Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Speck pumps badu Jet Super-Sport II

- Page 1 Installation Manual super-sport II ® Counter Swimming Unit Rev. 03/16...

- Page 2 Fax: 904-737-5261 Website: www.usa.speck-pumps.com Manufactured by Speck Pumps, Jacksonville Florida USA, © 2016 All Rights Reserved. This document is subject to change without notice. Safety CAUTION, WARNING, and Safety is emphasized throughout the user manual. These are safety alert symbols ( DANGER) .

-

Page 3: Table Of Contents

Table of Contents Important Safety Instructions SwimJet Combination Fitting Manufacturers Warnings. . 4 General Safety Instructions....5 General Description Installation Information Receiving Information ....7 Plumbing Installation . -

Page 4: Important Safety Instructions

Important Safety Instructions WARNING: Before Installing this product, read and follow all warning notices and instructions which are included. Failure to follow safety warnings and instructions can result in severe injury, death, or property damage. Call 1-800-223-8538 or visit www.usa.speck-pumps.com for additional copies of these instructions. Swim Jet Combination Fitting - Manufacturers Warnings MUST BE INSTALLED by an experienced and qualified pool industry professional ONLY. -

Page 5: General Safety Instructions

Swim Jet Combination Fitting - Manufacturers Warnings - continued As the manufacturer, Speck Pumps - Pool Products, Inc., hereby certifies that their Swim Jet Combination Fitting meets or exceed the requirements of the Virginia Graeme Baker Pool & Spa Safety Act, VGB 2008 and ANSI/APSP 16 standards and safety regulations as set forth by the Consumer Products Safety Commission. -

Page 6: General Description

General Description The BaduJet super-sport II from Speck Pumps has been designed to be installed during the construction of your pool to create a water treadmill for anyone wanting a therapeutic and effective exercise. The BaduJet super-sport can be installed in any type of pool, large or small, from gunite to vinyl liner. -

Page 7: Installation Information

Installation Information Receiving Information 1. Upon receipt of the swimjet system, check the cartons for damage. Open each carton and check the pump, jet housing, anti- entrapment cover, and control box for concealed damage, such as cracks, dents, or a bent base. If damage is found, contact the shipper or distributor where the swimjet was purchased. - Page 8 Plumbing Installation - Continued CAUTION: For trouble-free pump priming (up to 4 feet above the water line), first install a 6” long riser in the discharge connection on top of the pump. Then install an elbow and lead the discharge line downward to the discharge connection at the BaduJet Imperial jet housing.

-

Page 9: New Concrete Or Gunite Installation

Plumbing - continued Figure 3 Sample BaduJet super-sport II Installation (Self-Priming) Valves (Optional) Discharge Line Control Service Disconnect NOTE: Valves are recommended when pump is installed below water level (flooded suction applications). 4” Pneumatic NOTE: To avoid stress on the housing, the jet housing Hose and 2 to 3 inches of plumbing/conduit stub out may be encased in gunite or concrete. - Page 10 Jet Housing Installation - New Concrete or Gunite Construction The following is a list of all parts that ARE NOT USED IN A CONCRETE OR GUNITE INSTALLATION WITHOUT VINYL LINER: Gasket with knobs (part #26) Clamping ring gasket (part #27) M8 x 30mm Countersunk Screw (part #98) 1.

- Page 11 Jet Housing Installation - New Concrete or Gunite Construction - continued Slide the inner wall formwork over the studs in the WATER LEVEL jet housing through the pre-drilled holes. Secure the formwork to the jet housing with four (4) M8 washers (part #32) and four (4) M8 nuts (part #33).

- Page 12 Jet Housing Installation - New Concrete or Gunite Construction - continued Concrete pool with vinyl liner: Use the provided mounting template (small scale version of template shown in Figure 5) to mark and drill the holes through the liner (twelve (12) M8 clamping ring screw holes and 13.3” center hole). Insert the gasket with knobs in the front of the jet housing (part# 26).

-

Page 13: Existing Concrete Or Gunite Installation

Jet Housing Installation - Existing Concrete or Gunite Construction Materials: (NOT INCLUDED) One (1) piece of plywood 2’ x 3’ x 1/4” Eight (8) Lag screws 1/4” x 1-1/2” (minimum) Eight (8) Plastic lag shield anchors 1. Follow steps 1-4 under Jet Housing Installation - New Concrete or Gunite Construction on pages 9 - 10. 2. -

Page 14: Liner And/Or Fiberglass Pool Installation

Jet Housing Installation - Existing Concrete or Gunite Installation - continued 19" Beam Water Level 36" Figure 9 Layout for installing in existing gunite or concrete pools Jet Housing Installation - Liner and/or Fiberglass Pool Construction CAUTION: Locate discharge connector directly ABOVE the suction connection. Discharge and suction connectors must be exactly vertical or the stainless steel handles will not align properly. - Page 15 Jet Housing Installation - Liner and/or Fiberglass Pool Construction - continued 6. Align the clamping ring (part# 28) over the clamping WATER LEVEL ring gasket (part#27). 7. Install the twelve (12) M8 x 30 clamping ring screws (part# 52). 8. Follow steps 1-4 under Jet Housing Installation - New Gunite or Concrete Construction on page 9 - 10.

