Subscribe to Our Youtube Channel

Summary of Contents for Endress+Hauser Proline Promass I 500 PROFINET

- Page 1 Products Solutions Services BA01763D/06/EN/02.19 71443485 2019-07-01 Valid as of version 01.01.zz (Device firmware) Operating Instructions Proline Promass I 500 PROFINET Coriolis flowmeter...

- Page 2 • The manufacturer reserves the right to modify technical data without prior notice. Your Endress+Hauser Sales Center will supply you with current information and updates to these instructions. Endress+Hauser...

-

Page 3: Table Of Contents

Proline Promass I 500 PROFINET Table of contents Table of contents About this document ....6 Installation ..... . . 23 Document function . - Page 4 Table of contents Proline Promass I 500 PROFINET Structure and function of the operating 10.5.2 Setting the system units ..menu ......

- Page 5 13.2 Measuring and test equipment ... 250 13.3 Endress+Hauser services ....250 Repair ......251 14.1 General notes .

-

Page 6: About This Document

About this document Proline Promass I 500 PROFINET About this document Document function These Operating Instructions contain all the information that is required in various phases of the life cycle of the device: from product identification, incoming acceptance and storage, to mounting, connection, operation and commissioning through to troubleshooting, maintenance and disposal. -

Page 7: Tool Symbols

Proline Promass I 500 PROFINET About this document Symbol Meaning Light emitting diode is on. Light emitting diode is flashing. 1.2.4 Tool symbols Symbol Meaning Torx screwdriver Phillips head screwdriver Open-ended wrench 1.2.5 Symbols for certain types of information Symbol... -

Page 8: Documentation

• W@M Device Viewer (www.endress.com/deviceviewer): Enter the serial number from nameplate • Endress+Hauser Operations App: Enter the serial number from the nameplate or scan the 2D matrix code (QR code) on the nameplate Detailed list of the individual documents along with the documentation code →... - Page 9 Proline Promass I 500 PROFINET About this document TRI-CLAMP® Registered trademark of Ladish & Co., Inc., Kenosha, USA Endress+Hauser...

-

Page 10: Safety Instructions

Safety instructions Proline Promass I 500 PROFINET Safety instructions Requirements for the personnel The personnel for installation, commissioning, diagnostics and maintenance must fulfill the following requirements: ‣ Trained, qualified specialists must have a relevant qualification for this specific function and task. -

Page 11: Workplace Safety

Verification for borderline cases: ‣ For special fluids and fluids for cleaning, Endress+Hauser is glad to provide assistance in verifying the corrosion resistance of fluid-wetted materials, but does not accept any warranty or liability as minute changes in the temperature, concentration or level of contamination in the process can alter the corrosion resistance properties. -

Page 12: It Security

Safety instructions Proline Promass I 500 PROFINET IT security Our warranty is valid only if the device is installed and used as described in the Operating Instructions. The device is equipped with security mechanisms to protect it against any inadvertent changes to the settings. -

Page 13: Access Via Web Server

Proline Promass I 500 PROFINET Safety instructions • User-specific access code Protect write access to the device parameters via the local display, Web browser or operating tool (e.g. FieldCare, DeviceCare). Access authorization is clearly regulated through the use of a user-specific access code. -

Page 14: Access Via Service Interface (Cdi-Rj45)

Safety instructions Proline Promass I 500 PROFINET 2.7.4 Access via service interface (CDI-RJ45) The device can be connected to a network via the service interface (CDI-RJ45). Device- specific functions guarantee the secure operation of the device in a network. The use of relevant industrial standards and guidelines that have been defined by national and international safety committees, such as IEC/ISA62443 or the IEEE, is recommended. -

Page 15: Product Description

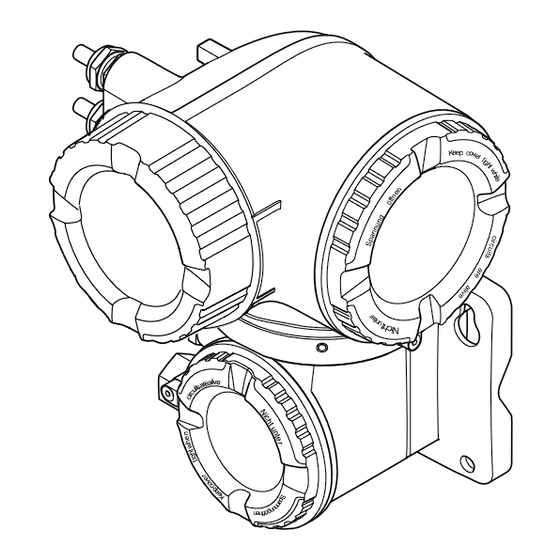

Proline Promass I 500 PROFINET Product description Product description The measuring system consists of a transmitter and a sensor. The transmitter and sensor are mounted in physically separate locations. They are interconnected by connecting cables. Product design Two versions of the transmitter are available. - Page 16 Product description Proline Promass I 500 PROFINET 3.1.2 Proline 500 Signal transmission: analog Order code for "Integrated ISEM electronics", option B "Transmitter" For use in applications required to meet special requirements due to ambient or operating conditions. As the electronics are located in the transmitter, the device is ideal in the event of: •...

-

Page 17: Incoming Acceptance And Product

Technical Documentation present? • If one of the conditions is not satisfied, contact your Endress+Hauser Sales Center. • Depending on the device version, the CD-ROM might not be part of the delivery! The Technical Documentation is available via the Internet or via the Endress+Hauser Operations App, see the "Product identification"... -

Page 18: Transmitter Nameplate

8 sections • The W@M Device Viewer: enter the serial number from the nameplate (www.endress.com/deviceviewer) • The Endress+Hauser Operations App: Enter the serial number from the nameplate or scan the 2-D matrix code (QR code) on the nameplate. 4.2.1 Transmitter nameplate Proline 500 –... - Page 19 Proline Promass I 500 PROFINET Incoming acceptance and product identification Proline 500 3 4 5 Order code: Ser. no.: Ext. ord. cd.: Date: A0029192 4 Example of a transmitter nameplate Manufacturing location Name of the transmitter Order code Serial number (ser. no.) Extended order code (ext.

-

Page 20: Sensor Nameplate

Incoming acceptance and product identification Proline Promass I 500 PROFINET 4.2.2 Sensor nameplate Order code: Ser. no.: Ext. ord. cd.: Date: A0029199 5 Example of a sensor nameplate Name of the sensor Manufacturing location Order code Serial number (ser. no.) Extended order code (Ext. -

Page 21: Symbols On Measuring Device

Proline Promass I 500 PROFINET Incoming acceptance and product identification 4.2.3 Symbols on measuring device Symbol Meaning WARNING! This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in serious or fatal injury. Reference to documentation Refers to the corresponding device documentation. -

Page 22: Storage And Transport

Storage and transport Proline Promass I 500 PROFINET Storage and transport Storage conditions Observe the following notes for storage: ‣ Store in the original packaging to ensure protection from shock. ‣ Do not remove protective covers or protective caps installed on process connections. -

Page 23: Measuring Devices With Lifting Lugs

Proline Promass I 500 PROFINET Installation 5.2.2 Measuring devices with lifting lugs CAUTION Special transportation instructions for devices with lifting lugs ‣ Only use the lifting lugs fitted on the device or flanges to transport the device. ‣ The device must always be secured at two lifting lugs at least. - Page 24 Installation Proline Promass I 500 PROFINET To prevent measuring errors arising from accumulation of gas bubbles in the measuring tube, avoid the following mounting locations in the pipe: • Highest point of a pipeline. • Directly upstream of a free pipe outlet in a down pipe.

-

Page 25: Environment And Process Requirements

Proline Promass I 500 PROFINET Installation Orientation Recommendation Vertical orientation A0015591 Horizontal orientation, transmitter at A0015589 Horizontal orientation, transmitter at bottom A0015590 Horizontal orientation, transmitter at side A0015592 This orientation is recommended to ensure self-draining. Applications with low process temperatures may decrease the ambient temperature. To maintain the minimum ambient temperature for the transmitter, this orientation is recommended. - Page 26 If operating outdoors: Avoid direct sunlight, particularly in warm climatic regions. You can order a weather protection cover from Endress+Hauser. → 253. System pressure It is important that cavitation does not occur, or that gases entrained in the liquids do not outgas.

