Table of Contents

Advertisement

Quick Links

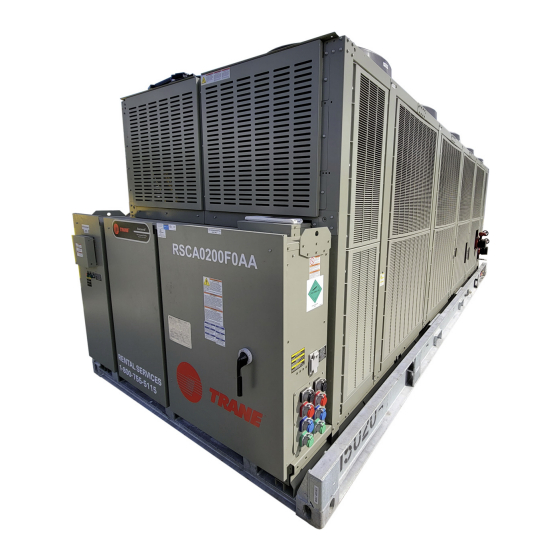

Installation, Operation, and Maintenance

Trane Rental Services

200 Tons

Models:

ACSA/ACXA

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of

heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and training.

Improperly installed, adjusted or altered equipment by an unqualified person could result in death or serious injury.

When working on the equipment, observe all precautions in the literature and on the tags, stickers, and labels that are

attached to the equipment.

August 2024

SAFETY WARNING

TEMP-SVX002A-EN

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Trane Ascend ACSA Series

- Page 1 Installation, Operation, and Maintenance Trane Rental Services 200 Tons Models: ACSA/ACXA SAFETY WARNING Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and air-conditioning equipment can be hazardous and requires specific knowledge and training.

-

Page 2: Warnings, Cautions, And Notices

When working with or around hazardous chemicals, these compounds have the same potential impact to the ALWAYS refer to the appropriate SDS and OSHA/GHS environment. Trane advocates the responsible handling of all (Global Harmonized System of Classification and refrigerants. Labeling of Chemicals) guidelines for information on... - Page 3 Copyright This document and the information in it are the property of Trane, and may not be used or reproduced in whole or in part without written permission. Trane reserves the right to revise this publication at any time, and to make changes to its content without obligation to notify any person of such revision or change.

-

Page 4: Table Of Contents

Table of Contents Model Number Description Water Shut-off Valves ....22 ....6 Pipe Unions and Connectors . - Page 5 Table of Contents Shutdown ......37 Sequence of Operation ....38 Software Operation Overview .

-

Page 6: Model Number Description

Model Number Description Digit 1, 2 — Unit Model RS = Rental Services Digit 3, 4 — Unit Type CA = Air-Cooled Chiller XA = Air-Cooled Heat Pump Digit 5, 6, 7, 8 — Unit Capacity 0200 = 200 Nominal Tons Digit 9, 10 —... -

Page 7: General Information

For flexible hose data, see Trane Rental Services Temporary Cooling - Flexible Water Hose - Installation, Operation, and Maintenance (CHS-SVX01*-EN). Electrical Cable For electrical cable data, refer to Electrical Cable in Trane Rental Services Electrical Cable - Engineering Bulletin (CHS-PRB005*-EN). Pig-Tail Connectors Each cable box has pigtails for non cam-type connections. -

Page 8: General Data

General Information General Data Table 1. General data - ACS (IP) Unit Size (tons) Refrigerant R-410A (F0); R-454B (F1) Compressor Model Quantity Tonnage/ckt 40+40+30 Evaporator Water storage - Standard Cooling 17.4 Min. flow Max. flow Water storage - Other Applications Water connection Max. - Page 9 General Information Table 2. General data - ACX (IP) Unit Size (tons) Refrigerant R-454B Compressor Model Quantity Tonnage/ckt 30+30+40 Evaporator Water storage - Standard Cooling 17.4 Water storage - Ice Making Min. flow Max. flow Water storage - Other Applications Water connection Max.

-

Page 10: Pre-Installation

Request an immediate, joint inspection of the unit installation process is provided. the damage with the carrier and the consignee. • Notify the Trane sales representative and arrange for repair. Do not repair the unit, until damage is inspected by the carrier representative. Table 3. -

Page 11: Dimensions And Weights

Dimensions and Weights Service Clearances Figure 3. Unit service clearance requirements Control Panel 85” (2160mm) See note 3 40” (1016 NO OBSTRUCTIONS ABOVE UNIT 36” (914.4mm) note 1 36” (914.4mm) TOP VIEW Notes: • A full 40 inch clearance is required in front of the control panel. -

