Subscribe to Our Youtube Channel

Summary of Contents for Major Trideck MJTDR-490

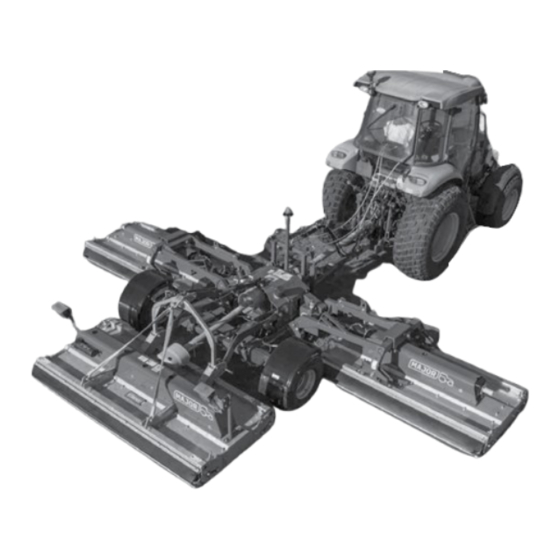

- Page 1 MJTDR-490 Operator’s Manual MJTDR-610 and Parts List WARNING Read this instruction manual thoroughly before using your machine and follow all safety precautions. www.major-equipment.com...

- Page 2 Major reserves the right to modify the machinery and the technical data contained within the manual without prior notice. Further to this, Major assumes no liability for any damages which may result from the use of the information contained within this manual.

-

Page 3: Table Of Contents

Machine storage PTO Shaft Maintenance Transmission Bolts Roller (if applicable) Replacement of wear parts Clearing out a blockage Wing shafts alignment (if applicable) Troubleshooting Lubrication schedule Wheel Nuts Belt Adjustment Belt Removal & Fitting Taper Bush Installation Taper Bush Removal www.major-equipment.com... - Page 4 MJTDR Blades MJTDR PTO Shafts 50 SQ 5 Stud braked axle stub MJTDR Scraper Bars MJTDR Rollers Roller End Assembly (RM-04RBE) LF205H (205 872) (1.92) LF205T (205.873) (1.47) LF205TH (205.874) (1.92) S2061258076 (2.58) - Selector gearbox JJ.03499 (1.9) (3Way) www.major-equipment.com...

-

Page 5: Thank You

(see “Product Specifications” section of this booklet) and driven by an adequate drive-line of the tractor PTO. All other use is strictly prohibited. Major will not be held responsible for any loss or damage caused due to a misuse of the machine. -

Page 6: Tractor Requirements

Operating Safely This MAJOR machine is designed to operate at a PTO rate which is stated in the Product Specifications part of this Crush Hazard booklet. Ensure tractor PTO output is set at a correct RPM rate. This MAJOR machine must only be used for purposes Bystanders can be injured when machine is lowered into mowing position. -

Page 7: Workstation

• Trim and chamfer the two cut ends of the PTO and clean off all swarf and shavings. • Grease the two profiles and join the two halves of the PTO together. • Mount the PTO shaft and check that its length is correct as before. www.major-equipment.com www.major-equipment.com... -

Page 8: Inspections Before Use

Always ensure the pins lock the PTO shaft yoke ends onto the spline shafts on both the tractor and the implement. An unlocked shaft could slip out of position, causing notable mechanical damage and serious injury to both operator and bystanders. www.major-equipment.com... -

Page 9: Product Identification

Machine Serial Numbers If you need to contact MAJOR or your MAJOR dealer for information on servicing or spare parts, always provide the product model and serial numbers. Model and Serial number can be found on the Serial Plate located on the machine. -

Page 10: Eec Certificate Of Conformity For Machines

EN ISO 13857 - Safety of machinery: Safety distances to prevent hazard zones being reached by upper and lower limbs. I hereby certify on behalf of Major Equipment Int. Ltd., that this machine when properly installed and Check wheel nuts daily operated correctly, complies with all the essential Health &... -