-

Page 27: Special Mounting Instructions

Proline Promass I 500 PROFINET Installation Heating NOTICE Electronics can overheat due to elevated ambient temperature! ‣ Observe maximum permitted ambient temperature for the transmitter . ‣ Depending on the fluid temperature, take the device orientation requirements into account . - Page 28 Installation Proline Promass I 500 PROFINET A0030297 Eccentric clamp connection "This side up" label indicates which side is up Slope the device in accordance with the hygiene guidelines. Slope: approx. 2 % or 21 mm/m (0.24 in/feet) Line on the underside indicates the lowest point of the eccentric process connection.

- Page 29 Proline Promass I 500 PROFINET Installation Zero point adjustment All measuring devices are calibrated in accordance with state-of-the-art technology. Calibration takes place under reference conditions→ 267. Therefore, a zero point adjustment in the field is generally not required. Experience shows that zero point adjustment is advisable only in special cases: •...

-

Page 30: Mounting The Measuring Device

Installation Proline Promass I 500 PROFINET SW 2.5 5 (0.2) min. 15 (0.6) A0029799 Cover borehole for the securing screw Securing screw to lock the cover Mounting the measuring device 6.2.1 Required tools For transmitter For mounting on a post: •... -

Page 31: Mounting The Transmitter Housing: Proline 500 - Digital

Proline Promass I 500 PROFINET Installation 2. Install the measuring device or turn the transmitter housing so that the cable entries do not point upwards. A0029263 6.2.4 Mounting the transmitter housing: Proline 500 – digital CAUTION Ambient temperature too high! Danger of electronics overheating and housing deformation. -

Page 32: Mounting The Transmitter Housing: Proline 500

Installation Proline Promass I 500 PROFINET Wall mounting 17 (0.67) 5.8 (0.23) 5.8 (0.23) 149 (5.85) A0029054 11 Engineering unit mm (in) Depends on order code for "Transmitter housing" Order code for "Transmitter housing" • Option A, aluminum coated: L =14 mm (0.55 in) •... - Page 33 Proline Promass I 500 PROFINET Installation Wall mounting 18 (0.71) 10 (0.39) 20 (0.79) 100 (3.94) A0029068 12 Engineering unit mm (in) 1. Drill the holes. 2. Insert wall plugs into the drilled holes. 3. Screw in the securing screws slightly at first.

-

Page 34: Turning The Transmitter Housing: Proline 500

Installation Proline Promass I 500 PROFINET Post mounting WARNING Order code for "Transmitter housing", option L "Cast, stainless": cast transmitters are very heavy. They are unstable if they are not mounted on a secure, fixed post. ‣ Only mount the transmitter on a secure, fixed post on a stable surface. -

Page 35: Turning The Display Module: Proline 500

Proline Promass I 500 PROFINET Installation 7. Depending on the device version: Attach the securing clamp of the connection compartment cover. 6.2.7 Turning the display module: Proline 500 The display module can be turned to optimize display readability and operability. -

Page 36: Electrical Connection

Electrical connection Proline Promass I 500 PROFINET Electrical connection NOTICE The measuring device does not have an internal circuit breaker. ‣ For this reason, assign the measuring device a switch or power-circuit breaker so that the power supply line can be easily disconnected from the mains. - Page 37 Proline Promass I 500 PROFINET Electrical connection Relay output Standard installation cable is sufficient. Current input 0/4 to 20 mA Standard installation cable is sufficient. Status input Standard installation cable is sufficient. Cable diameter • Cable glands supplied: M20 × 1.5 with cable ⌀ 6 to 12 mm (0.24 to 0.47 in) •...

- Page 38 Electrical connection Proline Promass I 500 PROFINET A: Connecting cable between sensor and transmitter: Proline 500 – digital Standard cable A standard cable with the following specifications can be used as the connecting cable. Design 4 cores (2 pairs); uninsulated stranded CU wires; pair-stranded with common...

- Page 39 Proline Promass I 500 PROFINET Electrical connection Cross-section Cable length [max.] Termination 2 x 2 x 0.50 mm 50 m (165 ft) 2 x 2 x 0.50 mm (AWG 20) (AWG 20) BN WT YE GN • +, – = 0.5 mm •...

-

Page 40: Terminal Assignment

Electrical connection Proline Promass I 500 PROFINET C: Connecting cable between sensor and transmitter: Proline 500 Standard cable 6 × 0.38 mm PVC cable with common shield and individually shielded cores Conductor resistance ≤50 Ω/km (0.015 Ω/ft) Capacitance: core/shield ≤420 pF/m (128 pF/ft) Cable length (max.) -

Page 41: Pin Assignment Of Device Plug

Proline Promass I 500 PROFINET Electrical connection 7.1.5 Pin assignment of device plug Assignment TD + RD + TD – RD – Coding Plug/socket A0032047 Socket 7.1.6 Preparing the measuring device Carry out the steps in the following order: 1. Mount the sensor and transmitter. -

Page 42: Connecting The Measuring Device: Proline 500 - Digital

Electrical connection Proline Promass I 500 PROFINET Connecting the measuring device: Proline 500 - digital NOTICE Limitation of electrical safety due to incorrect connection! ‣ Have electrical connection work carried out by appropriately trained specialists only. ‣ Observe applicable federal/national installation codes and regulations. - Page 43 Proline Promass I 500 PROFINET Electrical connection Connecting the sensor connection housing via terminals For the device version with the order code for "Sensor connection housing": • Option A "Aluminum coated" • Option L "Cast, stainless" 10 (0.4) 3 mm...

- Page 44 Electrical connection Proline Promass I 500 PROFINET Connecting the sensor connection housing via terminals For the device version with the order code for "Sensor connection housing": Option B "Stainless" 10 (0.4) 8 mm 22 mm 24 mm A0029613 1. Release the securing screw of the housing cover.

- Page 45 Proline Promass I 500 PROFINET Electrical connection Connecting the sensor connection housing via the connector For the device version with the order code for "Sensor connection housing": Option C "Ultra-compact hygienic, stainless" A0029615 1. Connect the protective ground. 2. Connect the connector.

- Page 46 Electrical connection Proline Promass I 500 PROFINET Connecting the connecting cable to the transmitter TX 20 TX 20 10 (0.4) 22 mm 24 mm A0029597 1. Loosen the 4 fixing screws on the housing cover. 2. Open the housing cover.

-

Page 47: Connecting The Transmitter

Proline Promass I 500 PROFINET Electrical connection 7.2.2 Connecting the transmitter A0028200 Terminal connection for supply voltage Terminal connection for signal transmission, input/output Terminal connection for signal transmission, input/output Terminal connection for connecting cable between sensor and transmitter Terminal connection for signal transmission, input/output or terminal connection for network connection via service interface (CDI-RJ45);... - Page 48 Electrical connection Proline Promass I 500 PROFINET 6. Connect the protective ground. 7. Plug in the RJ45 connector. 8. Firmly tighten the cable glands. This concludes the PROFINET connection process. Connecting the supply voltage and additional inputs/outputs TX 20 TX 20 10 (0.4)

- Page 49 Proline Promass I 500 PROFINET Electrical connection Removing a cable 3 (0.12) A0029598 14 Engineering unit mm (in) 1. To remove a cable from the terminal, use a flat-blade screwdriver to push the slot between the two terminal holes 2.

-

Page 50: Integrating The Transmitter Into A Network

Electrical connection Proline Promass I 500 PROFINET 7.2.3 Integrating the transmitter into a network This section only presents the basic options for integrating the device into a network. For information on the procedure to follow to connect the transmitter correctly → 42. - Page 51 Proline Promass I 500 PROFINET Electrical connection Integrating into a ring topology The device is integrated via the terminal connection for signal transmission (output 1) and the connection to the service interface (CDI-RJ45). Note the following when connecting: • Recommended cable: CAT5e, CAT6 or CAT7, with shielded connector (e.g. brand: YAMAICHI ;...

-

Page 52: Connecting The Measuring Device: Proline 500

Electrical connection Proline Promass I 500 PROFINET Connecting the measuring device: Proline 500 NOTICE Limitation of electrical safety due to incorrect connection! ‣ Have electrical connection work carried out by appropriately trained specialists only. ‣ Observe applicable federal/national installation codes and regulations. - Page 53 Proline Promass I 500 PROFINET Electrical connection Connecting the sensor connection housing via terminals For the device version with the order code for "Housing": Option L "Cast, stainless" 10 (0.4) 3 mm 22 mm 24 mm A0029612 1. Loosen the securing clamp of the housing cover.

