER ← → YES( /1-9*#) ← REDIAL TRIES Available for USA, INT’L, NOR, SWE, FIN. GER, HUN, ←...

- Page 143 The following table can be set depending on the National codes even if the service bit is "off". Table 2.11 Dial parameters setting if the service bit "OFF" NATIONAL CODE USA INT’L GBR IRL NOR SWE FIN DEN GER HUN TCH POL Redial tries Redial interval Dial tone detect...

-

Page 144: Clock Adjustment

2.2.1.6 Clock Adjustment Operations: The display shows: To bring the LCD up to the desired message, SELECT FUNCTION (OT) press SELECT FUNCTION key once and MEMORY AVAIL.=100% one-touch key No. 9 in the standby mode. (In case of no message in memory) Press OT9 Enter 3 using the ten-key pad. - Page 145 2.2.1.7 Dual Access Operation OKI TOKYO OKI TOKYO OKI TOKYO SENDING /144 RECEIVING/144 MEMORY-RX/144 Set documents during memory TX Set documents Set documents or set documents during feeder TX after the end of the pre-scanning RELOAD DOCUMENT Pre-feed error SELECT LOCATION...

- Page 146 2.2.1.8 System Data Programming • TSI/CSI (Defalut: Blank) • Registration of sender ID (Defalut: Blank) • Registration of telephone number for the call-back message (Defalut: Blank) Operations: The display shows: To bring the LCD up to the desired SELECT FUNCTION (OT) message, press SELECT FUNCTION MEMORY AVAIL.=100% key once and one-touch key No.

- Page 147 Operations: The display shows: Continued from the previous page. NO=03 3404 7123 ID=OKI (Example) START Press key. START NO=<CALL BACK NO.> 3 SEC LATER NO=_ 03..5 NO=03 3404 7765_ (Example) Press START key. START OF5650 January 2001...

- Page 148 2.2.1.9 Dial Parameters Settings (1) Procedure The following shows the case in which the service bit is on. Operations: The display shows: To bring the LCD up to the desired message, SELECT FUNCTION (OT) press SELECT FUNCTION key once and MEMORY AVAIL.=100% one-touch key No.

- Page 149 The display shows: Continued from the previous page. 2:DIAL PARAMETER ← → YES( /1-9*#) ← (1) Redial time REDIAL TRIES "0 TRY" to "10 TRY", ← → [2 TRY] YES( ) NO( "1 TRY" to "5 TRY" (country code=FRE) ← →...

- Page 150 C O U N T R Y C O D E User Setting Items Setting Selection INT'L REDIAL TRIES 0 - 10 TRIES REDIAL INTERVAL 1 - 6 min DIAL TONE DETECT ON / OFF BUSY TONE DETECT ON / OFF MF (TONE)/DP (PULSE) DP / MF 10 PPS / 16 PPS /...

- Page 151 Table 2.13 Dial Parameters Settings Item Specifications Dial parameters Redial tries Switches on the re-dial times to meet the regulations of the installed country. 0 to 10 tries (in one-try steps) 1 to 5 tries for FRE. Redial interval Switches on the re-dial intervals to meet the regulations of installed country.

-

Page 152: Self-Diagnosis

2.2.1.10 Off-line Tests (1) Purpose Activate self-diagnosis which includes: • Print test • CPU-ROM version printing • CPU-RAM check • PROG version printing • LANGUAGE version printing • DEFAULT version printing • RAM check • RAM check (memory board: optional) (2) Procedure Operations: The display shows:... - Page 153 LANGUAGE VERSION aaaa HASH hhhh DEFAULT VERSION aaaa HASH hhhh RAM1 RAM2 DEFAULT TYPE 03/03/2000 12:00 DEVICE ID MFG:OKI DATA CORP; MDL:FX-046FAX; DES:OKI FX-046FAX; OPT-RAM ISDN BOARD CPU-ROM VERSION aaaa HASH hhhh CPU-RAM PROGRAM VERSION aaaa HASH hhhh DPRAM Figure 2.7 Printed Data of Self-diagnosis Print Test (Example)

- Page 154 2.2.1.11 On-line Tests Transmission (1) Load documents (2) Make sure that • The loaded documents are fed in automatically. • The STD and NORMAL lamps light. • The display shows SELECT LOCATION. (3) Dial the telephone number of the remote machine by the ten-key pad. (4) Make sure that the telephone number of the remote machine is shown on the display.