Page 11: Key To Main Parts

Rear roller Strap Forward Roller height adjuster rod Roller height indicator Top Link Blade Front roller Scraper bar Wheel Lighting kit Hydraulic Ram Wing Parking Jack Hitch Hitch adjustment Drawbar height adjustment MJTDR-490 Wing pivot Wing arm Forward MJTDR-610 www.major-equipment.com www.major-equipment.com... -

Page 12: Blade System

8 Blade pivot bush 3 Gearbox split pin 9 Blade 4 Blade back 5 Blade back bolt 6 Blade back spacer Drive-line gearboxes Wing selector Primary gearbox Rotor gearbox gearbox Oil filler Oil filler plug plug Oil level Oil level plug plug www.major-equipment.com... -

Page 13: Operating The Machine

6. Fit the PTO shaft & secure the PTO cover chains. 7. Raise the parking jack. 8. Adjust drawbar instead of cutting PTO shaft. 9. Fold the PTO stand down Circlip Hitch Adjustable drawbar Drawbar lateral adjustment Parking jack Drawbar height adjustment PTO stand www.major-equipment.com... -

Page 14: Transport Position

NOTE: This machine is factory set to operate with ‘open centre’ hydraulic systems. When connecting to tractors with ‘closed centre’ hydraulics, the Pilot valve spool knob ‘C’ must be closed (screwed ‘in’). Transport Position Unlocked Locked Mowing Position www.major-equipment.com www.major-equipment.com... -

Page 15: Warnings

THE INFORMATION CONTAINED IN THIS DRAWING IS THE PROPERTY MAJOR OF MAJOR EQUIPMENT INTL. LTD. Vendor: ANY REPRODUCTION IN PART OR A WHOLE WITHOUT THE WRITTEN www.major-equipment.com PERMISSION OF MAJOR EQUIPMENT INTL. LTD. IS PROHIBITED. Quantity Date Stock Code: Rev. Drawing No. -

Page 16: Manual Override

IMPORTANT: The check will not work in this position & this should be used for maintenance purposes only. Manual override should not be used when operating the machine normally. 6 Button shown will make the wing go down. Button on the opposite side will raise the wing. www.major-equipment.com... -

Page 17: Maintenance

Maintenance 061120 In order to keep your Major machine in a good working order it is necessary to conduct maintenance on a regular basis. Only competent and skilled persons who have fully read and understood this operator’s manual are allowed to carry out maintenance on this machine. -

Page 18: Transmission Bolts

Possible build-up materials under mower Clean mower MAJOR recommends to visually check the blade assemblies every 40 hours of operation. This interval may change Blades mounted incorrectly (cutting edge against direction Change blades so that cutting edge is facing correct depending on the operational conditions. - Page 19 Replace seal or use a sealant on outside diameter Gearbox leaking Oil seal not sealing in the housing of seal Oil level too high Drain oil to proper level Hole in gearbox Replace the gearbox Gasket damaged Replace gasket Bolts loose Tighten bolts www.major-equipment.com...

-

Page 20: Lubrication Schedule

● Axle ● Rear deck lift hydraulic rams ● Check oil levels in the gearboxes 11/13 ● Replace oil in gearboxes 11/13 Wheel Nuts Wheel nuts should be torqued to 240Nm. Do not overtighten nuts as damage can occur. www.major-equipment.com... -

Page 21: Belt Adjustment

If the top of the Belt Key interferes with the taper bush then the bush will not tensioner tighten correctly & will loosen again over a short period of time. Idler Bolt www.major-equipment.com www.major-equipment.com... -