- Page 54 Electrical connection Proline Promass I 500 PROFINET Connecting the sensor connection housing via terminals For the device version with the order code for "Housing": Option B "Stainless" 10 (0.4) 8 mm 22 mm 24 mm A0029613 1. Release the securing screw of the housing cover.

- Page 55 Proline Promass I 500 PROFINET Electrical connection Connecting the connecting cable to the transmitter 10 (0.4) 3 mm 22 mm 24 mm A0029592 1. Loosen the securing clamp of the connection compartment cover. 2. Unscrew the connection compartment cover. 3. Push the cable through the cable entry . To ensure tight sealing, do not remove the sealing ring from the cable entry.

-

Page 56: Connecting The Transmitter

Electrical connection Proline Promass I 500 PROFINET 7.3.2 Connecting the transmitter A0026781 Terminal connection for supply voltage Terminal connection for signal transmission, input/output Terminal connection for signal transmission, input/output or terminal connection for network connection via service interface (CDI-RJ45) Protective earth (PE) - Page 57 Proline Promass I 500 PROFINET Electrical connection 22 mm 24 mm N ic t e r e r g ö f f iz e t e n s io r ir A0033722 7. Push the cable through the cable entry . To ensure tight sealing, do not remove the sealing ring from the cable entry.

- Page 58 Electrical connection Proline Promass I 500 PROFINET 22 mm 24 mm – A0033984 4. Connect the cable in accordance with the terminal assignment . Signal cable terminal assignment: The device-specific terminal assignment is documented on an adhesive label in the terminal cover.

-

Page 59: Integrating The Transmitter Into A Network

Proline Promass I 500 PROFINET Electrical connection 7.3.3 Integrating the transmitter into a network This section only presents the basic options for integrating the device into a network. For information on the procedure to follow to connect the transmitter correctly → 52. -

Page 60: Ensuring Potential Equalization

Electrical connection Proline Promass I 500 PROFINET Integrating into a ring topology The device is integrated via the terminal connection for signal transmission (output 1) and the connection to the service interface (CDI-RJ45). Note the following when connecting: • Recommended cable: CAT5e, CAT6 or CAT7, with shielded connector (e.g. brand: YAMAICHI ;... -

Page 61: Special Connection Instructions

Proline Promass I 500 PROFINET Electrical connection Special connection instructions 7.5.1 Connection examples PROFINET A0028767 16 Connection example for PROFINET Control system (e.g. PLC) Ethernet switch Observe cable specifications Device plug Transmitter PROFINET: MRP (Media Redundancy Protocol) A0027544 Control system (e.g. PLC) Ethernet switch Observe cable specifications →... - Page 62 Electrical connection Proline Promass I 500 PROFINET PROFINET: system redundancy S2 A0039553 17 Connection example for system redundancy S2 Control system 1 (e.g. PLC) Synchronization of control systems Control system 2 (e.g. PLC) Industrial Ethernet Managed Switch Transmitter Current output 4-20 mA 4...20 mA...

- Page 63 Proline Promass I 500 PROFINET Electrical connection Pulse/frequency output 12345 A0028761 20 Connection example for pulse/frequency output (passive) Automation system with pulse/frequency input (e.g. PLC) Power supply Transmitter: Observe input values → 261 Switch output A0028760 21 Connection example for switch output (passive) Automation system with switch input (e.g.

-

Page 64: Hardware Settings

Electrical connection Proline Promass I 500 PROFINET Current input A0028915 23 Connection example for 4 to 20 mA current input Power supply Terminal box External measuring device (to read in pressure or temperature, for instance) Transmitter Status input A0028764 ... - Page 65 Proline Promass I 500 PROFINET Electrical connection Setting the device name using the DIP switches The last part of the device name can be set using DIP switches 1-8. The address range is between 1 and 254 (factory setting: serial number of the device )

- Page 66 Electrical connection Proline Promass I 500 PROFINET 1 2 3 4 5 6 7 8 Name of Station A0034497 1. Loosen the 4 fixing screws on the housing cover. 2. Open the housing cover. 3. Fold open the terminal cover.

-

Page 67: Activating The Default Ip Address

Proline Promass I 500 PROFINET Electrical connection 5. Reconnect the device to the power supply. The configured device address is used once the device is restarted. Setting the device name via the automation system DIP switches 1-8 must all be set to OFF (factory setting) or all be set to ON to be able to set the device name via the automation system. -

Page 68: Ensuring The Degree Of Protection

Electrical connection Proline Promass I 500 PROFINET Activating the default IP address by DIP switch: Proline 500 Risk of electric shock when opening the transmitter housing. ‣ Before opening the transmitter housing: ‣ Disconnect the device from the power supply. -

Page 69: Post-Connection Check

Proline Promass I 500 PROFINET Electrical connection Post-connection check Are cables or the device undamaged (visual inspection)? Do the cables used meet the requirements? Do the cables have adequate strain relief? Are all the cable glands installed, firmly tightened and leak-tight? Cable run with "water trap"... -

Page 70: Operation Options

Operation options Proline Promass I 500 PROFINET Operation options Overview of operation options A0034513 Local operation via display module Computer with Web browser (e.g. Internet Explorer) or with operating tool (e.g. FieldCare, DeviceCare, AMS Device Manager, SIMATIC PDM) Field Xpert SFX350 or SFX370... -

Page 71: Structure And Function Of The Operating

Proline Promass I 500 PROFINET Operation options Structure and function of the operating menu 8.2.1 Structure of the operating menu For an overview of the operating menu for experts: "Description of Device Parameters" document supplied with the device→ 286... -

Page 72: Operating Philosophy

Operation options Proline Promass I 500 PROFINET 8.2.2 Operating philosophy The individual parts of the operating menu are assigned to certain user roles (operator, maintenance etc.). Each user role contains typical tasks within the device lifecycle. Menu/parameter User role and tasks... -

Page 73: Access To The Operating Menu Via The Local Display

Proline Promass I 500 PROFINET Operation options Access to the operating menu via the local display 8.3.1 Operational display X X X X X X X 1120.50 kg/h A0029348 Operational display Device tag Status area Display area for measured values (4-line) Operating elements→... -

Page 74: Navigation View

Operation options Proline Promass I 500 PROFINET Measurement channel numbers Symbol Meaning Measurement channel 1 to 4 The measurement channel number is displayed only if more than one channel is present for the same measured variable type (e.g. Totalizer 1 to 3). - Page 75 Proline Promass I 500 PROFINET Operation options Status area The following appears in the status area of the navigation view in the top right corner: • In the submenu • The direct access code for the parameter you are navigating to (e.g. 0022-1) •...

-

Page 76: Editing View

Operation options Proline Promass I 500 PROFINET 8.3.3 Editing view Numeric editor +0.000 Xx – A0034250 26 For entering values in parameters (e.g. limit values) Entry display area Input screen Confirm, delete or reject entry Operating elements Text editor... - Page 77 Proline Promass I 500 PROFINET Operation options Operating key(s) Meaning Enter key • Press the key briefly: confirm your selection. • Press the key for 2 s: confirm the entry. Escape key combination (press keys simultaneously) Close the editing view without accepting the changes.

-

Page 78: Operating Elements

Operation options Proline Promass I 500 PROFINET 8.3.4 Operating elements Operating key(s) Meaning Minus key In a menu, submenu Moves the selection bar upwards in a picklist. With a Wizard Confirms the parameter value and goes to the previous parameter. - Page 79 Proline Promass I 500 PROFINET Operation options Calling up and closing the context menu The user is in the operational display. 1. Press the and keys for longer than 3 seconds. The context menu opens. XXXXXXXXXX Setup Conf.backup...