- Page 155 X X : X X X X X (STANDBY CONDITION) (• LOAD DOCUMENT(S), SELECT RESOLUTION MODE) AUTO DIALING? Manual TX WHICH MODE? ONE-TOUCH TWO-DIGIT AUTO DIAL CODE • ONE-TOUCH KEY • PRESS "AUTO DIAL" KEY (e.g. No. 1) • SET THE CODE (e.g. 01) O K I T A K A S A K I 0 2 7 3 5 6 7 8 9 0 O K I T A K A S A K I...

- Page 156 X X : X X X X X (← STANDBY CONDITION) MANUAL RECEIVE MODE OFF-HOOK AND CONVERSATION PRESS "START" KEY AUTO RECEIVE MODE? ( RINGING DETECTED) A U T O R E C . S T A R T M A N U A L R X S T A R T TSI &...

-

Page 157: Installation Of Optional Units

Installation of Optional Units Items • Memory board • PC interface board • Telephone handset • Second paper cassette unit Procedure • Turn the facsimile power switch OFF and remove the AC power cord. Note: Unplug the AC power cord from the wall outlet first and then from the facsimile. •... - Page 158 Instllation of the memory board • In OKIFAX 5650, MEM, 2 or 4MB memory board can be mounted on to the connector CN13 of M60 board. Remove Rear Cover. Remove the rear cover by remov- ing the two screws S1 and S2 .

- Page 159 Installation of CTT (PC interface) board Remove Rear Cover. Remove the rear cover by removing the two screws S1 and S2 . Rear Cover Figure 2.14 Install CTT board. First, install CTT board on to the connector CN12 of M60 board, and then tighten the two screws to the separation plate.

- Page 160 Figure 2.16 Insert the tip of a cutter or Nipper between the mold of Rear Cover and cut out it. Note: Be careful not to rotate the cutter or Nipper, since this can cause scratching on the Rear Cover. Grasp the mold of Rear Cover, and rotate it up and down until you can able to easily remove it.

- Page 161 Installation of an optional telephone set (1) Dial Mode Setting (For TEL-UK) Set the DIAL MODE slide switch on the rear side of the telephone set according to the dial mode of the connecting line. (Set to MF for UK, Norway, Denmark, Belgium and Italy) (2) Ringer Volume Setting (For TEL-UK and TEL-S)

- Page 162 (4) After installing the connection cable to the telephone set, extend the connection cable like Figure 2.19. Figure 2.19 (5) After installing the cradle assembly to the telephone set, fix the screw like Figure 2.20. (6) Install the telephone assembly on the facsimile transceiver unit.

- Page 163 (7) Connect the terminal on the other side of the connection cable formed on the rear side of the equipment (TEL1), like Figure 2.22, to the telephone set. Figure 2.22 OF5650 January 2001...

- Page 164 Second Paper Cassette Unit This item explains how to install the Second Paper Cassette Unit option. Second Paper Cassette Unit installation (1) Turn the facsimile power switch off and remove the ACpower cord. Note: Unplug the AC power cord from the wall outlet first and then from the facsimile. AC Inlet AC power cord Figure 2.23...

- Page 165 (3) Gently lower the facsimile on the Second Paper Cassette Unit. Note: Make sure that the positioning boss of the Second Paper Cassette Unit fits into the 2 holes at the bottom of the facsimile transceiver main unit. Hole Positioning boss Hole Second paper cassetle unit Figure 2.24...

- Page 166 (5) Install the Second Paper Cassette. Approximately 500 sheets of recording paper (20-Ib bond) can be loaded. Paper can be loaded up to this line. Second Paper Cassette Figure 2.26 (6) Reconnect the power cord to the wall and the facsimile, and Turn the facsimile power on.

-

Page 167: Brief Thchnical Description

Paper eject roller Paper eject Image data (Face down) board LED head Charger Exposure Toner Doctor board cartridge blade board Charging Paper path Cleaning Developing Toner selector Cleaning Developing roller roller supply roller Inlet sensor Fusing Outlet sensor Paper Paper Paper Transfer registration... -

Page 168: Fundamentals Of The Electro-Photographic Process

Fundamentals of the Electro-Photographic Process The electro-photographic process involves six sub-processes: (1) Charging (2) Exposure (3) Development (4) Transfer (5) Fusing (6) Cleaning Outline of each process is explained below. Process Illustration Description The surface of the electro-photo- graphic Image drum is uniformly charged with negative charges by applying a negative voltage to the Charge roller... - Page 169 Process Illustration Description the Image drum is attracted to the developing roller by static electricity. EP drum The recording paper is placed over the Image drum surface and a positive charge, opposite in polarity to the toner, is applied to the reverse side of the paper from the transfer roller.