Page 22: Mjtdr-490 Overview

TDR WING PTO SHAFT M12x30SKBH M12x30 SOCKET BUTTON HEAD 10.9 TRI-ARM2 AXLE RAM (PLUNGER) M24 NYLOC NUT TRI-WRM3 WING RAM ASSEMBLE 1x WASHER BOLT SIDE AND 1xWASHER WS601136 SLIP CLUTCH 1200 Nm PIN SIDE. Items in bold - further details provided www.major-equipment.com www.major-equipment.com... -

Page 23: Mjtdr-610 Overview

PIN SIDE. M12 NYLOC NUT T500350F132132 TDR WING PTO SHAFT M12x30SKBH M12x30 SOCKET BUTTON HEAD 10.9 TRI-ARM2 AXLE RAM (PLUNGER) M24 NYLOC NUT TRI-WRM3 WING RAM WS601136 SLIP CLUTCH 1200 Nm Items in bold - further details provided www.major-equipment.com www.major-equipment.com... -

Page 24: Tdr-610-Bg-Ga01 Bogey Assembly

DIA 50mm FLANGE BRG CAT 2 PIN DIA 25.4x110mm XPB1800 XPB BELT x1800mm GREASE NIPPLE M8x1.25 STR 12837 PULL CORD 2800mm 8SM14 DIA 1 1/4" BUSHx1 3/4" DIA 1" FLAT WASHER Items in bold - further details provided www.major-equipment.com www.major-equipment.com... -

Page 25: Tdd-Ga1 Drawbar Assembly - Parts List

DIA 1 1/4" BUSHx1 3/4" AGC2 DIA 50 EXT HEAVY CIRCLIP M12 NYLOC NUT M12x30SZP M12x30 SET BOLT M12x35BZP M12x35 BOLT M12x50BZP M12x50 BOLT M20 NYLOC NUT M20x130BZP M20x130 BOLT S849 GREASE NIPPLE M6 STR TL3702711KR Top Link M27 Cat 1 www.major-equipment.com www.major-equipment.com... - Page 26 SHAFT COLLAR DIA 35 M8x30SKBH M8x30 SOCKET BUTTON HEAD 10.9 111044 DIA 26-30mm INSERT NL12SP M12 SP NORDLOCK 11874 CAT 1/2 LINK PIN 12HEX109 1/2HEX10.9 Items in bold - further details provided 12x112FSKS 1/2"x1 1/2" FINE SOCKET HEAD 12.9 www.major-equipment.com www.major-equipment.com...

-

Page 27: Sw2-240-Ga01 Rear Deck Assembly

SHAFT COLLAR DIA 35 M8x30SKBH M8x30 SOCKET BUTTON HEAD 10.9 111044 DIA 26-30mm INSERT NL12SP M12 SP NORDLOCK 11874 CAT 1/2 LINK PIN 12HEX109 1/2HEX10.9 Items in bold - further details provided 12x112FSKS 1/2"x1 1/2" FINE SOCKET HEAD 12.9 www.major-equipment.com www.major-equipment.com... -

Page 28: Mjtdr-490-Wgga01 Wing Assembly Rh (Mjtdr-490)

M8x20 SOCKET BUTTON HEAD 10.9 SW2-240-DF02 REAR DEFLECTOR (RH) M8x30SKBH M8x30 SOCKET BUTTON HEAD 10.9 SW2-240-DF02H REAR DEFLECTOR (LH) NL12SP M12 SP NORDLOCK RM-RSN3 SHAFT COLLAR DIA 35 111044 DIA 26-30mm INSERT Items in bold - further details provided 12HEX109 1/2HEX10.9 www.major-equipment.com www.major-equipment.com... -

Page 29: Mjtdr-490-Wgga02 Wing Assembly Lh (Mjtdr-490)

M8x20 SOCKET BUTTON HEAD 10.9 SW2-240-DF02 REAR DEFLECTOR (RH) M8x30SKBH M8x30 SOCKET BUTTON HEAD 10.9 SW2-240-DF02H REAR DEFLECTOR (LH) NL12SP M12 SP NORDLOCK RM-RSN3 SHAFT COLLAR DIA 35 111044 DIA 26-30mm INSERT Items in bold - further details provided 12HEX109 1/2HEX10.9 www.major-equipment.com www.major-equipment.com... -