Page 12: Unit Drawings

Dimensions and Weights Unit Drawings Figure 4. 200T ACSA (RSCA0200F0-F1) TEMP-SVX002A-EN... -

Page 13: Unit Weights

Dimensions and Weights Figure 5. 200T ACXA (RSXA0200F1) Unit Weights Table 4. Unit weights Weight (lb) Unit Shipping Operational RSCA0200F0-F1 15,020 15,520 RSXA0200F1 18,769 19,328 TEMP-SVX002A-EN... -

Page 14: A2L Work Procedures

Failure to follow instructions below could result in death or serious injury, and equipment damage. At all times, Trane’s maintenance and service guidelines shall be followed. If in doubt, contact Trane technical support for • To be repaired only by trained service personnel. -

Page 15: Leak Detection

Verify continuity of earth bonding. manually open all electronically controlled valves using • Replace electrical components with Trane replacement acceptable service procedures. parts, or those meeting the same ratings and qualified for The recovery equipment shall be in good working order with flame arrest protection, UL LZGH2 category. -

Page 16: Decommissioning

A2L Work Procedures • Ensure that the refrigerating system is earthed prior to 11. Recovered refrigerant shall not be charged into another charging the system with refrigerant. refrigerating system unless it has been cleaned and checked. When equipment has been decommissioned, •... -

Page 17: Installation

Installation Location Requirements • Install rubber vibration isolators in all water piping. • Seal all wall penetrations. Sound Considerations Note: Sound data does not include on-board pump. Consult an acoustical engineer for critical applications. • Locate the unit away from sound-sensitive areas. •... -

Page 18: Unit Location And Mounting

Once in place, the unit must be level within 1/4-inch cables (chains or slings), hooks, and shackles used to (6.4 mm) over its length and width. The Trane Company is not lift the unit must be capable of supporting the entire responsible for equipment problems resulting from an weight of the unit. - Page 19 Installation Lifting using either a single spreader bar or an H-type spreader between the base lifting holes. The following adjustments must is acceptable. Attach chains or cables to lifting beam. Lifting be made to produce a level lift: beam crossbars MUST be positioned so lifting cables do not •...

- Page 20 Installation Figure 7. 200T ACSA/ACXA rigging diagram TEMP-SVX002A-EN...

-

Page 21: Handling

Trane assumes no responsibility for equipment failures which result from untreated or • Evaporator water connections are grooved. -

Page 22: Water Shut-Off Valves

Installation Water Shut-off Valves Nominal Tons Installation, Operation, and Maintenance (AC-SVX004*-EN). Shut-off valves are provided in the supply and return pipe Balancing Valves near the chiller so the gauge(s), thermostats, sensors, strainer, etc., can be isolated during service. A balancing valve is installed in the leaving water line. It will be Pipe Unions and Connectors used to establish a balanced flow. -

Page 23: Water Piping Connections

Trane assumes no specialist to determine what water treatment, if any, is responsibility for equipment damage caused by required. Trane assumes no responsibility for flushing/cleaning solutions or water-borne debris. equipment failures which result from untreated or improperly treated water, or saline or brackish water. -

Page 24: Flexible Hose And Hard Pipe Installation

3. Place it back in the shipping box. To minimize premature or catastrophic failure of flexible hose provided as part of a Trane Rental Services rental or hard pipe, refer to CHS-SVX01*-EN for installation data. Figure 11. Water inlet/outlet connections... -

Page 25: Ambient Freeze Avoidance

For information on specific conditions, contact Trane product support. Table 10. Low evaporator refrigerant temperature cutout (LERTC) and low water temperature cutout (LWTC) — ethlyene glycol Minimum Recommended... - Page 26 Installation Table 10. Low evaporator refrigerant temperature cutout (LERTC) and low water temperature cutout (LWTC) — ethlyene glycol (continued) Minimum Recommended Minimum Recommended Minimum Chilled Water Glycol Percentage (%) Solution Freeze Point (°F) LERTC (°F) LWTC (°F) Setpoint (°F) 26.2 20.2 30.2 35.9...

- Page 27 Installation Table 10. Low evaporator refrigerant temperature cutout (LERTC) and low water temperature cutout (LWTC) — ethlyene glycol (continued) Minimum Recommended Minimum Recommended Minimum Chilled Water Glycol Percentage (%) Solution Freeze Point (°F) LERTC (°F) LWTC (°F) Setpoint (°F) -34.5 -21.0 -7.0 -37.1...

-

Page 28: Integral Pump Package

Installation Table 11. Low evaporator refrigerant temperature cutout (LERTC) and low water temperature cutout (LWTC) — propylene glycol (continued) Minimum Recommended Minimum Recommended Minimum Chilled Water Glycol Percentage (%) Solution Freeze Point (°F) LERTC (°F) LWTC (°F) Setpoint (°F) 10.8 16.5 -0.5 15.2... - Page 29 Installation Figure 13. Pump package unit schematic - RSCA0200F0-RSCA0200F1, and RSXA0200F1 TEMP-SVX002A-EN...