-

Page 16: Final Assembly

Final Assembly 1. Insert the o-ring (part# 62) in the jet housing as shown in Figure 14. 2. Start the ten (10) nozzle housing tapping screws (part# 61) into the pre-assembled nozzle housing (part# 102.1). Place the nozzle housing at the main jet housing. 3. -

Page 17: Electrical Installation

Final Assembly - continued 21/1 38/1 38/2 Figure 15 Figure 16 Installation of Light Cover Installation of Knobs Electrical Installation WARNING: The wiring of the pool motor and control box should be done by a licensed electrician in accordance with all local, state, and federal codes. - Page 18 Electrical Installation - continued GROUNDING: Permanently ground the pump motor and control box using a conductor of appropriate size. Pump Motor: Connect to the No. 10 green headed ground screw provided inside the motor terminal box. Control Box: Connect to the aluminum grounding terminal strip on the inside of the control box enclosure. CAUTION: DO NOT connect to electric power supply until the unit is permanently grounded.

- Page 19 Electrical Installation - continued BLK-2 BLK-2 RELAY RED-2 RED-2 BLK-4 120V ORG-0 T0RQUE DATA BLK-5 BLU-2 Wire Range Torque in.-lbs. 14-10 CU Coil 8 CU 120V CONTACTOR YEL-3 YEL-2 BLU-3 SWITCH (PUMP) LATCHING AIR SWITCH (LIGHT) GROUND NOTE: Use TO & FROM Control for remote SERVICE GROUND...

-

Page 20: Service And Maintenance

Service and Maintenance Nozzle Adjustments When setting the nozzles for basic swimming, it is recommended that you set the nozzles in such a way that each nozzle intersects 4 feet away while breaking the surface at the same time. To help set the nozzles in position for best performance, please follow these instructions: 1. -

Page 21: Winterizing

Winterizing In areas subject to freezing water temperatures, you should protect your equipment. We recommend you purchase a winter cover kit part #2326000010K. This kit includes one (1) winter plate, one (1) gasket, four (4) M8 washers, and four (4) M8 x 30mm screws. (See Figure 20) Also, you can protect your swimjet system as follows: ~12”... -

Page 22: Troubleshooting

Frequently Asked Questions - continued Does the LED light come in different colors? Yes. The LED light comes in blue or a multi-color option. Does it matter if the housing is installed higher or lower than the manual states? Yes, the center of the jet must be 12” BELOW estimated water level for proper performance of unit. If installed too high, the pump will draw in air from the top of the water level. - Page 23 Trouble Shooting - continued PROBLEM POSSIBLE CAUSES SOLUTION 5. Motor runs hot. These motors will run hot to the touch, however, this is normal. They are designed that way. Thermal overload protector will function to turn them off if there is an overload or high temperature problem.

-

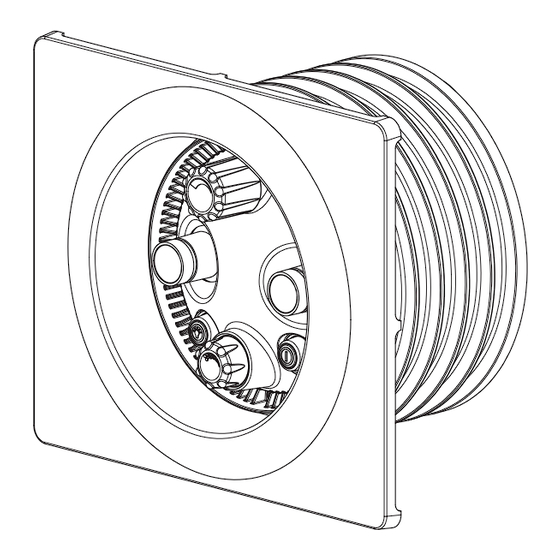

Page 24: Product Specification

Trouble Shooting - continued PROBLEM POSSIBLE CAUSES SOLUTION 12. I have the volume a. Debris in pump casing/impeller. Check inside pump casing for any debris. control knob turned com- pletely up but the flow is b. Improper swim jet assembly. The internals may need to be removed for inspection weak? of the spindle. - Page 25 Exploded View PART DRAWING DESCRIPTION NUMBER NUMBER REQUIRED 2326000002 JET HOUSING 2301001007 3 FT HOSE - AIR REGULATOR 8 x 3mm (PRICE PER FOOT) 2326000408 HOSE (3X) WITH Y- HOSE BARB 2301001008 CLAMP - HOSE, AIR REGULATOR 14/9 SS A4 2326000031 STRAIN RELIEF - LIGHT CABLE, 3/4”...

-

Page 26: Limited Warranty

Badu SwimJet System(s). 2. To the fullest extent permitted by law, the Limited Warranty will be void and of no force or effect and Speck Pumps-Pool Products, Inc. will have no liability, responsibilities or obligations to Buyer or with respect to the Badu SwimJet System(s) in... - Page 27 Buyer’s protection to the manufacturer at 8125 Bayberry Road, Jacksonville, Florida 32256 USA. Under no condition will products be accepted after the expiration of the Limited Warranty Period. Speck Pumps- Pool Products, Inc. shall not bear any costs or risks incurred by Buyer in shipping a defective Badu SwimJet System(s) to Speck...

Need help?

Do you have a question about the badu Jet Super-Sport II and is the answer not in the manual?

Questions and answers