-

Page 170: Actual Electro-Photographic Process

Actual Electro-photographic Process The electro-photographic process consists of six essential processes. The following Figure 3.2 provides a general description. 2 LED head Electro-photographic drum 1 Charge roller Toner 6 Cleaning roller 5 Heater roller 3 Developing roller Recording paper Back-up roller 4 Transfer roller * Process: 1 : Charging... -

Page 171: Boards And Units

Boards and Units 3.3.1 Boards and Units The following three boards, Memory board (option), Telephone interface board (option), PC interface board (option) and three units constitute facsimile transceiver machine. • Main control board MCNT: (M60_) • Network control unit board NCU: (EN9, INU)* •... - Page 172 AC Line PC Interface MEM (Option) (2MB/4MB) Battery OPE Unit CTT (Option) CN12 CN13 AC INLET Scanner Unit CN10 Battery S MOTOR Low Power Unit MPW1581 (120V) MPW1461 (230V) PSDN Line Speaker CN2 CN1 INU/EN9 CN16 ISDN Line High Power Unit ISDN (Option) R MOTOR D MOTOR...

-

Page 173: Overall Dimension And Mechanical Structure

Overall Dimension and Mechanical Structure POW board (H08) (MPW) PC-IF board (Option) HV board (M60-) MCNT board Memory board (Option) NCU board Separation rubber Pinch roller ADF roller Scan roller Sub roller Heater roller Feed roller EP drum NCU board Hopping roller Back-up roller Image sensor... -

Page 174: Mechanical Disassembly And Reassembly

MECHANICAL DISASSEMBLY AND REASSEMBLY This chapter explains the procedures for replacement of assemblies and units in the field. The section explains the procedures for replacement of parts, assemblies, and units in the field. Only the disassembly procedures are explained here. For reassembly, reverse the disassembly procedure. - Page 175 (2) Do not try to disassemble as long as the facsimile is operating normally. (3) Do not remove unnecessary parts: Try to keep disassembly to a minimum. (4) When disassembling, follow the prescribed sequence. Otherwise, parts may be damaged. (5) Since screws and small parts are likely to be lost, they should temporarily be attached to their original positions.

-

Page 176: Tools

Tools Table 4.1 shows the tools required for the replacement of parts such as circuit boards and mechanical units. Table 4.1 Tools Q’ty Remarks Service tools Philips screw driver (L) Philips screw driver (M) Philips screw driver (S) Flat screw drivers (S) Philips screw driver (S) Radio pliers Nippers... - Page 177 Start Item number for detailed description (4.3.1) (4.3.1) Open the Doc. LED Print Head Table, Stacker Cover (4.3.2) (4.3.2) (4.3.2) (4.3.2) Open the Doc. Separation Plate Font Cover, NCU Table Cover, Main Cover (4.3.2) NCU Board (4.3.2) Open the Copy Stacker (4.3.2) (4.3.2) Font Cover, NCU...

- Page 178 (4.3.4) Scan Motor (4.3.4) (4.3.5) Scan Frame Release Guide Assembly Assembly (4.3.4) Eject Roller Assembly (4.3.5) Manual Feed Assembly (4.3.5) Copy Stacker, Fusing Unit (4.3.7) Resist Motor, Drum Motor (4.3.6) (4.3.6) (4.3.6) Lower Base Motor Ass’y Back-up Roller (Resist & Drum Transfer Roller Motors) (4.3.8)

-

Page 179: 4.3.1 Led Print Head

• The detailed disassembly procedure is explained from sub-section 4.3.1 to 4.3.8. 4.3.1 LED Print Head It is used two kind of head as the LED print head. (208 mm width or 216 mm width) (1) Disassembly procedure Document Table a) Open the Document Table assembly. -

Page 180: Id Unit, Rear Cover, Ncu Cover, Main Cover, Separation Plate, Ncu Board, Modem Board

4.3.2 ID Unit, Rear Cover, NCU Cover, Main Cover, Separation Plate, NCU Board, Document Table Modem Board (1) Disassembly procedure 1) ID Unit, Rear Cover, NCU Cover, Main Cover a) Open the Document Table assembly. Stacker Cover b) Open the stack cover by removing the buttons. - Page 181 g) First, open the Main Cover from the front side, and then, remove the Main Cover by removing the Main Cover nails at both sides on the rear side. Nail (at both sides) 2) Separation Plate a) Remove the Separation Plate by removing the two screws 4.