-

Page 80: Navigating And Selecting From List

Operation options Proline Promass I 500 PROFINET 8.3.6 Navigating and selecting from list Different operating elements are used to navigate through the operating menu. The navigation path is displayed on the left in the header. Icons are displayed in front of the individual menus. -

Page 81: Calling Up Help Text

Proline Promass I 500 PROFINET Operation options The direct access code consists of a 5-digit number (at maximum) and the channel number, which identifies the channel of a process variable: e.g. 00914-2. In the navigation view, this appears on the right-hand side in the header of the selected parameter. -

Page 82: User Roles And Related Access Authorization

Operation options Proline Promass I 500 PROFINET Ent. access code Invalid or out of range input value Min:0 Max:9999 A0014049-EN For a description of the editing view - consisting of the text editor and numeric editor - with symbols → 76, for a description of the operating elements → 78 8.3.10... -

Page 83: Enabling And Disabling The Keypad

Proline Promass I 500 PROFINET Operation options 2. Enter the access code. The -symbol in front of the parameters disappears; all previously write- protected parameters are now re-enabled. 8.3.12 Enabling and disabling the keypad lock The keypad lock makes it possible to block access to the entire operating menu via local operation. -

Page 84: Prerequisites

Operation options Proline Promass I 500 PROFINET 8.4.2 Prerequisites Computer hardware Hardware Interface CDI-RJ45 WLAN Interface The computer must have an RJ45 The operating unit must have a interface. WLAN interface. Connection Standard Ethernet cable with RJ45 Connection via Wireless LAN. -

Page 85: Establishing A Connection

Proline Promass I 500 PROFINET Operation options Measuring device: Via CDI-RJ45 service interface Device CDI-RJ45 service interface Measuring device The measuring device has an RJ45 interface. Web server Web server must be enabled; factory setting: ON For information on enabling the Web server → 89... - Page 86 Operation options Proline Promass I 500 PROFINET The measuring device works with the Dynamic Configuration Protocol (DCP), on leaving the factory, i.e. the IP address of the measuring device is automatically assigned by the automation system (e.g. Siemens S7). To establish a network connection via the service interface (CDI-RJ45): set the "Default IP address"...

-

Page 87: Logging On

Proline Promass I 500 PROFINET Operation options 3. Enter the password: serial number of the measuring device ex-works (e.g. L100A802000). LED on display module flashes: it is now possible to operate the measuring device with the Web browser, FieldCare or DeviceCare. -

Page 88: User Interface

Operation options Proline Promass I 500 PROFINET 2. Enter the user-specific access code. 3. Press OK to confirm your entry. Access code 0000 (factory setting); can be changed by customer If no action is performed for 10 minutes, the Web browser automatically returns to the login page. -

Page 89: Disabling The Web Server

Proline Promass I 500 PROFINET Operation options Functions Meaning Configuration and checking of all the parameters required for establishing the connection to Network the measuring device: configuration • Network settings (e.g. IP address, MAC address) • Device information (e.g. serial number, firmware version) -

Page 90: Logging Out

Operation options Proline Promass I 500 PROFINET 8.4.7 Logging out Before logging out, perform a data backup via the Data management function (upload configuration from device) if necessary. 1. Select the Logout entry in the function row. The home page with the Login box appears. - Page 91 Proline Promass I 500 PROFINET Operation options A0033719 30 Options for remote operation via PROFINET network: ring topology Automation system, e.g. Simatic S7 (Siemens) Computer with Web browser (e.g. Internet Explorer) for accessing the integrated device Web server or computer with operating tool (e.g.

- Page 92 Operation options Proline Promass I 500 PROFINET Proline 500 transmitter A0027563 32 Connection via service interface (CDI-RJ45) Computer with Web browser (e.g. Microsoft Internet Explorer, Microsoft Edge) for accessing the integrated device Web server or with "FieldCare", "DeviceCare" operating tool with COM DTM "CDI Communication TCP/IP"...

- Page 93 Proline Promass I 500 PROFINET Operation options Function WLAN: IEEE 802.11 b/g (2.4 GHz) Encryption WPA2-PSK AES-128 (in accordance with IEEE 802.11i) Configurable WLAN channels 1 to 11 Degree of protection IP67 Available antennas • Internal antenna • External antenna (optional) In the event of poor transmission/reception conditions at the place of installation.

-

Page 94: Fieldcare

FieldCare Function scope FDT-based plant asset management tool from Endress+Hauser. It can configure all smart field devices in a system and helps you manage them. By using the status information, it is also a simple but effective way of checking their status and condition. -

Page 95: Devicecare

DeviceCare Function scope Tool to connect and configure Endress+Hauser field devices. The fastest way to configure Endress+Hauser field devices is with the dedicated "DeviceCare" tool. Together with the device type managers (DTMs) it presents a convenient, comprehensive solution. For details, see Innovation Brochure IN01047S Source for device description files See information →... -

Page 96: System Integration

System integration Proline Promass I 500 PROFINET System integration Overview of device description files 9.1.1 Current version data for the device Firmware version 01.01.zz • On the title page of the Operating instructions • On the transmitter nameplate • Firmware version Diagnostics →... -

Page 97: Device Master File (Gsd)

Proline Promass I 500 PROFINET System integration Device master file (GSD) In order to integrate field devices into a bus system, the PROFINET system needs a description of the device parameters, such as output data, input data, data format and data volume. -

Page 98: Cyclic Data Transmission

System integration Proline Promass I 500 PROFINET Cyclic data transmission 9.3.1 Overview of the modules The following tables shows which modules are available to the measuring device for cyclic data exchange. Cyclic data exchange is performed with an automation system. - Page 99 Proline Promass I 500 PROFINET System integration Selection: input variable Slot Input variables • Mass flow • Volume flow • Corrected volume flow • Density • Reference density • Temperature • Electronic temperature • Oscillation frequency 1 to 14 • Frequency fluctuation •...

- Page 100 System integration Proline Promass I 500 PROFINET Data structure Input data of Analog Input Byte 1 Byte 2 Byte 3 Byte 4 Byte 5 Measured value: floating point number (IEEE 754) Status Status coding → 107 Application-specific Input module Transmit compensation values from the automation system to the measuring device.

- Page 101 Proline Promass I 500 PROFINET System integration Digital input values are used by the measuring device to transmit the state of device functions to the automation system. Digital Input modules cyclically transmit discrete input values, including the status, from the measuring device to the automation system. The discrete input value is depicted in the first byte.

- Page 102 System integration Proline Promass I 500 PROFINET Coding (hex) Status Function check (C): 0x02 The device is in service mode (e.g. during a simulation). Maintenance required (M): 0x04 Maintenance is required. The measured value is still valid. Out of specification (S): 0x08 The device is being operated outside its technical specification limits (e.g.

- Page 103 Proline Promass I 500 PROFINET System integration Data structure of output data (Totalizer Control submodule) Byte 1 Control variable Totalizer Mode submodule Configure the totalizer via the automation system. Selection: totalizer configuration Slot Sub-slot Value Control totalizer Balancing 15…17 Balance the positive flow...

- Page 104 System integration Proline Promass I 500 PROFINET Pressure Temperature Density Percent Unit code Unit Unit code Unit Unit code Unit Unit code Unit 1137 1003 °R 32843 kg/Scm 1611 Pa g 32844 lb/Sft 1617 kPa g 1615 MPa g 32797...

- Page 105 Proline Promass I 500 PROFINET System integration Assigned device functions Slot Device function Status (meaning) Flow override • 0 (disable device function) • 1 (enable device function) Zero point adjustment Relay output value: 24 to 26 Relay output • 0 •...

- Page 106 System integration Proline Promass I 500 PROFINET Data structure Output data of the Heartbeat Verification module Byte 1 Discrete Output Input data of the Heartbeat Verification module Byte 1 Byte 2 Discrete Input Status Status coding → 107 Concentration module Only available with the Concentration Measurement application package.

-

Page 107: Status Coding

Proline Promass I 500 PROFINET System integration Liquid type Enum code Ammonium nitrate in water Iron(III) chloride in water % mass / % volume User Profile Coef Set No. 1 User Profile Coef Set No. 2 User Profile Coef Set No. 3 9.3.3... - Page 108 System integration Proline Promass I 500 PROFINET Slot Factory setting Temperature 7-14 – Totalizer 1 Totalizer 2 Totalizer 3 Endress+Hauser...