Page 30: Mjtdr-610-Wgga01 Wing Assembly Rh (Mjtdr-610)

M8x20 SOCKET BUTTON HEAD 10.9 SW2-240-DF02 REAR DEFLECTOR (RH) M8x30SKBH M8x30 SOCKET BUTTON HEAD 10.9 SW2-240-DF02H REAR DEFLECTOR (LH) NL12SP M12 SP NORDLOCK RM-RSN3 SHAFT COLLAR DIA 35 111044 DIA 26-30mm INSERT Items in bold - further details provided www.major-equipment.com www.major-equipment.com... -

Page 31: Mjtdr-610-Wgga02 Wing Assembly Lh (Mjtdr-610)

M8x20 SOCKET BUTTON HEAD 10.9 SW2-240-DF02 REAR DEFLECTOR (RH) M8x30SKBH M8x30 SOCKET BUTTON HEAD 10.9 SW2-240-DF02H REAR DEFLECTOR (LH) NL12SP M12 SP NORDLOCK RM-RSN3 SHAFT COLLAR DIA 35 Items in bold - further details provided 111044 DIA 26-30mm INSERT www.major-equipment.com www.major-equipment.com... -

Page 32: Tdr-610-Ax-Ga01 Axle Assembly

Item Part No. Description 8400RM-HG65 M20 THREADED ADJUSTER 8400RM-HG76 HEIGHT PIVOT BLOCK 8400RM-HG77 M20 HEX ADJUSTER GREASE NIPPLE M8x1.25 STR GREASE NIPPLE M8x90x1.25P FWM12 M12 FLAT WASHER M12 NYLOC NUT M12x60BZP M12x60 BOLT S1215 ROLL PIN DIA 6x40 www.major-equipment.com www.major-equipment.com... -

Page 33: Tdr-610-Wa-Ga01 Wing Arm Assembly Rh

2517 35mm BORE 53005803 DIA 50x40xM10 BUFFER 53005803 DIA 50x40xM10 BUFFER Items in bold - further details provided Items in bold - further details provided 8SM14 DIA 1 1/4" BUSHx1 3/4" 190000592 PTO HAT CM95 PUMP GUARD CM95 PUMP GUARD www.major-equipment.com www.major-equipment.com... -

Page 34: Mjtdr Hydraulics

Rear Deck (right) ‘out’ 22 TDR-SUPPLY 3/8”x2800mm Str to Str 23 VUR03C 1/2” CHECK VALVE 1/4” Tee fixed on bogey Rear Deck (left) ‘out’ Hydraulic Ram spares Item Part No. Description TRI-ARM2SK SEAL KIT FOR TRI-ARM2 TRI-WRM3-SK SEAL KIT FOR TRI-WRM3 www.major-equipment.com www.major-equipment.com... -

Page 35: Mjtdr Blades

DIA 1" THIN FLAT WASHER M10 NYLOC NUT M10 NYLOC NUT M10x30SKBH M10x30 SOCKET BUTTON HEAD 10.9 M10x30SKBH M10x30 SOCKET BUTTON HEAD 10.9 M16 NYLOC NUT M16 NYLOC NUT 4 off MJTDR-490 4 off MJTDR-490 5 off MJTDR-610 5 off MJTDR-610 www.major-equipment.com www.major-equipment.com... -

Page 36: Mjtdr Scraper Bars

Roller 2 per MJTDR-490 (rear deck) 2 per MJTDR-610 (rear deck) 19000RM-WR01 Roller 4 per MJTDR-610 (wings) RM-RSN3 Collar 35mm c/w bolt 2 per roller RM-04RBE Roller end assembly 2 per roller Items in bold - further details provided www.major-equipment.com... -