-

Page 182: 4.3.3 Control Panel Assembly, Paper Guide (U) Assembly

4.3.3 Control Panel Assembly, Paper Guide (U) Assembly (1) Disassembly procedure 1) Control Panel Assembly and Paper Guide (U) Assembly Screw 2 Screw 2 a) First, carry out the disassembly Paper Guide U procedure up to the point of the Assembly Control Panel 4.3.2 (Main Cover, NCU Cover... - Page 183 Separation Rubber 3) Paper guide (U) Assembly a) Separation Rubber a. The Separation Rubber can be removed from the Paper Guide (U) Assembly. b) Feed Roller Feed Roller a. Remove the ground cable by removing the two screws 5. Screw 5 b.

-

Page 184: Sub-Roller, Adf Roller Assembly, Pinch Roller, Contact Image Sensor, Document Detectors (Pc1 And Pc2)

4.3.4 Sub-roller, ADF Roller Assembly, Pinch Roller, Contact Image Sensor, Docu- ment Detectors (PC1 and PC2). (1) Disassembly procedure Screw 1 1) Scanner Unit a) First, carry out the disassembly procedure up to the point of the 4.3.2 (Rear Cover and Main Cover) and 4.3.3 (Control Panel Assembly and Paper Guide (U) Assembly). - Page 185 • Turn the Scanner Frame Assembly inside out and perform the disas- sembly procedure. Sub-roller a) Remove the Bottom Plate by removing the three screws 4. ADF Roller Earth Plate 1 Assembly b) Remove the Sub-roller from the Scanner Frame. c) Remove the Earth Plate 1 from the Scanner Frame.

-

Page 186: Resist Motor, Drum Motor, Release Guide Assembly, Manual Guide Assembly, Stacker Cover, Fusing Unit

4.3.5 Resist Motor, Drum Motor, Release Guide Assembly, Manual Guide Assembly, Stacker Cover, Fusing Unit (1) Disassembly procedure • First, carry out the disassembly procedure up to the point of the Scanner Unit Assembly removal (Refer to Sub-section 4.3.4.) 1) Resist Motor and Drum Motor a) Remove the Resist Motor by removing the two screws 1. - Page 187 3) Stacker Cover a) Disconnect the flat cable. Stacker Cover b) Remove the Stacker Cover by Flat cable pressing inward the two latches on it from the two reset levers. c) Remove the Stacker Cover by spreading it from the lower base. Reset lever Reset lever 4) Fusing Unit...

-

Page 188: 4.3.6 Lower Base, Motor Assembly, Back-Up Roller, Transfer Roller

4.3.6 Lower Base, Motor Assembly, Back-up Roller, Transfer Roller (1) Disassembly procedure Screw 1 1) Lower Base, Motor Assembly Screw 3 a) First, carry out the disassembly Lower Base procedure up to the point of the Screw 2 Fusing Unit removal. (Refer to sub-item 4.3.5.) b) Disconnect the two connectors (CN3 and CN4 on the MCNT... - Page 189 c) Release the gear by unlocking Lower Base Latch the latch on the Lower Base. d) Lift the right side of the Transfer Roller and shift rightwards, then Gear pull it out from the Lower Base. Transfer Roller (2) Reassembly procedure Reverse the disassembly procedures.

-

Page 190: 4.3.7 Resist Roller, Hopping Roller, Sensor Plates

4.3.7 Resist Roller, Hopping Roller, Sensor Plates (1) Disassembly procedure 1) Resist Roller, Hopping Roller Resist Roller One-way Clutch Gear a) First, carry out the disassembly procedure up to the point of the Lower Base removal. (Refer to sub-item 4.3.6.) b) Remove the One-way Clutch Gear. - Page 191 b) Press and hold the Clutch while pushing the Toner Sensor up and out. Toner Sensor (2) Reassembly procedure Reverse the disassembly procedures. OF5650 January 2001...

-

Page 192: 4.3.8 Mcnt Board, Power Supply Unit, Contact Assembly

4.3.8 MCNT Board, Power Supply Unit, Contact Assembly (1) Disassembly procedure Screw 2 • First, carry out the disassembly procedure up to the point of the Printer Unit removal. (Refer to sub- section 4.3.6.) Note: MCNT board is shown below. MCNT Board Screw 2 1) MCNT Board... -

Page 193: Adjustments

ADJUSTMENTS Setting of LED Print Head Drive Time • Adjustment point: Technical Function No. 26. * To bring the LCD up to Technical Function, press SELECT FUNCTION key once, COPY key twice and "2" key (In case of no message in memory). Note: When the rank marking of the replaced LED print head (new part) is the same as that of the used LED print head (old part), you do not always have to set the LED print head drive time. -

Page 194: 5.2.1 Confirmation Items

5.2.1 Confirmation Items The clock frequency and power voltage of the machine are not possible to adjust in the field. However, their measurement procedures are described here for confirmation of clock frequency and each voltage. Clock Frequency • Measurement point: M60 board;... -