-

Page 109: Startup Configuration

Proline Promass I 500 PROFINET System integration 9.3.5 Startup configuration If startup configuration is enabled, the configuration of the most important device parameters is taken from the automation system and used. The following configuration is taken from the automation system. - Page 110 System integration Proline Promass I 500 PROFINET Startup configuration • Management: (NSU) • Software revision • Write protection • Web server functionality • WLAN functionality • System units: • Mass flow • Mass • Volume flow • Volume • Corrected volume flow •...

-

Page 111: System Redundancy S2

Proline Promass I 500 PROFINET System integration System redundancy S2 A redundant layout with two automation systems is necessary for processes that are in continuous operation. If one system fails the second system guarantees continued, uninterrupted operation. The measuring device supports S2 system redundancy and can communicate with both automation systems simultaneously. -

Page 112: Commissioning

Commissioning Proline Promass I 500 PROFINET Commissioning 10.1 Function check Before commissioning the measuring device: ‣ Make sure that the post-installation and post-connection checks have been performed. • "Post-installation check" checklist→ 35 • "Post-connection check" checklist → 69 10.2... -

Page 113: Configuring The Measuring Device

Proline Promass I 500 PROFINET Commissioning 10.5 Configuring the measuring device • The Setup menu with its guided wizards contains all the parameters needed for standard operation. • Navigation to the Setup menu X X X X X X X 20.50... -

Page 114: Defining The Tag Name

Commissioning Proline Promass I 500 PROFINET ‣ Relay output 1 to n → 133 ‣ Display → 136 ‣ Low flow cut off → 140 ‣ Partially filled pipe detection → 141 ‣ → 142 Advanced setup 10.5.1... - Page 115 Proline Promass I 500 PROFINET Commissioning Corrected volume unit → 115 Density unit → 115 Reference density unit → 115 Temperature unit → 116 → 116 Pressure unit Parameter overview with brief description Parameter Description...

-

Page 116: 10.5.3 Displaying The Communication

Commissioning Proline Promass I 500 PROFINET Parameter Description Selection Factory setting Temperature unit Select temperature unit. Unit choose list Country-specific: • °C Result • °F The selected unit applies for: • Electronic temperature parameter (6053) • Maximum value parameter (6051) •... - Page 117 Proline Promass I 500 PROFINET Commissioning Parameter Description User interface / User entry Factory setting Subnet mask Displays the subnet mask. 4 octet: 0 to 255 (in the 255.255.255.0 particular octet) If the DHCP client is switched off and write access is enabled, the Subnet mask can also be entered.

- Page 118 Commissioning Proline Promass I 500 PROFINET 10.5.4 Selecting and setting the medium The Select medium wizard submenu contains parameters that must be configured in order to select and set the medium. Navigation "Setup" menu → Select medium ‣ Medium selection →...

-

Page 119: Interface

Proline Promass I 500 PROFINET Commissioning Parameter overview with brief description Parameter Prerequisite Description Selection / User Factory setting entry / User interface Select medium – Select medium type. • Liquid Liquid • Gas Select gas type The Gas option is selected in Select measured gas type. -

Page 120: Configuring The Current Input

Commissioning Proline Promass I 500 PROFINET Navigation "Setup" menu → I/O configuration ‣ I/O configuration → 120 I/O module 1 to n terminal numbers → 120 I/O module 1 to n information I/O module 1 to n type →... - Page 121 Proline Promass I 500 PROFINET Commissioning Navigation "Setup" menu → Current input ‣ Current input 1 to n → 121 Terminal number → 121 Signal mode 0/4 mA value → 121 20 mA value → 121 Current span →...

-

Page 122: Configuring The Status Input

Commissioning Proline Promass I 500 PROFINET 10.5.7 Configuring the status input The Status input submenu guides the user systematically through all the parameters that have to be set for configuring the status input. Navigation "Setup" menu → Status input ‣... - Page 123 Proline Promass I 500 PROFINET Commissioning Navigation "Setup" menu → Current output ‣ Current output 1 to n → 123 Terminal number → 123 Signal mode Assign current output 1 to n → 124 Current span → 125 0/4 mA value →...

- Page 124 Commissioning Proline Promass I 500 PROFINET Parameter Prerequisite Description User interface / Factory setting Selection / User entry Assign current output 1 to n – Select process variable for • Off Mass flow current output. • Mass flow • Volume flow • Corrected volume flow •...

- Page 125 Proline Promass I 500 PROFINET Commissioning Parameter Prerequisite Description User interface / Factory setting Selection / User entry • Index suspended bubbles Current span – Select current range for • 4...20 mA NAMUR Country-specific: process value output and (3.8...20.5 mA) • 4...20 mA NAMUR upper/lower level for alarm •...

-

Page 126: Configuring The Pulse/Frequency

Commissioning Proline Promass I 500 PROFINET 10.5.9 Configuring the pulse/frequency/switch output The Pulse/frequency/switch output wizard guides you systematically through all the parameters that can be set for configuring the selected output type. Navigation "Setup" menu → Advanced setup → Pulse/frequency/switch output ‣... - Page 127 Proline Promass I 500 PROFINET Commissioning Parameter overview with brief description Parameter Prerequisite Description Selection / User Factory setting interface / User entry Operating mode – Define the output as a pulse, • Pulse Pulse frequency or switch output. • Frequency • Switch Terminal number –...

- Page 128 Commissioning Proline Promass I 500 PROFINET Configuring the frequency output Navigation "Setup" menu → Pulse/frequency/switch output ‣ Pulse/frequency/switch output 1 to n Operating mode → 128 Terminal number → 128 Signal mode → 128 → 129...

- Page 129 Proline Promass I 500 PROFINET Commissioning Parameter Prerequisite Description Selection / User Factory setting interface / User entry Assign frequency output The Frequency option is Select process variable for • Off selected in the Operating frequency output. • Mass flow mode parameter (→ 126).

- Page 130 Commissioning Proline Promass I 500 PROFINET Parameter Prerequisite Description Selection / User Factory setting interface / User entry • Index suspended bubbles Minimum frequency value The Frequency option is Enter minimum frequency. 0.0 to 10 000.0 Hz 0.0 Hz selected in the Operating mode parameter (→ 126)

- Page 131 Proline Promass I 500 PROFINET Commissioning Configuring the switch output Navigation "Setup" menu → Pulse/frequency/switch output ‣ Pulse/frequency/switch output 1 to n Operating mode → 131 Terminal number → 131 Signal mode → 131 → 132...

- Page 132 Commissioning Proline Promass I 500 PROFINET Parameter Prerequisite Description Selection / User Factory setting interface / User entry Switch output function The Switch option is selected Select function for switch • Off in the Operating mode output. • On parameter. • Diagnostic behavior • Limit •...

-

Page 133: 10.5.10 Configuring The Relay Output

Proline Promass I 500 PROFINET Commissioning Parameter Prerequisite Description Selection / User Factory setting interface / User entry Assign status • The Switch option is Select device status for switch • Partially filled pipe Partially filled pipe selected in the Operating output. detection detection mode parameter. - Page 134 Commissioning Proline Promass I 500 PROFINET Assign status → 135 Switch-off value → 135 Switch-on value → 135 Failure mode → 136 Parameter overview with brief description Parameter Prerequisite Description Selection / User Factory setting interface / User entry Relay output function –...

- Page 135 Proline Promass I 500 PROFINET Commissioning Parameter Prerequisite Description Selection / User Factory setting interface / User entry Assign limit The Limit option is selected in Select process variable for limit • Mass flow Mass flow the Relay output function function. • Volume flow parameter.

-

Page 136: 10.5.11 Configuring The Local Display

Commissioning Proline Promass I 500 PROFINET Parameter Prerequisite Description Selection / User Factory setting interface / User entry Switch-on delay In the Relay output function Define delay for the switch-on 0.0 to 100.0 s 0.0 s parameter, the Limit option is of status output. - Page 137 Proline Promass I 500 PROFINET Commissioning Parameter overview with brief description Parameter Prerequisite Description Selection / User Factory setting entry Format display A local display is provided. Select how measured values • 1 value, max. size 1 value, max. size are shown on the display.

- Page 138 Commissioning Proline Promass I 500 PROFINET Parameter Prerequisite Description Selection / User Factory setting entry Value 1 display A local display is provided. Select the measured value that • Mass flow Mass flow is shown on the local display. • Volume flow •...

- Page 139 Proline Promass I 500 PROFINET Commissioning Parameter Prerequisite Description Selection / User Factory setting entry • Index inhomogeneous medium • Application specific output 0 • Index suspended bubbles 0% bargraph value 1 A local display is provided. Enter 0% value for bar graph...