Page 37: Roller End Assembly (Rm-04Rbe)

THE INFORMATION CONTAINED IN THIS DRAWING IS THE PROPERTY MAJOR OF MAJOR EQUIPMENT INTL. LTD. Vendor: ANY REPRODUCTION IN PART OR A WHOLE WITHOUT THE WRITTEN www.major-equipment.com PERMISSION OF MAJOR EQUIPMENT INTL. LTD. IS PROHIBITED. Quantity Date Stock Code: Rev. Drawing No. -

Page 38: Lf205H (205 872) (1.92)

10 LF135/9 8.0.1.00871 Bearing 6208 26 T4A/5 0.248.7500.00 Shim Kit (60.3x71.7) 11 LF135/1 8.2.2.00515 Castle Nut 27 8.5.2.00131 8.5.2.00131 Snap Ring (72x75x2.5) 12 LF135/2 8.3.2.00409 Bolt Washer 25x44x4 13 LF135/19 8.4.1.00993 Parallel Key B 10x8x30 14 M10x20SZP 8.1.1.00054 Bolts M10x20 www.major-equipment.com... -

Page 39: Lf205T (205.873) (1.47)

Bearing 6208 (LF135/9) 25 N/A 0.205.7100.00 Name Plate 11 8.2.2.00515 8.2.2.00515 Castle Nut (LF135/1) 26 0.248.7500.00 Shim Kit (60.3x71.7) 12 8.3.2.00409 8.3.2.00409 Bolt Washer (LF135/2) 27 LF135/27 8.5.2.00131 LF205/27 Circlip Parallel Key 10x8x30 13 8.4.1.00993 8.4.1.00993 (LF135/19) 28 LF135/16 0.113.7500.00 Shim www.major-equipment.com... -

Page 40: Lf205Th (205.874) (1.92)

11 8.2.2.00515 8.2.2.00515 Castle Nut (LF135/1) 8.5.2.00131 27 8.5.2.00131 LF205/27 Circlip (LF135/27) 12 8.3.2.00409 8.3.2.00409 Bolt Washer (LF135/2) 0.113.7500.00 13 8.4.1.00993 8.4.1.00993 Parallel Key (LF135/19) 28 0.113.7500.00 Shim (LF135/16) 14 8.1.1.00054 8.1.1.00054 Bolts M10x20 15 8.5.2.00030 8.5.2.00030 Snap Ring (LF135/6) www.major-equipment.com... -

Page 41: S2061258076 (2.58) - Selector Gearbox

S2061258076 (2.58) - Selector gearbox www.major-equipment.com... - Page 42 0.248.7500 adjusting washer (60.3x71.7) 0.285.7500 adjusting washer(40.3x61.7) 33109 tapered roller bearing 33109 (45x80x26) 0.175.7500 adjusting washer 45.2x54.8 8.5.1.02368 Circlip Φ45x2.5 8.7.1.00999 double-lip seal 45x80x10 GB-03512-7100 Protective washer GB-03512-2000 Input shaft GB-03512-6001 Bevel gear 9510.204.125 1/2 GAS oil plug+copper washer www.major-equipment.com...

- Page 43 All MAJOR machines must be registered when sold, to ensure that you receive the correct warranty cover and service bulletins. To register your machine for warranty, please go to the SALES & SUPPORT section of our website www.major-equipment.com and enter your details.

- Page 44 Ballyhaunis, Co. Mayo, F35 C891, Ireland Tel: + 353 (0) 9496 30572 info@major-equipment.com UK Office Major Equipment Ltd Major Ind. Estate, Heysham, Lancs, LA3 3JJ, UK Tel: + 44 (0) 1524 850501 ukinfo@major-equipment.com Netherlands Office Major Equipment Intl Ltd (EU)

Need help?

Do you have a question about the Trideck MJTDR-490 and is the answer not in the manual?

Questions and answers