Page 195: 5.2.2 Measurement

5.2.2 Measurement Turn AC power OFF. Carry out the disassembly procedure up to Main Cover and Scanner Unit removal. (Refer to the Mechanical Disassembly and Reassembly in Chapter 4.2.) Connect extension cables to the M60 board. Connect the frequency counter (for clock frequency), digital voltmeter (for power voltage) and Oscilloscope (for SIG signal). - Page 196 Connector CN1—12pin (+5VSUB) CN1—7/8pin (+5VDC) CN1—10pin (+8VDC) Crystal Oscilator CN1—11pin (-8VDC) Ground Terminal CN1—15pin (+24VDC) LC1—3pin (Clock) CN1—1/2pin (+30VDC) CN18 CN11 IC20 TR17 IC16 CN16 CN15 TR12 TR19 RAM2 RAM3 BAT1 TR14 RAM1 RM11 IC14 IC19 RM10 IC18 D13 D15 TR23 CN14 TR22...

-

Page 197: Cleaning And Maintenance

CLEANING AND MAINTENANCE Replacement of Consumable Parts The user (or service personnel) is required to replace the following items as consumable parts. (1) User side Expected Use Before Reference Item No. Part name Replacement in Figure 6.1 Toner Cartrige 2500 sheets/cartrige (at 4% duty) (ITU-T document sample No.1) (For the second or later cartridge to a new I/D Unit) - Page 198 (3) Others Table 6.1 Reliability Item Specifications Document feeder Jam occurrence and misfeeds in the automatic document feeder will be less than one in 500 operations for all specified documents. Recording paper Jam occurrence in the automatic paper feeder will be less than feeder one in 1,500 operations and misfeeds will be less than one in 500 operations for all specified recording paper.

-

Page 199: Routine Inspection

Routine Inspection Basically, the routine inspection of following items is performed about half-yearly (or every one year) after the machine is installed. The description of routine inspection is shown in Table 6.2. Table 6.2 Routine Inspection Expected Use Before Reference Item Part name Replacement No. - Page 200 (7) Separation rubber (4) Pinch roller (3) Sub roller (1) Scan roller (8) LED print head (2) Feed roller (5) ADF roller (6) Image sensor Figure 6.2 Parts of Routine Inspection OF5650 January 2001...

-

Page 201: Printer Counter Display/Clear

Printer Counter Display/Clear Note: The fonts displayed on the LCD operation panel may differ from the fonts written this manual. Purpose A user can clear the image drum unit and check some of the counters (such as the print counter, scan counter) by using the ¨ key or Æ key. 2-1. -

Page 202: The Display Shows

2-2. Procedure The following shows the case when the service bit has been set OFF & TONER COUNT CLEAR = ON. Operations: The display shows: 1 4 : 1 4 F A X To bring the LCD up to the desired message, press SELECT FUNCTION key once and Press FUNCTION key. -

Page 203: Printer Counter Display/Clear

Printer Counter Display/Clear Purpose The service personnel can clear and check the following data: • Image Drum • Toner • Image Drum (Total) • Print • Scan Procedure The following shows the case when the service bit has been set ON. Operations: The display shows: To bring the LCD up to the desired message,... -

Page 204: Local Test

Local Test 6.5.1 When G4 option board is not installed 1 : L O C A L T E S T Y E S ( ← ) N O ( → / 1 - 5 ) → key or 1-5 ←... - Page 205 6.5.2 When G4 option baord is installed 1 : L O C A L T E S T Y E S ( ← ) N O ( → / 1 - 6 ) → key or 1-6 ← key Technical Programming LT-1 ←...

-

Page 206: Self-Diagnosis Test

Self-diagnosis Test Purpose To check ROMs, RAMs and printing function. Procedure (in Case of not G4 Boad) Operations: The display shows: To bring the LCD up to the desired message, TECH. PROGRAMMING press SELECT FUNCTION key once and COPY YES(←/1-5) NO(→) key twice in the standby mode. - Page 207 • Image processor LSI RAM check • Setting DEFAULT TYPE and reading clock at self diagnosis execution. The following printing differs depending on the machine type of OKIFAX 5650 and on the condition of option provided or not. “4M” is printed for OKIFAX 5650.

- Page 208 LANGUAGE VERSION aaaa HASH hhhh DEFAULT VERSION aaaa HASH hhhh RAM1 RAM2 DEFAULT TYPE 03/03/2000 12:00 DEVICE ID MFG:OKI DATA CORP; MDL:FX-046FAX; DES:OKI FX-046FAX; OPT-RAM ISDN BOARD CPU-ROM VERSION aaaa HASH hhhh CPU-RAM PROGRAM VERSION aaaa HASH hhhh DPRAM Figure 6.3 Self-diagnosis Data...