-

Page 140: 10.5.12 Configuring The Low Flow Cut Off

Commissioning Proline Promass I 500 PROFINET 10.5.12 Configuring the low flow cut off The Low flow cut off wizard systematically guides the user through all the parameters that must be set to configure low flow cut off. Navigation "Setup" menu → Low flow cut off ‣... -

Page 141: Configuring The Partial Filled Pipe

Proline Promass I 500 PROFINET Commissioning 10.5.13 Configuring the partial filled pipe detection The Partial filled pipe detection wizard guides you systematically through all parameters that have to be set for configuring the monitoring of the pipe filling. Navigation "Setup" menu → Partially filled pipe detection ‣... -

Page 142: Advanced Settings

Commissioning Proline Promass I 500 PROFINET 10.6 Advanced settings The Advanced setup submenu together with its submenus contains parameters for specific settings. Navigation to the "Advanced setup" submenu X X X X X X X 20.50 0104-1 Main menu Display language English Display/operat. -

Page 143: Using The Parameter To Enter The Access Code

Proline Promass I 500 PROFINET Commissioning ‣ WLAN settings → 151 ‣ Viscosity ‣ Concentration ‣ Heartbeat setup ‣ → 153 Configuration backup ‣ Administration → 154 10.6.1 Using the parameter to enter the access code Navigation "Setup"... -

Page 144: Carrying Out A Sensor Adjustment

Commissioning Proline Promass I 500 PROFINET Parameter overview with brief description Parameter Prerequisite Description Selection / User Factory setting interface / User entry Corrected volume flow calculation – Select reference density for • Fixed reference Calculated reference calculating the corrected density density volume flow. -

Page 145: Configuring The Totalizer

Proline Promass I 500 PROFINET Commissioning Parameter overview with brief description Parameter Description Selection Factory setting Installation direction Set sign of flow direction to match the • Flow in arrow direction Flow in arrow direction direction of the arrow on the sensor. - Page 146 Commissioning Proline Promass I 500 PROFINET Parameter overview with brief description Parameter Description Selection Factory setting Assign process variable Select process variable for totalizer. • Volume flow Volume flow • Mass flow • Corrected volume flow • Total mass flow •...

-

Page 147: Carrying Out Additional Display Configurations

Proline Promass I 500 PROFINET Commissioning 10.6.5 Carrying out additional display configurations In the Display submenu you can set all the parameters associated with the configuration of the local display. Navigation "Setup" menu → Advanced setup → Display ‣ Display Format display →... - Page 148 Commissioning Proline Promass I 500 PROFINET Parameter overview with brief description Parameter Prerequisite Description Selection / User Factory setting entry Format display A local display is provided. Select how measured values • 1 value, max. size 1 value, max. size are shown on the display.

- Page 149 Proline Promass I 500 PROFINET Commissioning Parameter Prerequisite Description Selection / User Factory setting entry Value 1 display A local display is provided. Select the measured value that • Mass flow Mass flow is shown on the local display. • Volume flow •...

- Page 150 Commissioning Proline Promass I 500 PROFINET Parameter Prerequisite Description Selection / User Factory setting entry • Index inhomogeneous medium • Application specific output 0 • Index suspended bubbles 0% bargraph value 1 A local display is provided. Enter 0% value for bar graph...

-

Page 151: Wlan Configuration

Proline Promass I 500 PROFINET Commissioning Parameter Prerequisite Description Selection / User Factory setting entry Display language A local display is provided. Set display language. • English English • Deutsch (alternatively, the • Français ordered language is • Español preset in the device) •... - Page 152 Commissioning Proline Promass I 500 PROFINET WLAN mode → 152 SSID name → 152 Network security → 152 Security identification → 152 → 152 User name WLAN password → 153 WLAN IP address → 153...

-

Page 153: Configuration Management

Proline Promass I 500 PROFINET Commissioning Parameter Prerequisite Description Selection / User Factory setting entry / User interface WLAN password – Enter WLAN password. – – WLAN IP address – Enter IP address of the WLAN 4 octet: 0 to 255 (in 192.168.1.212 interface of the device. -

Page 154: Using Parameters For Device Administration

Commissioning Proline Promass I 500 PROFINET Parameter overview with brief description Parameter Description User interface / Selection Factory setting Operating time Indicates how long the device has been in Days (d), hours (h), minutes – operation. (m) and seconds (s) Last backup... - Page 155 Proline Promass I 500 PROFINET Commissioning Navigation "Setup" menu → Advanced setup → Administration ‣ Administration ‣ → 155 Define access code ‣ → 155 Reset access code Device reset → 156 Using the parameter to define the access code Navigation "Setup"...

-

Page 156: Simulation

Commissioning Proline Promass I 500 PROFINET Parameter overview with brief description Parameter Description User interface / User entry Factory setting Operating time Indicates how long the device has been in Days (d), hours (h), minutes – operation. (m) and seconds (s) Reset access code Reset access code to factory settings. - Page 157 Proline Promass I 500 PROFINET Commissioning Current output 1 to n simulation → 158 Value current output 1 to n → 158 Frequency output simulation 1 to n → 158 Frequency value 1 to n → 158 Pulse output simulation 1 to n →...

- Page 158 Commissioning Proline Promass I 500 PROFINET Parameter overview with brief description Parameter Prerequisite Description Selection / User Factory setting entry / User interface Assign simulation process variable – Select a process variable for • Off the simulation process that is • Mass flow activated.

- Page 159 Proline Promass I 500 PROFINET Commissioning Parameter Prerequisite Description Selection / User Factory setting entry / User interface Pulse output simulation 1 to n In the Operating mode Set and switch off the pulse • Off parameter, the Pulse option is output simulation. • Fixed value selected.

-

Page 160: Protecting Settings From Unauthorized

Commissioning Proline Promass I 500 PROFINET 10.8 Protecting settings from unauthorized access The following write protection options exist in order to protect the configuration of the measuring device from unintentional modification: • Protect access to parameters via access code → 160 •... -

Page 161: Write Protection Via Write Protection

Via Web browser, FieldCare, DeviceCare (via CDI-RJ45 service interface), fieldbus For a reset code, contact your Endress+Hauser service organization. 1. Navigate to the Reset access code parameter (→ 156). 2. Enter the reset code. - Page 162 Commissioning Proline Promass I 500 PROFINET A0029673 1. Open the housing cover. 2. Remove the display module. 3. Fold open the terminal cover. 4. Setting the write protection (WP) switch on the main electronics module to the ON position enables hardware write protection.

- Page 163 Proline Promass I 500 PROFINET Commissioning Proline 500 A0029630 Setting the write protection (WP) switch on the main electronics module to the ON position enables hardware write protection. In the Locking status parameter the Hardware locked option is displayed →...

-

Page 164: Operation

Operation Proline Promass I 500 PROFINET Operation 11.1 Reading the device locking status Device active write protection: Locking status parameter Operation → Locking status Function scope of the "Locking status" parameter Options Description None The access status displayed in the Access status parameter applies → 82. Only appears on local display. -

Page 165: Measured Variables" Submenu

Proline Promass I 500 PROFINET Operation 11.4.1 "Measured variables" submenu The Measured variables submenu contains all the parameters needed to display the current measured values for each process variable. Navigation "Diagnostics" menu → Measured values → Measured variables ‣ Measured variables →... - Page 166 Operation Proline Promass I 500 PROFINET Parameter Prerequisite Description User interface Corrected volume flow – Displays the corrected volume flow that Signed floating-point is currently calculated. number Dependency The unit is taken from the Corrected volume flow unit parameter (→ 115).

-

Page 167: Totalizer

Proline Promass I 500 PROFINET Operation Parameter Prerequisite Description User interface Concentration For the following order code: Displays the concentration that is Signed floating-point Order code for "Application package", currently calculated. number option ED "Concentration" Dependency The software options currently... -

Page 168: Input Values" Submenu

Operation Proline Promass I 500 PROFINET Parameter overview with brief description Parameter Prerequisite Description Selection / User Factory setting entry / User interface Assign process variable – Select process variable for • Volume flow Volume flow totalizer. • Mass flow • Corrected volume flow •... -

Page 169: Output Values

Proline Promass I 500 PROFINET Operation Navigation "Diagnostics" menu → Measured values → Input values → Current input 1 to n ‣ Current input 1 to n → 169 Measured values 1 to n → 169 Measured current 1 to n... - Page 170 Operation Proline Promass I 500 PROFINET ‣ Pulse/frequency/switch output → 170 1 to n ‣ Relay output 1 to n → 171 Output values of current output The Value current output submenu contains all the parameters needed to display the current measured values for every current output.