-

Page 30: Pump Curves

Installation Pump Curves Figure 14. 200T ACSA/ACXA single-speed pressure curve Figure 15. 200T ACSA/ACXA multi-speed pressure curve TEMP-SVX002A-EN... -

Page 31: Pump Package Requirements

Shore Power Supply (115 Vac) tasks. Each Trane Rental Services ACSA/ACXA unit comes with a Electrical power to the unit must meet stringent requirements shore power connection. The shore power connection for the unit to operate properly. Total voltage supply and supplies power to the Symbio 800 controls and interface. -

Page 32: Voltage Supply

Fully open all compressor service valves conductors. Contact Trane Rental Services for further (suction, discharge, liquid line, and oil line) prior to information. -

Page 33: Electrical Wiring

Tons Installation, Operation, and Maintenance specialist to determine what water treatment, if any, is (AC-SVX004*-EN) or refer to unit wiring schematics. required. Trane assumes no responsibility for equipment failures which result from untreated or improperly treated water, or saline or brackish water. -

Page 34: Chilled Water Pump Control

Installation Chilled Water Pump Control If evaporator water flow is lost once it had been established, the EWP relay remains energized and a nonlatching diagnostic is generated. If flow returns, the diagnostic is Water Pump Power Supply cleared and the chiller returns to normal operation. Power is provided to the pump through a separate factory- NOTICE wired VFD panel, which is integrated into the chiller unit power. -

Page 35: Emergency Stop

Installation Emergency Stop Variable Frequency Drive Operation Symbio™ 800 provides auxiliary control for a customer specified/installed latching trip out. When this customer Each unit comes with a TR200 pump VFD permanently furnished remote contact 5S1 is provided, the chiller will run installed on the unit. -

Page 36: Communications Interface Options

Installation Communications Interface Options BACnet Interface (BCI-C) The BACnet® control network for Symbio™ 800 expands communications from the unit UCM network to the Tracer Ensemble or Tracer SC+ building automation system or third party building automation system. Utilizing BACnet, the BAS allows external setpoint and configuration adjustment and monitoring of status and diagnostics. -

Page 37: Start-Up And Shutdown

Clear fans of build up prior to machine start-up. been operating properly for a minimum of 24 hours before starting. Contact Trane Rental Services for any questions. 6. With water running, adjust water flow, check pressure drop Shutdown and adjust flow switch. -

Page 38: Sequence Of Operation

Start-Up and Shutdown Sequence of Operation • The text in the circles is the internal software designations for each state. This section provides basic information on chiller operation for • The shading of each software state circle corresponds to common events. Adaptive control algorithms are used on the shading on the time lines that show the chiller’s state. -

Page 39: Power Up Diagram

'Auto', the transition from 'Stopped' to 'Starting' process takes 15 seconds for the Symbio 800 and 105 occurs, but it is not apparent to the user. Figure 18. Sequence of operation: power up diagram Second Trane Logo - Loading User Interface Template... Display Ready Black Screen Grey Screen Loading Data…. -

Page 40: Power Up To Starting

Start-Up and Shutdown Power Up to Starting • Power up Start Delay set to 0 minutes • Need to cool (differential to start) already exists The following diagram shows the timing from a power up event • Oil level is detected immediately to energizing the first compressor. -

Page 41: Normal Shutdown To Stopped

Start-Up and Shutdown Normal Shutdown to Stopped The following diagram shows the Transition from Running through a Normal (friendly) Shutdown. The dashed lines on the top attempt to show the final mode if stop is selected via various inputs. Figure 21. Sequence of operation: normal shutdown to shopped or run inhibit Local Stop Normal Shutdown Diagnostic* , Latched Normal Shutdown Diagnostic* , Non-Latched... -

Page 42: Maintenance And Diagnostics

5. Secure any loose panels. Replace any sheet metal screws or bolts to prevent panel from blowing off during transportation. 6. Return hose, fittings or cables (if furnished by Trane Rental Services) to appropriate containers for return shipment. 7. Notify Trane Rental Services if unit needs repairs or has damage. - Page 43 Notes TEMP-SVX002A-EN...

- Page 44 For more information, please visit trane.com or tranetechnologies.com. Trane has a policy of continuous product and product data improvement and reserves the right to change design and specifications without notice. We are committed to using environmentally conscious print practices.

Need help?

Do you have a question about the Ascend ACSA Series and is the answer not in the manual?

Questions and answers