-

Page 209: Sensor Calibration Test

Sensor Calibration Test Purpose To adjust the linearity of output levels of contact image sensor. Operations: The display shows: To bring the LCD up to the desired message, TECH. PROGRAMMING press SELECT FUNCTION key once and COPY ← → YES( /1-5) key twice in the standby mode. -

Page 210: Sensor Calibration

Operations: The display shows: Continued from the previous page Enter "2". 2:SENSOR CALIBRATION ← → YES( /1-8) ← ← Press key. 2:SENSOR CALIBRATION End of prefeed PLEASE SET DOCUMENT Set white document. Load document(s). For adjustment of levels, use white plain bond paper(s) of NA Letter or A4 2:SENSOR CALIBRAION size. -

Page 211: Led Test

LEDs Test Purpose To check all LEDs on operation panel by lighting. Procedure Operations: The display shows: To bring the LCD up to the desired message, TECH. PROGRAMMING ? press SELECT FUNCTION key once and COPY ← → YES( /1-5) key twice in the standby mode. -

Page 212: Tone Send Test

Tone Send Test Purpose To send the G3 tonal frequencies to the line. Procedure Operations: The display shows: To bring the LCD up to the desired message, 1:SELF DIAGNOSIS press SELECT FUNCTION key once, COPY ← → YES( /1-8) ← key twice and key twice. -

Page 213: Mf Send Test

6.10 High-speed Modem Send Test Purpose To check the telephone line quality in combination with a remote station programmed to the high-speed modem receive test mode. Procedure Operations: The display shows: To bring the LCD up to the desired message, 1:SELF DIAGNOSIS press SELECT FUNCTION key once, COPY ←... - Page 214 TX Side RX Side 5:MODEM SEND TEST 6:MODEM REC TEST ← → YES( /1-8) ← → YES( /1-8) ← ← Press key. Press key. CML relay operates. CML relay operates. The display shows: 5:MODEM SEND TEST " Training MODEM rate The display shows: (e.g.

-

Page 215: 6.11 High-Speed Modem Receive Test

6.11 High-speed Modem Receive Test Purpose To check the telephone line quality in combination with a remote station programmed to the high-speed modem send test mode. Procedure Operations: The display shows: To bring the LCD up to the desired message, 1:SELF DIAGNOSIS press SELECT FUNCTION key once, COPY ←... -

Page 216: Mf(Tone) Send Test

6.12 MF Send Test Purpose To send the multi-frequencies of tone dialling to the line. Procedure Operations: The display shows: To bring the LCD up to the desired message, 1:SELF DIAGNOSIS press SELECT FUNCTION key once, COPY ← → YES( /1-8) ←... -

Page 217: Tone (Tel/Fax)

6.13 Tone (TEL/FAX) Purpose To check the pseudo-ring back tone of TEL/FAX automatic switching. Procedure Operations: The display shows: To bring the LCD up to the desired message, 1:SELF DIAGNOSIS press SELECT FUNCTION key once, COPY ← → YES( /1-8) ←... -

Page 218: Protocol Dump Data Printing

6.14 Protocol Dump Data Printing Purpose To analyze the transmitted/received G3 protocol signals. Procedure • Manual print-out of the last communication. (a) Manual print-out Operations: The display shows: 14:14 FAX Press SELECT FUNCTION key, provided FUNCTION (Standby) that the service bit is ON. SELECT FUNCTION (OT) MEMORY AVAIL.=100% Press one-touch key No.6... -

Page 219: System Reset

6.14.1 G3 Protocol Dump Purpose: To allow the serviceman to obtain a list of protocol signals transferred between the transmitter and receiver. Print conditions: • Modem trace information for each TX/RX is printed. (Informeation for RX is added on 2nd page.) •... - Page 220 G3 Protocol Dump Image PROTOCOL DUMP P1 12/24/1998 19:00 ID=OKI TAKASAKI DATE TIME S,R-TIME DISTANT STATION ID MODE PAGES RESULT 12/24 18:56 00'33" 123456789012345678901234 0000 PPS_MPS PPS_EOP TRANSMITTED FRAME 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00...

- Page 221 PROTOCOL DUMP P2 12/24/1998 19:00 ID=OKI TAKASAKI RECEIVED FRAME FF C8 01 00 73 17 22 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00...

- Page 222 6.14.2 Analysis from the data The printed out data permits to analyze G3 facsimile communication protocol signals between two facsimile machines. Figure 6.5 (2/2) shows the result of an analysis on the printed data referring to Figure 6.5 (1/2) (Protocol dump data). (Transmitter) (Receiver) Dialling...