-

Page 171: Adapting The Measuring Device To The Process

Proline Promass I 500 PROFINET Operation Parameter overview with brief description Parameter Prerequisite Description User interface Output frequency 1 to n In the Operating mode parameter, the Displays the value currently measured 0.0 to 12 500.0 Hz Frequency option is selected. -

Page 172: Function Scope Of The "Control Totalizer" Parameter

Operation Proline Promass I 500 PROFINET Navigation "Operation" menu → Totalizer handling ‣ Totalizer handling → 172 Control Totalizer 1 to n → 172 Preset value 1 to n Reset all totalizers → 172 Parameter overview with brief description... -

Page 173: Showing Data Logging

Proline Promass I 500 PROFINET Operation 11.7 Showing data logging The Extended HistoROM application package must be enabled in the device (order option) for the Data logging submenu to appear. This contains all the parameters for the measured value history. - Page 174 Operation Proline Promass I 500 PROFINET Data logging status → 176 Entire logging duration → 176 ‣ Display channel 1 ‣ Display channel 2 ‣ Display channel 3 ‣ Display channel 4 Endress+Hauser...

- Page 175 Proline Promass I 500 PROFINET Operation Parameter overview with brief description Parameter Prerequisite Description Selection / User Factory setting entry / User interface Assign channel 1 The Extended HistoROM Assign process variable to • Off application package is logging channel. • Mass flow available.

- Page 176 Operation Proline Promass I 500 PROFINET Parameter Prerequisite Description Selection / User Factory setting entry / User interface • Application specific output 1 • Index inhomogeneous medium • Application specific output 0 • Index suspended bubbles Assign channel 2 The Extended HistoROM Assign process variable to...

-

Page 177: Diagnostics And Troubleshooting

Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostics and troubleshooting 12.1 General troubleshooting For local display Error Possible causes Solution Local display dark and no output Supply voltage does not match the Apply the correct supply voltage . signals value indicated on the nameplate. - Page 178 Diagnostics and troubleshooting Proline Promass I 500 PROFINET For output signals Error Possible causes Solution Signal output outside the valid Main electronics module is Order spare part → 251. range defective. Device shows correct value on local Configuration error...

- Page 179 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Error Possible causes Solution Apart from the active network • Make sure that no other network connection to the measuring device, connections are established by other network connections are also the computer (also no WLAN) being used.

-

Page 180: Diagnostic Information Via Light Emitting

Diagnostics and troubleshooting Proline Promass I 500 PROFINET For system integration Error Possible causes Solution The device name is not displayed A device name containing one or Specify a correct device name correctly and contains coding. more underscores has been... - Page 181 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Color Meaning Flashing red A diagnostic event with "Warning" diagnostic behavior has occurred. A diagnostic event with "Alarm" diagnostic behavior has occurred. Flashing red/green The device restarts. Device status (during Flashes red slowly If >...

-

Page 182: Sensor Connection Housing

Diagnostics and troubleshooting Proline Promass I 500 PROFINET Color Meaning Flashing green Device is not configured. Flashing red A diagnostic event with "Warning" diagnostic behavior has occurred. A diagnostic event with "Alarm" diagnostic behavior has occurred. Flashing red/green The device restarts. - Page 183 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Color Meaning Communication White Communication active. Device status (normal Problem operation) Flashing red Warning Device status (during Flashes red slowly If > 30 seconds: problem with the boot loader. start-up) Flashes red quickly If >...

-

Page 184: Diagnostic Information On Local Display

Diagnostics and troubleshooting Proline Promass I 500 PROFINET 12.3 Diagnostic information on local display 12.3.1 Diagnostic message Faults detected by the self-monitoring system of the measuring device are displayed as a diagnostic message in alternation with the operational display. Operational display in alarm condition... - Page 185 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic behavior Symbol Meaning Alarm • Measurement is interrupted. • Signal outputs and totalizers assume the defined alarm condition. • A diagnostic message is generated. Warning Measurement is resumed. The signal outputs and totalizers are not affected. A diagnostic message is generated.

-

Page 186: Calling Up Remedial Measures

Diagnostics and troubleshooting Proline Promass I 500 PROFINET 12.3.2 Calling up remedial measures X X X X X X X X X X X X X X 20.50 S801 Supply voltage Menu Diagnostic list Diagnostics 1 S801 Supply voltage Diagnostics 2... -

Page 187: Calling Up Remedy Information

Proline Promass I 500 PROFINET Diagnostics and troubleshooting A0031056 Status area with status signal Diagnostic information Remedy information with Service ID In addition, diagnostic events which have occurred can be shown in the Diagnostics menu: • Via parameter → 243 •... -

Page 188: Calling Up Remedy Information

Diagnostics and troubleshooting Proline Promass I 500 PROFINET Xxxxxx/…/…/ Device name: Xxxxxxx Mass flow: kg/h 12.34 Device tag: Xxxxxxx Volume flow: 12.34 m /h ³ Status signal: Function check (C) Xxxxxx Diagnostics 1: C485 Simu... Remedy information: Deactivate... Failure (F) -

Page 189: Adapting The Diagnostic Information

Proline Promass I 500 PROFINET Diagnostics and troubleshooting 12.6 Adapting the diagnostic information 12.6.1 Adapting the diagnostic behavior Each item of diagnostic information is assigned a specific diagnostic behavior at the factory. The user can change this assignment for specific diagnostic information in the Diagnostic behavior submenu. - Page 190 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Supported status information Status Coding (hex) BAD - Maintenance alarm 0x24 BAD - Process related 0x28 BAD - Function check 0x3C UNCERTAIN - Initial value 0x4F UNCERTAIN - Maintenance demanded 0x68 UNCERTAIN - Process related...

- Page 191 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Measured value status (fixed assignment) Diagnostic behavior Device diagnosis Quality Coding Category (configurable) (fixed assignment) Quality Substatus (hex) (NE107) Logbook entry only GOOD 0x80 to 0x8E – – Diagnostic information 302 Measured value status (fixed assignment)

-

Page 192: Overview Of Diagnostic Information

Diagnostics and troubleshooting Proline Promass I 500 PROFINET 12.7 Overview of diagnostic information • The amount of diagnostic information and the number of measured variables affected increase if the measuring device has one or more application packages. • All of the measured variables affected in the entire Promass instrument family are always listed under "Measured variables affected". - Page 193 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 046 Sensor limit exceeded 1. Inspect sensor 2. Check process condition Measured variable status [from the factory] Quality Good Quality substatus Coding (hex) 0x80 to 0x83...

- Page 194 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 062 Sensor connection faulty 1. Check or replace sensor electronic module (ISEM) 2. If available: Check connection cable between sensor and transmitter Measured variable status 3. Replace sensor...

- Page 195 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 082 Data storage 1. Check module connections 2. Contact service Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal Diagnostic behavior...

- Page 196 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 083 Memory content 1. Restart device 2. Restore HistoROM S-DAT backup (' D evice reset' parameter) Measured variable status 3. Replace HistoROM S-DAT Quality Quality substatus...

- Page 197 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 140 Sensor signal asymmetrical 1. Check or replace sensor electronic module (ISEM) 2. If available: Check connection cable between sensor and transmitter Measured variable status [from the factory] 3.

- Page 198 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 144 Measurement error too high 1. Check or change sensor 2. Check process conditions Measured variable status [from the factory] Quality Good Quality substatus Coding (hex)

-

Page 199: Diagnostic Of Electronic

Proline Promass I 500 PROFINET Diagnostics and troubleshooting 12.7.2 Diagnostic of electronic Diagnostic information Remedy instructions Short text 201 Device failure 1. Restart device 2. Contact service Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27... - Page 200 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 242 Software incompatible 1. Check software 2. Flash or change main electronics module Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27...