- Page 223 6.14.3 FCF (Facsimile Control Field) conversion table Table 6.2 shows all FCF signals which are needed to analyze the printed out protocol dump data. Some signals have two different hexadecimal codes in accordance with the calling party or called party. Table 6.2 FCF Signals Conversion Table Abbreviation Hex.

- Page 224 6.14.4 G4 Protocol Dump Purpose: To allow the serviceman to obtain a list of protocol signals transmitter and receiver. Method: The report will be manually printed out for maintenance purpose. If it is G4, the G4 communication protocol dump is printed out. 1.

- Page 225 Protocol Dump The printing image is as follows: PROTOCOL DUMP P1 08/25/2000 19:00 ID=OKI TAKASAKI DATA TIME S,R-TIME DISTANT STATION ID MODE PAGES RESULT 04/19 14:49 00’07" OKI SHIBAURA(6412) TX-G4 0000 Dch. SETUP CONN-ACK +Bch+ DISC REL-C STATUS SETUP-ACK CONN +Bch+ Bch.

- Page 226 PROTOCOL DUMP P2 CR/CN 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 CA/CC 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00...

- Page 227 6.15 System Reset Purpose To clear or initialize the following data: (a) Location data (b) Configuration data (default) Procedure Operations: The display shows: Press SELECT FUNCTION key, COPY key twice. TECH. PROGRAMMING (In case of no message in the memory) ←...

-

Page 228: Service Code

6.16 Service Codes The service code can be printed on Activity Report to recognize the result of each communication. The activity report indicates the code ”0000", should a communication terminates on normal status as a service code. The activity report indicates one of the codes of “90XX”, should a communication terminates on abnormal status, as an error code. - Page 229 6.16.1 G3 Service Code List Table 6.3 (1/3) Service Codes List Code Description 0000 Successful end of communication. 1080 STOP key has been pressed while calling a remote fax. 10A2 Busy tone detected. 14C0 Dial tone not detected. 14C1 Line current not detected. 14C2 Calling-and-waiting for line connection time out.

- Page 230 Table 6.3 (2/3) Service Codes List Code Description 29C1 In closed Network setting, TSI/CSI is either not received or, if received, it is not autho- rized one. 29E0 Contents of CM/JM are faulty at receive side. 29E1 Phase 2 time out at receive side. 29E2 Phase 3 time out at receive side.

- Page 231 Table 6.3 (3/3) Service Codes List Code Description 9083 T3 time out. 9084 No recording paper. 9087 Document jam. 9088 60-minute or 70-minute time out. 9089 Document length has exceeded its maximum limit. 908E Recording paper jam. 9090 Received DCN. 909D Telephone number to be called to the Fax2Net is the wrong number.

- Page 232 6.16.2 G4 Service Code Lists Table 6.4 (1/3) G4 Service Code Lists Classification Code Description Alarm Result Remarks Dch layer 2 ISDN board error BB02 LSI NG BB05 TEI release by network BB06 TEI verification procedure failure Dch layer 3 BA01 Unallocated (unassigned) number BA02...

- Page 233 Table 6.4 (2/3) G4 Service COde Lists Classification Code Description Alarm Result Remarks N2 times time out BC02 Bch layer 2 BC03 FRMR reception FRMR transmission BC04 BC05 The other party link disconnection T3 time out BC08 BD01 SABME wait time out The other party terminal busy B201 Bch layer 3...

- Page 234 Table 6.4 (3/3) G4 Service COde Lists Classification Description Alarm Result Remarks Code B901 Command response reception error Bch layer 5 B902 Non-implicit command response received B903 Lack of essential parameter B904 Invalid parameter reception B905 Invalid parameter value reception B906 Window size over reception B907...

-

Page 235: Troubleshooting And Repair For Okifax 5650

TROUBLESHOOTING AND REPAIR FOR OKIFAX 5650 OF5650 January 2001... - Page 236 This chapter contains: (a) Troubleshooting flow charts related to general operations (b) Troubleshooting flow charts by test operations Troubleshooting flow charts placing an emphasis on mechanical portions Section Name of Flow Chart Page Overall troubleshooting flow chart No LCD operation ALARM LED on Printing test failure No local copy...

-

Page 237: Overall Troubleshooting Flow Chart

ALARM LED lights? Go to 7.3 (ALARM LED on). Key operation activates Replace MCNT and/or OPE unit. the OKIFAX 5650 (Pressing SELECT FUNCTION key causes "SELECT FUCTION (OT) MEMORY AVALI=100%" to appear on LCD? Pressing STOP key makes a key touch-tone?) Note * : OPT-RAM "OK"... -

Page 238: No Lcd Operation

No LCD Operation Start TIME on LCD? AC power switch ON? Turn ON power switch. LPSU=230V? +5V at Pin 7,8 of CN1 (MCNT)? SUB +5V at Pin 12 of CN1 (MCNT)? Check LPSU, MCNT boards and their connectors. SUB +5V at Pin 6 and 7 of CN1 (OPE)? Replace OPE Solved? -

Page 239: Alarm Led On

ALARM LED On Start Checking Points: Communication error? "COVER OPEN" on LCD? Press STOP key. "PRINTER ALARM i" alarm? ALARM LED goes off? "PAPER JAM" alarm? "NO PAPER" alarm? Go to 7.22 (Printer unit). "TONER LOW" alarm? Return to section 7.1 1. -

Page 240: Printing Test Failure

Printing Test Failure Start Perform SELF DIAGNOSIS Print test OK? Replace MCNT Board Solved? Return to section 7.1 Go to 7.22 (printer unit) OF5650 January 2001... -

Page 241: No Local Copy

No Local Copy Checking Points: Start Printing function of Go to 7.4 (Printing test failure). self-diagnosis is OK? Load a document. The document is fed by any length? 1. Check PC1. 2. Replace MCNT board. 3. Check the mechanical portion. (Scan motor, etc.) The document is fed by about 7cm and stops with... -

Page 242: Auto Dial Failure

Replace MCNT Board. code Note 1: If you do not have any other fax machine (OKIFAX 5650) for testing, follow this route. Then, if the problem is unsolved, return to the main route. Return to section 7.1 Note 2: NCU Board is shown as EN9 for UK, France... -

Page 243: Transmission Problem

Transmission Problem This section explains how to localize the cause of problems occurred after completion of connection with a remote station. Start Step 1: Set MH ONLY (Technical function No. 13) to ON. Solved? Step 2: Set HIGH-SPEED MODEM RATE (Technical function No. - Page 244 Test other fax machine under the same conditions, especially concerning Step 1-4. Do they transmit normally? Check the line and the network. The hardware of the troubled fax machine may be damaged. Go to 7.13 (High-speed Modem Test) to localize the cause. Note: Even if the high-speed modem test results in success, 300 bps signal route remains unchecked.

-

Page 245: Auto Reception Failure

Auto Reception Failure Start Manual reception OK? Your handset telephone Placed in the auto receive rings when a call arrives? mode? If not, place the 1. Check the handset fax machine in that mode of telephone set. by pressing AUTO REC key. 2. -

Page 246: Reception Problem

Reception Problem This section explains how to localize the cause of problems occurred after completion of connection with a remote station. Start Step 1: Set MH ONLY (Technical function No. 13) to ON. Solved? Step 2: Set HIGH-SPEED MODEM RATE (Technical function No. -

Page 247: Sensor Calibration Test

7.10 Sensor Calibration Test Start Perform SENSOR CALI- Checking Points: BRATION. (See Chapter 6.6) "SCANNING ERROR" appears on LCD while adjusting for level. Check that white plain bond paper of NA Letter size or A4 is loaded on the f eeder. -

Page 248: Led Test

7.11 LED Test Start Checking Points: Perform LED TEST. (See Chapter 6.7) All LEDs light? No (No LED lights) Any LED does not light? Yes (One LED or some LEDs light.) 1. Check the connection cable. 2. Check the oscillator OSC (OPE). 3. -

Page 249: Tone Send Test

7.12 Tone Send Test Start Note 1: The tonal frequency (2100 Hz) will be sequentially sent for 5 seconds on the line terminals L1 and L2. Perform TONE SEND TEST. (See Chapter 6.8.) As an example, signal route uses the EN9 (NCU) board. -

Page 250: High-Speed Modem Test

7.13 High-speed Modem Test Start Connect oscilloscope probe across the line terminals L1 and L2 Perform H-MODEM SEND TEST for the transmitter and H-MODEM REC TEST for the receiver. (See Fig. 6.9.1) Which mode, TX or RX? Modem’s signal appears across L1 and L2? TX End Modem’s signal appears... - Page 251 RX (Receiver) The error counter of LCD stops counting up? RX End Receive signal appears across L1 and L2? Check the line. Receive signal appears across CN3-48 (R) and CN3-49 (GND) of NCU board? Replace MCNT Board. Signal route: CN6-A2 (R)→IC12-1→IC10-32 →IC10-87 to 91, 93 to 95 (D0 to D7) Signal route: Replace NCU Board.

-

Page 252: Mf Send Test