- Page 201 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 252 Modules incompatible 1. Check electronic modules 2. Check if correct modules are available (e.g. NEx, Ex) Measured variable status 3. Replace electronic modules Quality Quality substatus...

- Page 202 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 262 Sensor electronic connection faulty 1. Check or replace connection cable between sensor electronic module (ISEM) and main electronics Measured variable status 2. Check or replace ISEM or main electronics...

- Page 203 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 270 Main electronic failure Change main electronic module Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal Diagnostic behavior Alarm Influenced measured variables •...

- Page 204 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 271 Main electronic failure 1. Restart device 2. Change main electronic module Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal...

- Page 205 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 272 Main electronic failure 1. Restart device 2. Contact service Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal Diagnostic behavior...

- Page 206 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 273 Main electronic failure Change electronic Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal Diagnostic behavior Alarm Influenced measured variables •...

- Page 207 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 276 I/O module 1 to n faulty 1. Restart device 2. Change I/O module Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27...

- Page 208 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 302 Device verification active Device verification active, please wait. Measured variable status Quality Good Quality substatus Function check Coding (hex) 0xBC to 0xBF Status signal Diagnostic behavior...

- Page 209 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 311 Electronic failure 1. Do not reset device 2. Contact service Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal...

- Page 210 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 332 Writing in HistoROM backup failed Replace user interface board Ex d/XP: replace transmitter Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27...

- Page 211 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 372 Sensor electronic (ISEM) faulty 1. Restart device 2. Check if failure recurs Measured variable status 3. Replace sensor electronic module (ISEM) Quality Quality substatus Maintenance alarm...

- Page 212 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 373 Sensor electronic (ISEM) faulty 1. Transfer data or reset device 2. Contact service Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27...

- Page 213 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 375 I/O- 1 to n communication failed 1. Restart device 2. Check if failure recurs Measured variable status 3. Replace module rack inclusive electronic modules Quality...

- Page 214 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 382 Data storage 1. Insert T-DAT 2. Replace T-DAT Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal Diagnostic behavior...

- Page 215 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 383 Memory content 1. Restart device 2. Delete T-DAT via ' R eset device' parameter Measured variable status 3. Replace T-DAT Quality Quality substatus Maintenance alarm...

-

Page 216: Diagnostic Of Configuration

Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 387 HistoROM data faulty Contact service organization Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal Diagnostic behavior Alarm Influenced measured variables •... - Page 217 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 331 Firmware update failed 1. Update firmware of device 2. Restart device Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal...

- Page 218 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 410 Data transfer 1. Check connection 2. Retry data transfer Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal Diagnostic behavior...

- Page 219 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 412 Processing download Download active, please wait Measured variable status Quality Uncertain Quality substatus Initial value Coding (hex) 0x4C to 0x4F Status signal Diagnostic behavior Warning Influenced measured variables •...

- Page 220 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 437 Configuration incompatible 1. Restart device 2. Contact service Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal Diagnostic behavior...

- Page 221 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 438 Dataset 1. Check data set file 2. Check device configuration Measured variable status 3. Up- and download new configuration Quality Uncertain Quality substatus Maintenance demanded...

- Page 222 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 442 Frequency output 1 to n 1. Check process 2. Check frequency output settings Measured variable status [from the factory] Quality Good Quality substatus Coding (hex)

- Page 223 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 453 Flow override Deactivate flow override Measured variable status Quality Good Quality substatus Function check Coding (hex) 0xBC to 0xBF Status signal Diagnostic behavior Warning Influenced measured variables •...

- Page 224 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 484 Failure mode simulation Deactivate simulation Measured variable status Quality Quality substatus Function check Coding (hex) 0x3C to 0x3F Status signal Diagnostic behavior Alarm Influenced measured variables •...

- Page 225 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 485 Measured variable simulation Deactivate simulation Measured variable status Quality Good Quality substatus Function check Coding (hex) 0xBC to 0xBF Status signal Diagnostic behavior Warning Influenced measured variables •...

- Page 226 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 491 Current output 1 to n simulation Deactivate simulation Measured variable status Quality Good Quality substatus Coding (hex) 0x80 to 0x83 Status signal Diagnostic behavior Warning Influenced measured variables –...

- Page 227 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 494 Switch output simulation 1 to n Deactivate simulation switch output Measured variable status Quality Good Quality substatus Coding (hex) 0x80 to 0x83 Status signal Diagnostic behavior...

- Page 228 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 520 I/O 1 to n hardware configuration invalid 1. Check I/O hardware configuration 2. Replace wrong I/O module Measured variable status 3. Plug the module of double pulse output on correct slot...

-

Page 229: Diagnostic Of Process

Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 537 Configuration 1. Check IP addresses in network 2. Change IP address Measured variable status Quality Good Quality substatus Coding (hex) 0x80 to 0x83 Status signal... - Page 230 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 830 Sensor temperature too high Reduce ambient temp. around the sensor housing Measured variable status [from the factory] Quality Good Quality substatus Coding (hex) 0x80 to 0x83...

- Page 231 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 831 Sensor temperature too low Increase ambient temp. around the sensor housing Measured variable status [from the factory] Quality Good Quality substatus Coding (hex) 0x80 to 0x83...

- Page 232 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 832 Electronic temperature too high Reduce ambient temperature Measured variable status [from the factory] Quality Good Quality substatus Coding (hex) 0x80 to 0x83 Status signal Diagnostic behavior...

- Page 233 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 833 Electronic temperature too low Increase ambient temperature Measured variable status [from the factory] Quality Good Quality substatus Coding (hex) 0x80 to 0x83 Status signal Diagnostic behavior...

- Page 234 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 834 Process temperature too high Reduce process temperature Measured variable status [from the factory] Quality Good Quality substatus Coding (hex) 0x80 to 0x83 Status signal Diagnostic behavior...

- Page 235 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 835 Process temperature too low Increase process temperature Measured variable status [from the factory] Quality Good Quality substatus Coding (hex) 0x80 to 0x83 Status signal Diagnostic behavior...

- Page 236 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 842 Process limit Low flow cut off active! 1. Check low flow cut off configuration Measured variable status [from the factory] Quality Good Quality substatus Coding (hex)

- Page 237 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 882 Input signal 1. Check input configuration 2. Check external device or process conditions Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27...

- Page 238 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 910 Tubes not oscillating 1. Check electronic 2. Inspect sensor Measured variable status Quality Quality substatus Maintenance alarm Coding (hex) 0x24 to 0x27 Status signal Diagnostic behavior...

- Page 239 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 912 Medium inhomogeneous 1. Check process cond. 2. Increase system pressure Measured variable status [from the factory] Quality Good Quality substatus Coding (hex) 0x80 to 0x83...

- Page 240 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 913 Medium unsuitable 1. Check process conditions 2. Check electronic modules or sensor Measured variable status [from the factory] Quality Good Quality substatus Coding (hex) 0x80 to 0x83...

- Page 241 Proline Promass I 500 PROFINET Diagnostics and troubleshooting Diagnostic information Remedy instructions Short text 942 API density out of specification 1. Check process density with selected API commodity group 2. Check API related parameters Measured variable status [from the factory]...

- Page 242 Diagnostics and troubleshooting Proline Promass I 500 PROFINET Diagnostic information Remedy instructions Short text 944 Monitoring failed Check process conditions for Heartbeat Monitoring Measured variable status [from the factory] Quality Good Quality substatus Coding (hex) 0x80 to 0x83 Status signal...

-

Page 243: Pending Diagnostic Events

Proline Promass I 500 PROFINET Diagnostics and troubleshooting 12.8 Pending diagnostic events The Diagnostics menu allows the user to view the current diagnostic event and the previous diagnostic event separately. To call up the measures to rectify a diagnostic event: •... -

Page 244: 12.10 Event Logbook

Diagnostics and troubleshooting Proline Promass I 500 PROFINET / ../Diagnose list Diagnostics F273 Main electronic Diagnostics 2 Diagnostics 3 A0014006-EN 40 Taking the example of the local display To call up the measures to rectify a diagnostic event: • Via local display → 186 •... -

Page 245: 12.10.2 Filtering The Event Logbook

Proline Promass I 500 PROFINET Diagnostics and troubleshooting 12.10.2 Filtering the event logbook Using the Filter options parameter you can define which category of event message is displayed in the Events list submenu. Navigation path Diagnostics → Event logbook → Filter options Filter categories •... -